Combined light source and mask optimization method for lithography machine

A technology of joint optimization and lithography machine, applied in the field of lithography machine, can solve problems such as increasing the complexity of optimization methods, difficult to solve analytical expressions, and inability to solve problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment and figure, but should not limit protection scope of the present invention with this embodiment, but for those skilled in the art, under the premise of not departing from the principle of the present invention, can also make some Replacement and improvement, these should also be regarded as belonging to the protection scope of the present invention.

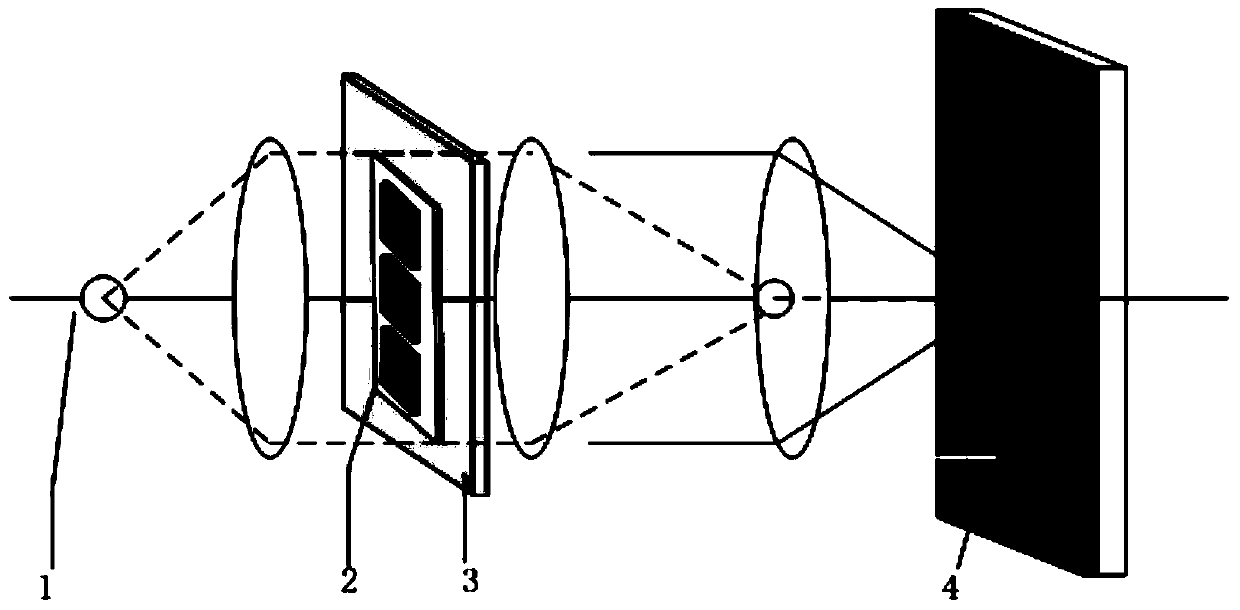

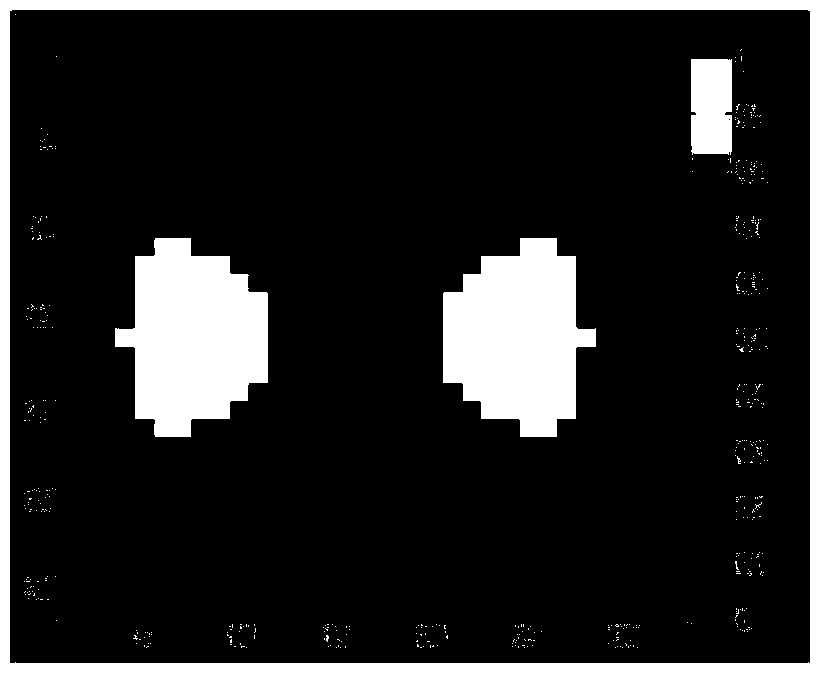

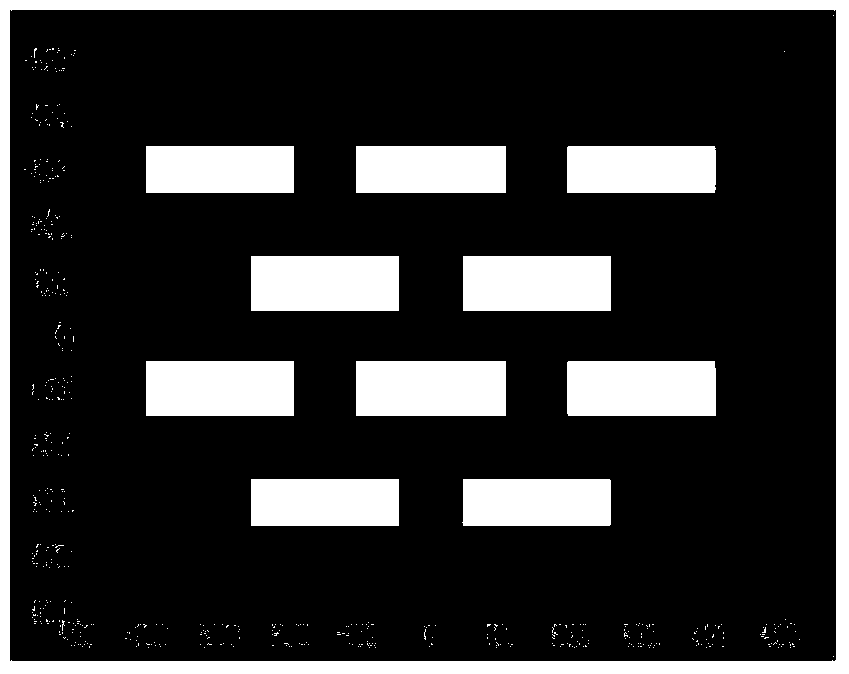

[0038] refer to figure 1 , figure 1 It is a schematic diagram of the lithography machine system of the method for optimizing the light source mask of the lithography machine used in the present invention. It can be seen from the figure that the method involves the light source illumination mode 1 generated by the lithography machine lighting system, the mask pattern 2, and the bearing Mask stage 3 of mask pattern 2, photoresist 4. refer to figure 2 , figure 2It is a schematic diagram of the initial lighting mode of the light source u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com