Multi-junction Iii-v Solar Cell And Manufacturing Method Thereof

A multi-junction solar cell, III-V technology, applied in the field of physical science, can solve the problem of high cost of inverted metamorphic solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

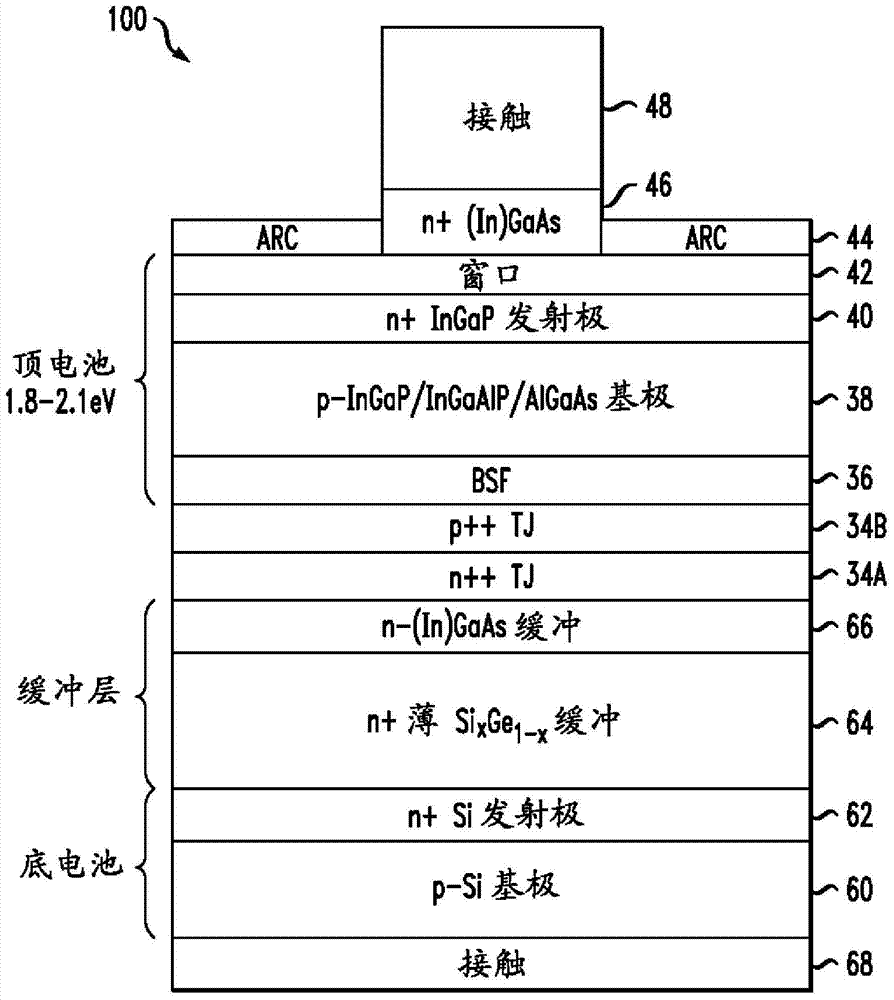

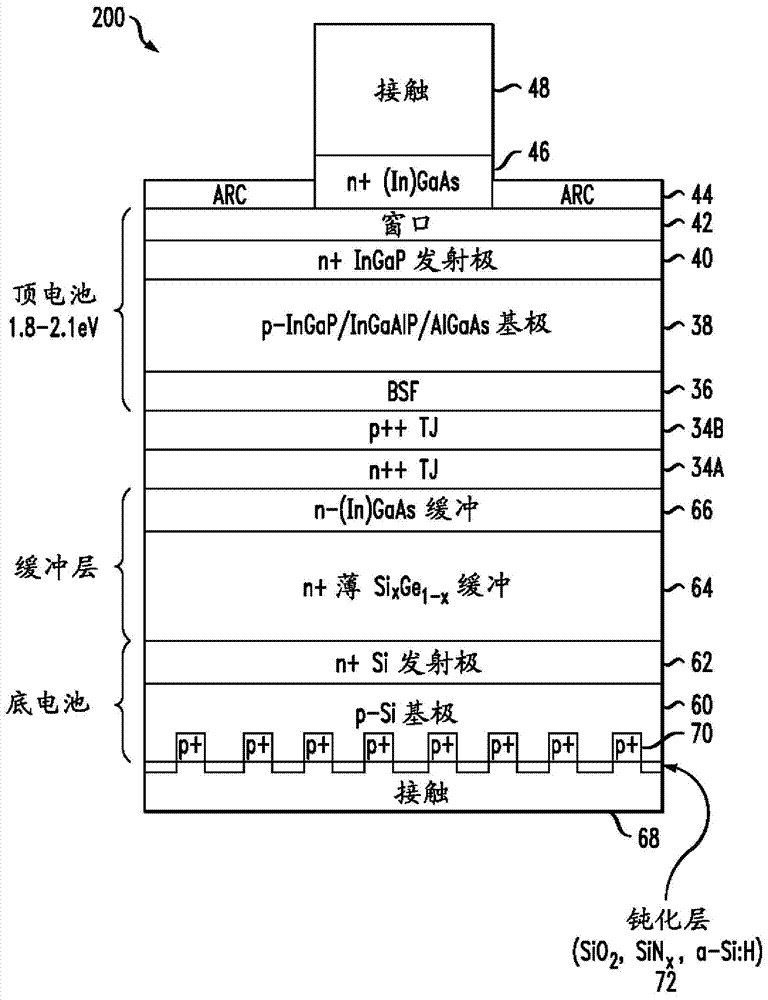

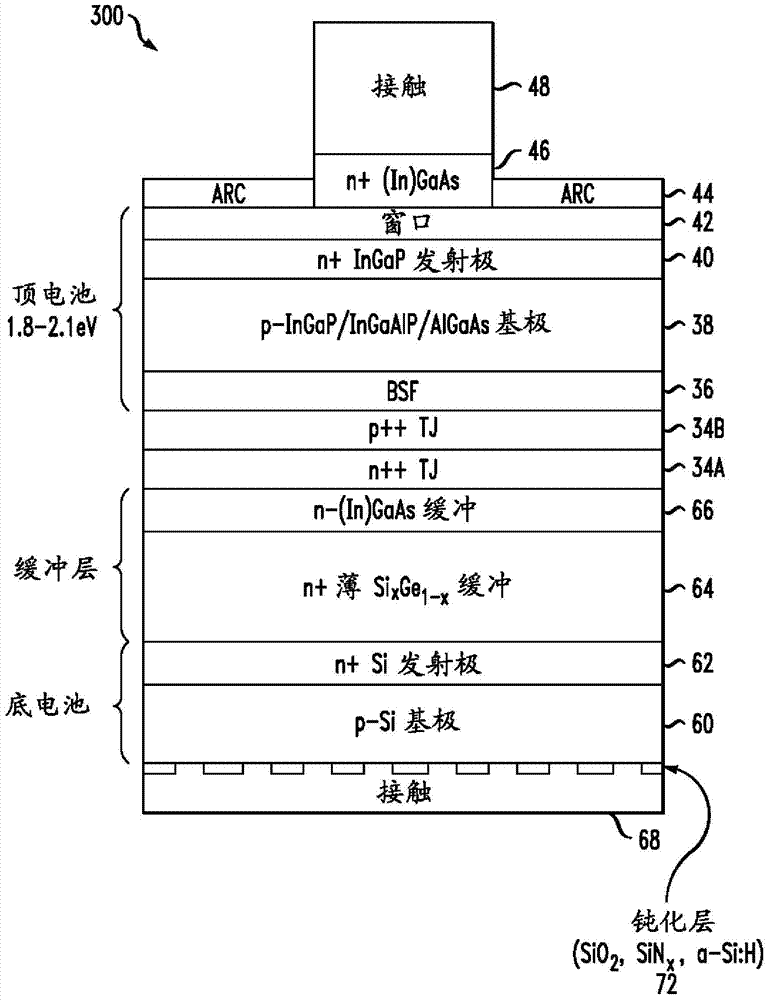

[0020] A germanium lattice-matched or pseudomorphic germanium multijunction III-V solar cell structure on a compliant silicon substrate is disclosed, in which silicon is used as the bottom cell. Growing III-V based cells on silicon is advantageous for a number of reasons including: (1) the abundance of Si substrates, (2) the lower cost of silicon compared to germanium and III-V semiconductor materials, ( 3) Mechanical stability, and (4) Silicon has the best bandgap for fabricating high-efficiency tandem junction solar cells. Lattice mismatch between silicon and III-V semiconductor materials is an obstacle to the realization of III-V solar cells on tandem silicon, where silicon serves as the bottom junction. Due to the challenging nature of growing III-V semiconductor materials directly on silicon over large areas as opposed to small patterned areas, researchers have attempted to use graded SiGe buffer layers as templates for growing III-V on silicon substrates. In principle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com