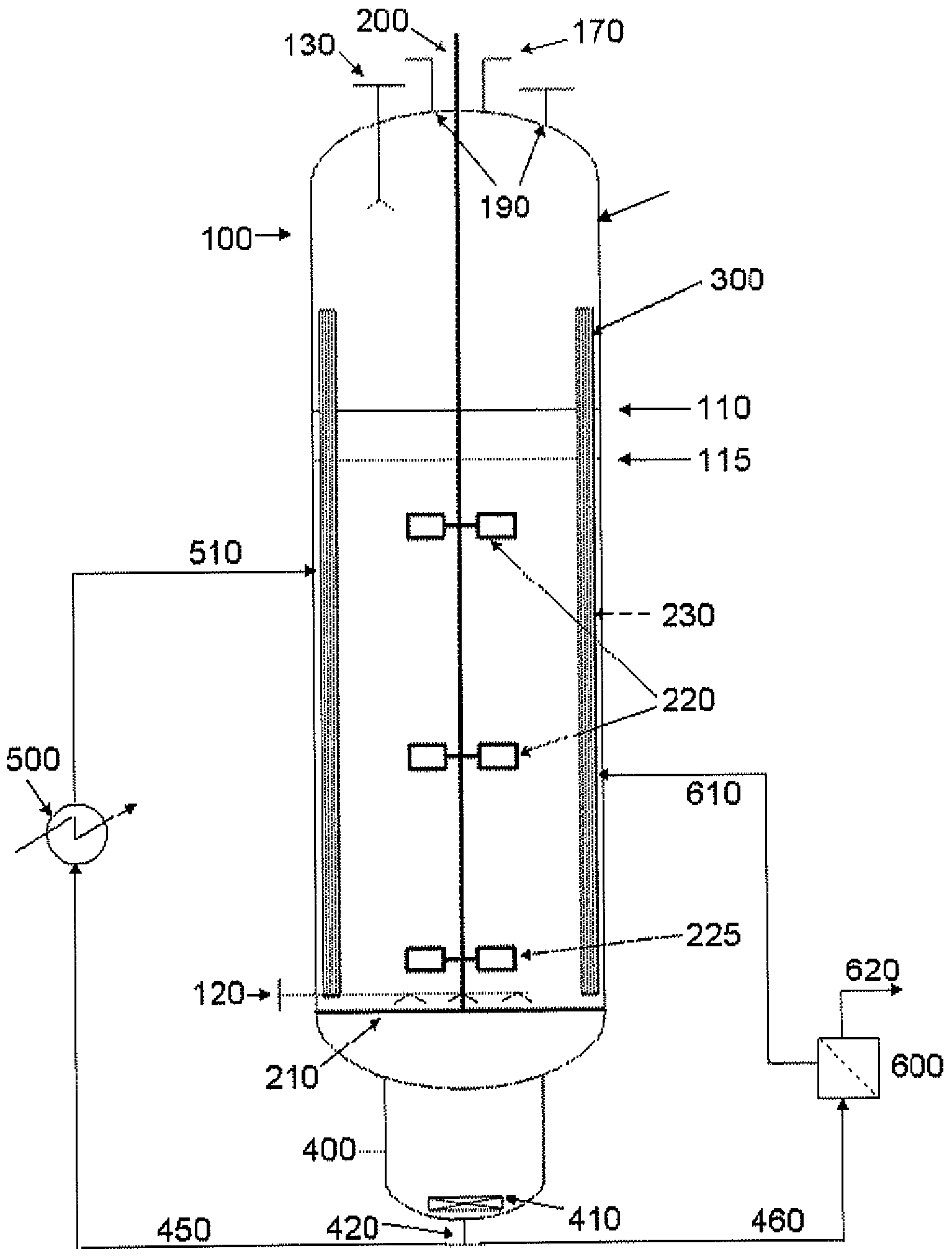

Method and apparatus for syngas fermentation with high CO mass transfer coefficient

A mass transfer coefficient and syngas technology, applied in mixers with rotating stirring devices, fermentation, bioreactors/fermenters for specific purposes, etc., to achieve the effect of increasing the mass transfer coefficient of volume CO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

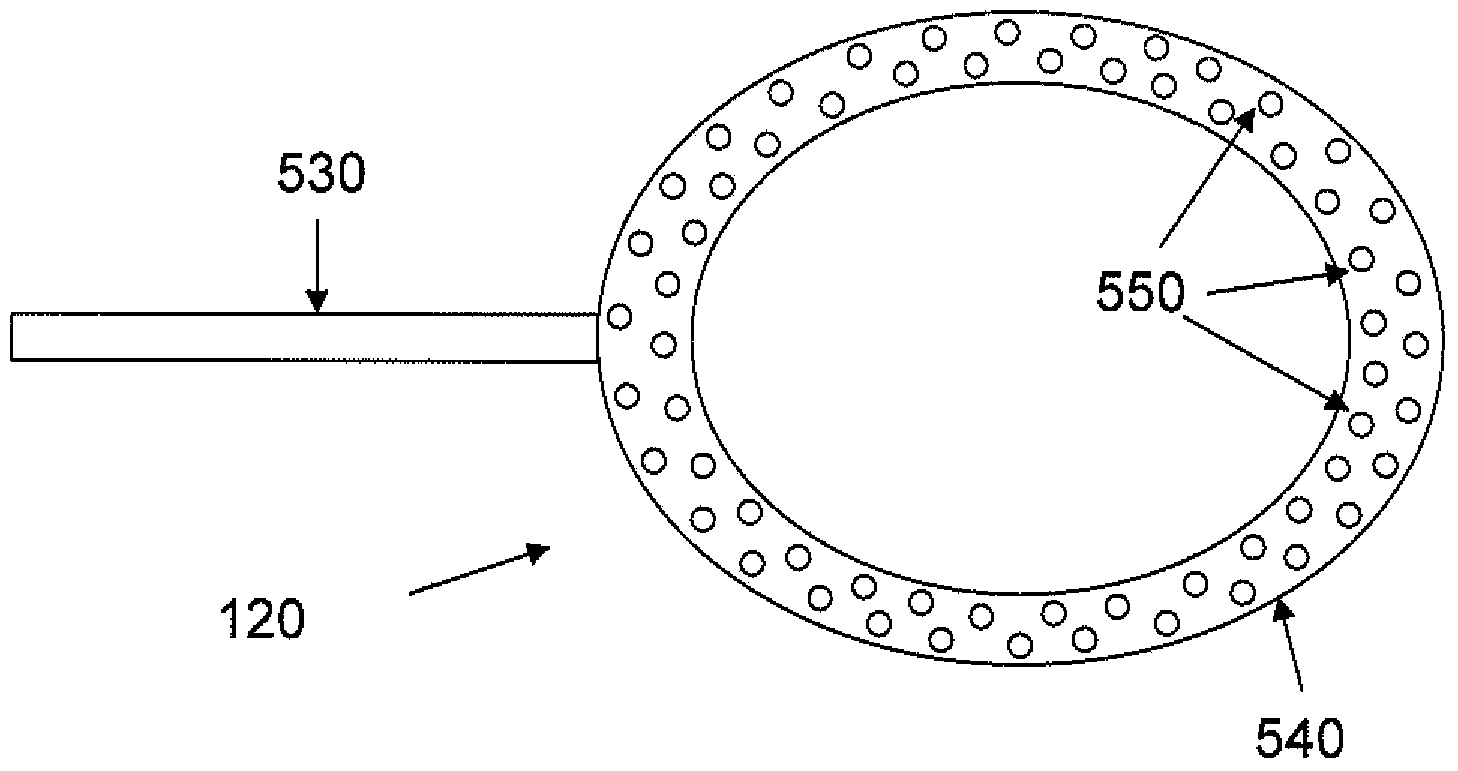

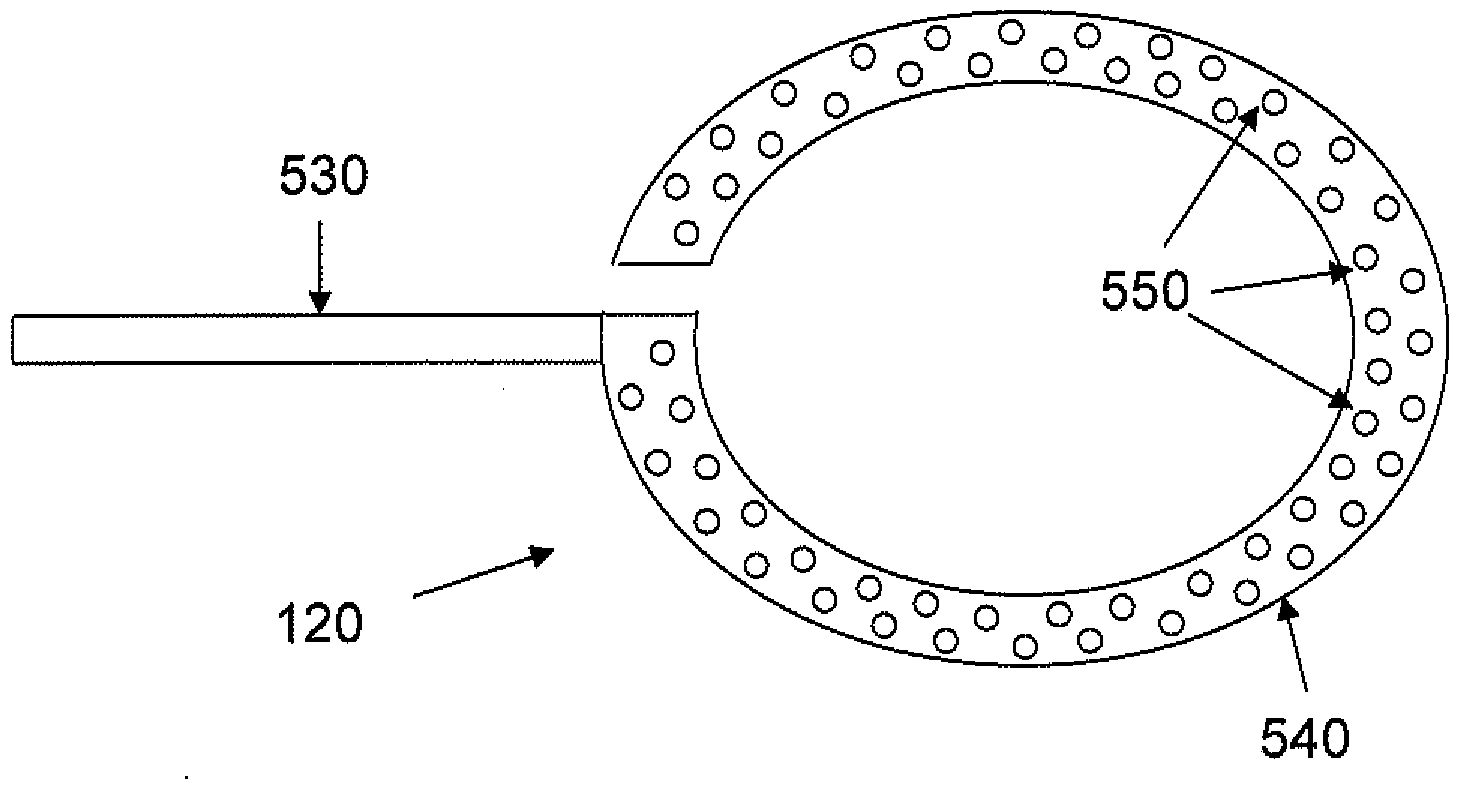

Embodiment Construction

[0077] Carry out pilot plant scale fermentation to determine k L a. measured k L a is about 60g ethanol / (L·day) STY (space-time yield). k by forcing the reaction under mass transfer limiting conditions or zero dissolved CO concentration L an estimate of a. This is achieved by performing a momentary reduction in the gas flow rate or agitation rate so that the cells are in excess relative to the available gas. Under these conditions, the CO is reacted away once dissolved, making the reaction mass transfer limited. The CO dissolved in solution is the same as the difference between CO in the feed gas and CO in the product. In a mass transfer limited system, the difference is the mass transfer rate for the given conditions.

[0078] The basic equation used is k L a=C kla (P g / V l ) a v b sg

[0079] in

[0080] k L a = volume mass transfer coefficient (m 3 Gas / s / m 3 liquid)

[0081] C kla = constant for a given system

[0082] P g = Aerated mixer power consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com