Patents

Literature

54 results about "Syngas fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

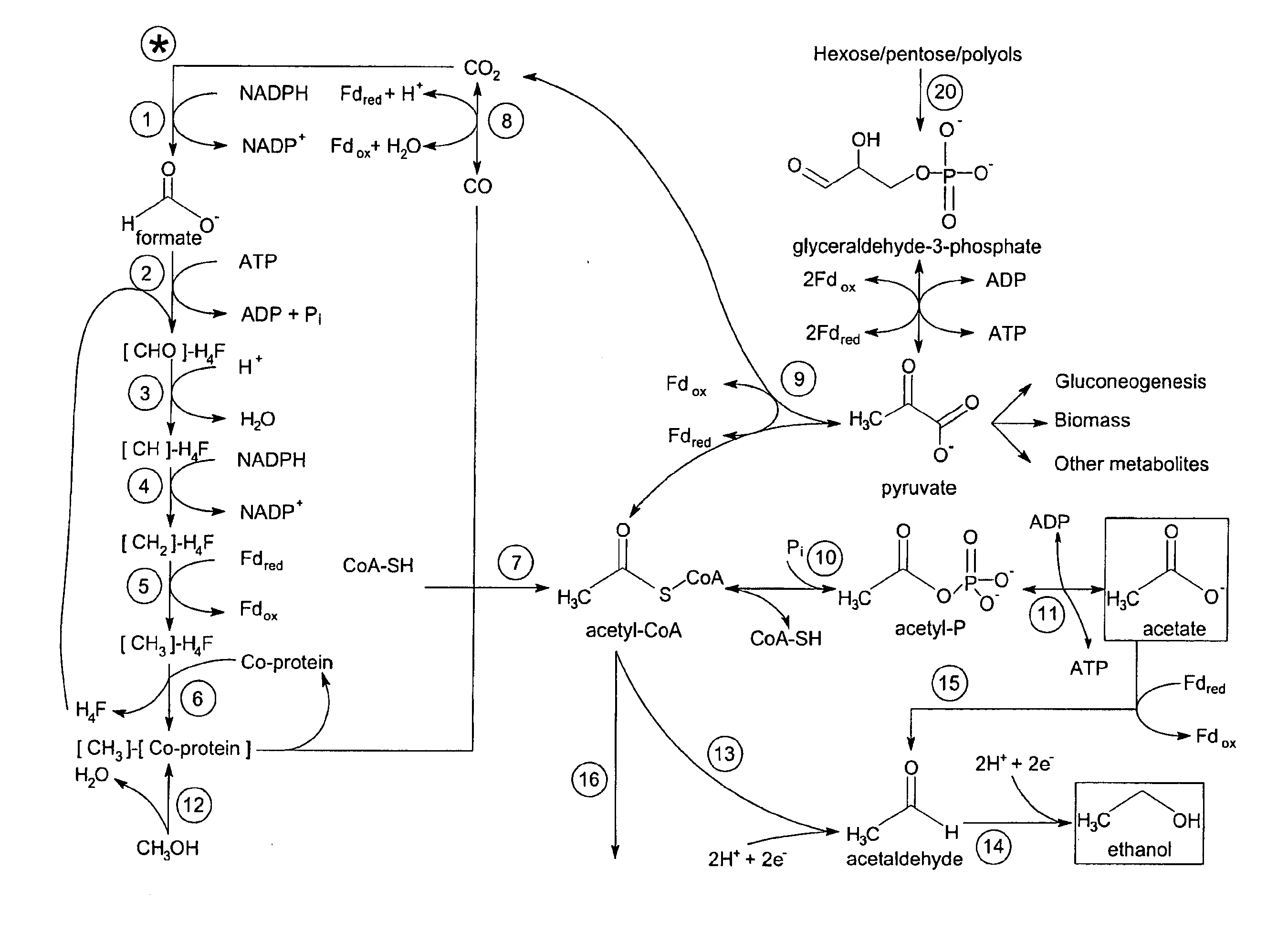

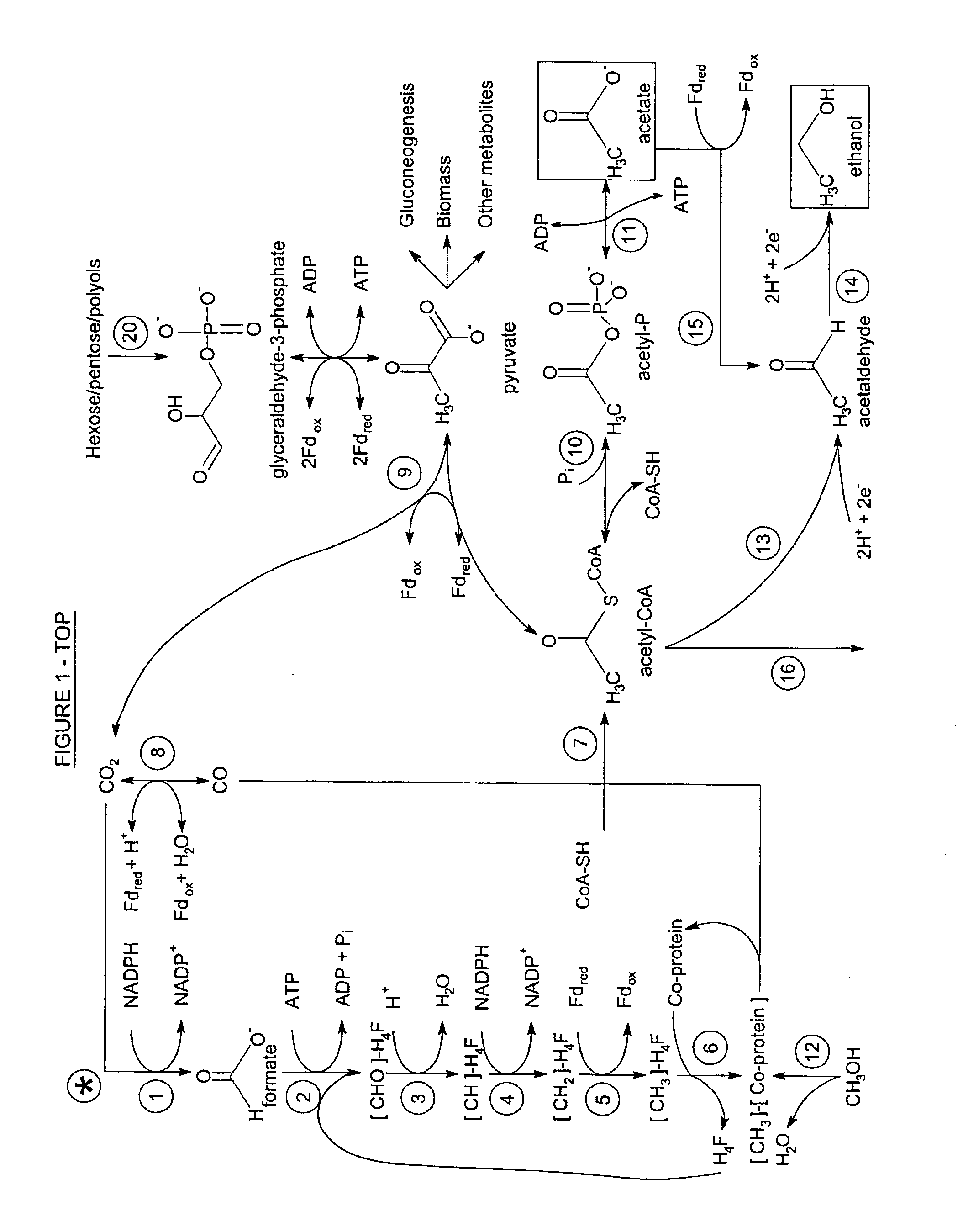

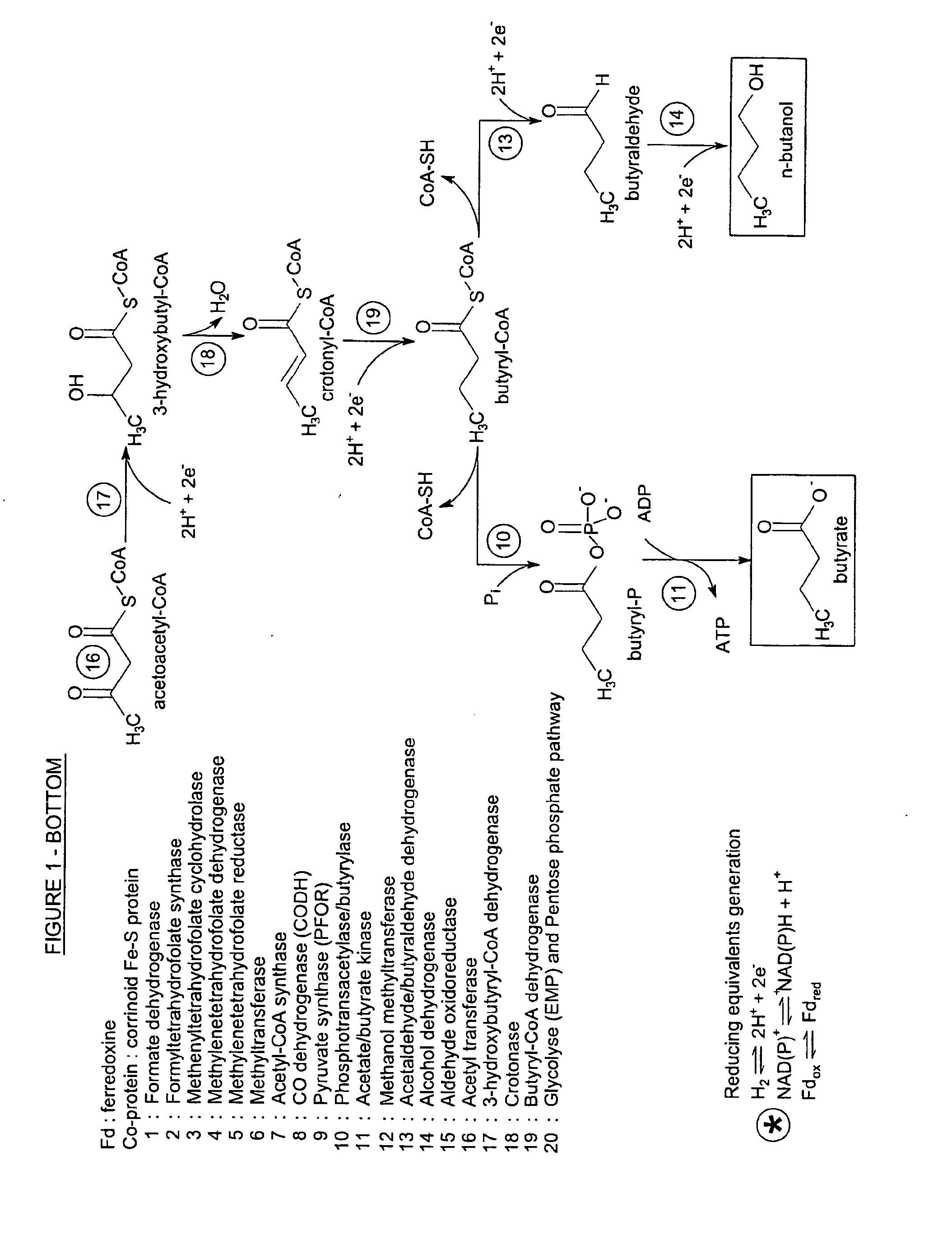

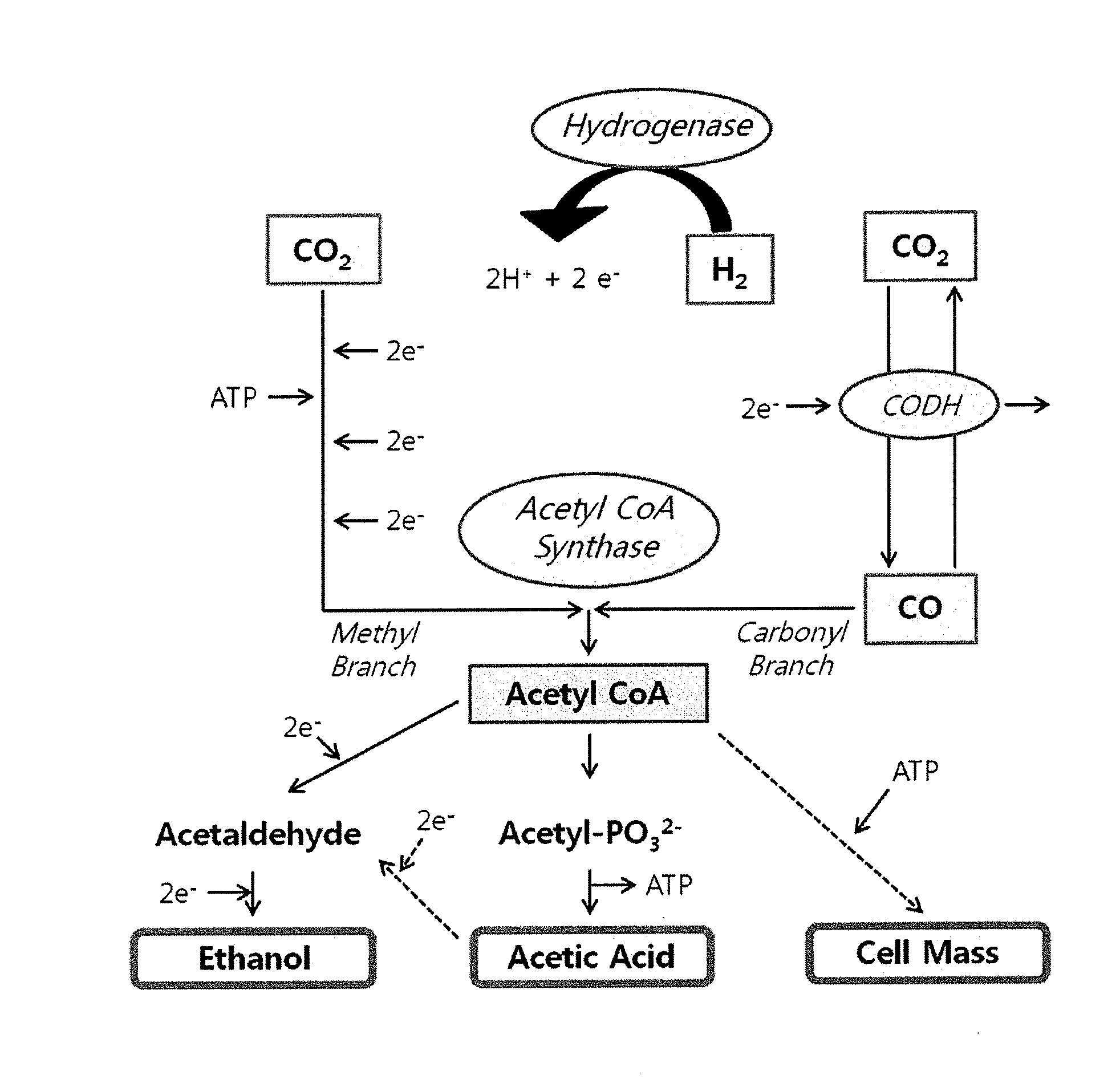

Syngas fermentation, also known as synthesis gas fermentation, is a microbial process. In this process, a mixture of hydrogen, carbon monoxide, and carbon dioxide, known as syngas, is used as carbon and energy sources, and then converted into fuel and chemicals by microorganisms.

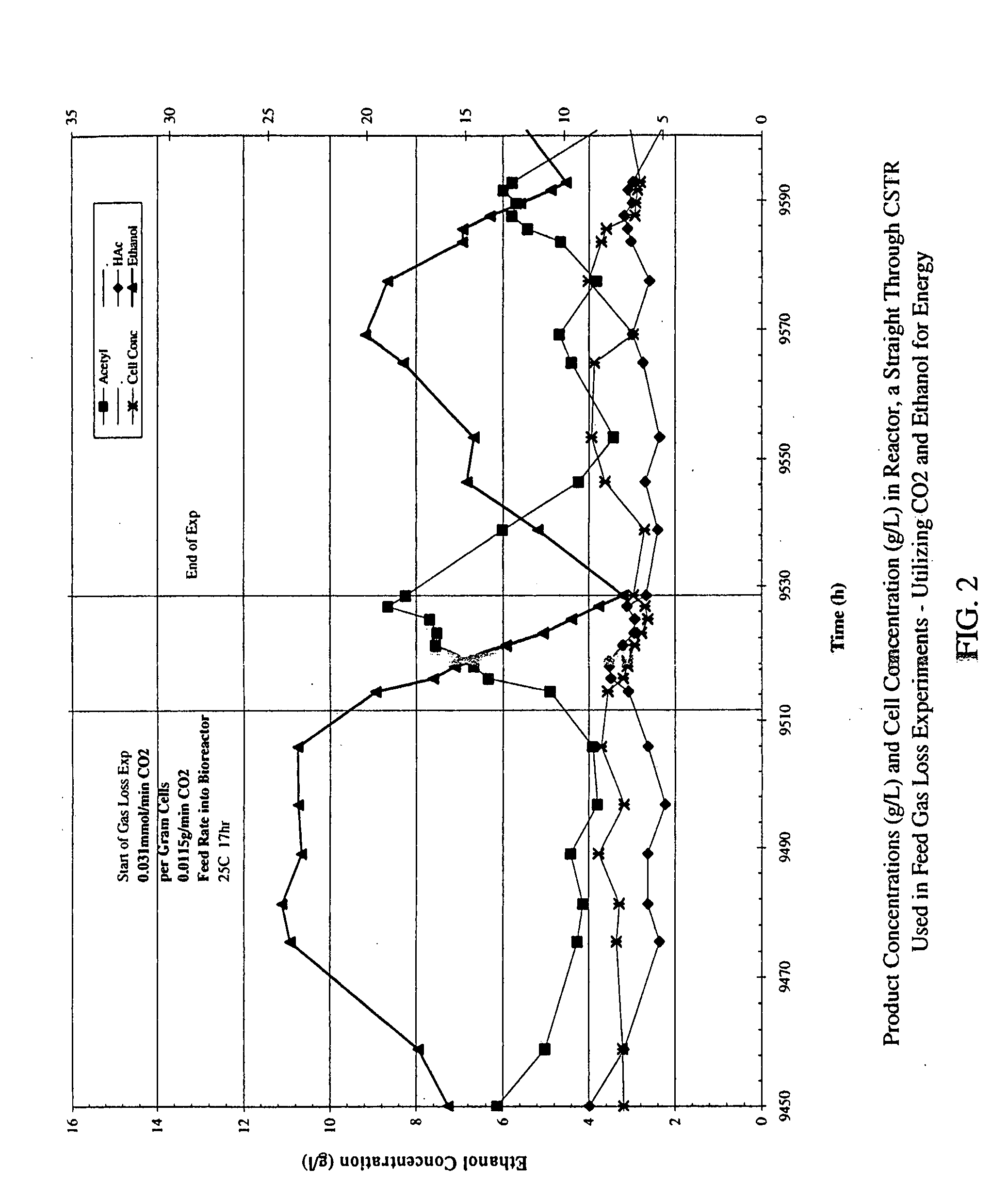

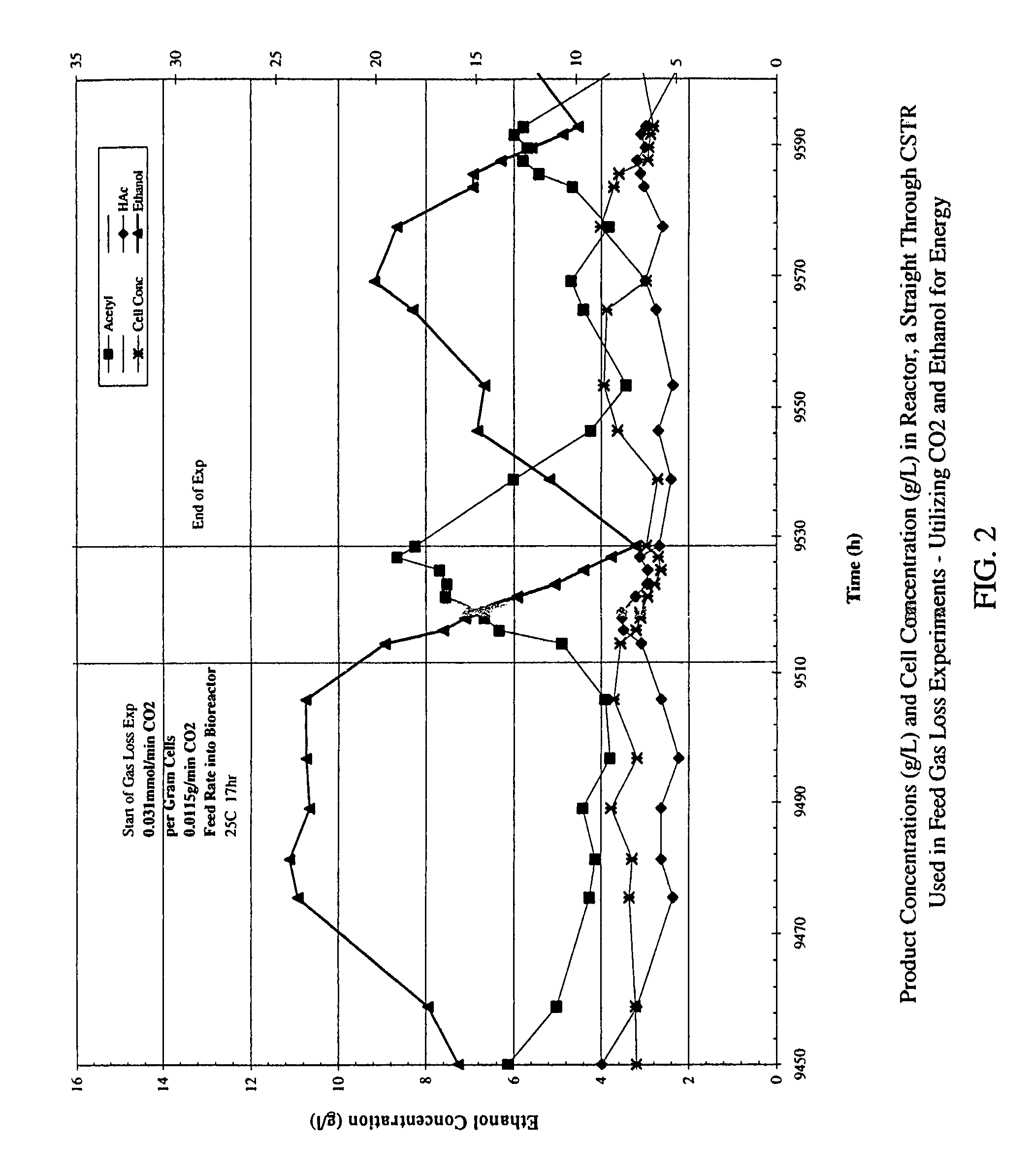

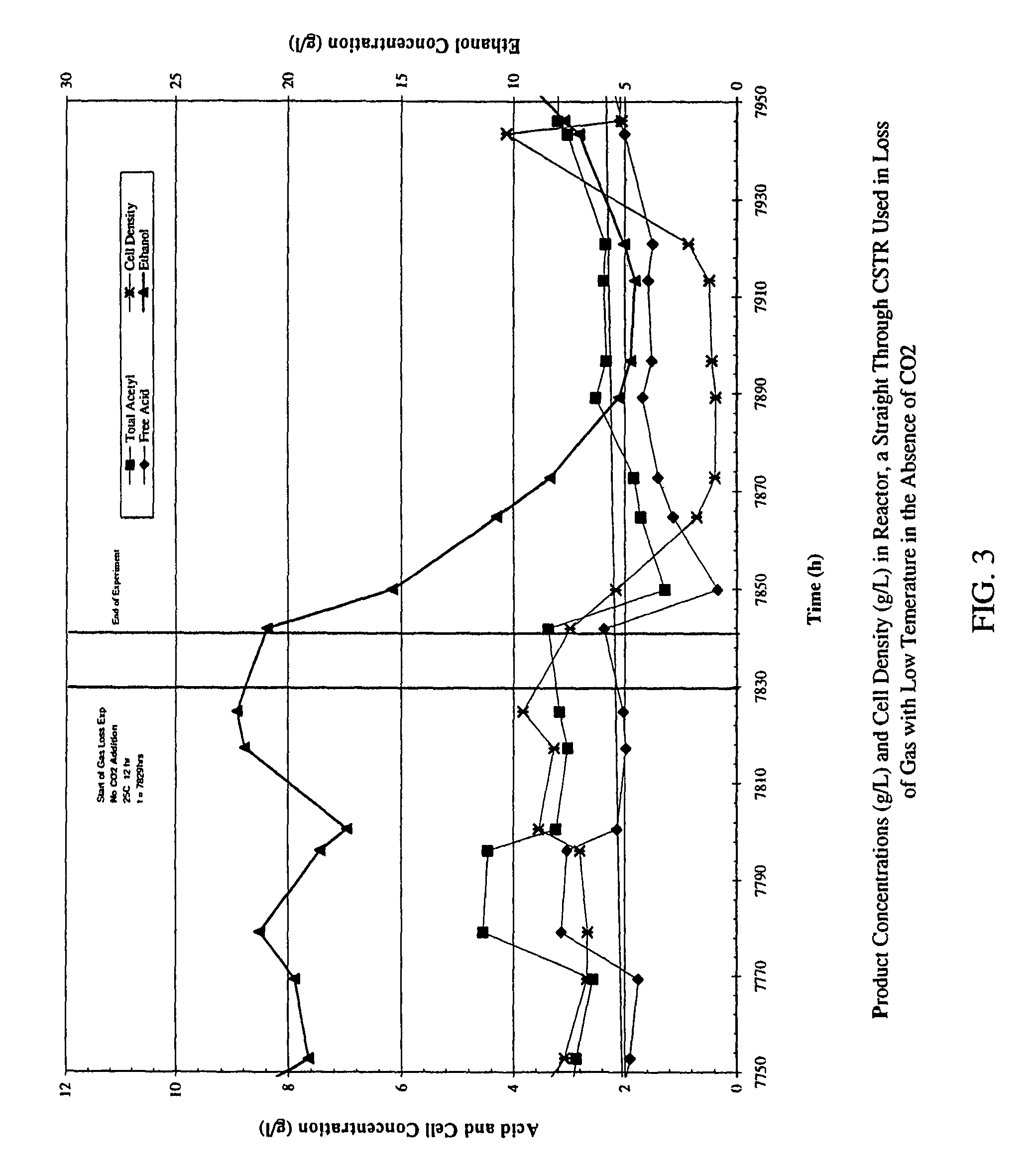

Method for sustaining Microorganism culture in Syngas fermentation process in decreased concentration or absence of various substrates

ActiveUS20100227377A1Preventing rapid lossDecreased absenceBacteriaUnicellular algaeMicroorganismAlcohol

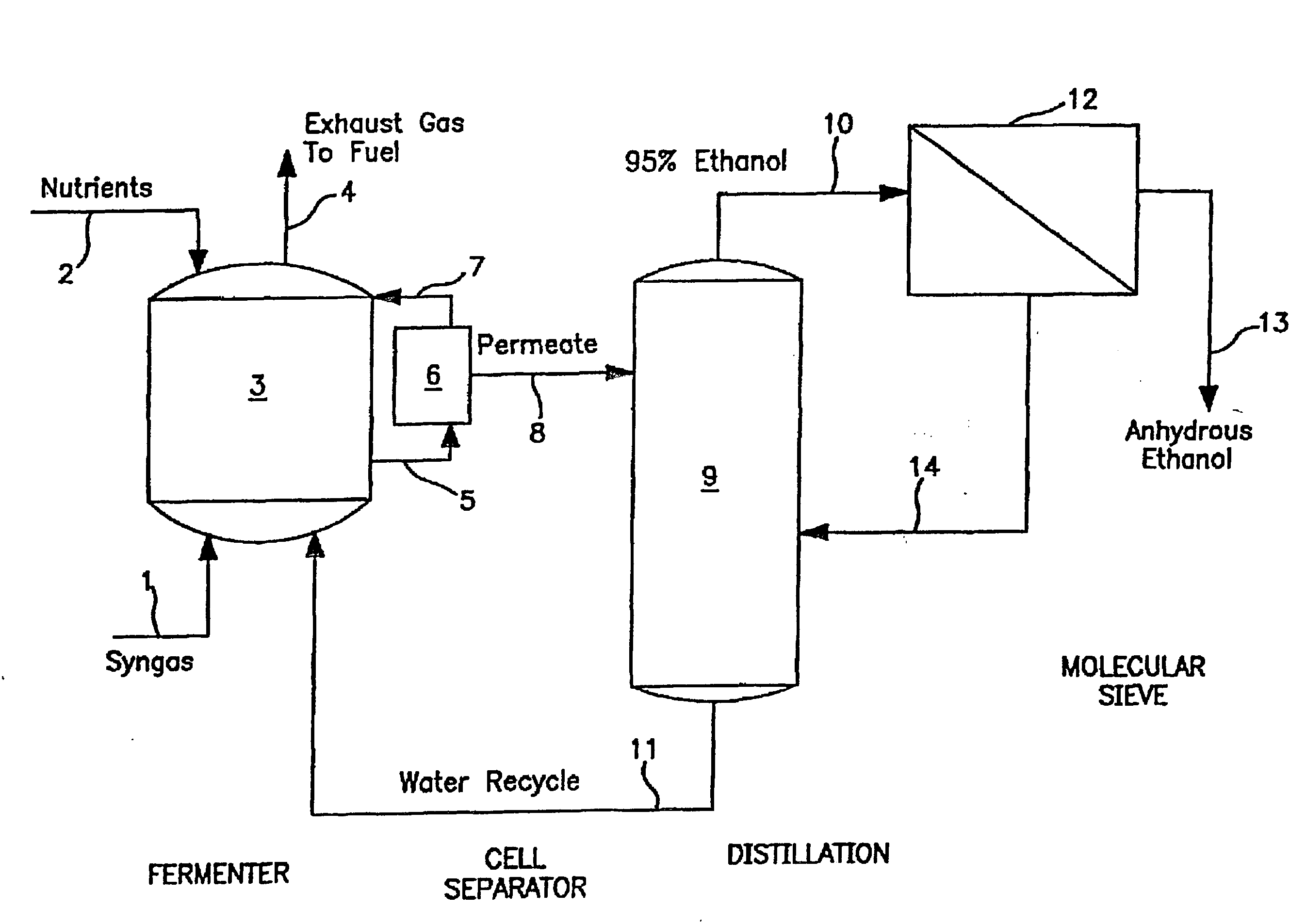

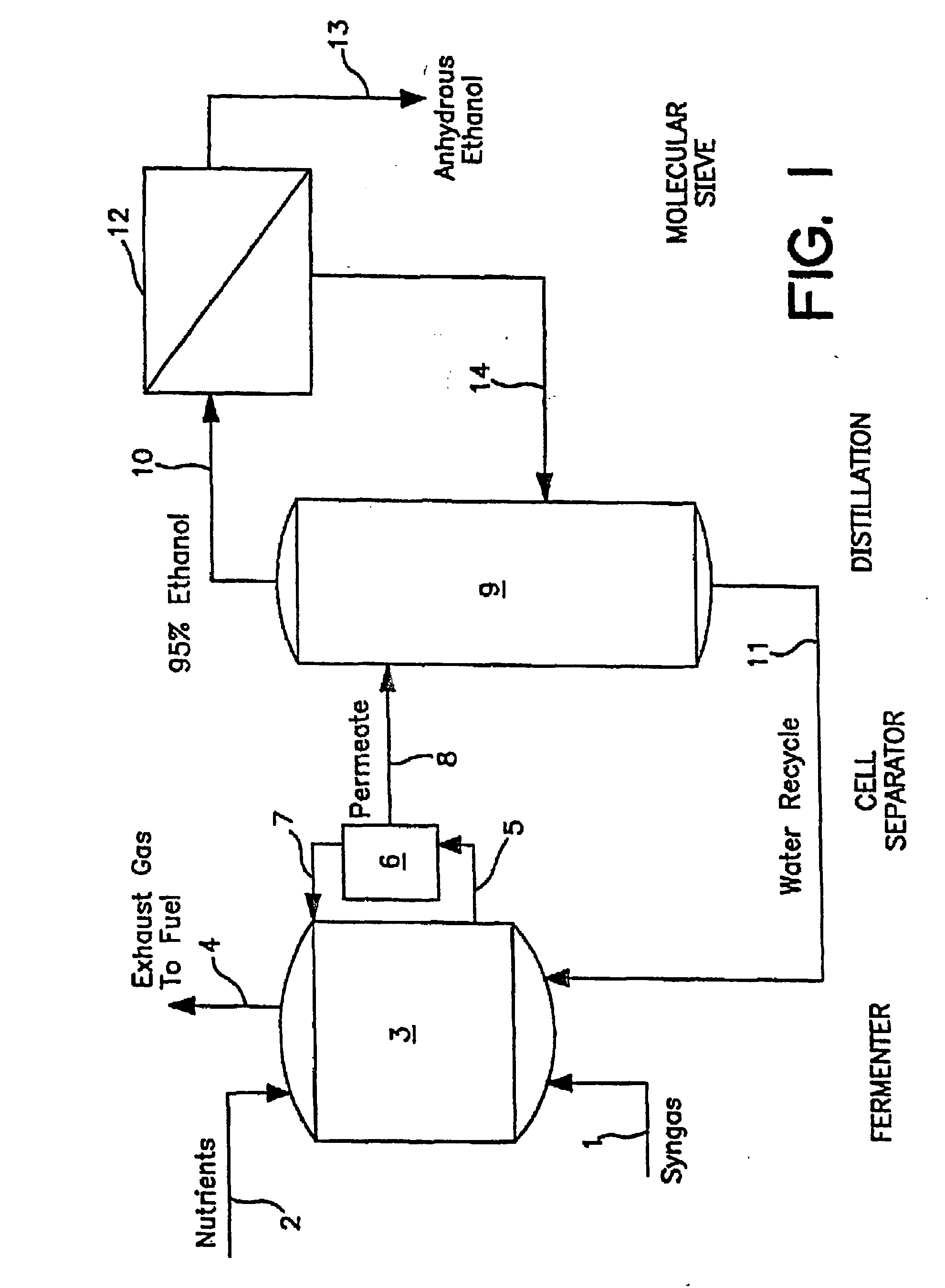

The present invention relates to methods for sustaining microorganism culture in a syngas fermentation reactor in decreased concentration or absence of various substrates comprising: adding carbon dioxide and optionally alcohol; maintaining free acetic acid concentrations; and performing the above mentioned steps within specified time.

Owner:JUPENG BIO HK LTD

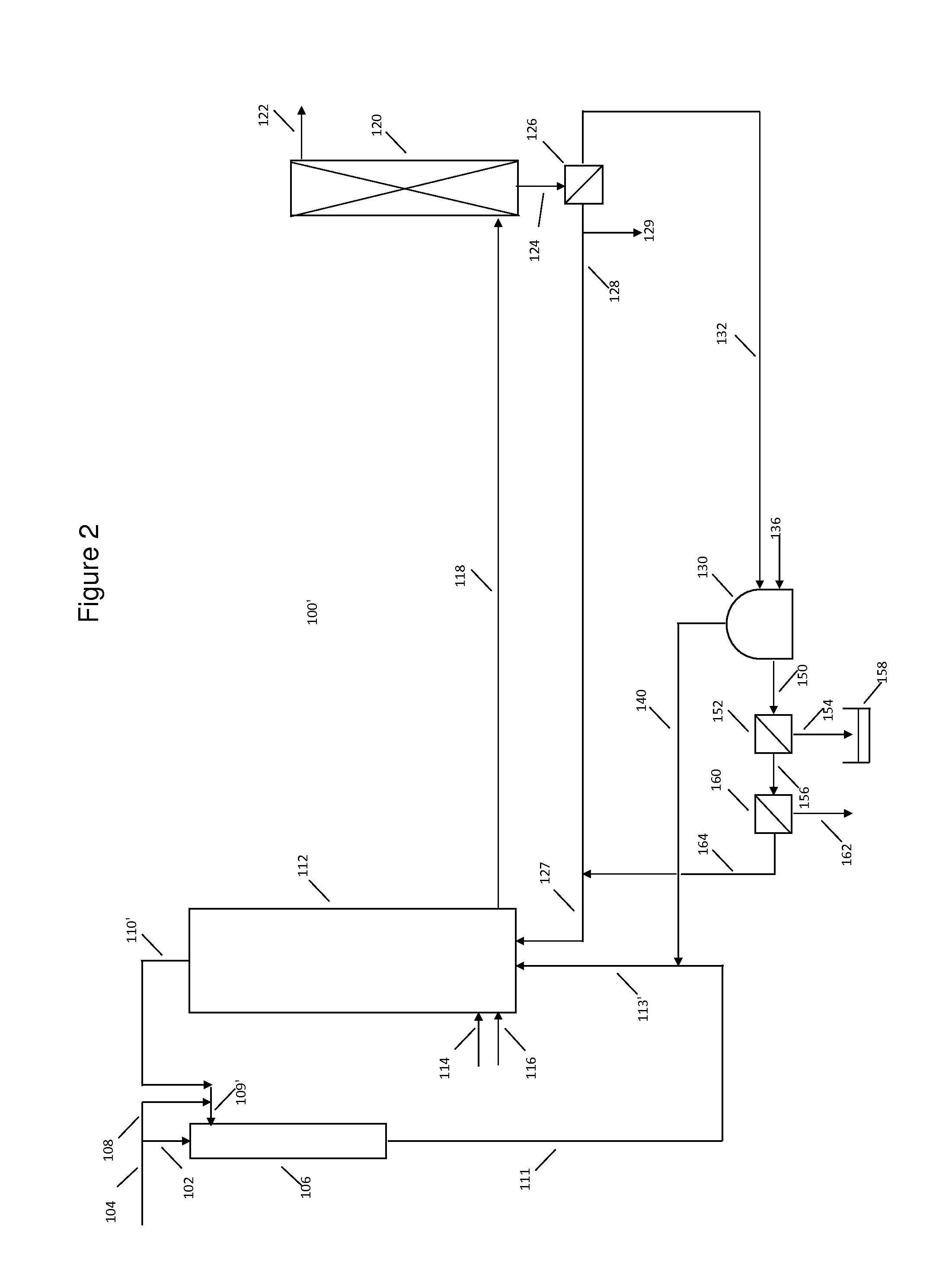

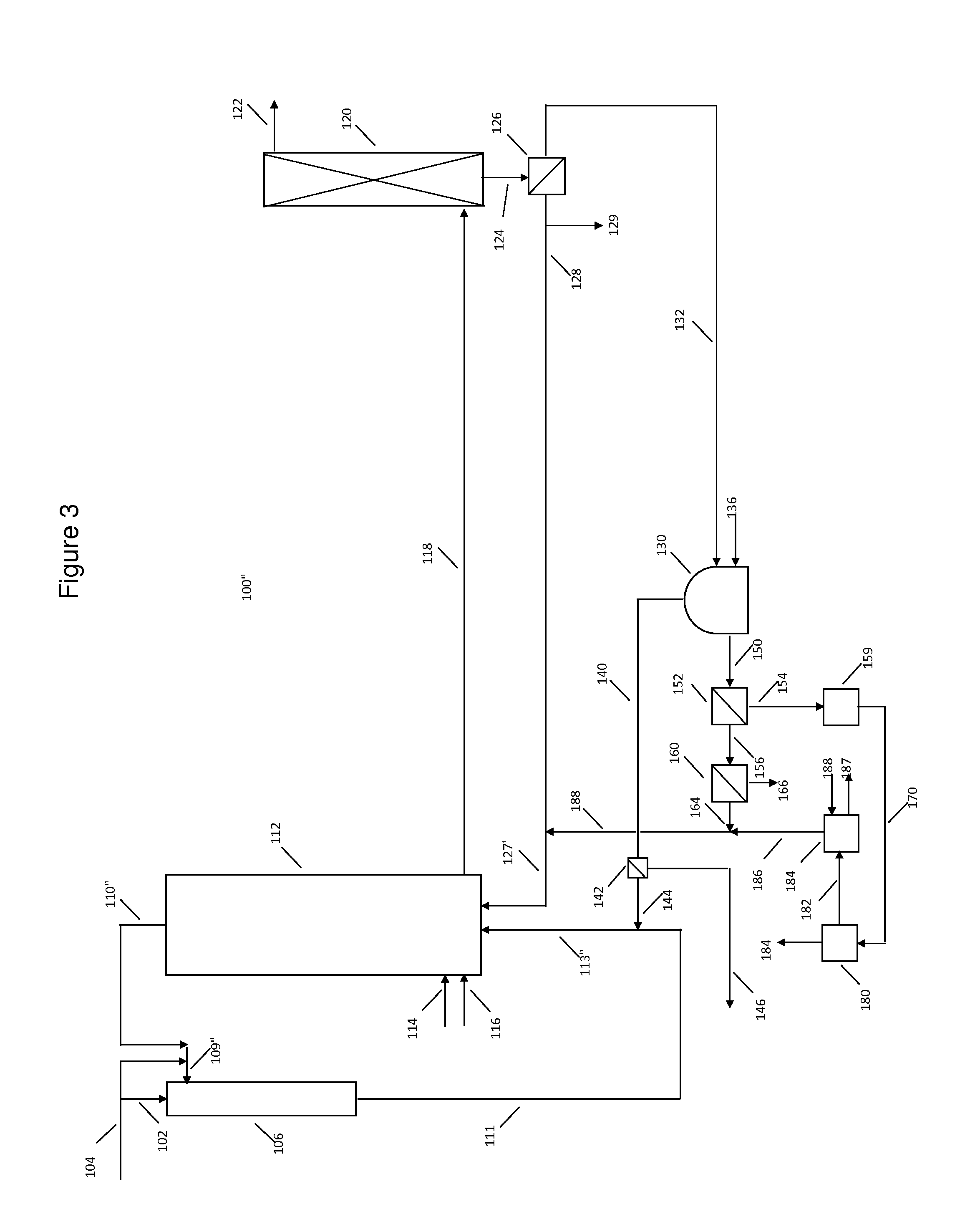

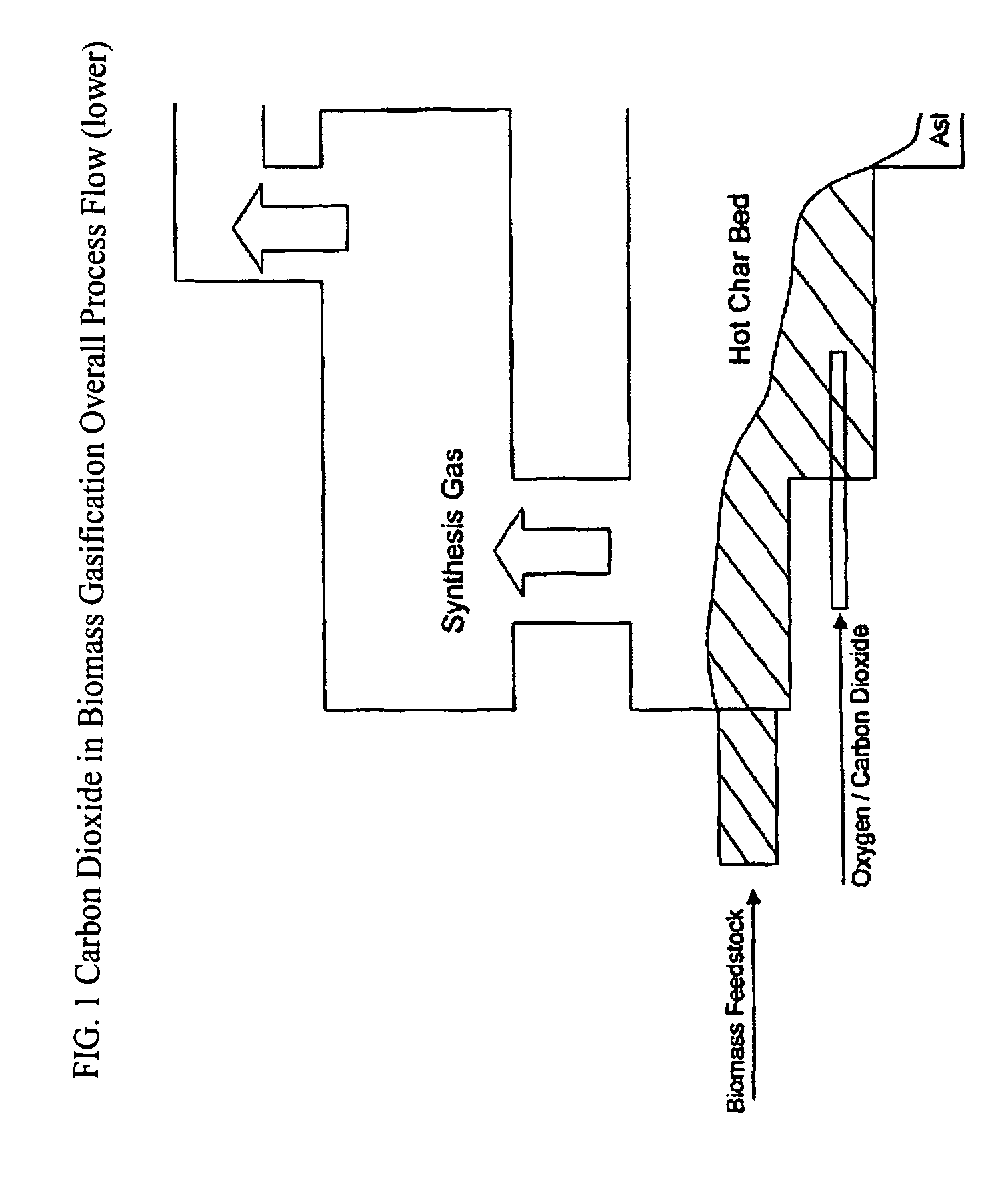

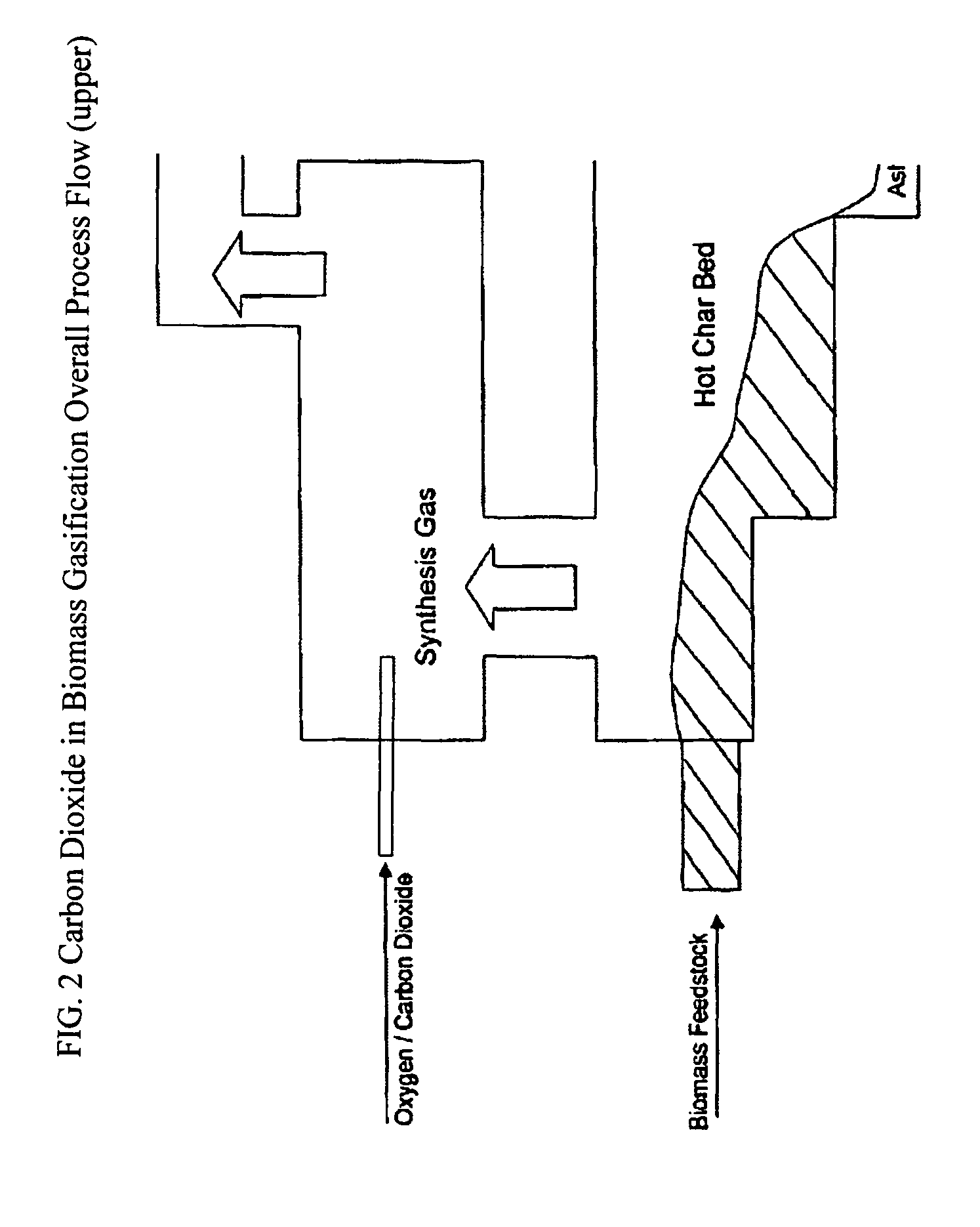

Methods for sequestering carbon dioxide into alcohols via gasification fermentation

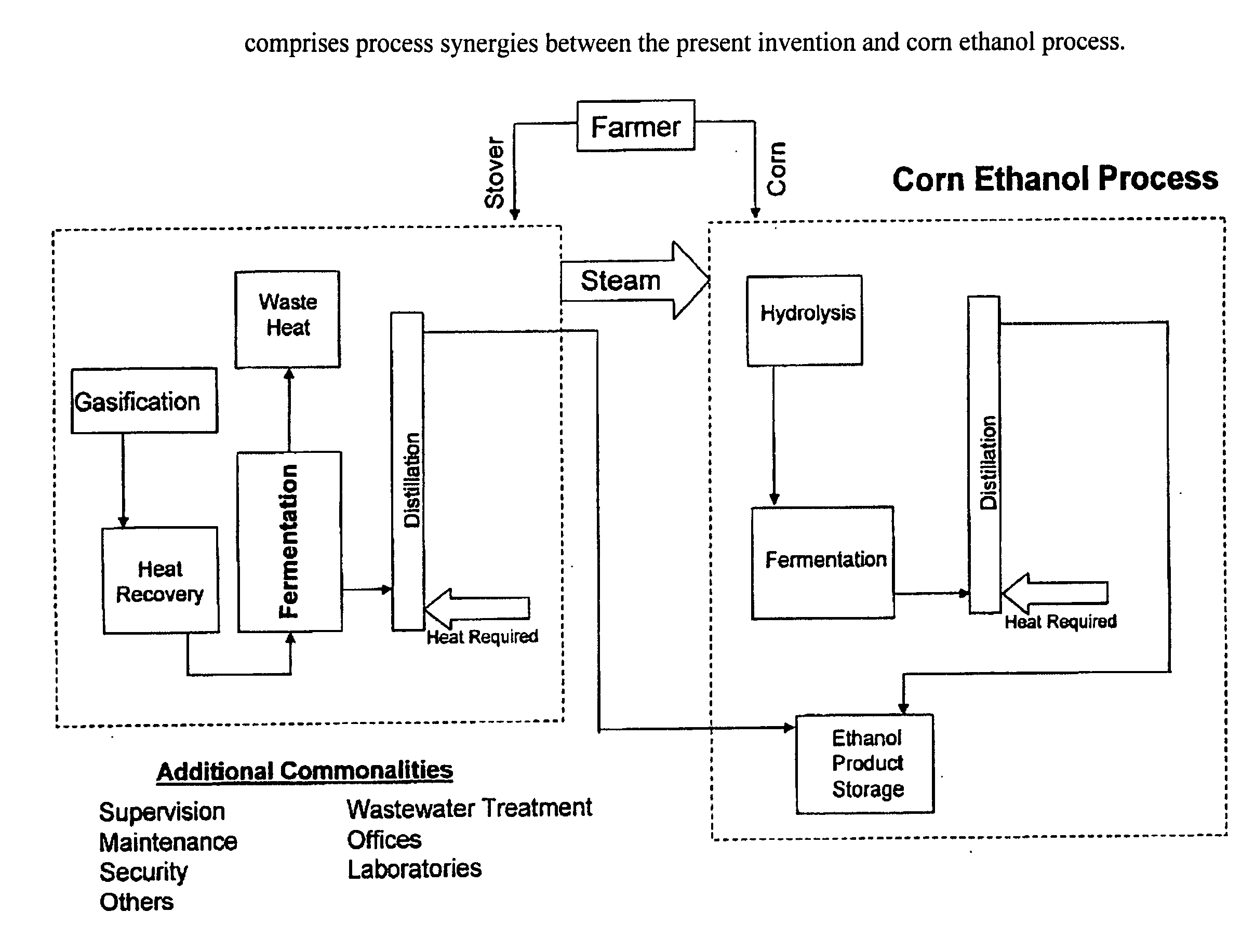

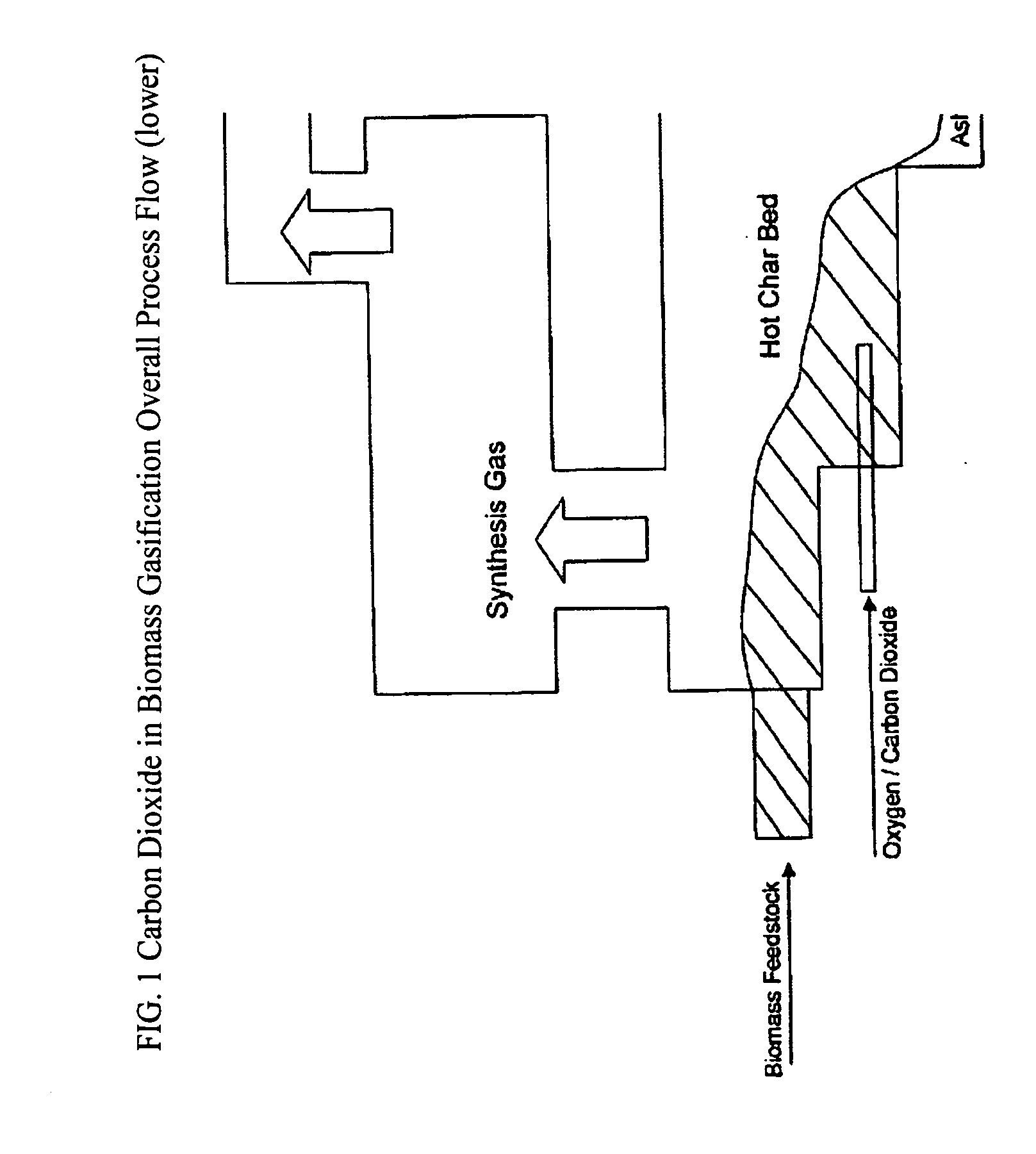

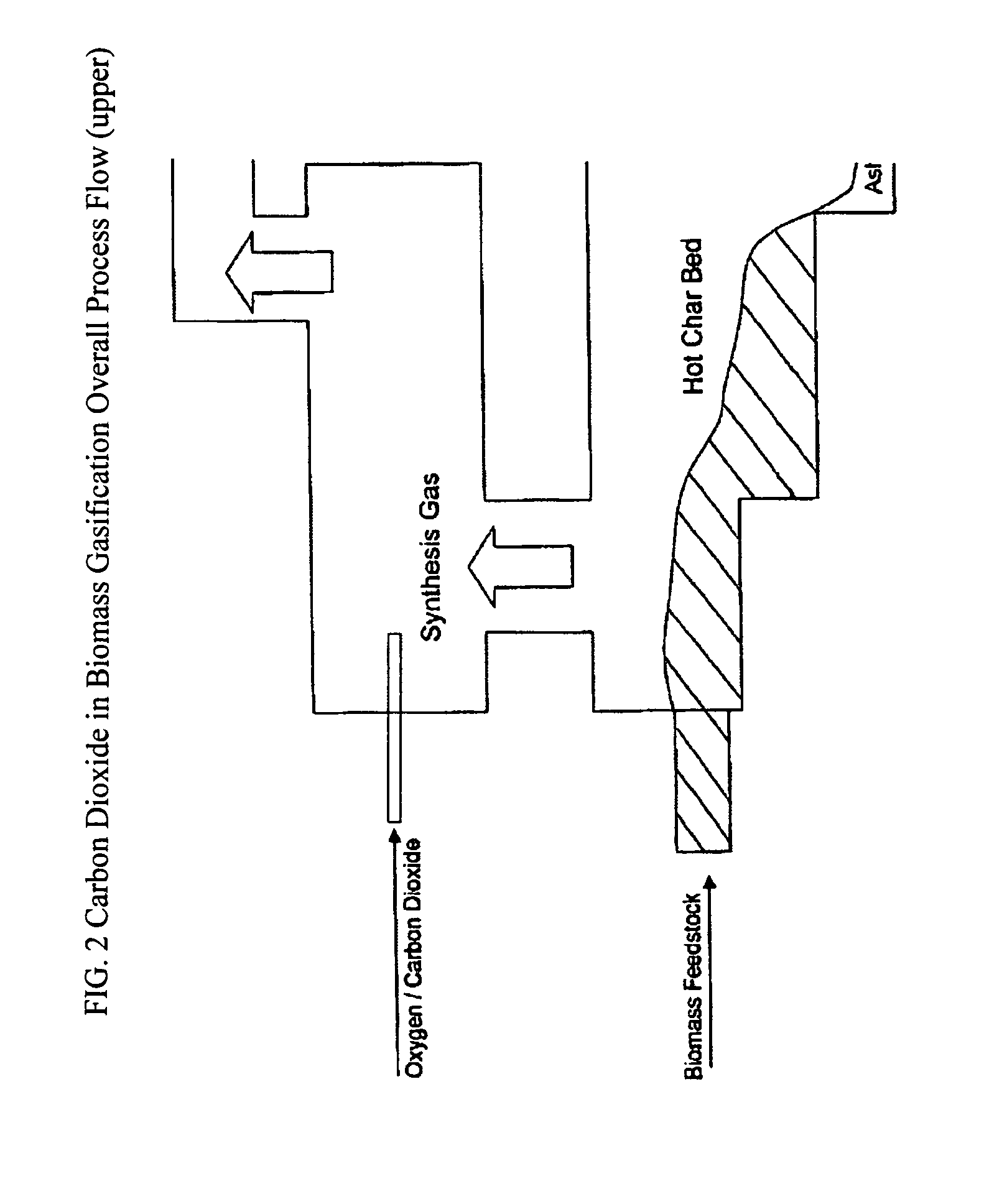

The present invention is directed to improvements in gasification for use with synthesis gas fermentation. Further, the present invention is directed to improvements in gasification for the production of alcohols from a gaseous substrate containing at least one reducing gas containing at least one microorganism.

Owner:JUPENG BIO HK LTD

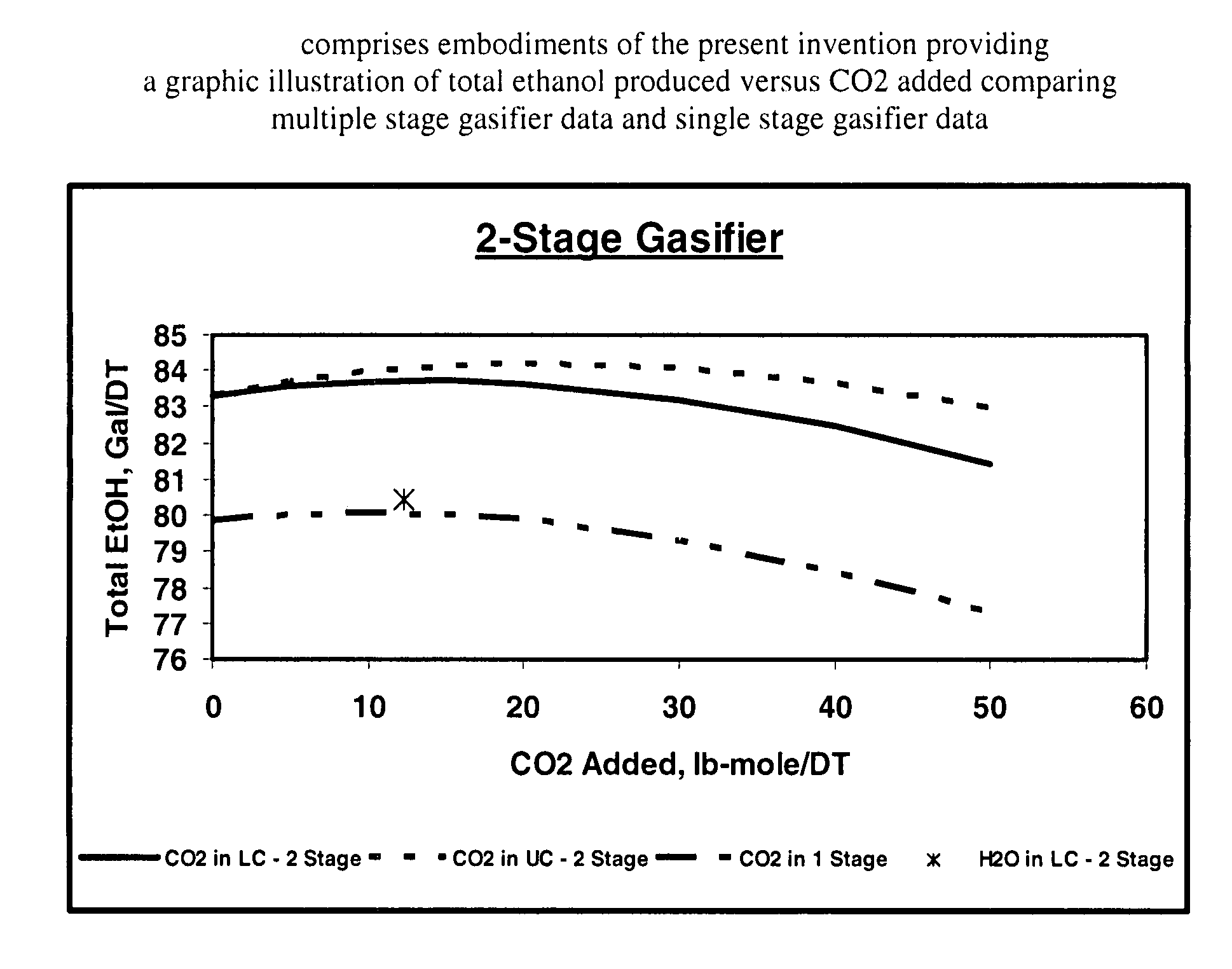

Improved carbon capture in fermentation

ActiveUS20120052541A1Increasing carbon captureImproving overall efficiency and carbon captureBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholFermentation

The present invention relates to improvement in efficiency in gasification for use with syngas fermentation. In particular, the invention relates to increasing the overall carbon capture efficiency of a gasification / fermentation process to produce products such as alcohols.

Owner:LANZATECH NZ INC

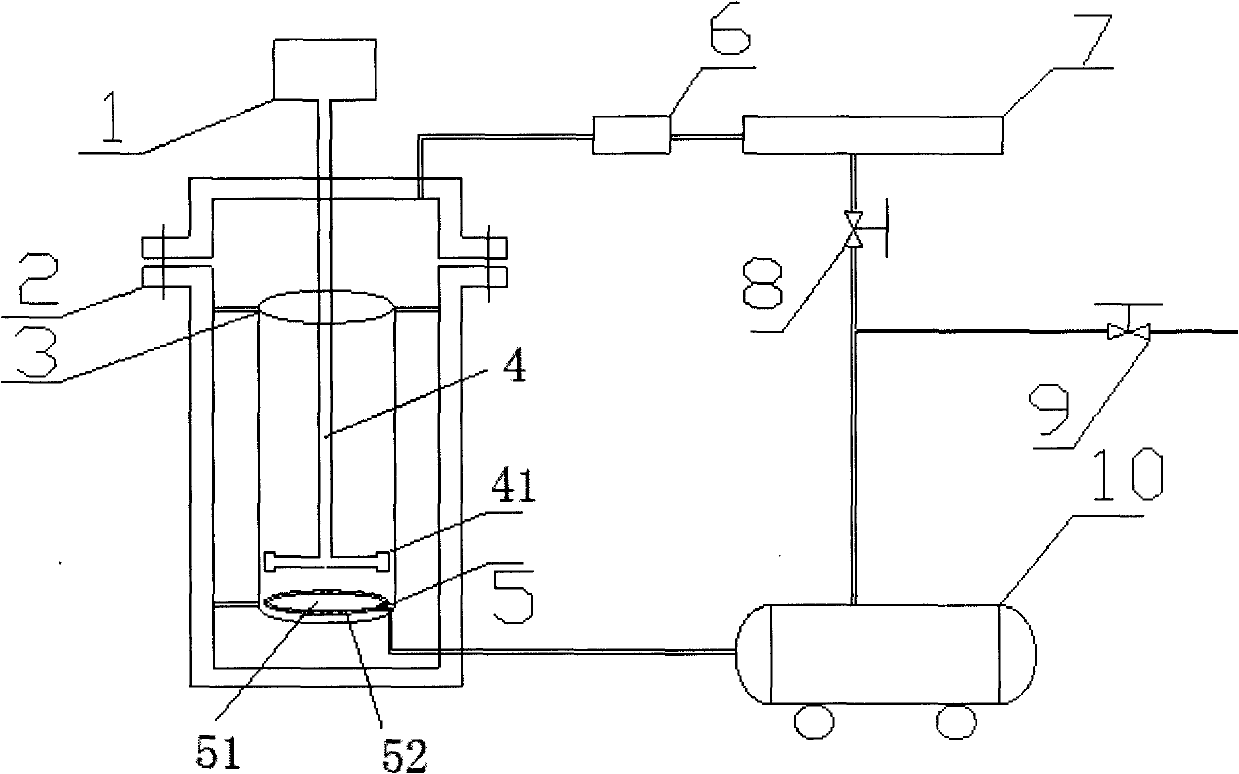

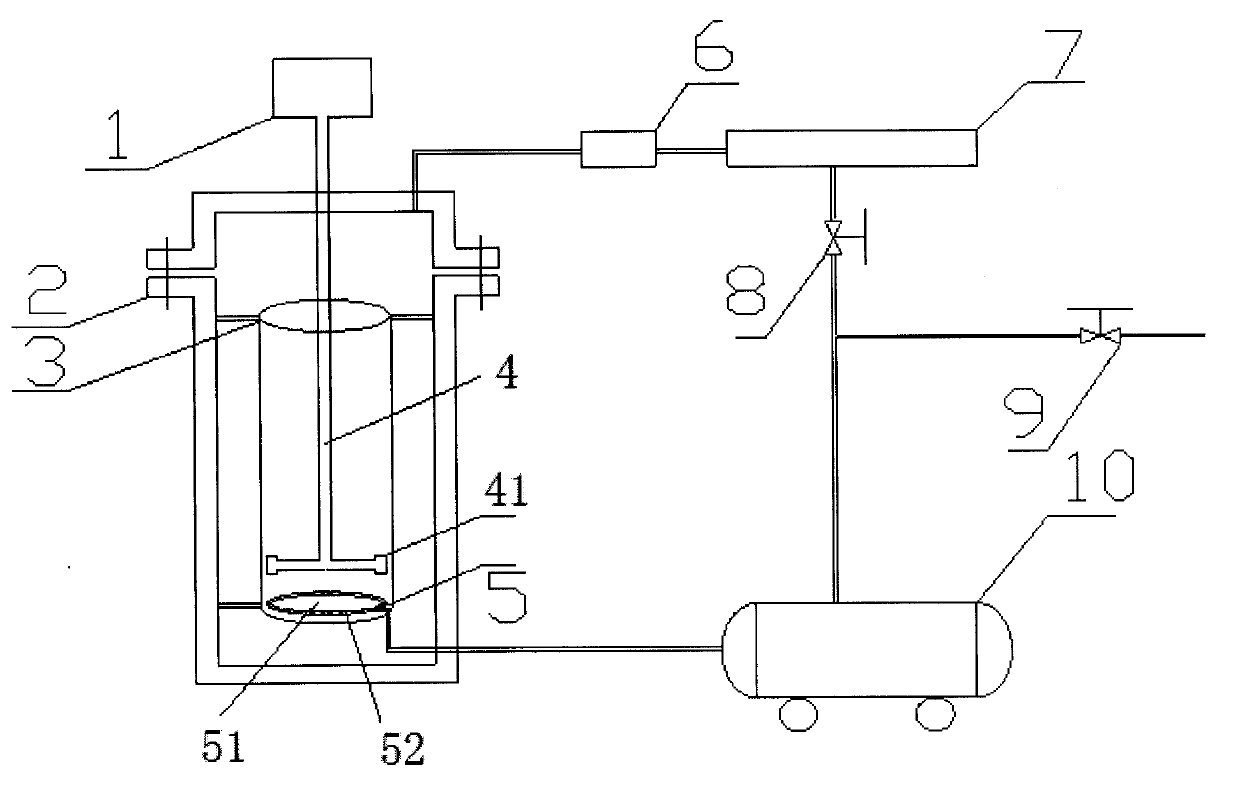

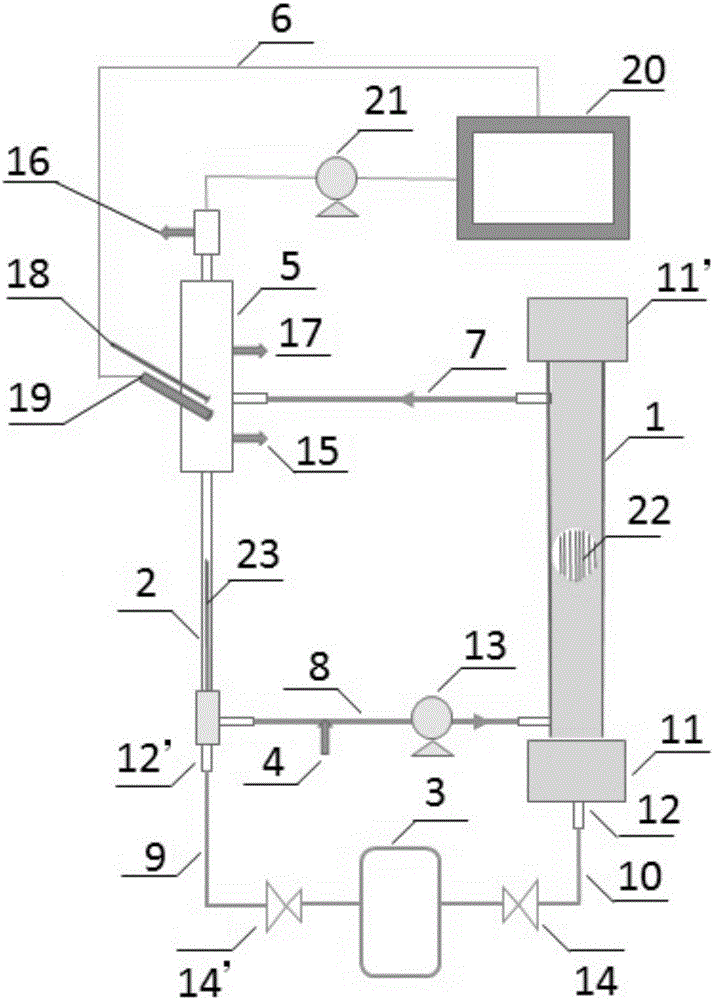

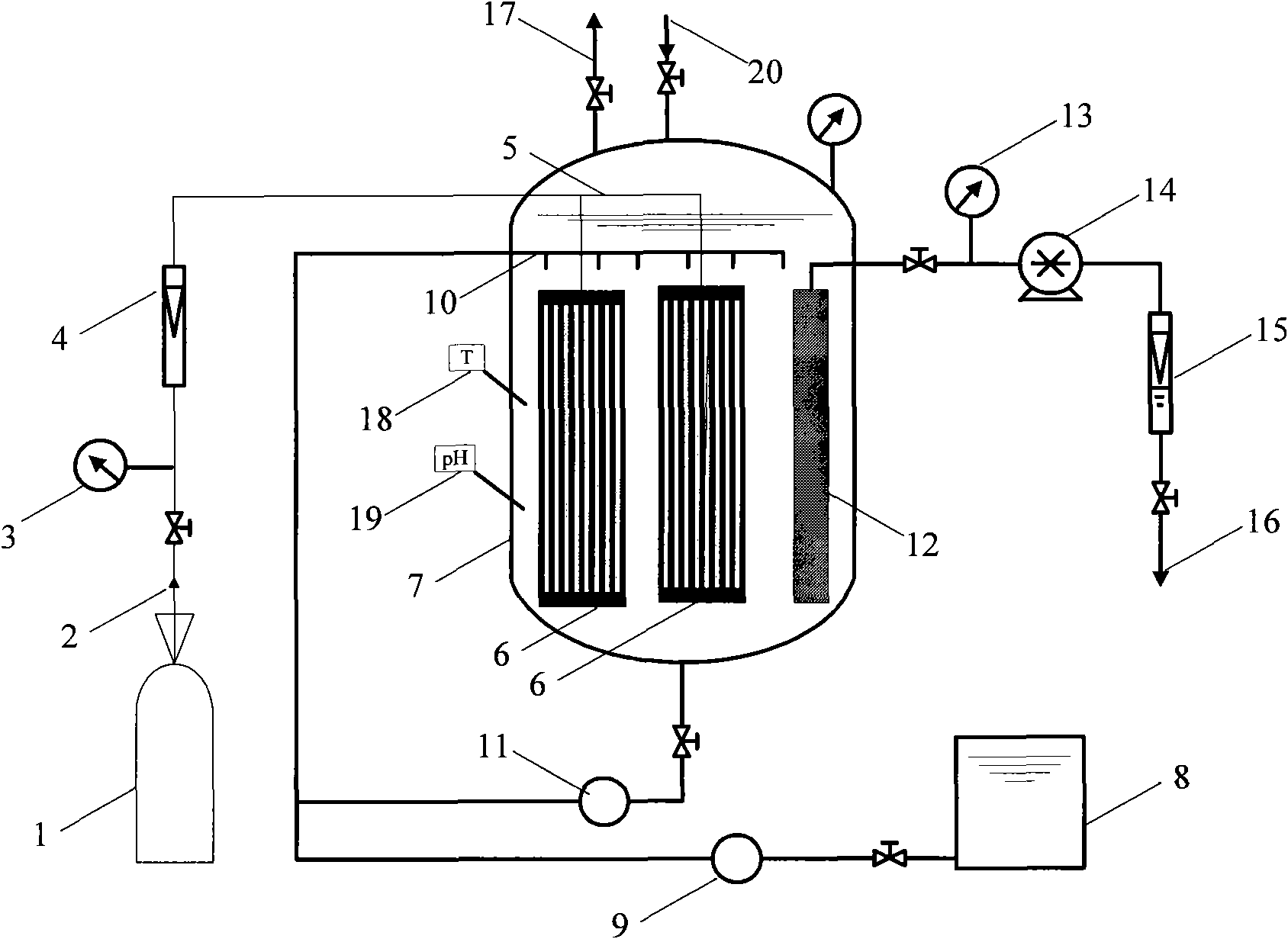

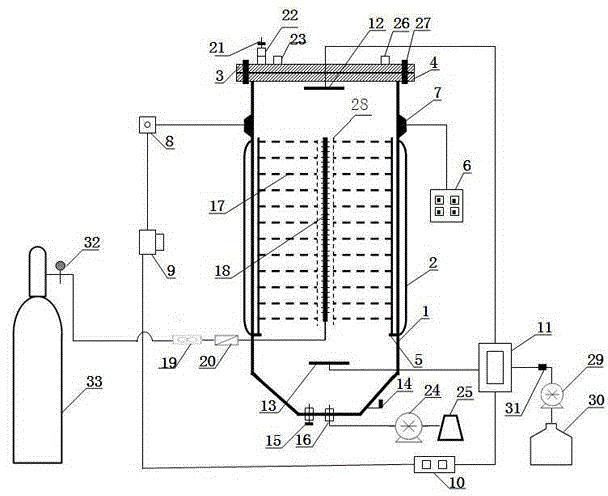

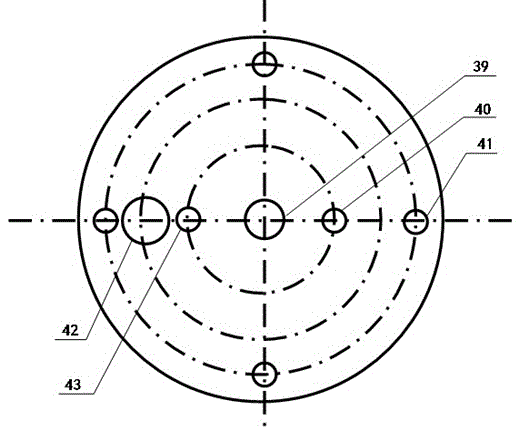

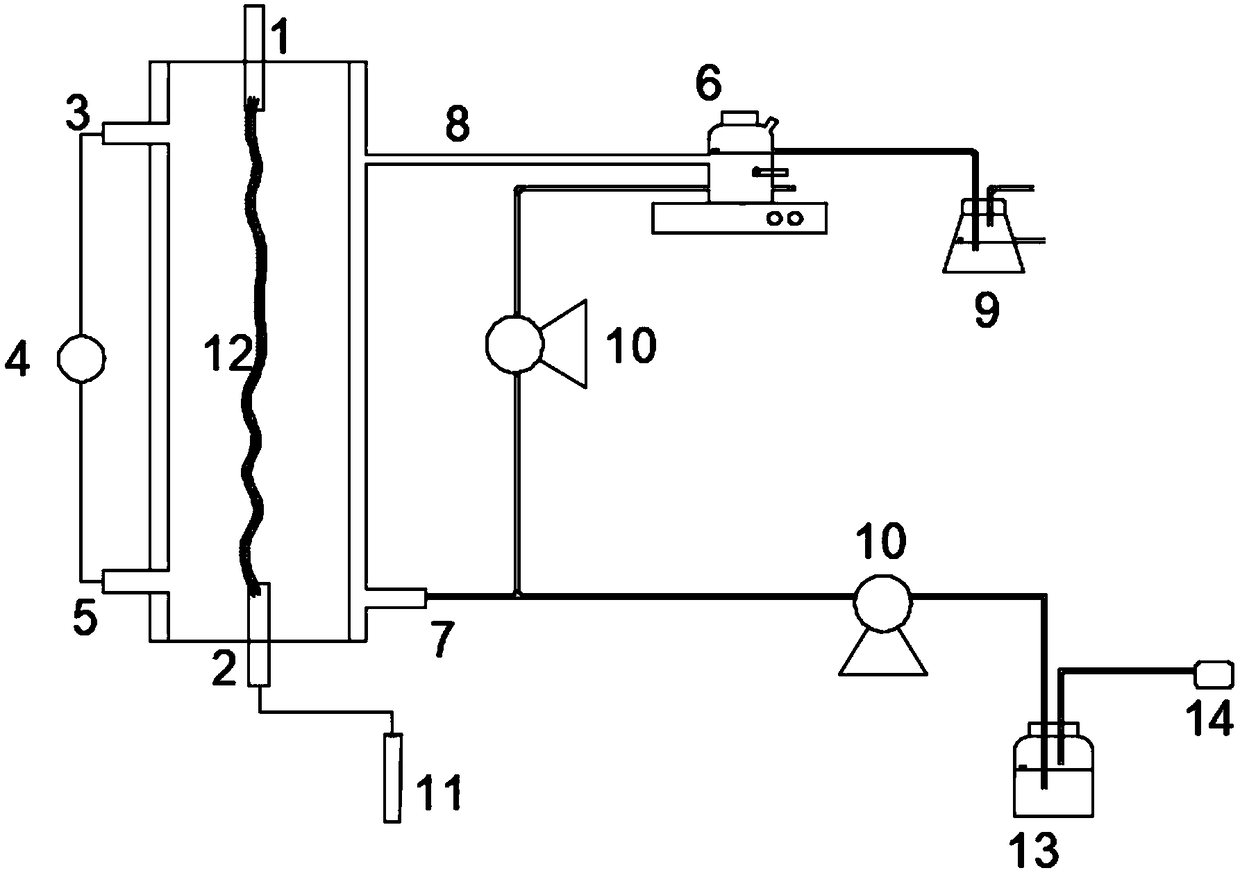

Reaction device for producing organic acid and alcohol through synthesis gas fermentation

InactiveCN101768540ASimple structureEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsOrganic acidAlcohol

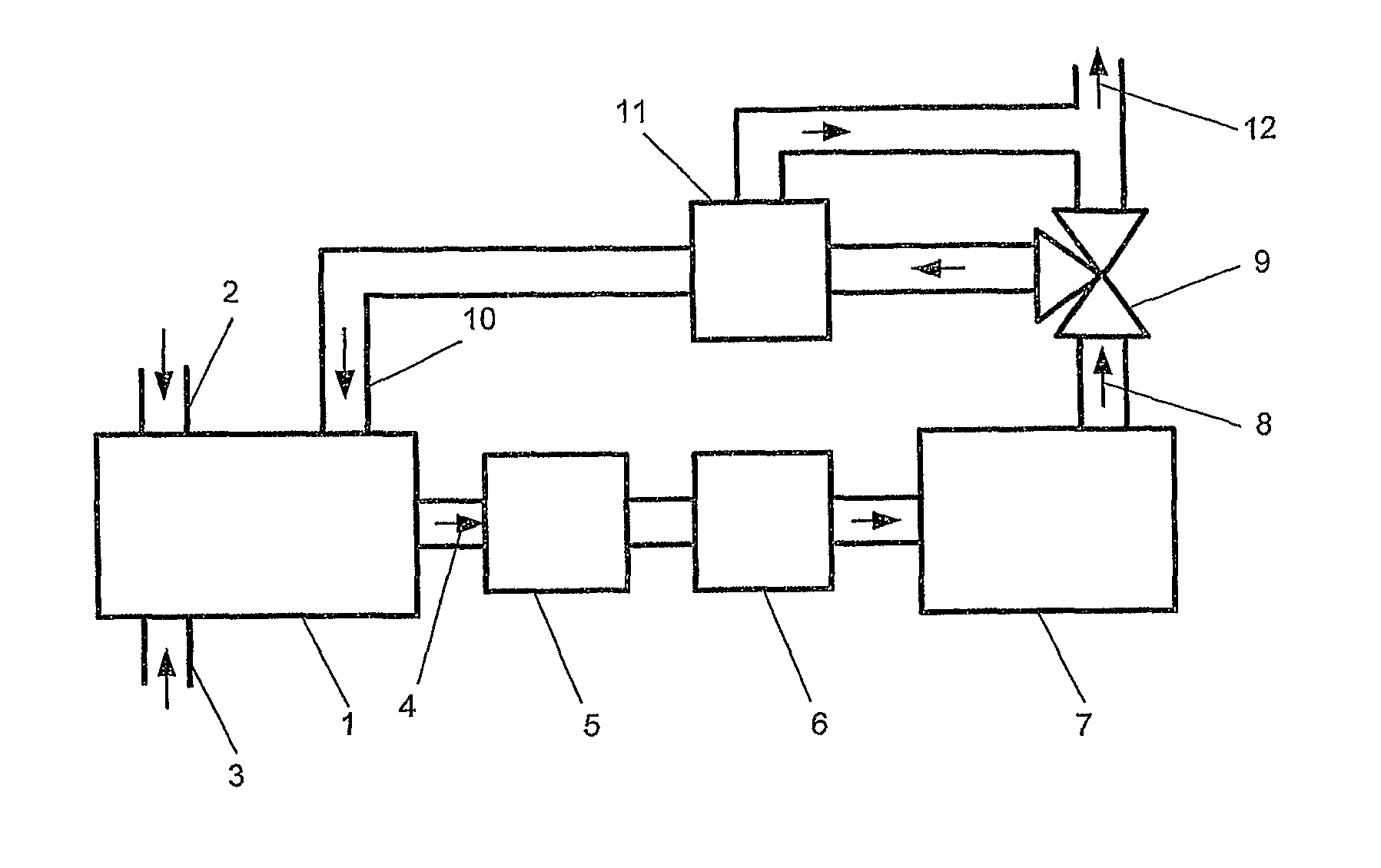

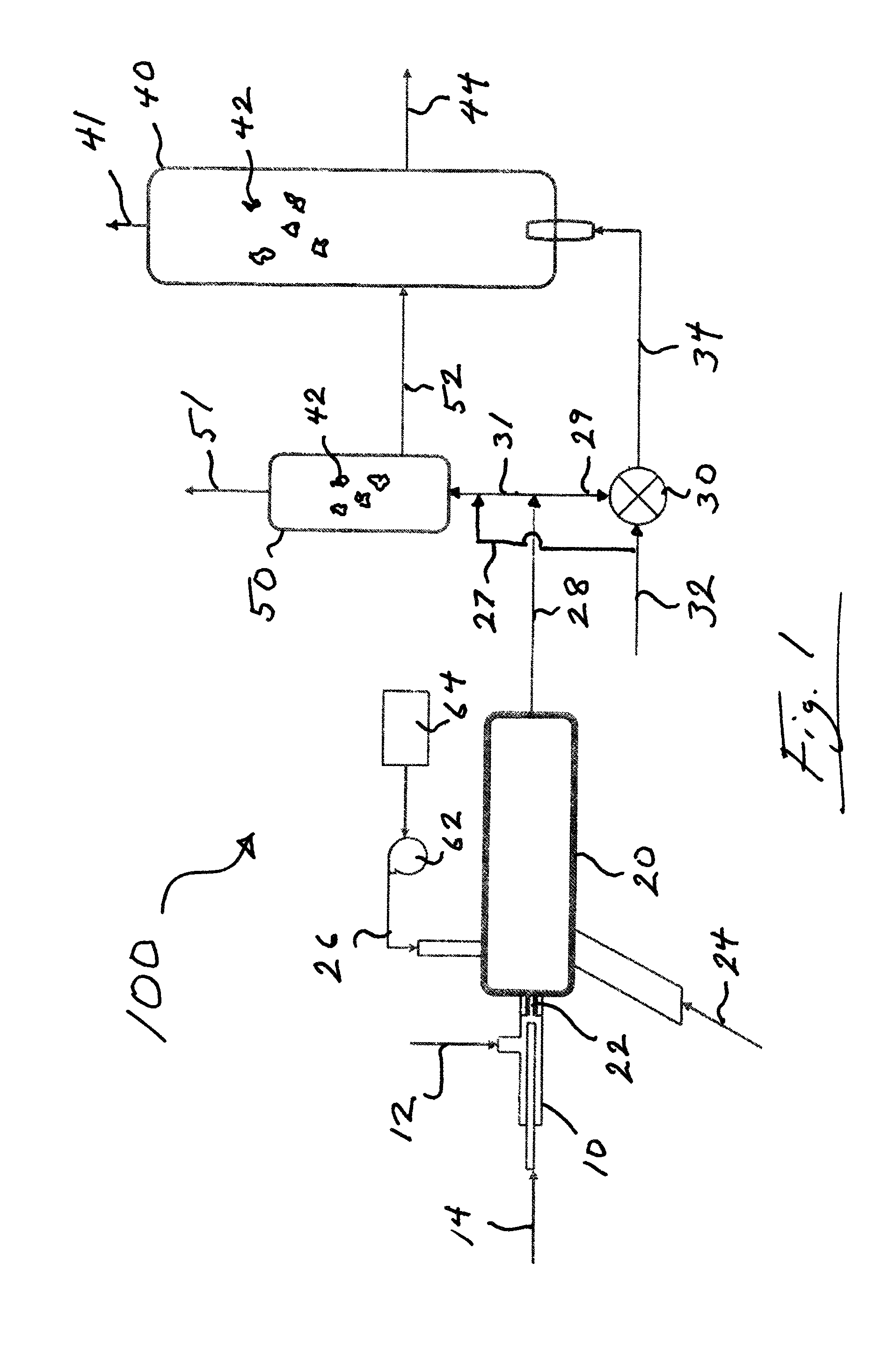

The invention discloses a reaction device for producing organic acid and alcohol through synthesis gas fermentation, comprising a main body reactor and an external gas cycle system which is connected with the main body reactor and cycles the gas generated in the main body reactor, wherein the main body reactor comprises a reactor pot body and a guide cylinder which is arranged in the reactor pot body, is fixed by a support and is a concentric cylinder of the reactor pot body; a blade type blender is arranged along the axis of the guide cylinder, the end, with a blending blade, of the blender is arranged close to the bottom end of the guide cylinder and the other end of the blender is connected with a drive motor; a vent pipe of a gas distributor stretches into the position between the bottom in the guide cylinder and the lower part of the blending blade, and the other end of the gas distributor is communicated with a gas input pipeline by stretching out of the guide cylinder. A cycle gas circuit and a normal gas supply gas circuit are alternately used in the external gas cycle system. The reaction device of the invention has the advantage of simple structure and operation, can obtain good gas-liquid mass transfer without high blending power and ventilation volume, can not only realize continuous gas supply but also realize gas cycle utilization, and greatly improves the use ratio of the gas substrate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

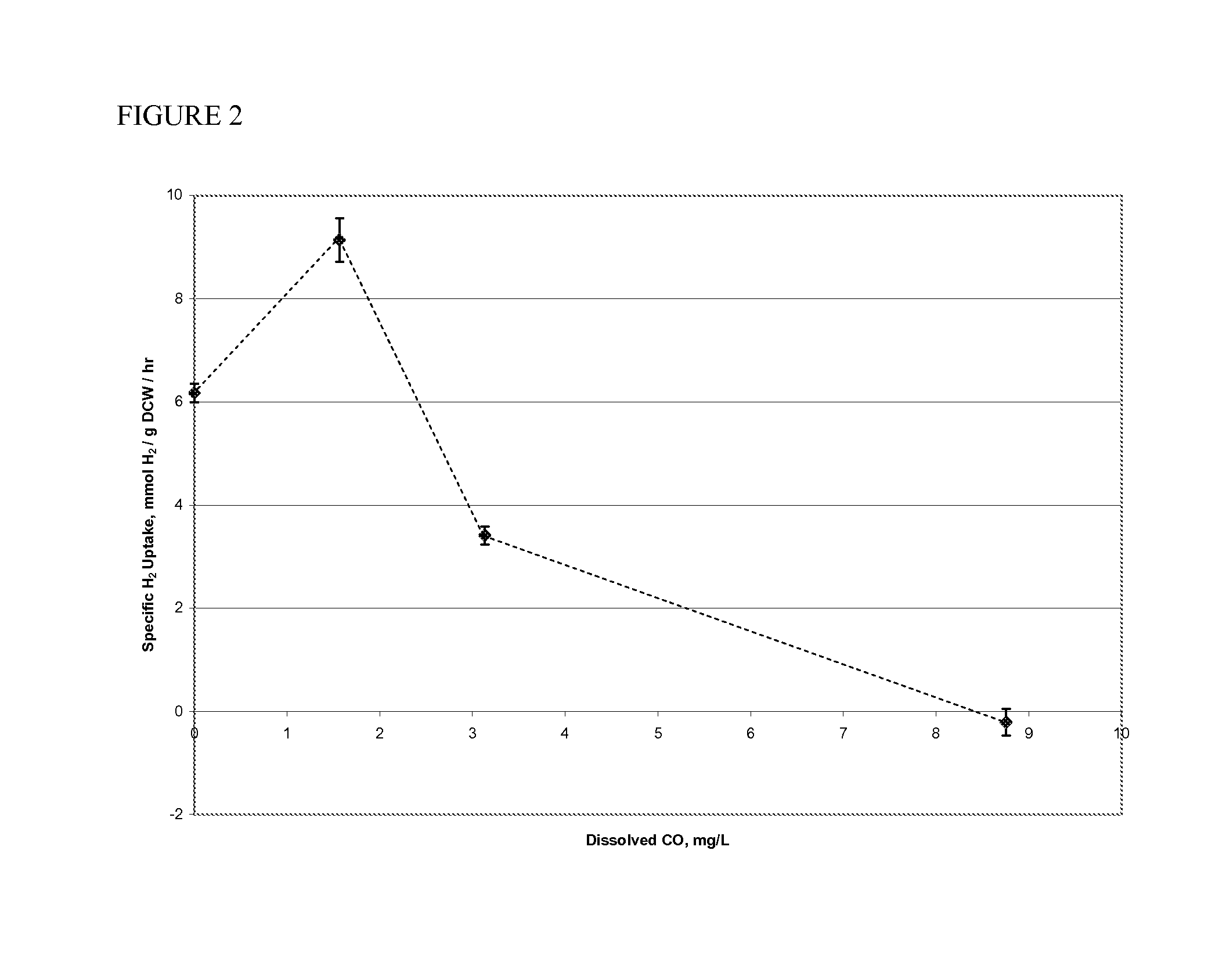

Process for restricting carbon monoxide dissolution in a syngas fermentation

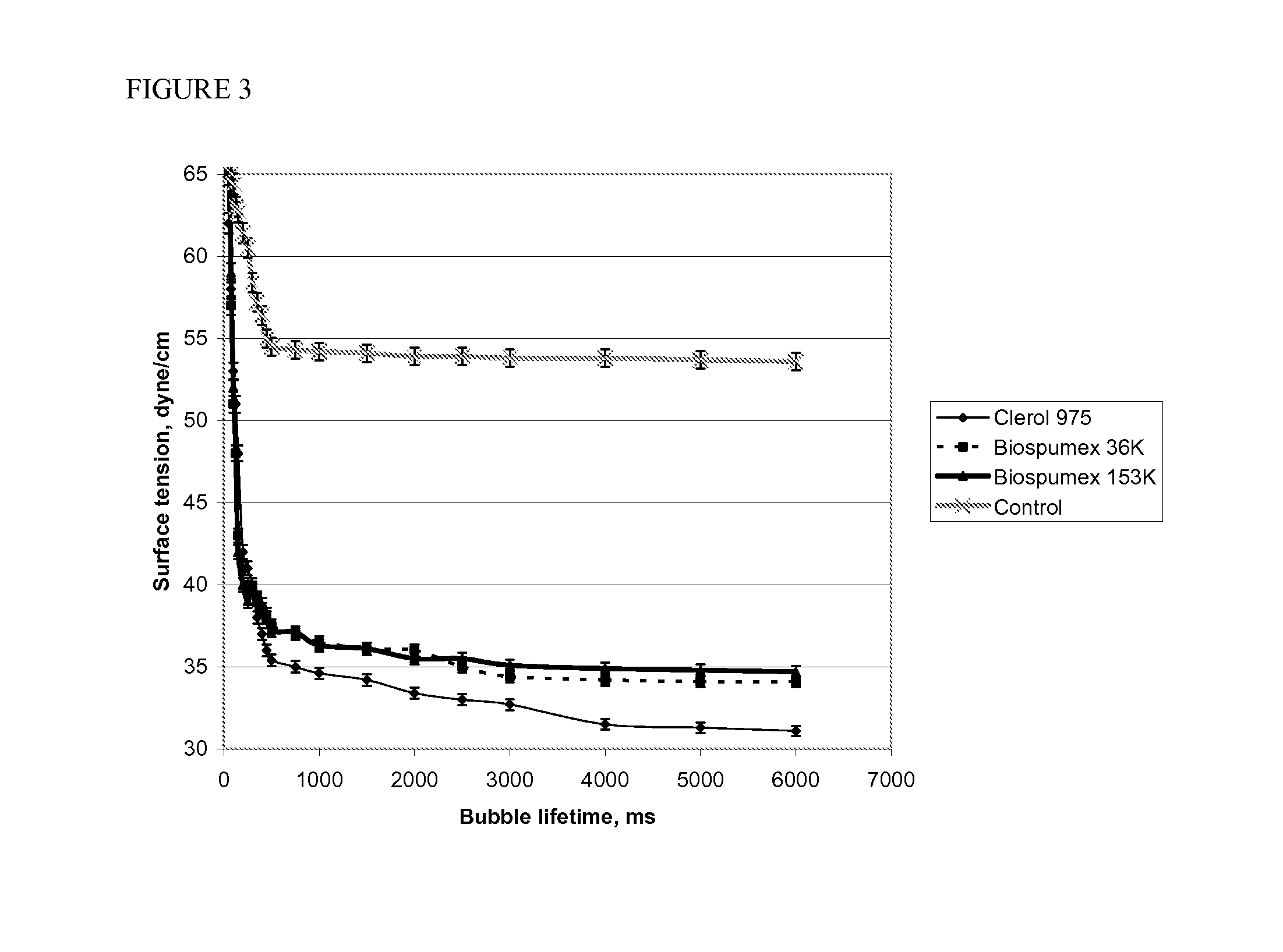

A process to temporarily and selectively control the dissolved concentration of CO in the feed medium portion of a fermentation liquid by addition of a surface tension active compound (STAC), particularly during seed train scale-up operations and during recovery from process upsets, to support improved production of biofuels from a syngas fermentation. The process inoculates the fermentation liquid when the cell density level is from 0.05 to 0.5 OD with the surface tension active compound at a concentration of from 20 to 800 mg per liter of syngas fermentation liquid. The surface tension active compound may be a polyol or glycol.

Owner:COSKATA ENERGY

Ammonium recovery methods

ActiveUS20130029405A1Increase energy densityIncrease volumeMicroorganismsDispersed particle separationWater useRecovery method

The methods are utilized to recover ammonium from waste water using CO2 acidified absorption water. The process is particularly suited for utilization of cellular matter and a CO2 rich tail gas from a syngas fermentation process and derives significant benefit from the recovery of ammonium bicarbonate and ammonium carbonate. Ammonia and ammonium are recovered from the treatment of the syngas as an ammonium rich solution, at least a portion of which is recycled to the fermentation zone to aid in the production of liquid products. A carbon dioxide rich gas produced by fermentation is used to capture the ammonia and ammonium, forming the ammonium rich solution.

Owner:SYNATA BIO INC

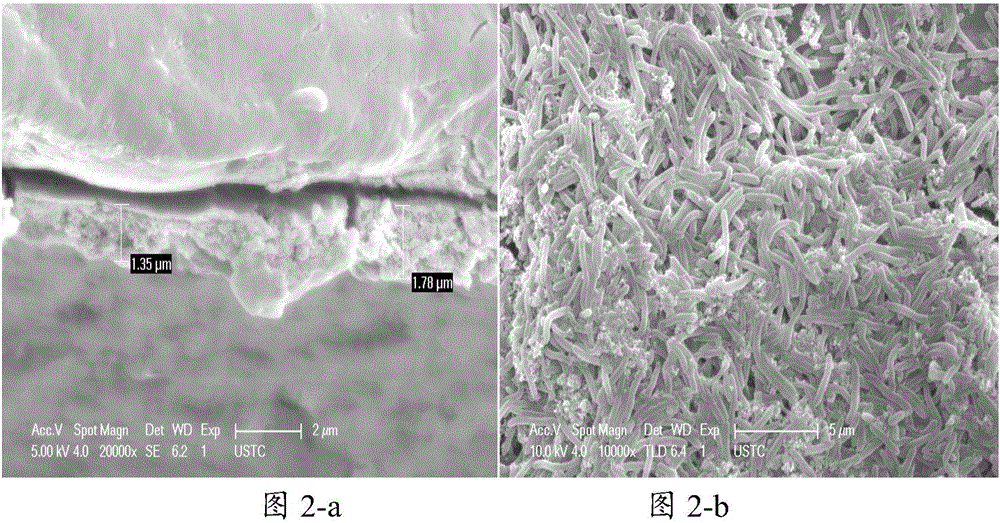

Complex microbial community and application thereof in alcohol production by syngas fermentation

InactiveCN105087441ASignificant changeImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasContinuous fermentation

The invention relates to the field of fermentation engineering, in particular to a complex microbial community and application thereof in alcohol production by syngas fermentation. The complex microbial community is high in stability and alcohol production efficiency, and is free of infectious microbes contamination within 30 days of continuous fermentation; by using the complex microbial community in syngas biological fermentation, alcohol can be produced stably and abundantly; alcohol concentration in fermentation broth is up to 17.2 g / L, and alcohol in a fermentation product is up to 92% in mass percent.

Owner:安徽科灵环境科技有限公司

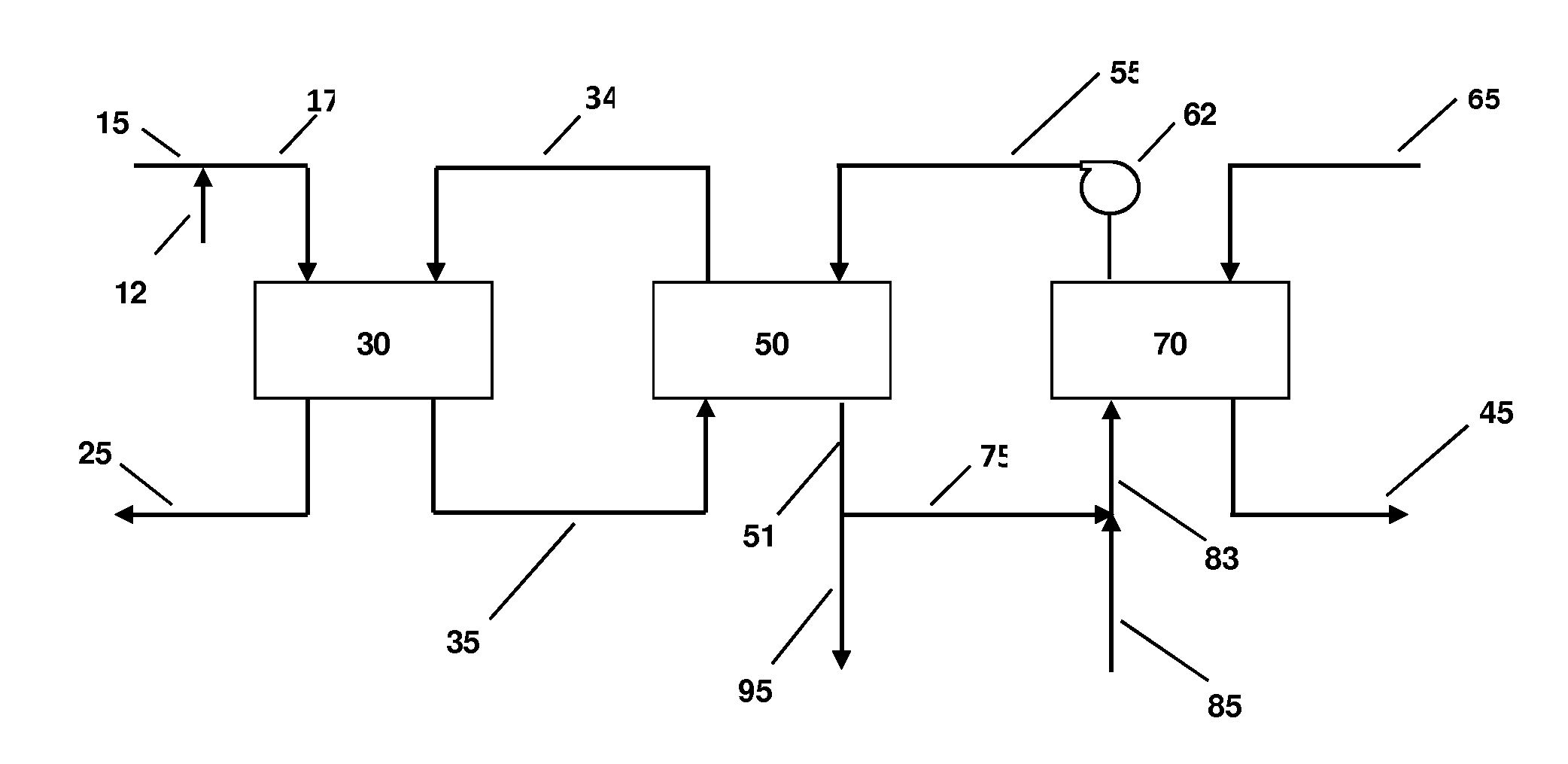

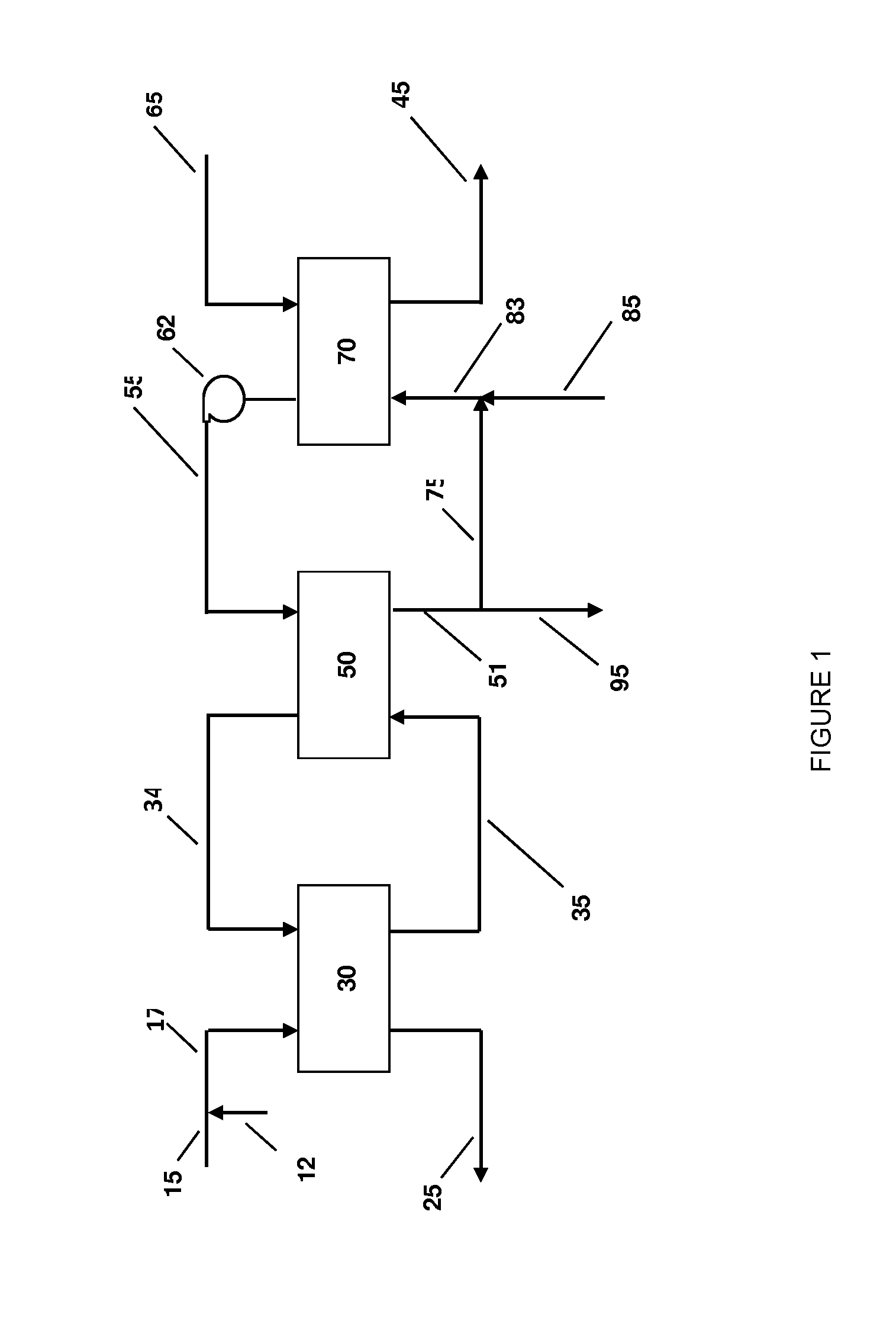

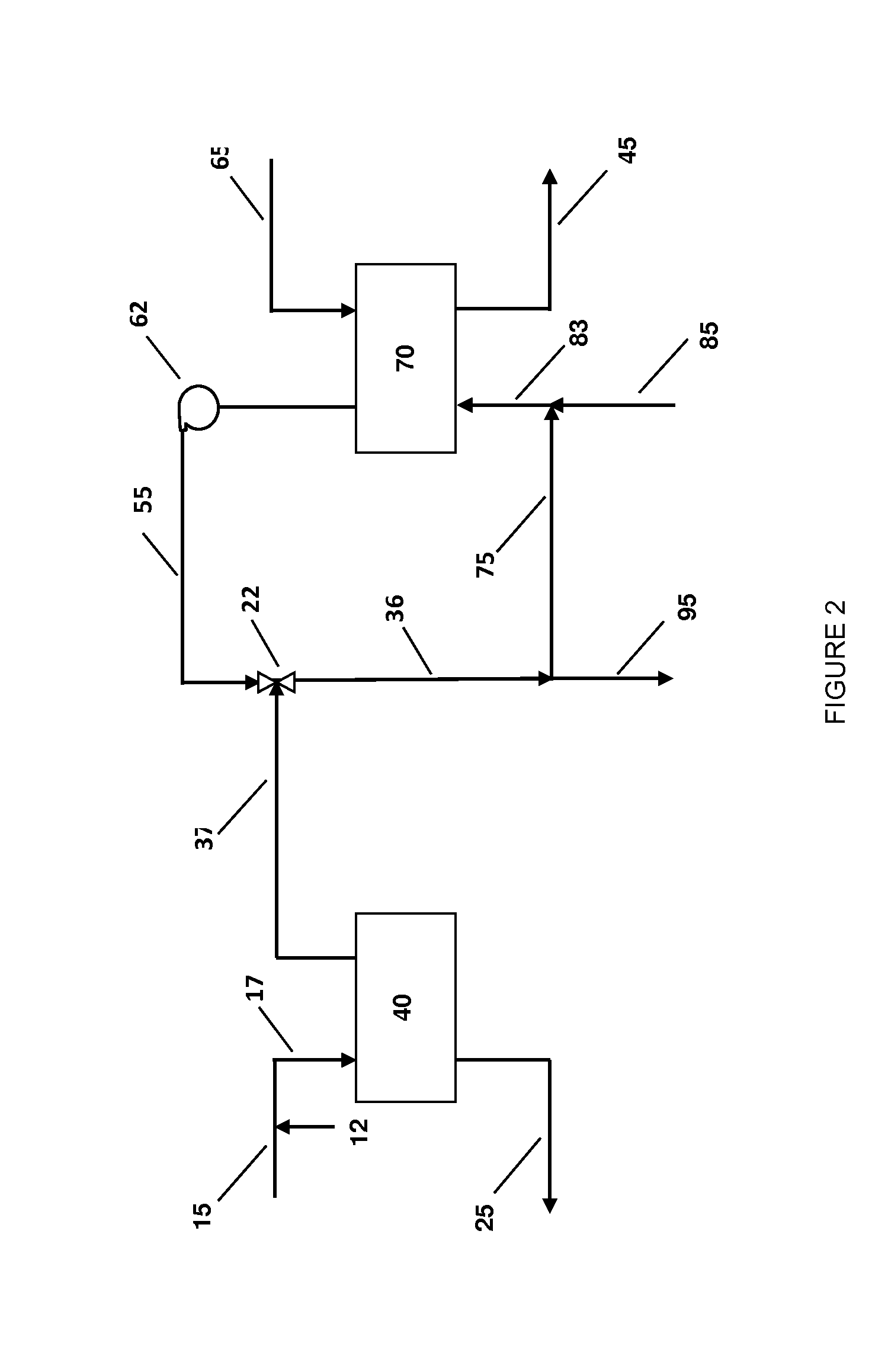

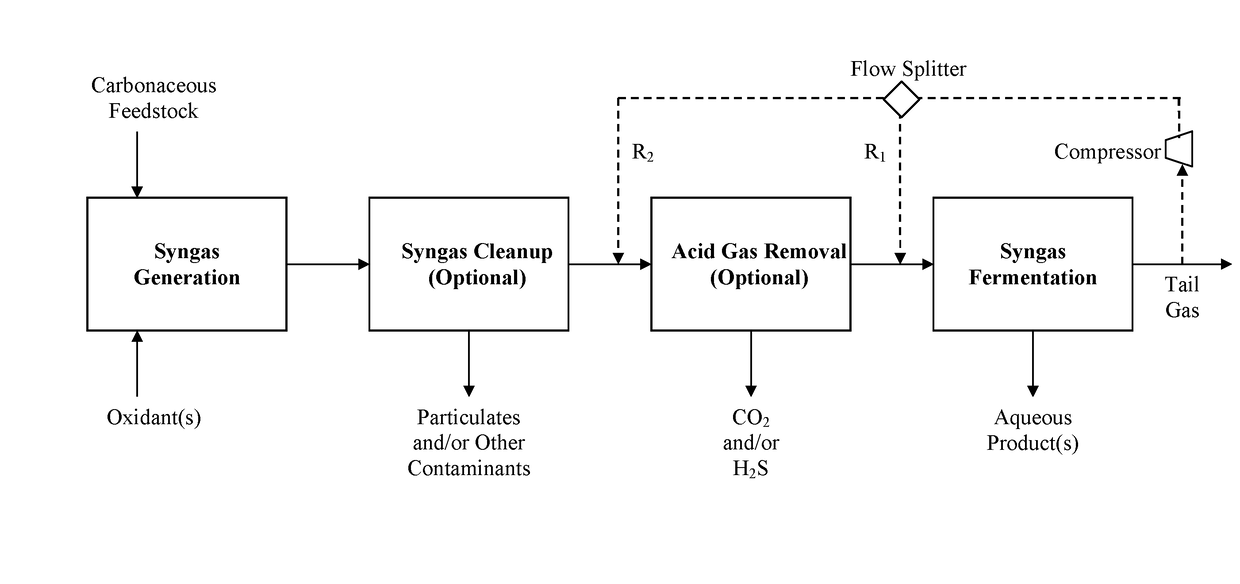

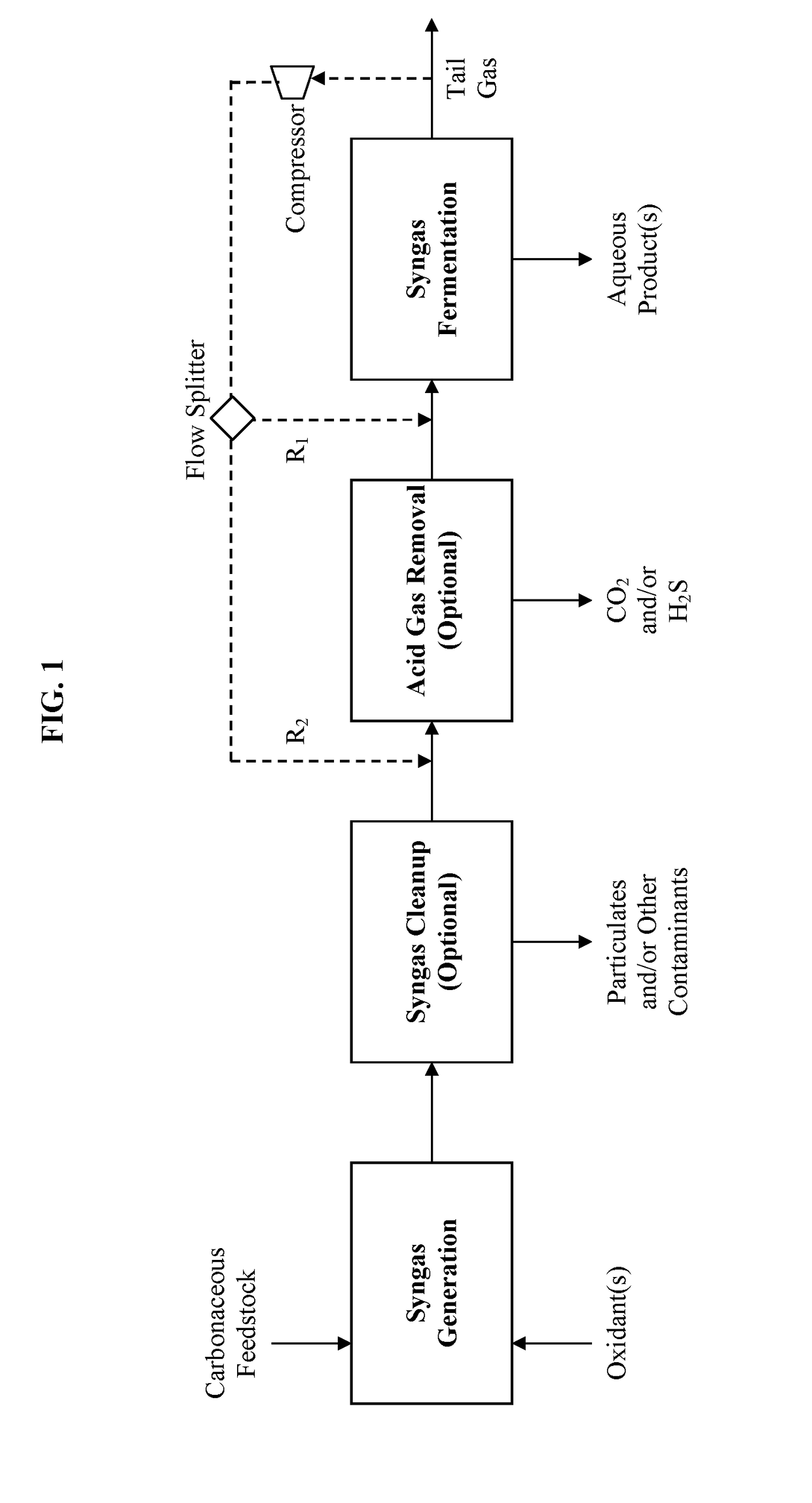

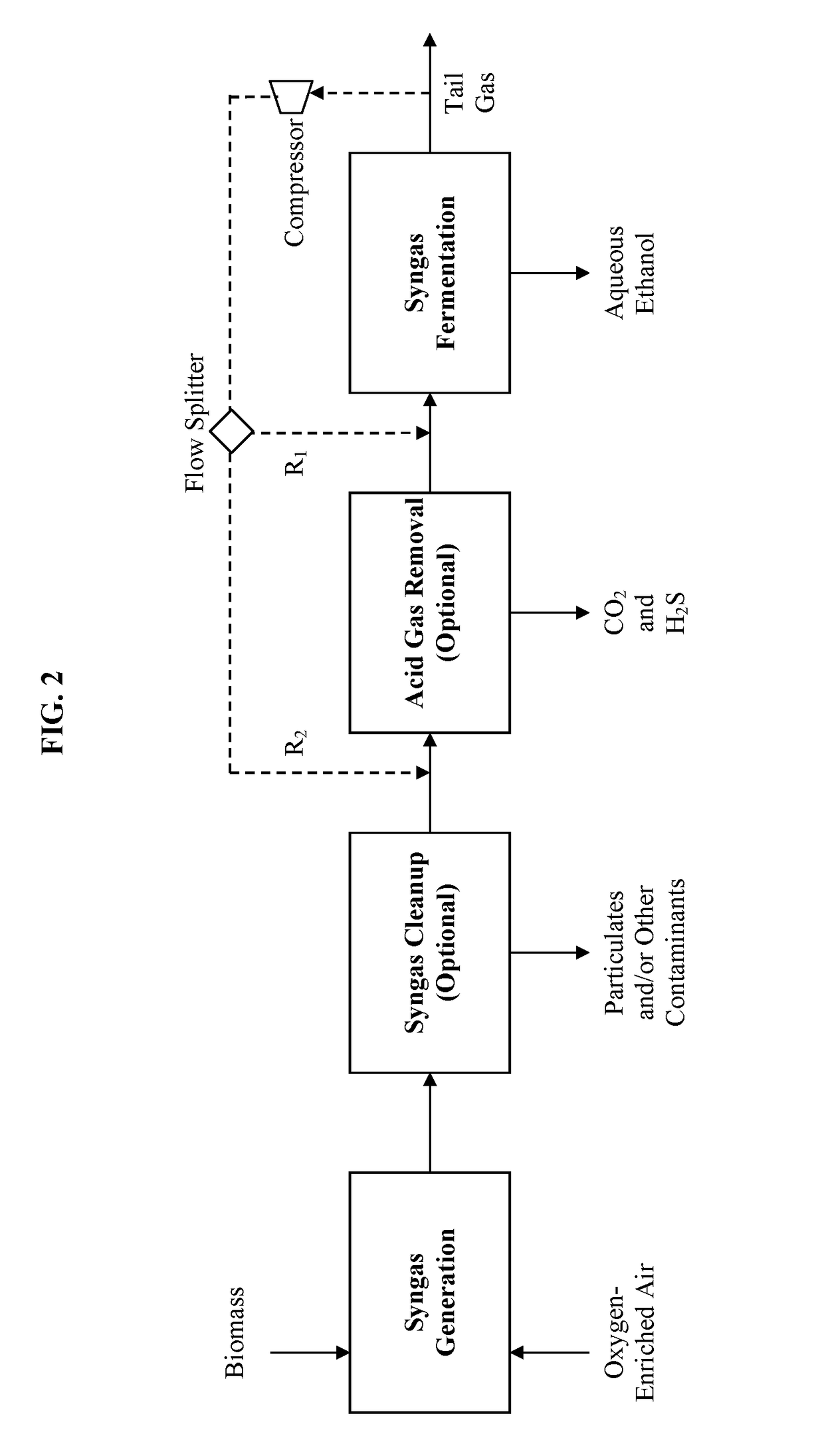

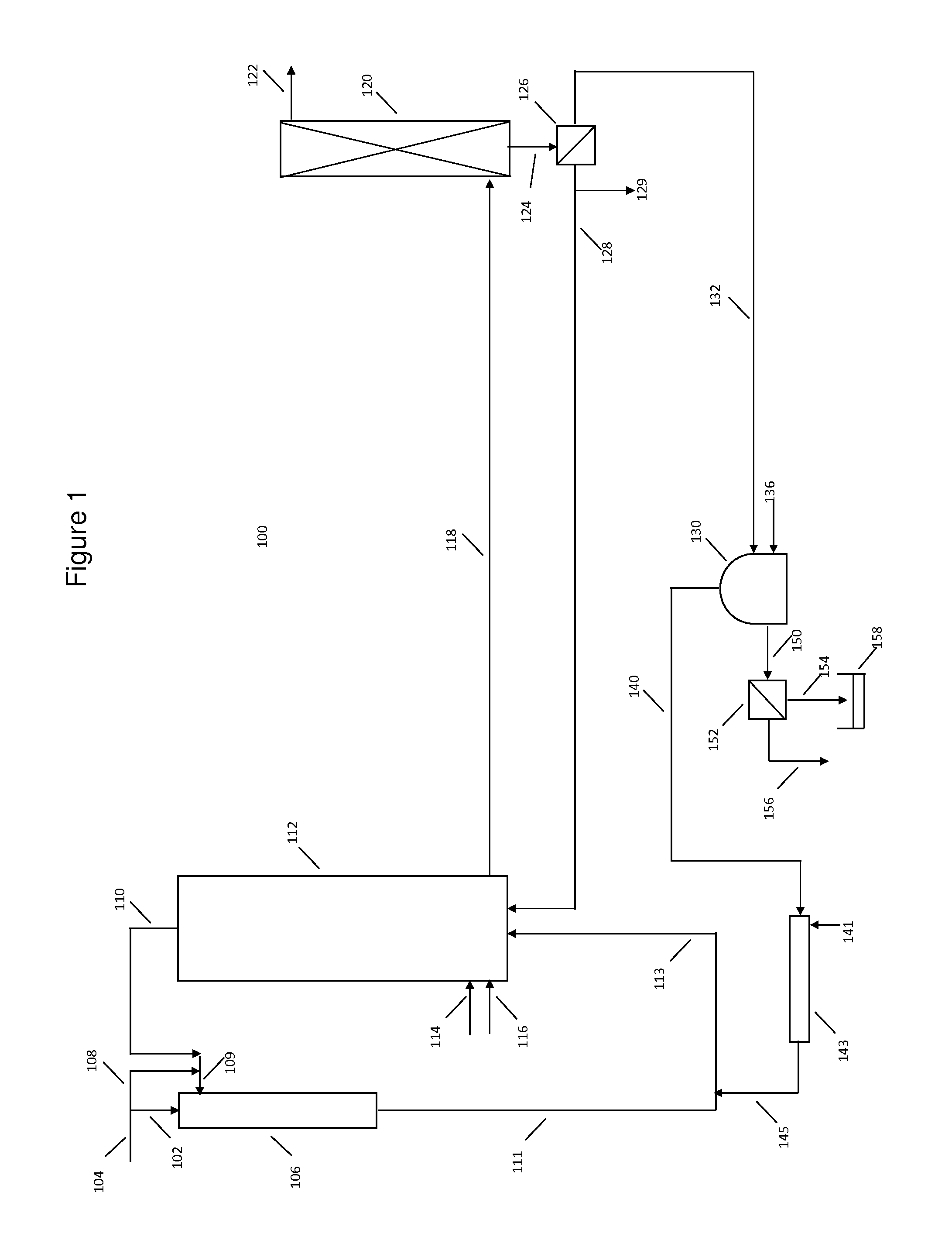

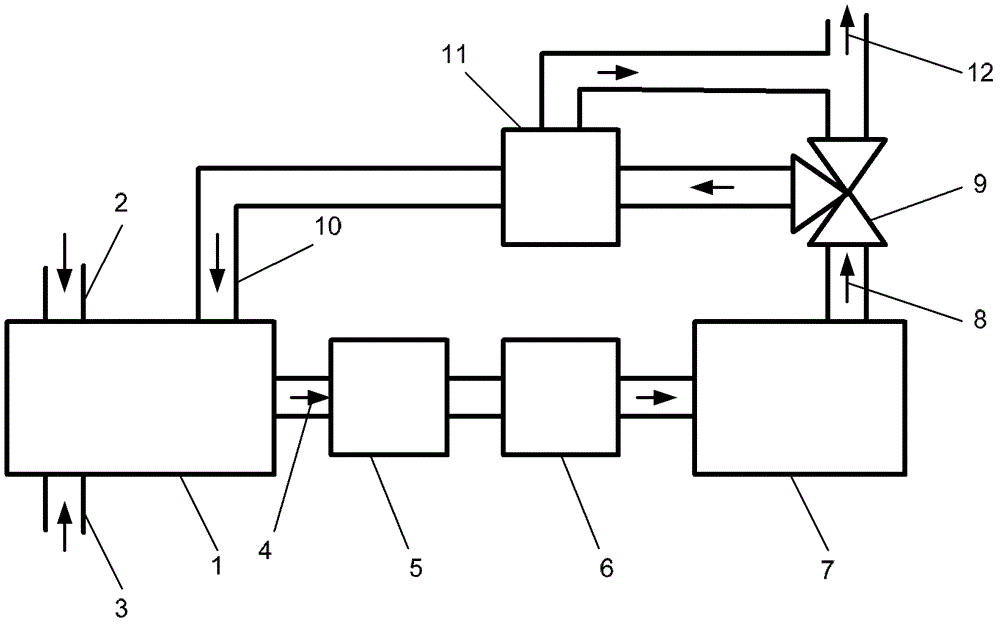

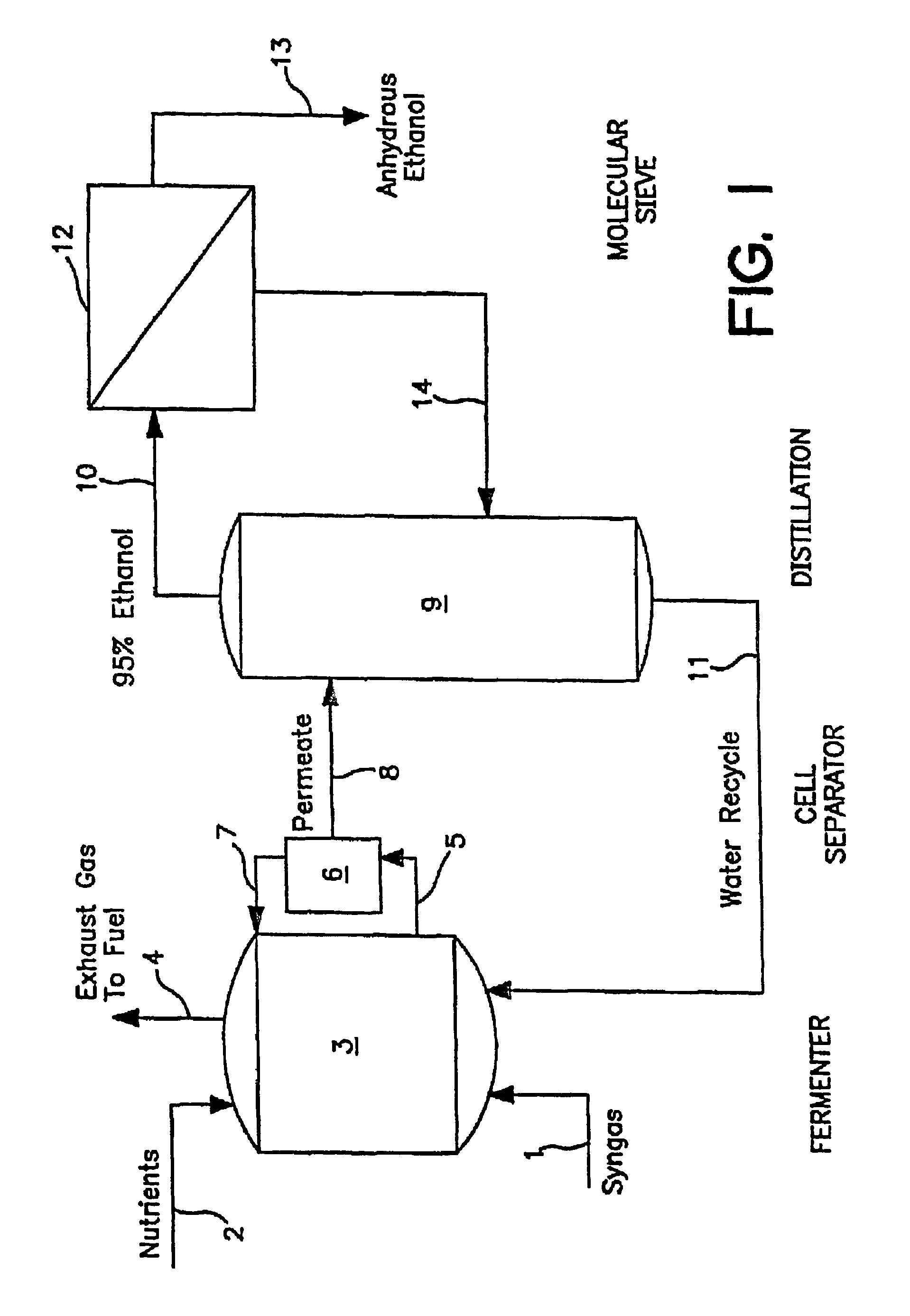

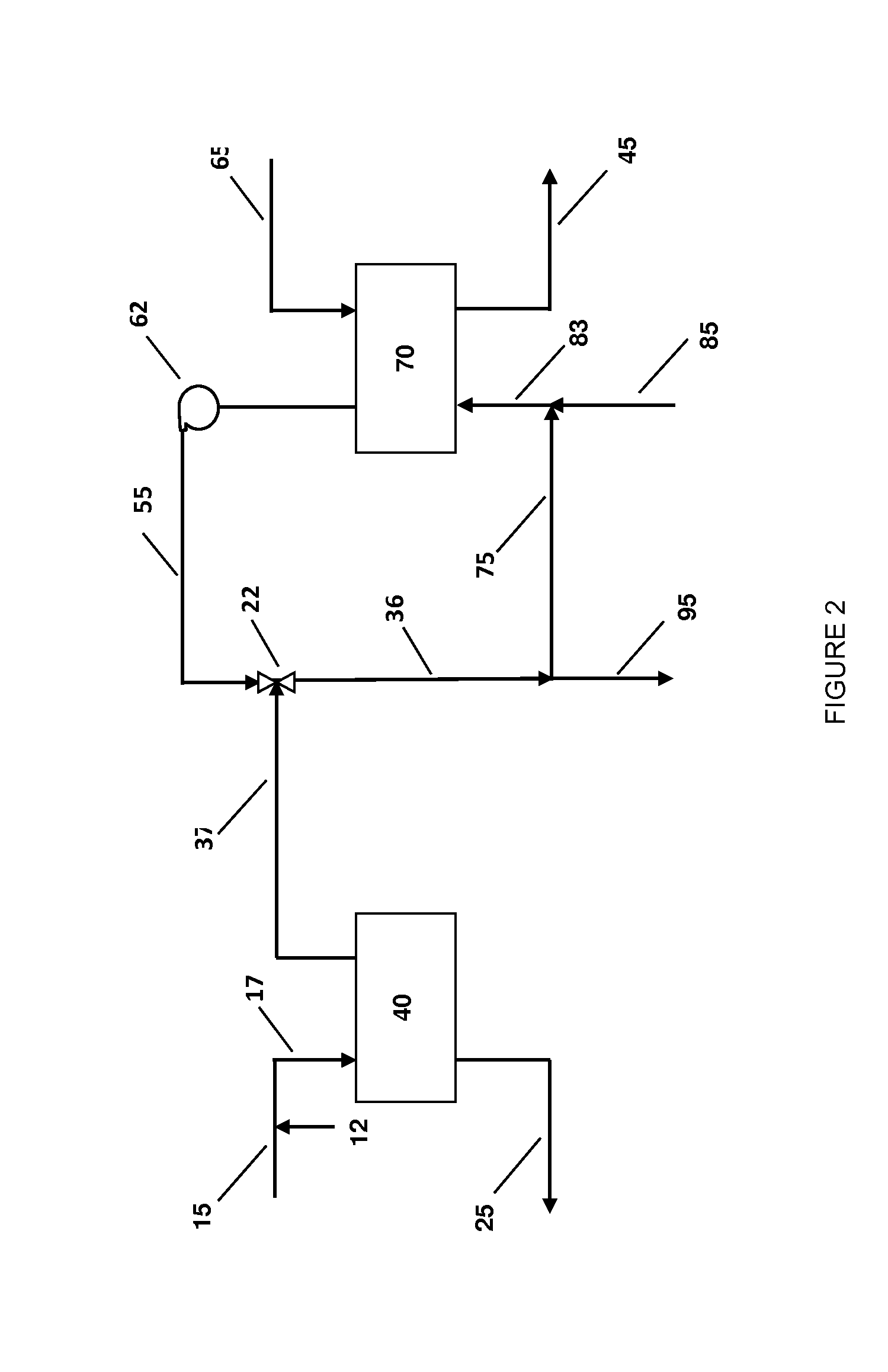

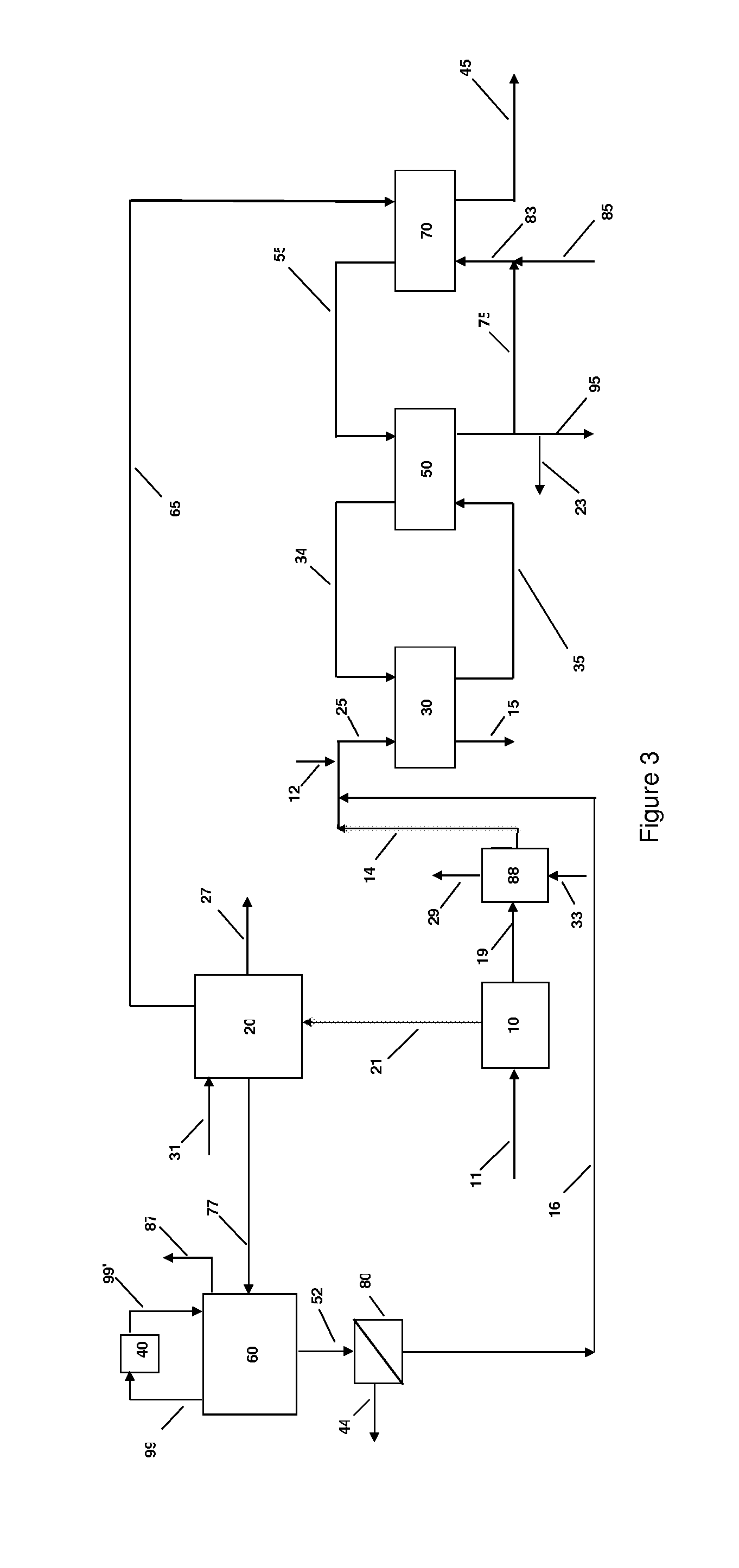

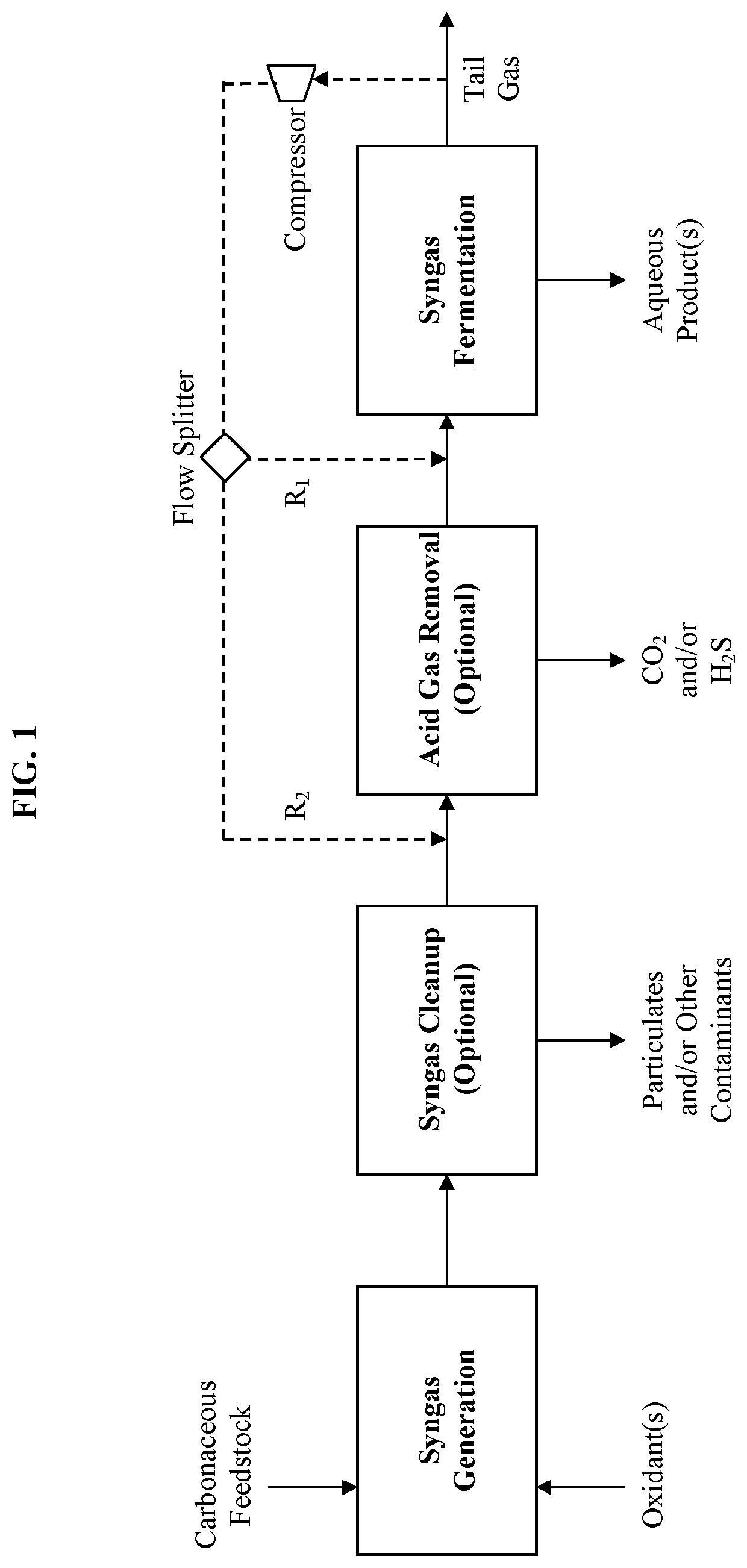

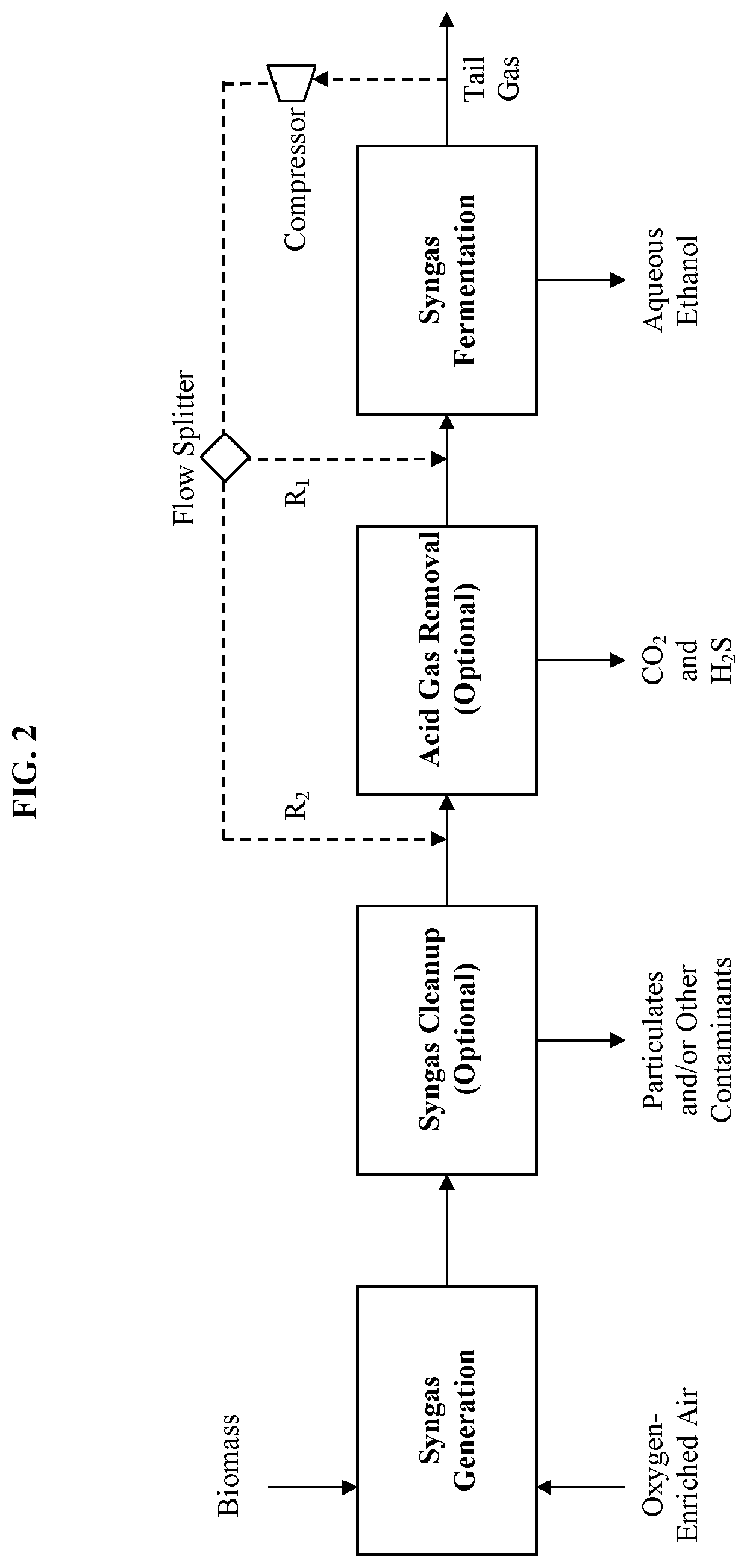

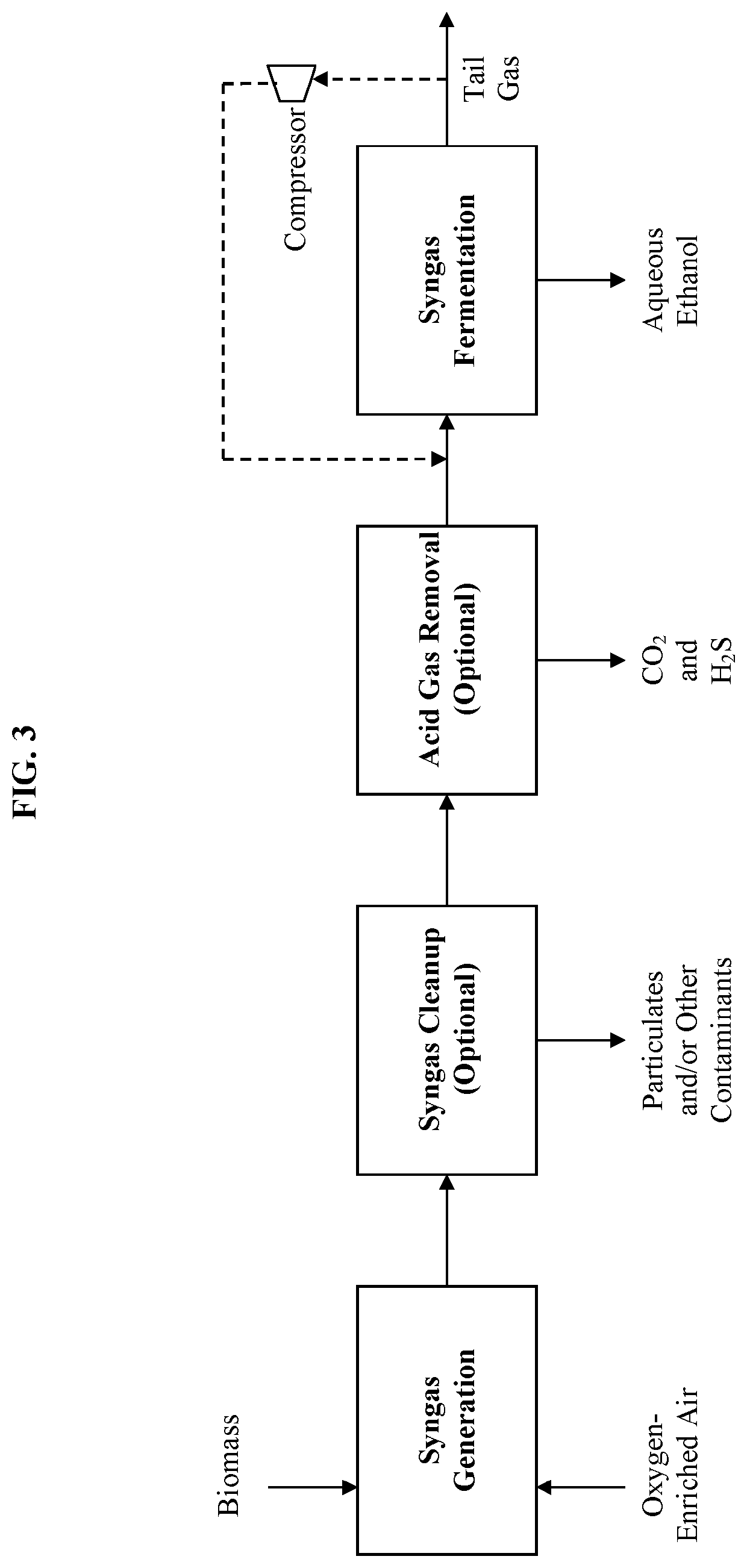

Methods and apparatus for recycling tail gas in syngas fermentation to ethanol

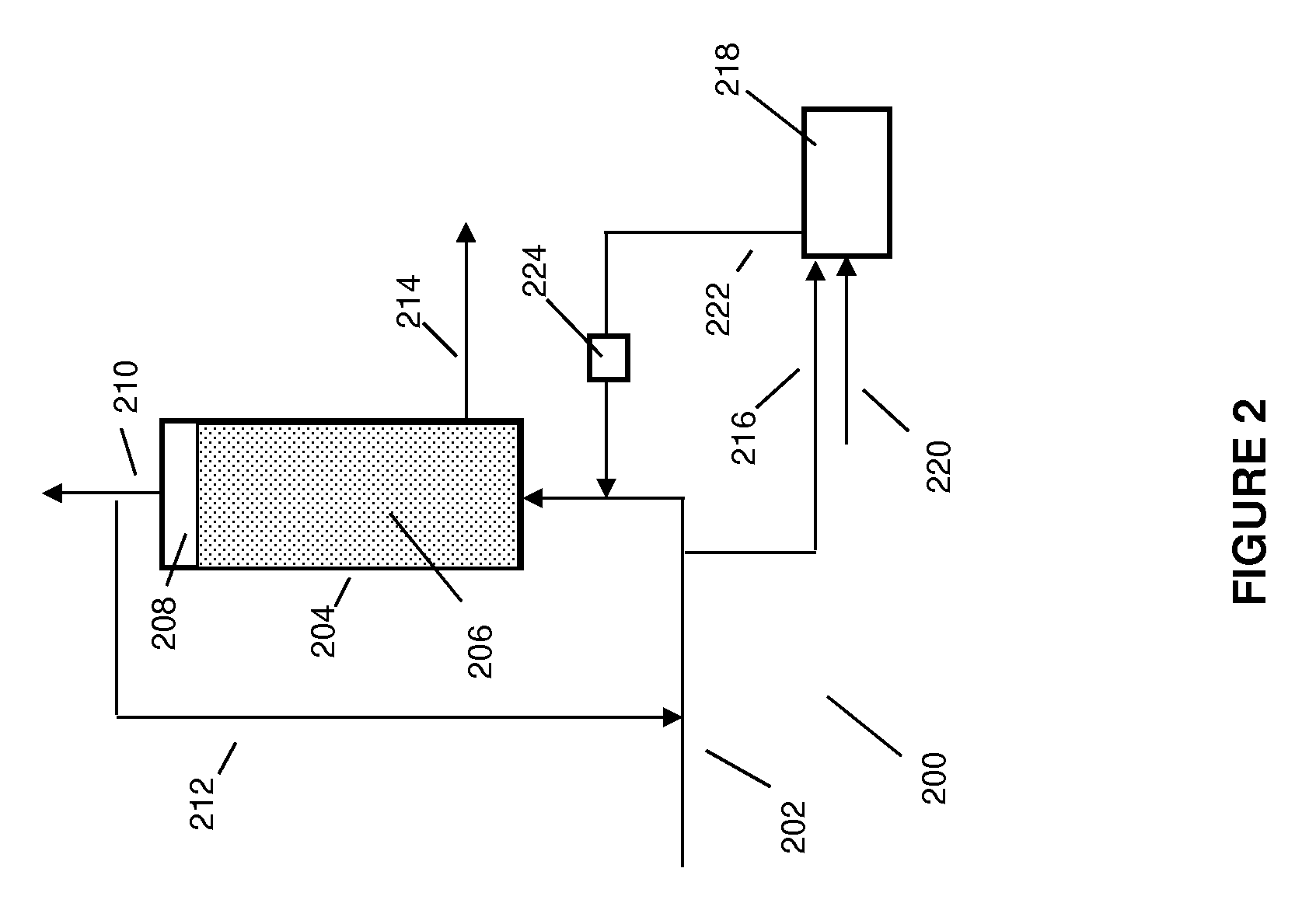

The invention present provides a method (and suitable apparatus) to convert biomass to ethanol, comprising gasifying the biomass to produce raw syngas; feeding the raw syngas to an acid-gas removal unit to remove at least some CO2 and produce a conditioned syngas stream; feeding the conditioned syngas stream to a fermentor to biologically convert the syngas to ethanol; capturing a tail gas from an exit of the fermentor, wherein the tail gas comprises at least CO2 and unconverted CO or H2; and recycling a first portion of the tail gas to the fermentor and / or a second portion of the tail gas to the acid-gas removal unit. This invention allows for increased syngas conversion to ethanol, improved process efficiency, and better overall biorefinery economics for conversion of biomass to ethanol.

Owner:LANZATECH INC

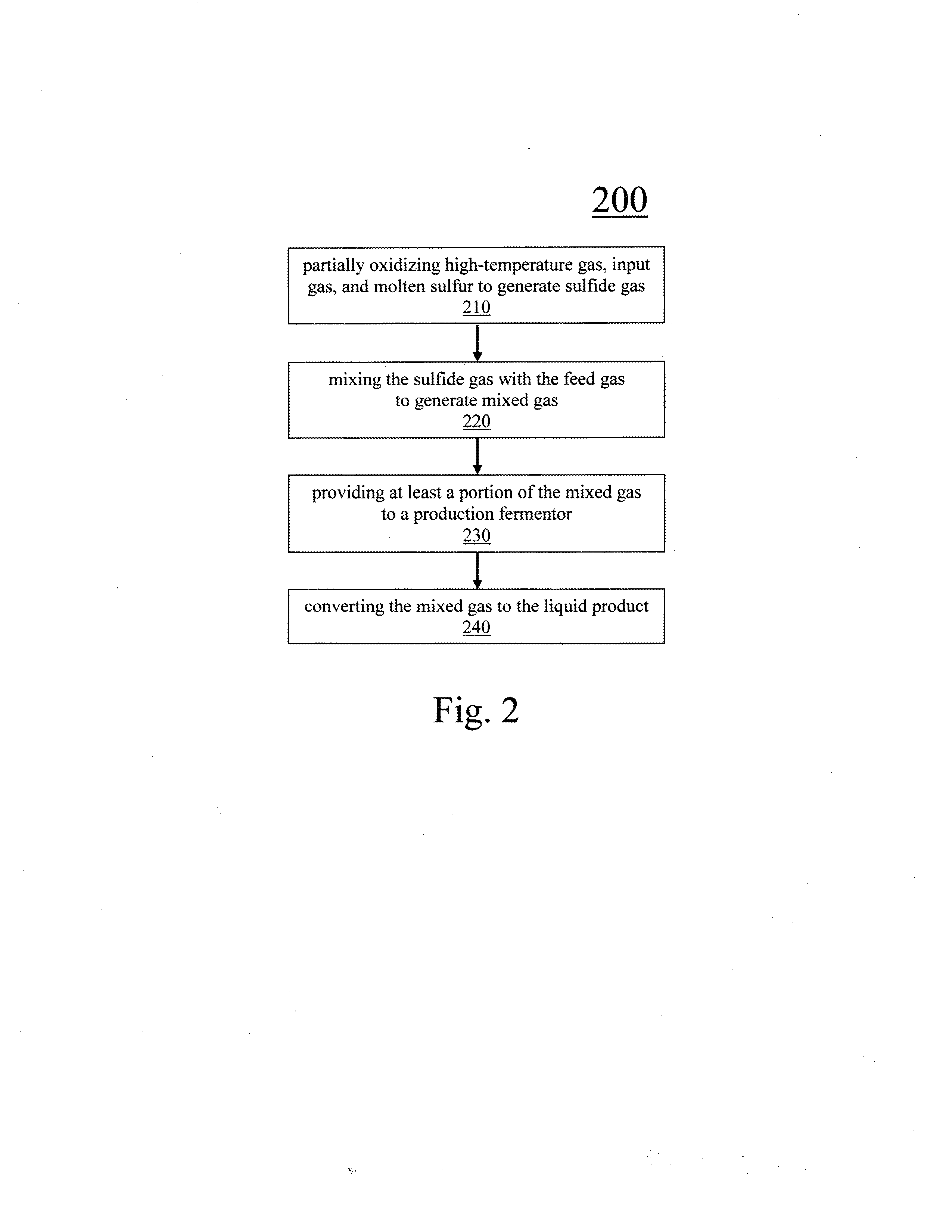

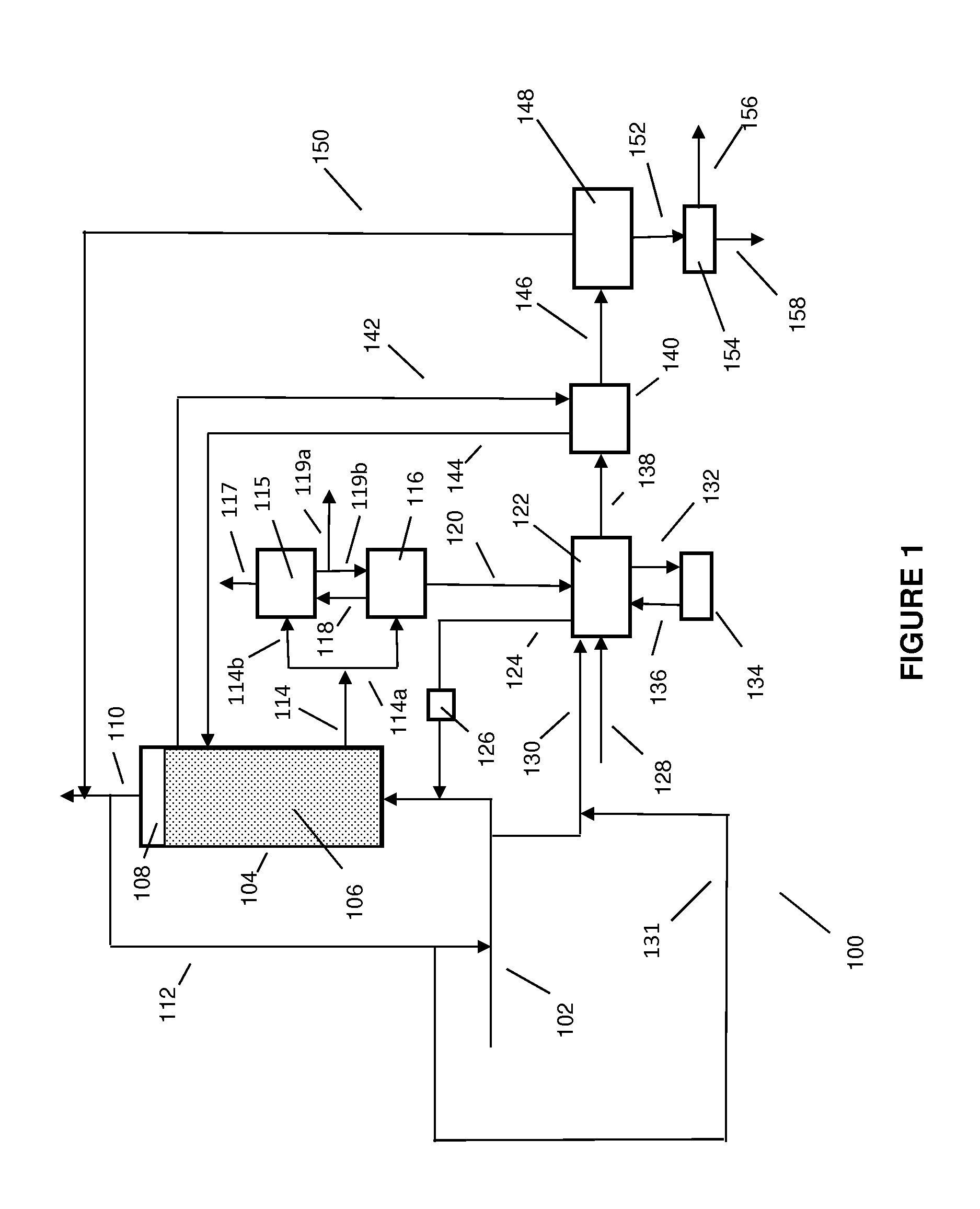

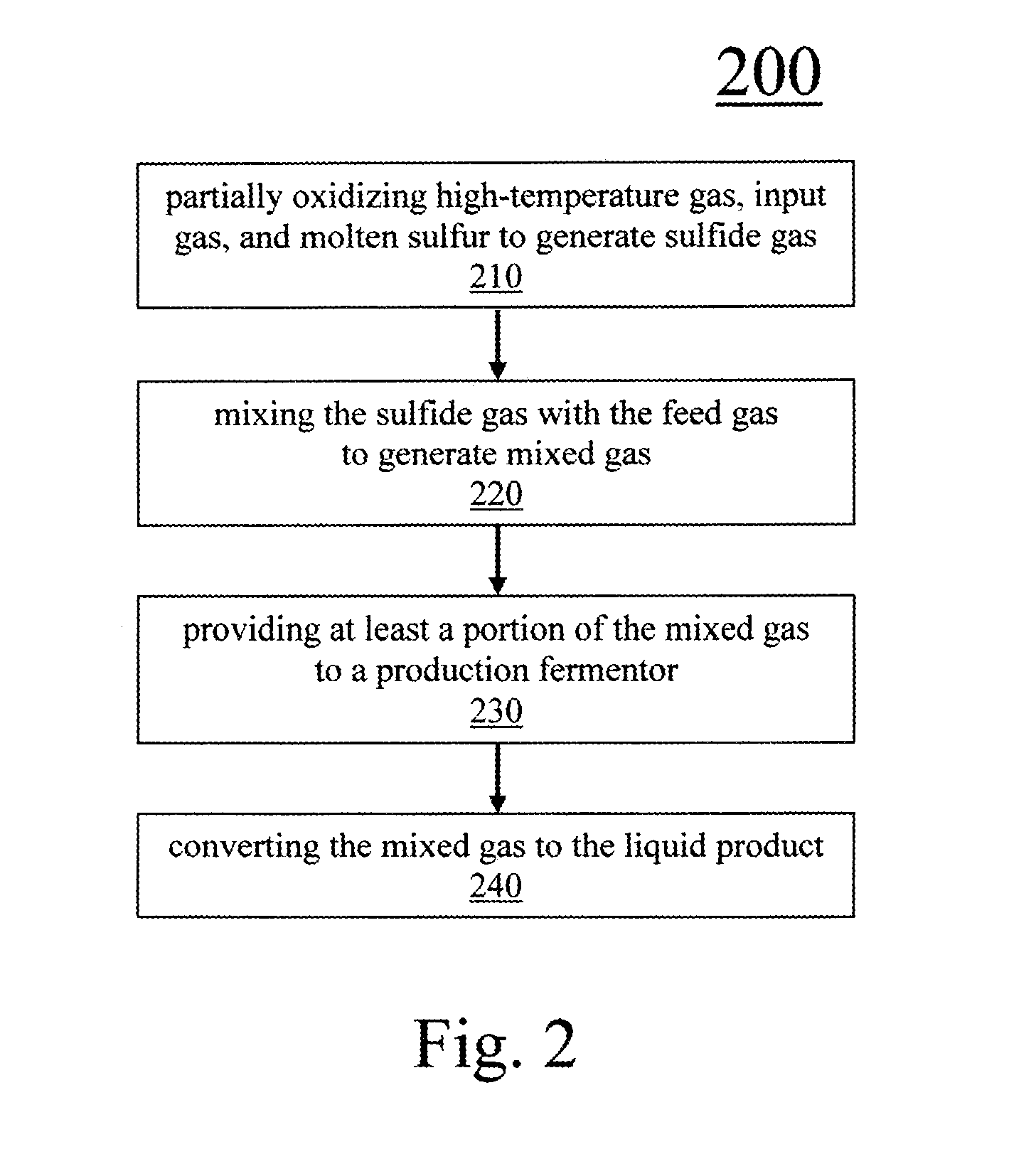

Sulfide generation process and system for syngas fermentation

InactiveUS20130177957A1Simple deliveryImprove concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productSulfide generation

A process that generates sulfide in production of liquid products from syngas and a system for syngas fermentation including a sulfide generation process to convert feed gas to liquid product, the process including: partially oxidizing high-temperature gas, input gas, and molten sulfur to generate sulfide gas, the high-temperature gas containing oxygen, the input gas containing carbonaceous fuel and the sulfide gas containing hydrogen sulfide, CO, CO2, and H2; mixing the sulfide gas with the feed gas to generate mixed gas having a predetermined hydrogen sulfide concentration; providing at least a portion of the mixed gas to a production fermentor containing microorganisms; and converting the mixed gas to the liquid product by contact with the microorganisms.

Owner:SYNATA BIO INC

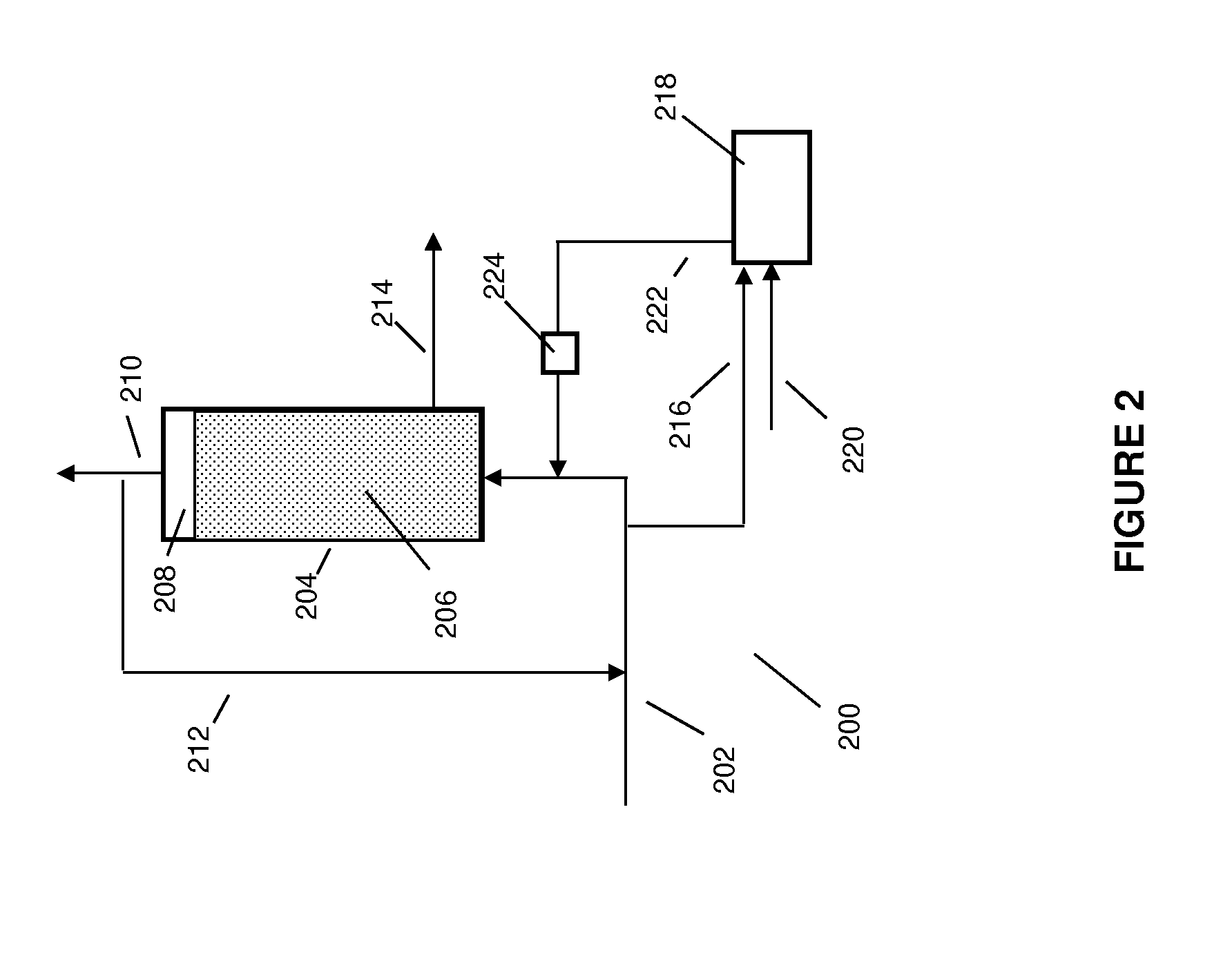

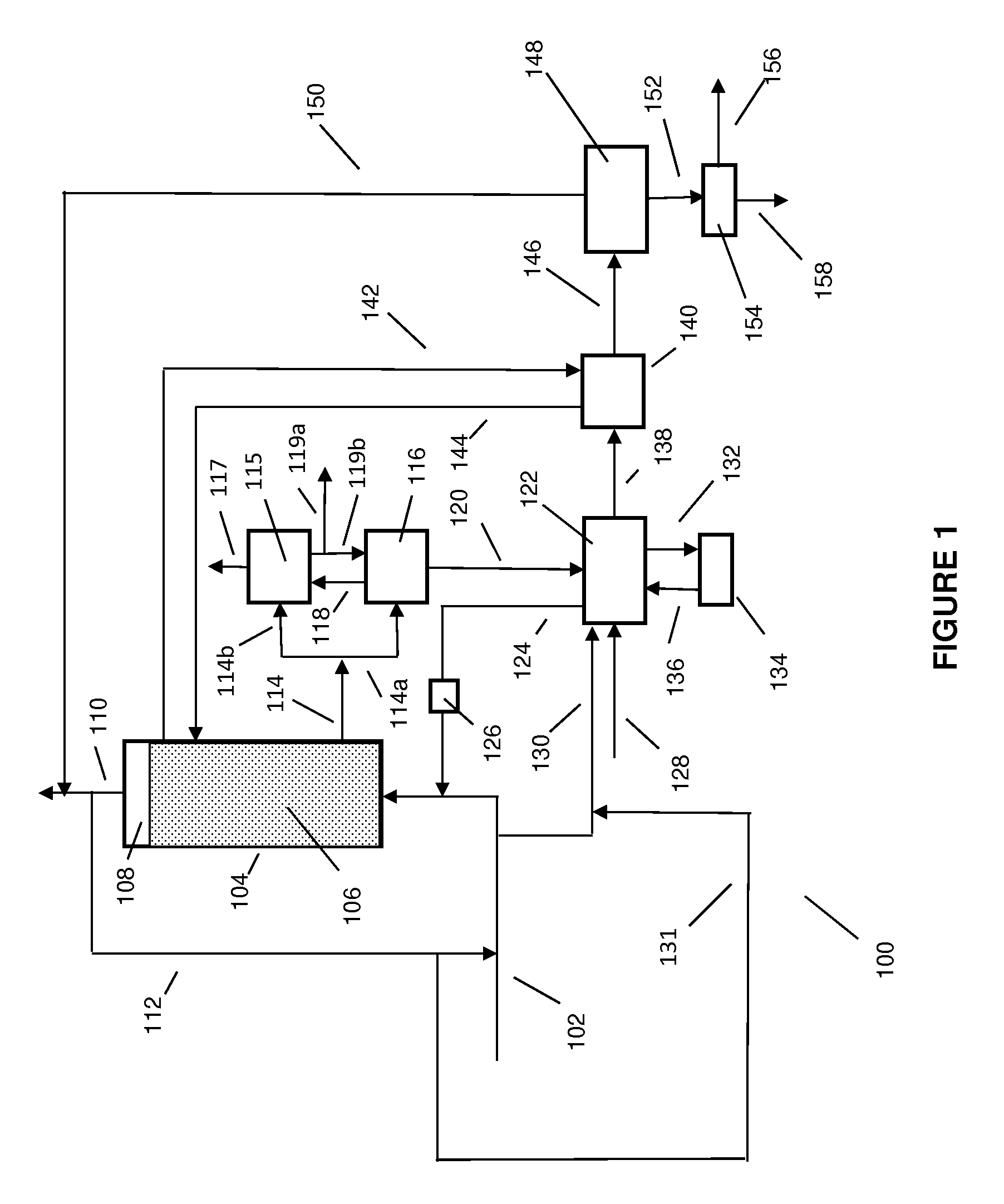

Integrated processes for bioconverting syngas to oxygenated organic compound with sulfur supply

ActiveUS20130337513A1Easy maintenanceSufficient amountChemical industryBiofuelsSyngasMethane fermentation

Integrated processes are provided for the bioconversion of syngas to oxygenated organic compound with the ability to recycle sulfur nutrient and generate sulfur nutrient to the syngas fermentation in a safe and cost-effective manner. In preferred aspects of the invention, an acidogenic digestion is used to provide a biogas containing hydrogen sulfide, and then a methanogenic fermentation can follow to provide a methane-containing biogas that has a low hydrogen sulfide concentration.

Owner:SYNATA BIO INC

High moisture, renewable feedstock use in integrated anaerobic treatment and syngas fermentation to alcohols

InactiveUS20150225749A1Saving in overall production costIncrease nutritionHydrogenBiofuelsGreen wasteBiological waste

The present invention relates to use of high moisture, renewable feedstocks in integrated anaerobic digestion treatment (AD) and Syngas fermentation to alcohols and other soluble products. More specifically, the invention relates to use of high moisture, renewable feedstocks such as the organic fraction of municipal solid waste (OFMSW), biological waste sludge, source separated organics, green wastes such as FW from supermarkets, cafeterias, etc., and other such plentiful sources for power and fermentation, significantly increasing yield of a desired alcohol.Even for relatively large Syngas to ethanol (or other chemical) production facilities, such wastes could represent a significant fraction of needed resources for Syngas fermentation. The proper integration of the anaerobic digestion process, post treatment, and use of fractionated components are also believed to represent a considerable savings in overall production costs.

Owner:SYNATA BIO INC

Methods for sequestering carbon dioxide into alcohols via gasification fermentation

The present invention is directed to improvements in gasification for use with synthesis gas fermentation. Further, the present invention is directed to improvements in gasification for the production of alcohols from a gaseous substrate containing at least one reducing gas containing at least one microorganism.

Owner:JUPENG BIO HK LTD

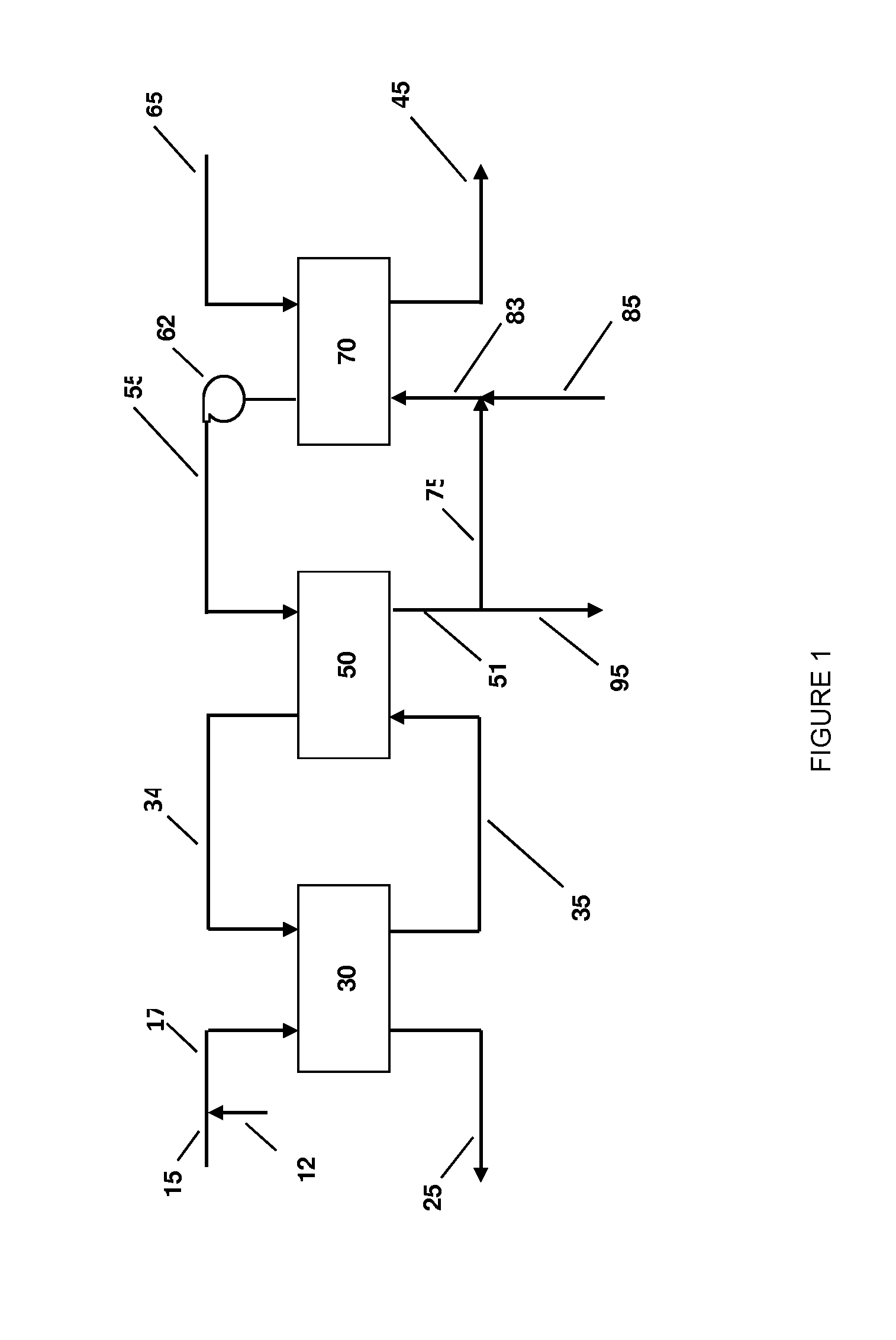

Improved carbon capture in fermentation

The present invention relates to improvement in efficiency in gasification for use with syngas fermentation. In particular, the invention relates to increasing the overall carbon capture efficiency of a gasification / fermentation process to produce products such as alcohols.

Owner:LANZATECH NEW ZEALAND LTD

Carbon capture in fermentation

ActiveUS8263372B2Improving overall efficiency and carbon captureImprove processing efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholFermentation

The present invention relates to improvement in efficiency in gasification for use with syngas fermentation. In particular, the invention relates to increasing the overall carbon capture efficiency of a gasification / fermentation process to produce products such as alcohols.

Owner:LANZATECH NZ INC

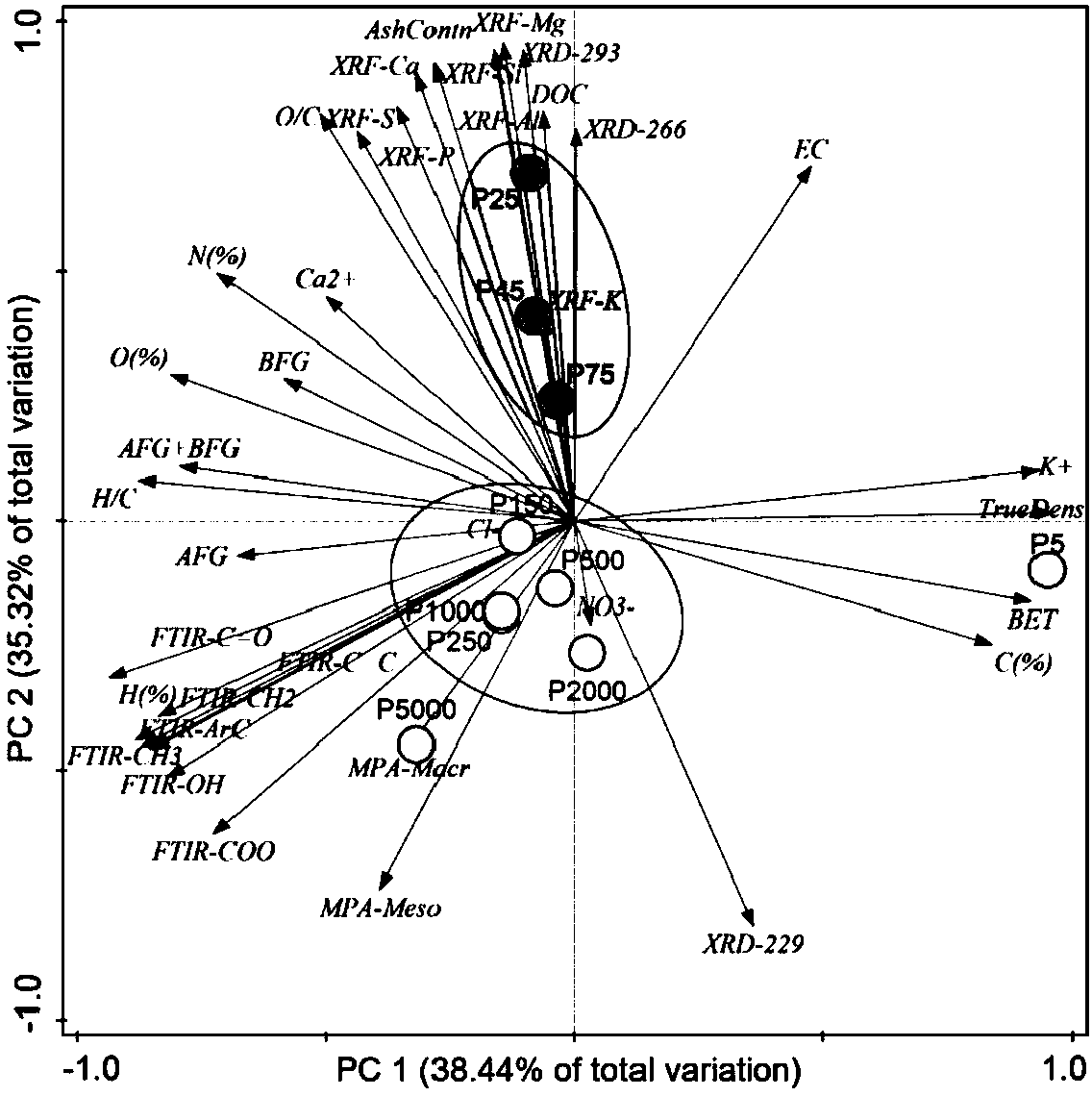

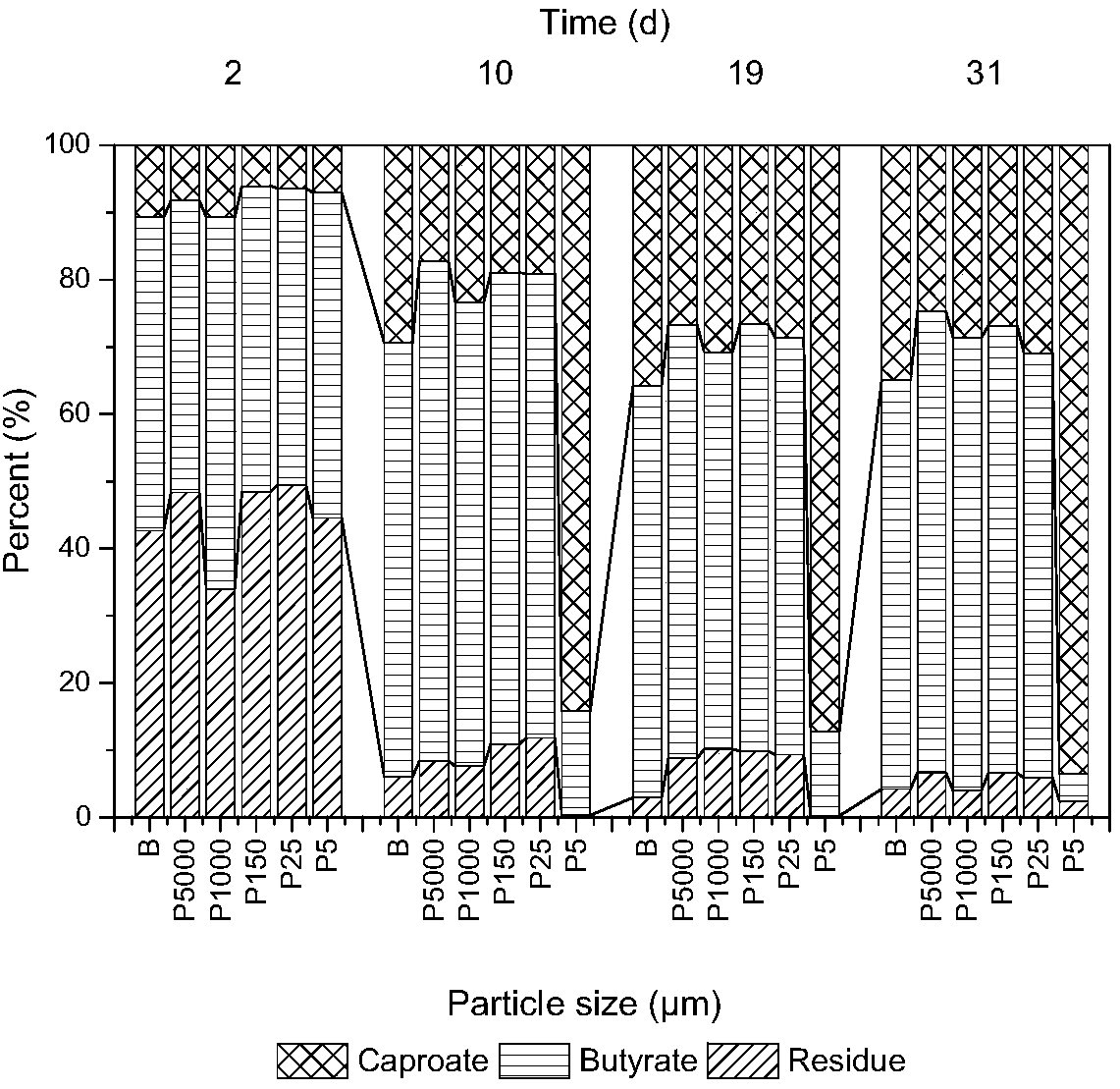

Biochar finish machining method capable of improving anaerobic biological reaction efficiency

ActiveCN108046234AImprove conductivityAvoid reverse effectsWaste based fuelTreatment with anaerobic digestion processesPulp and paper industryCarbon chain

The invention relates to a biochar finish machining method capable of improving anaerobic biological reaction efficiency. The method comprises crushing crude biochar powder to obtain powder in a certain particle size range so that ultrafine biochar is obtained, and immersing the ultrafine biochar through an immersion solution. In anaerobic biological reactions such anaerobic digestion, carbon chain bio-extending and syngas fermentation, the biochar obtained by the biochar finish machining method can significantly increase the efficiency of anaerobic biological reactions, improve the effectiveness and stability of biochar application effects, reduce the dosage of biochar in application and reduce an application cost.

Owner:TONGJI UNIV

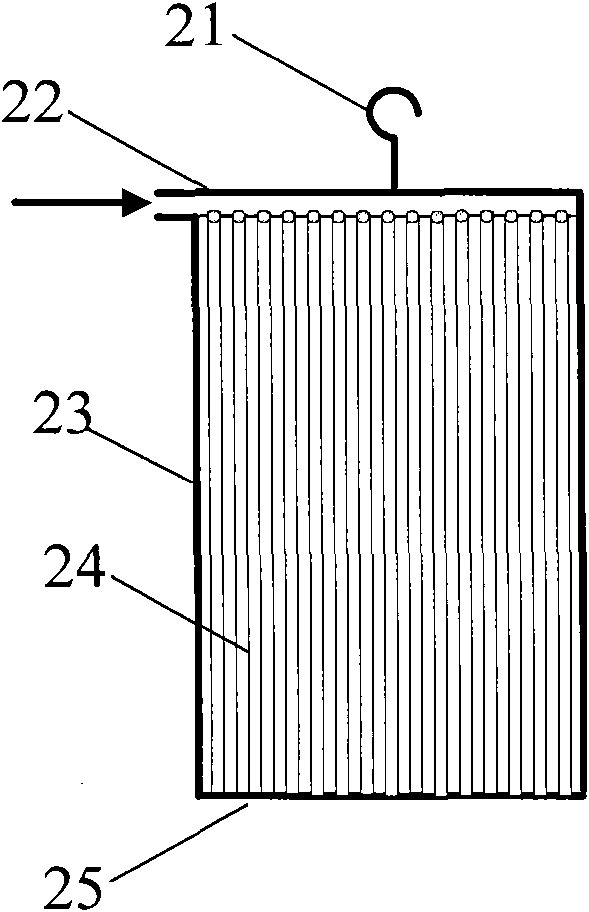

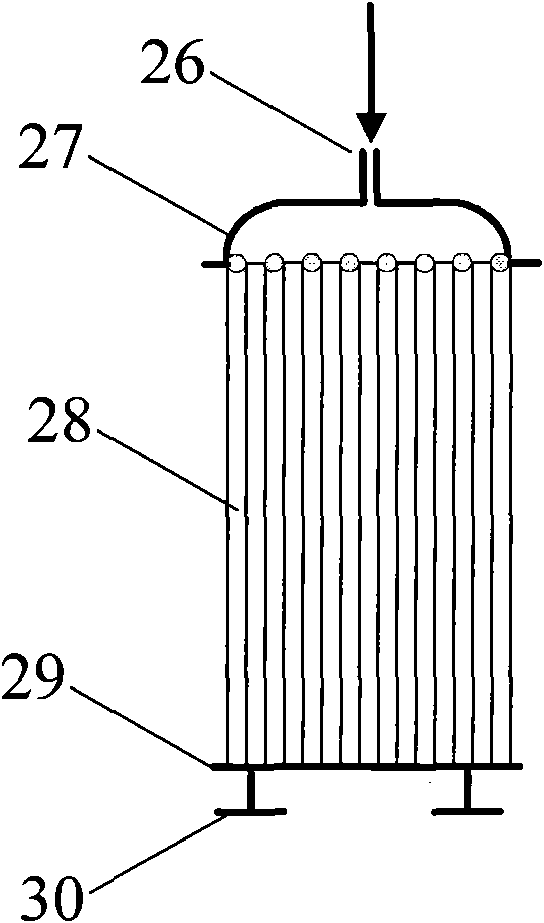

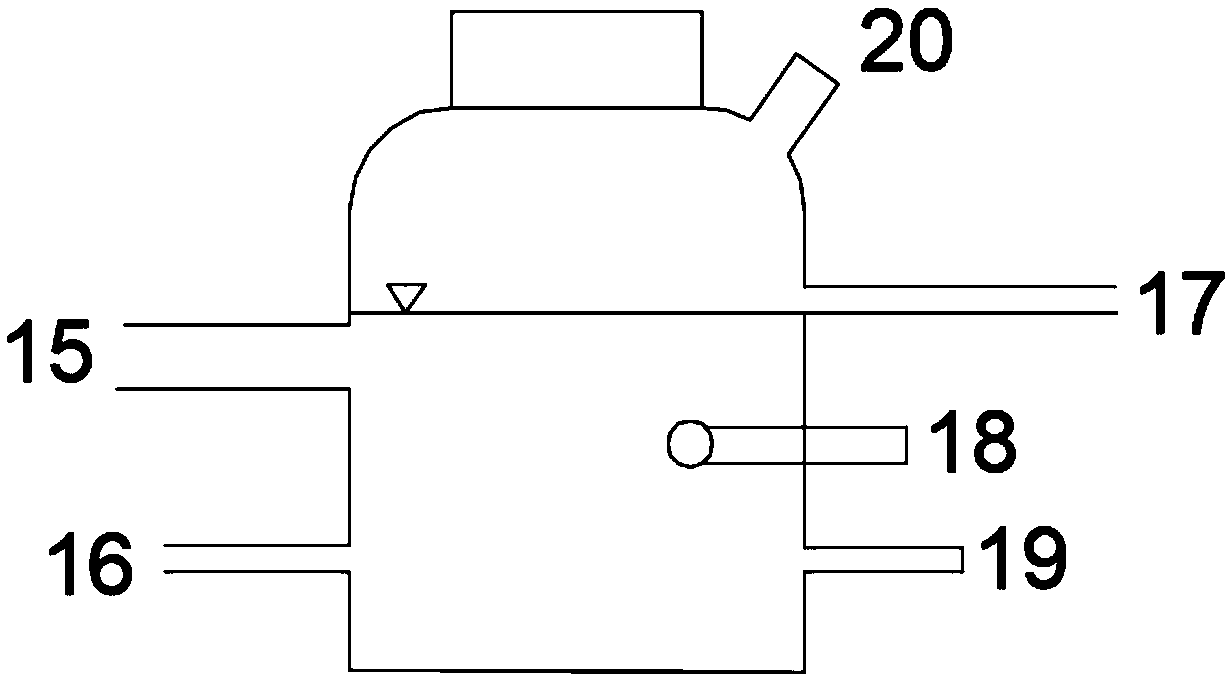

Bubble-free air supply and solid-liquid separation integrated membrane biomembrane reactor taking indissoluble gases as fermentation raw materials

InactiveCN101831382AAvoid mass transfer stepsClose contactBiological substance pretreatmentsApparatus sterilizationLiquid productFiber

The invention provides a bubble-free air supply and solid-liquid separation integrated membrane biomembrane reactor comprising a gas distribution pipe, a hollow bubble-free air supply fiber membrane module, a water distribution pipe and a solid-liquid separation membrane module which are arranged in a tank body of the reactor, wherein the top ends of the hollow bubble-free air supply fiber membrane module and the solid-liquid separation membrane module are lower than the liquid level in the tank body; the hollow bubble-free air supply fiber membrane module is communicated with a feed gas storage tank through the gas distribution pipe, the water distribution pipe is communicated with a culture medium storage tank through a feeding pump, and the solid-liquid separation membrane module is communicated with a liquid product outlet through a sorption pump; the tank body is also provided with a circulating water outlet, a gas product outlet, a feed supplement hole, a thermometer, a pH meter and a pressure gage; and partial pressure of gas in the cavity of a hollow fiber membrane is lower than the pressure of a bubble point so as to ensure that the hollow bubble-free air supply fiber membrane module realizes bubble-free air supply. The reactor has higher fermentation reaction rate and product concentration, and can enhance economic feasibility of fermentation of synthesis gas and other indissoluble gases, thereby being suitable for a biological fermentation process taking various indissoluble gases as raw materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

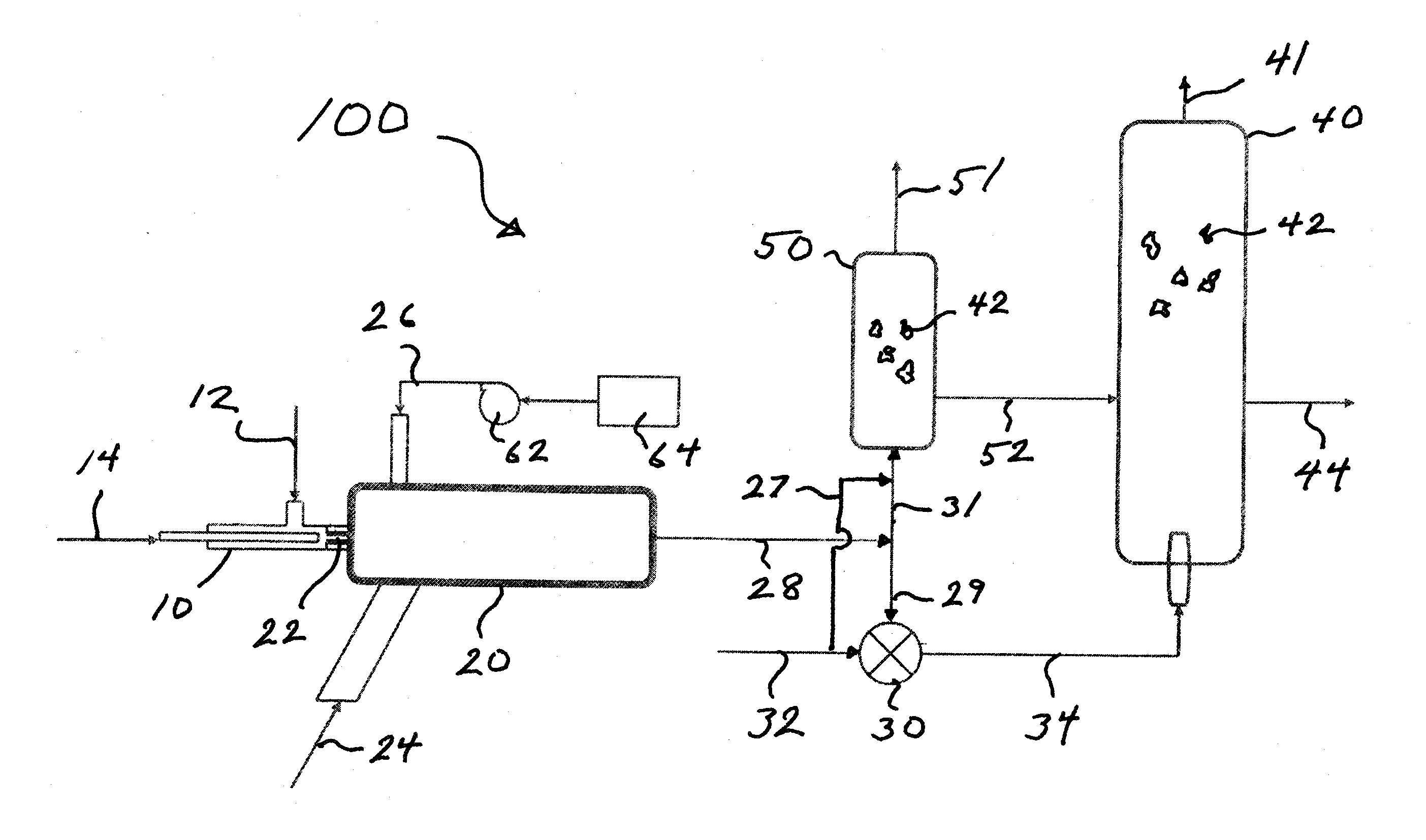

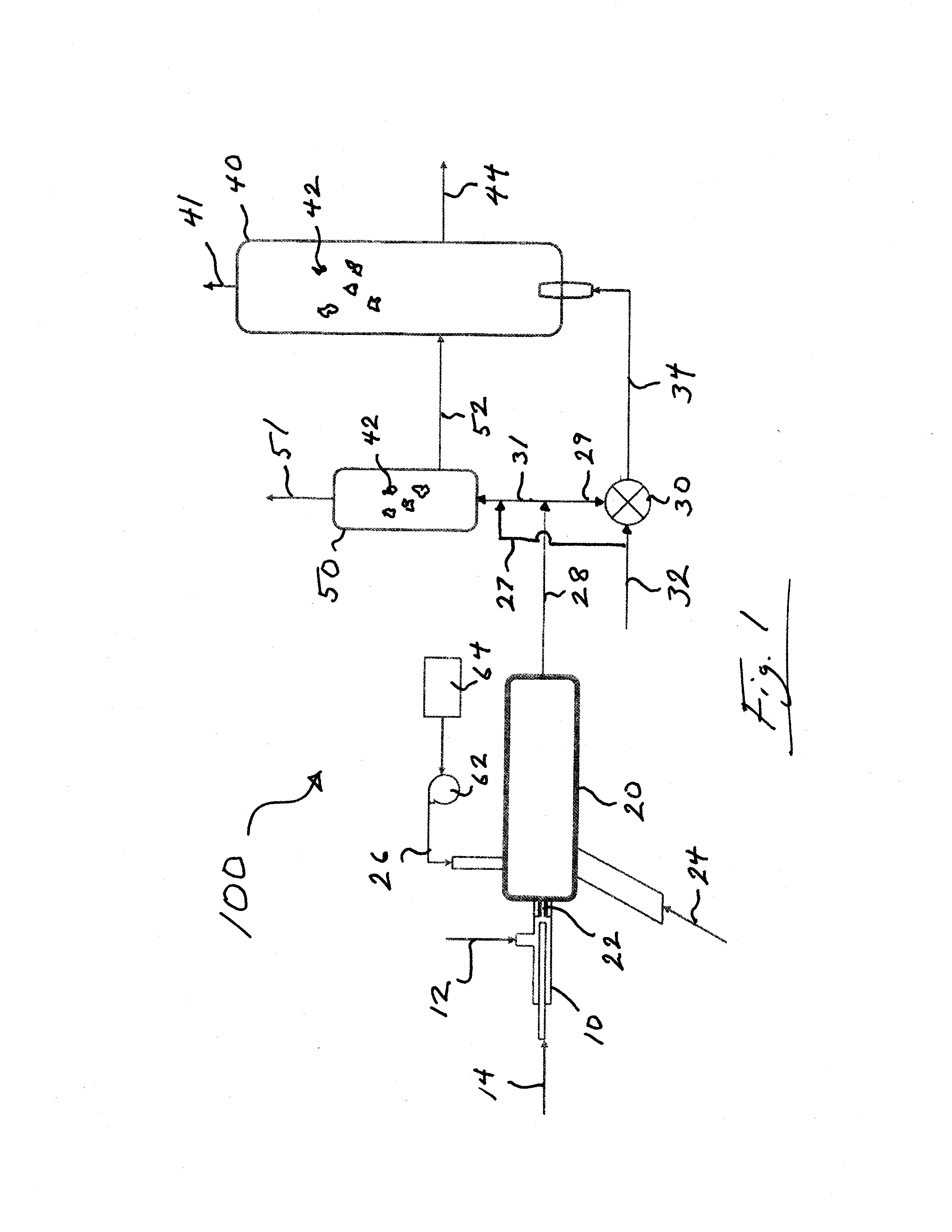

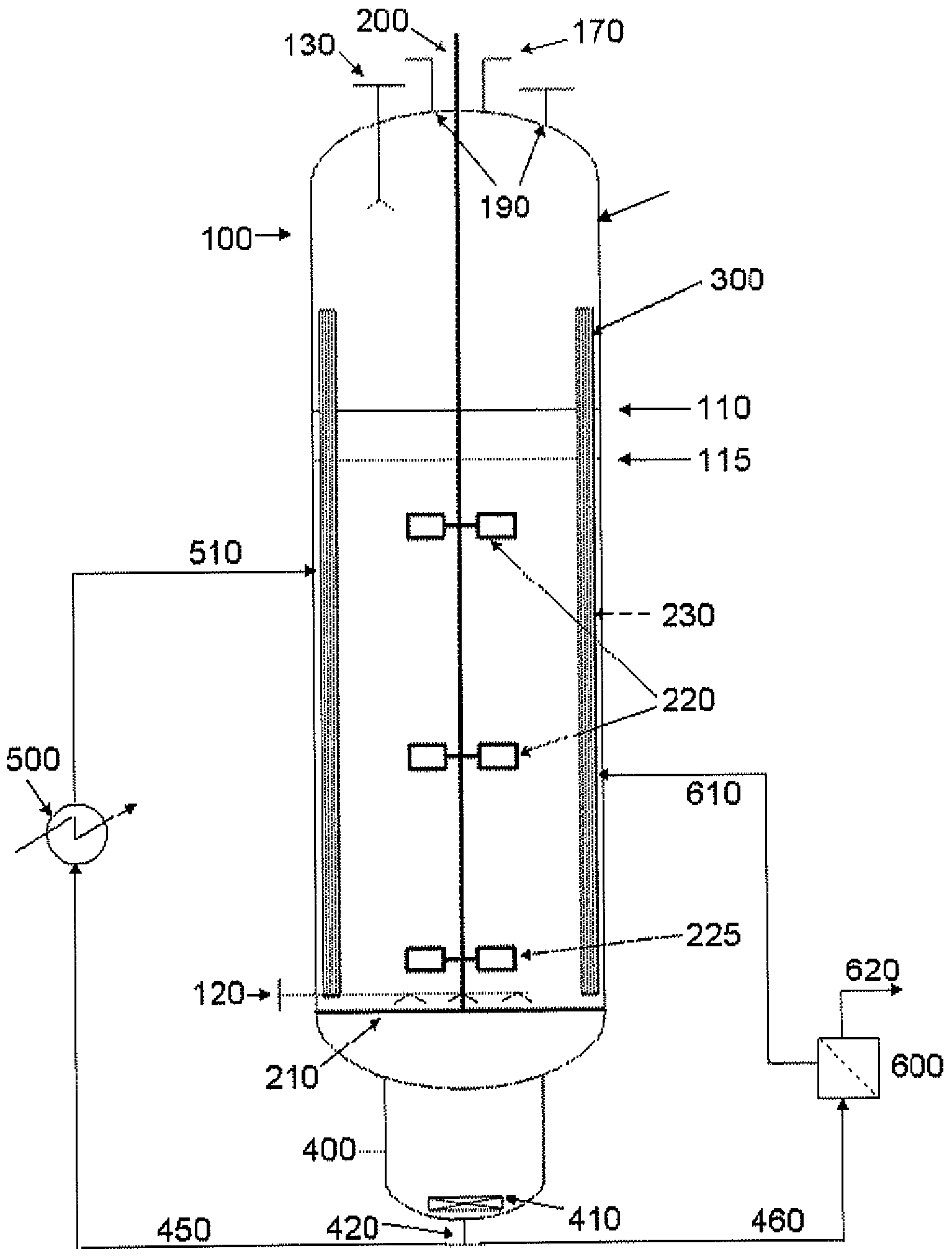

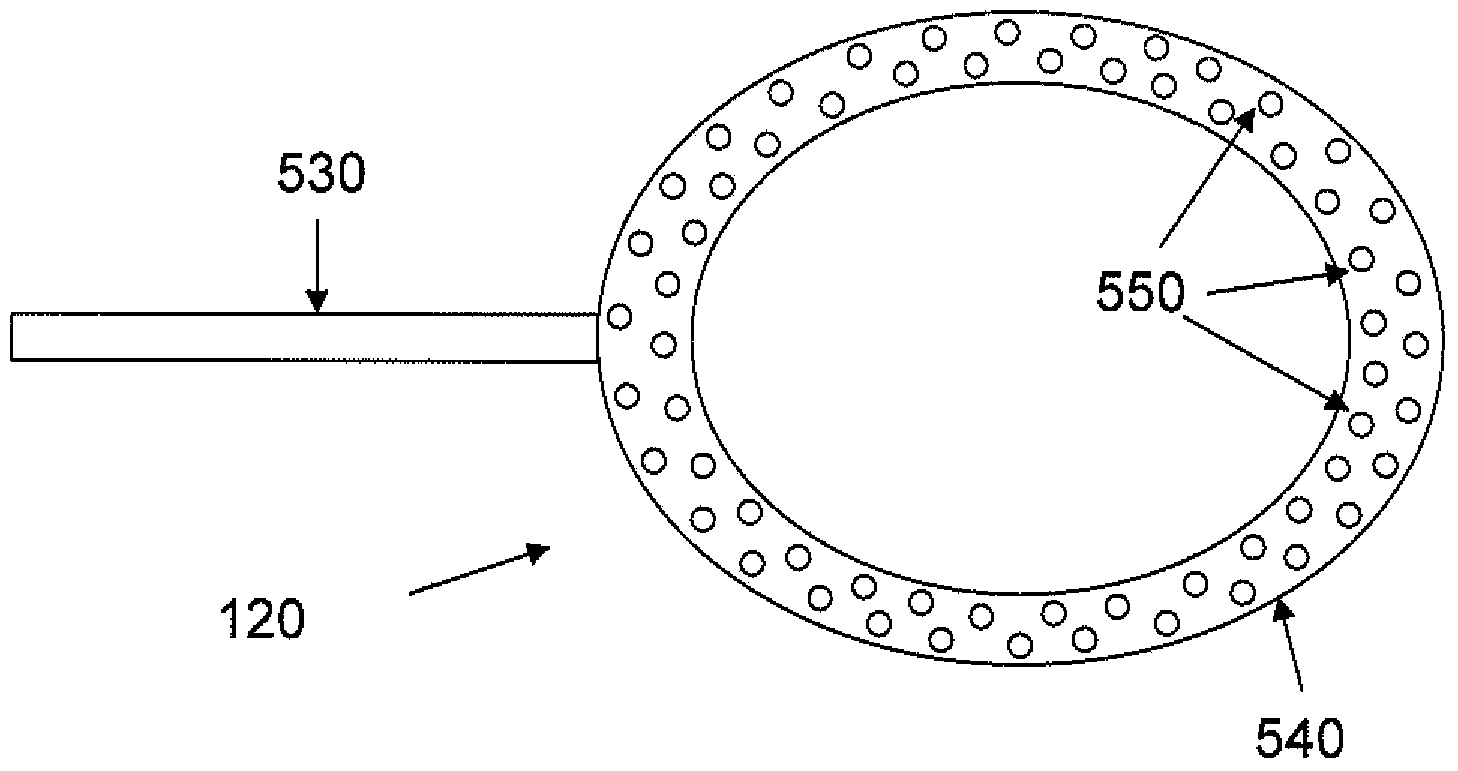

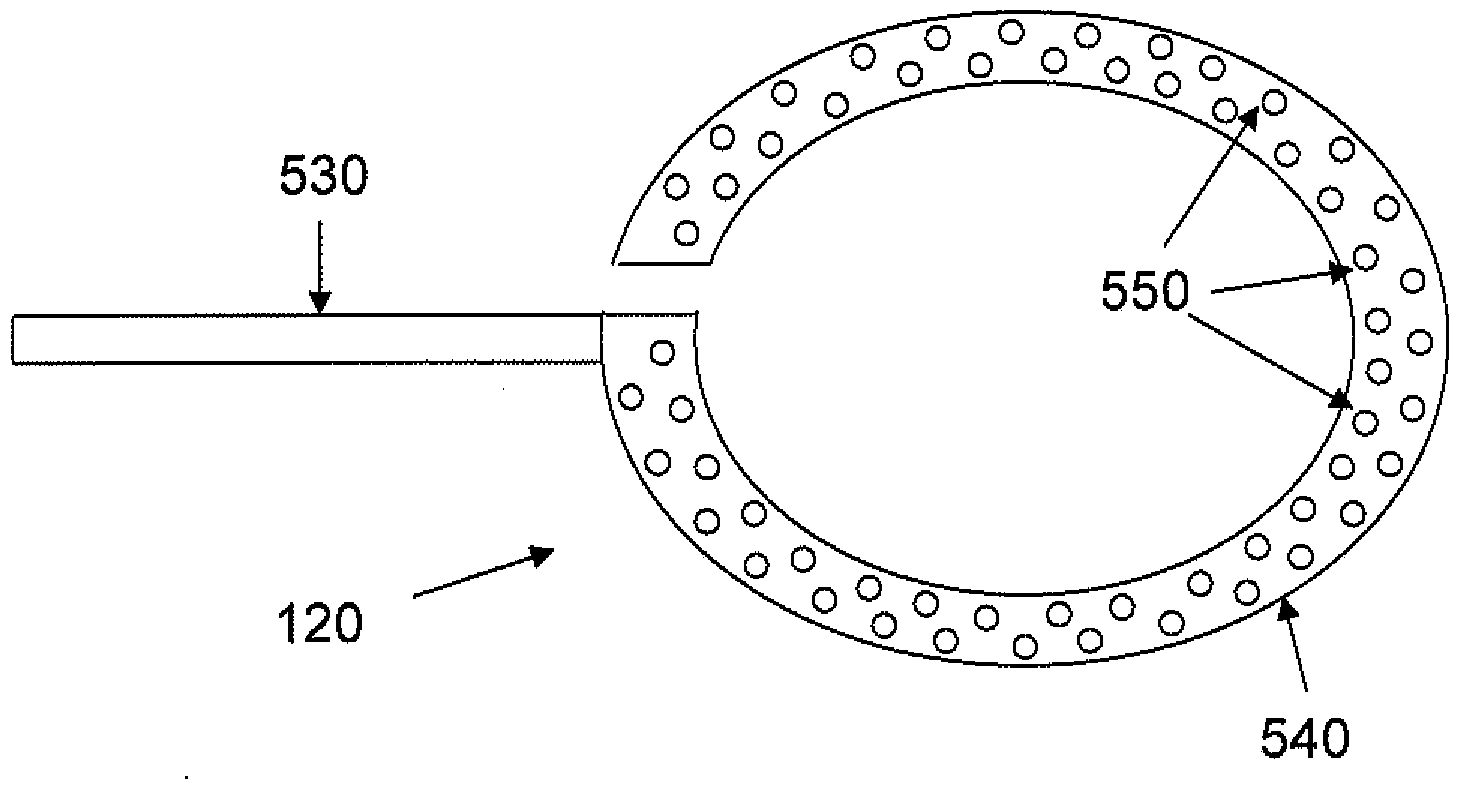

Method and apparatus for syngas fermentation with high CO mass transfer coefficient

InactiveCN103930538AEnhanced mass transferIncrease volumetric CO mass transfer coefficientBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasSyngas fermentation

A process and apparatus is provided which are effective for improving CO mass transfer. The process includes introducing syngas into a reactor vessel through a gas sparger located below a liquid level in the reactor vessel. The syngas being introduced at a flow rate effective for maintaining a pressure inside of the reactor vessel of at least about 1 psig. An agitation energy of about 0.01 to about 12 kWatts / m3 medium is provided. The process is effective for providing a volumetric CO mass transfer coefficient of about 100 to about 1500 per hour.

Owner:INEOS BIO SA

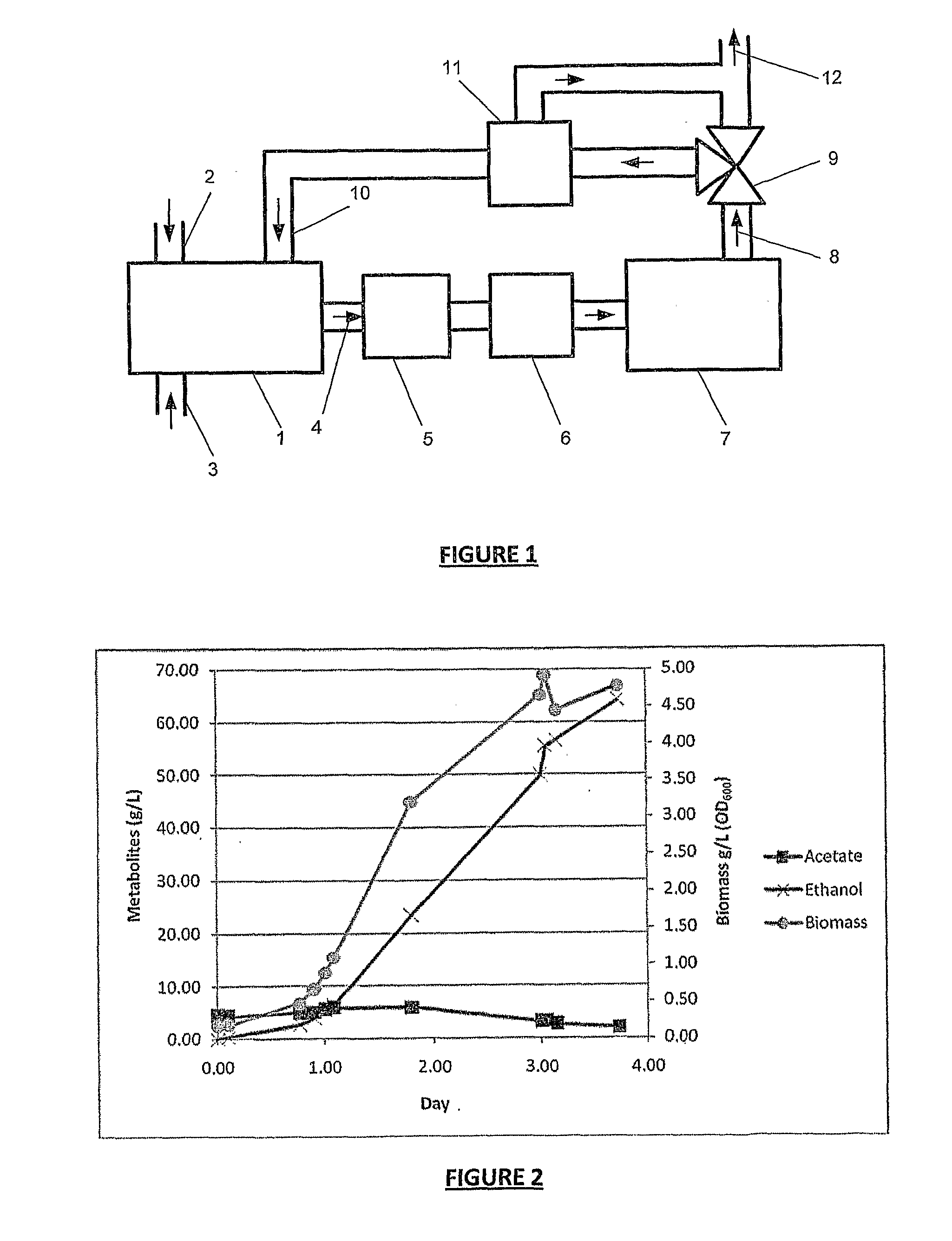

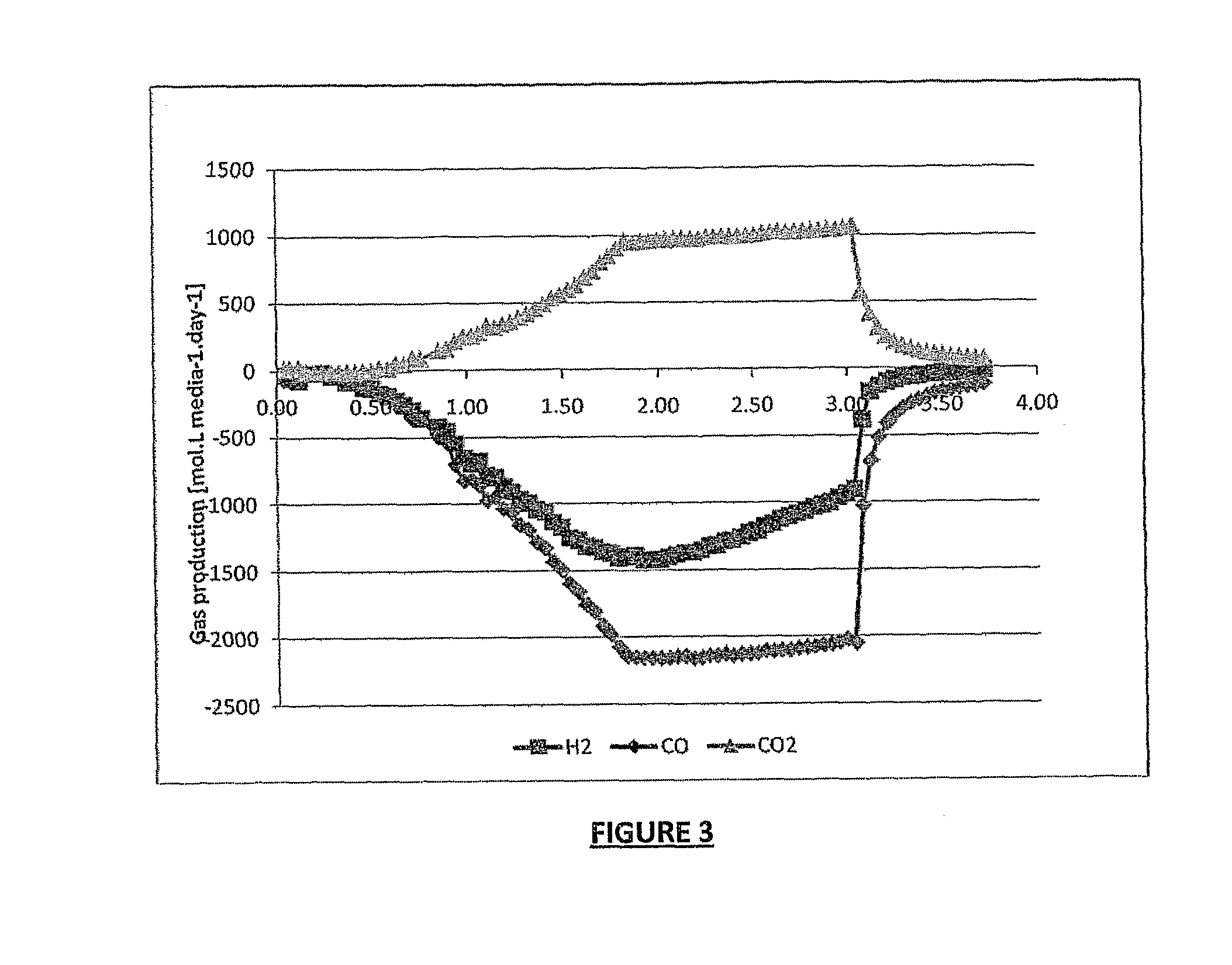

Method for sustaining microorganism culture in syngas fermentation process in decreased concentration or absence of various substrates

ActiveUS9034618B2Preventing rapid lossDecreased absenceBacteriaUnicellular algaeMicroorganismAlcohol

Owner:JUPENG BIO HK LTD

Atomization bioreactor based on synthesis gas fermented ethanol or butanol

ActiveCN103952289AReduce wasteImprove automation controlBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlNutrient solution

The invention discloses an atomization bioreactor based on synthesis gas fermented ethanol or butanol. The atomization bioreactor comprises a transparent thallus cultivation tank, a culture medium atomization reaction tank system, an atomization automatic control system, a synthesis gas pneumatic control system and a mash recycling pipeline system. The atomization bioreactor is characterized in that an immobilized fermentation thallus is put on a mesh cultivation layer, then the mesh cultivation layer is put in the thallus cultivation tank, and the fermentation reaction is carried out in the thallus cultivation tank; meanwhile, a culture medium is sprayed to the thallus cultivation tank by using the culture medium atomization reaction tank system so as to provide a nutrient solution for the thallus, and then the atomization automatic control system is used for increasing automatic control, so that the nutrient solution is automatically sprayed as required, and the effect of saving both time and labor is achieved; the synthesis gas pneumatic control system is used for feeding synthesis gas into the thallus cultivation tank so as to supply a carbon source component and an energy source component which are required for anaerobic fermentation bacteria, and in addition, a liquid condensed after atomization is recycled through the mash recycling pipeline system, and the wasting of resources is reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

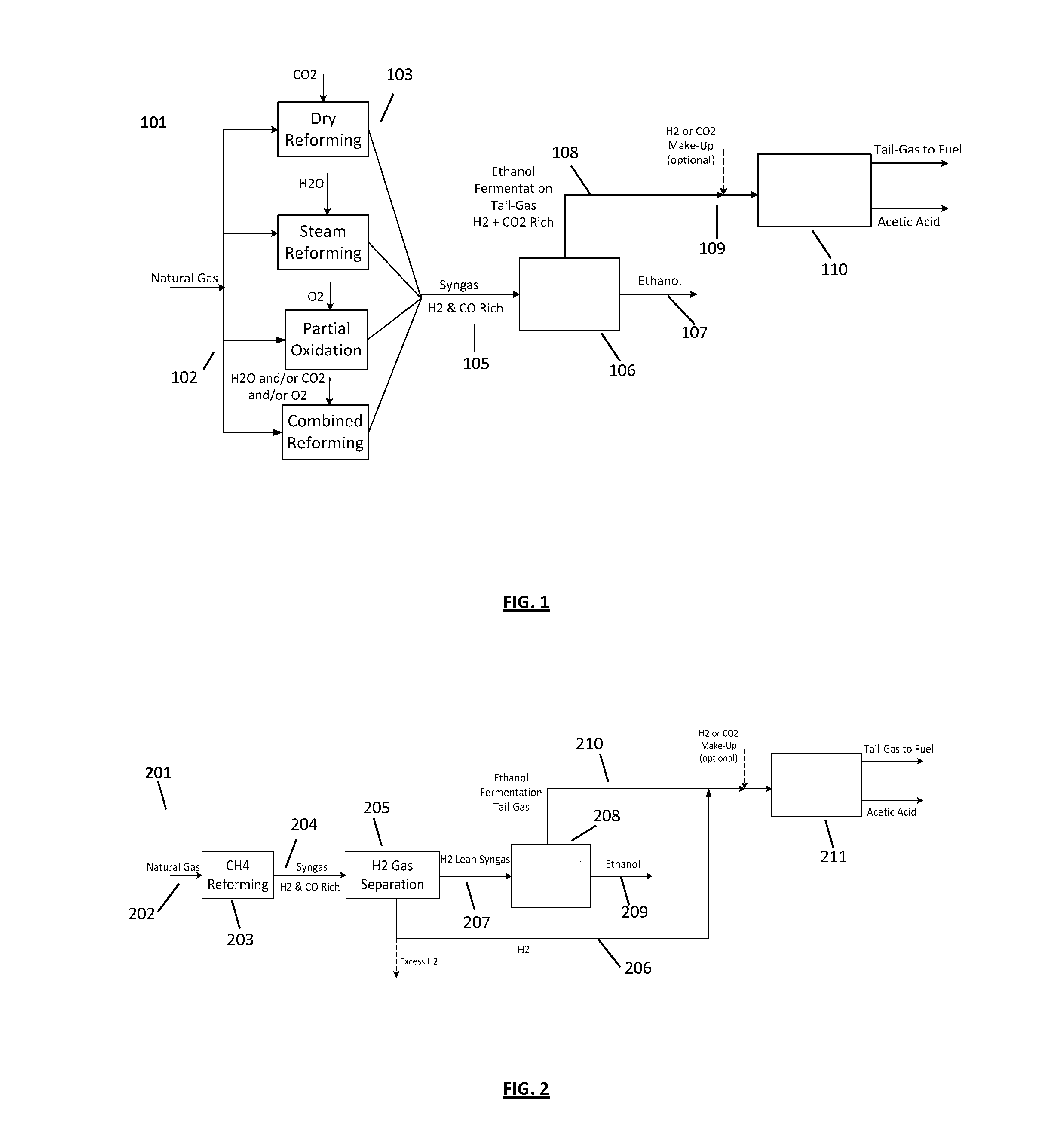

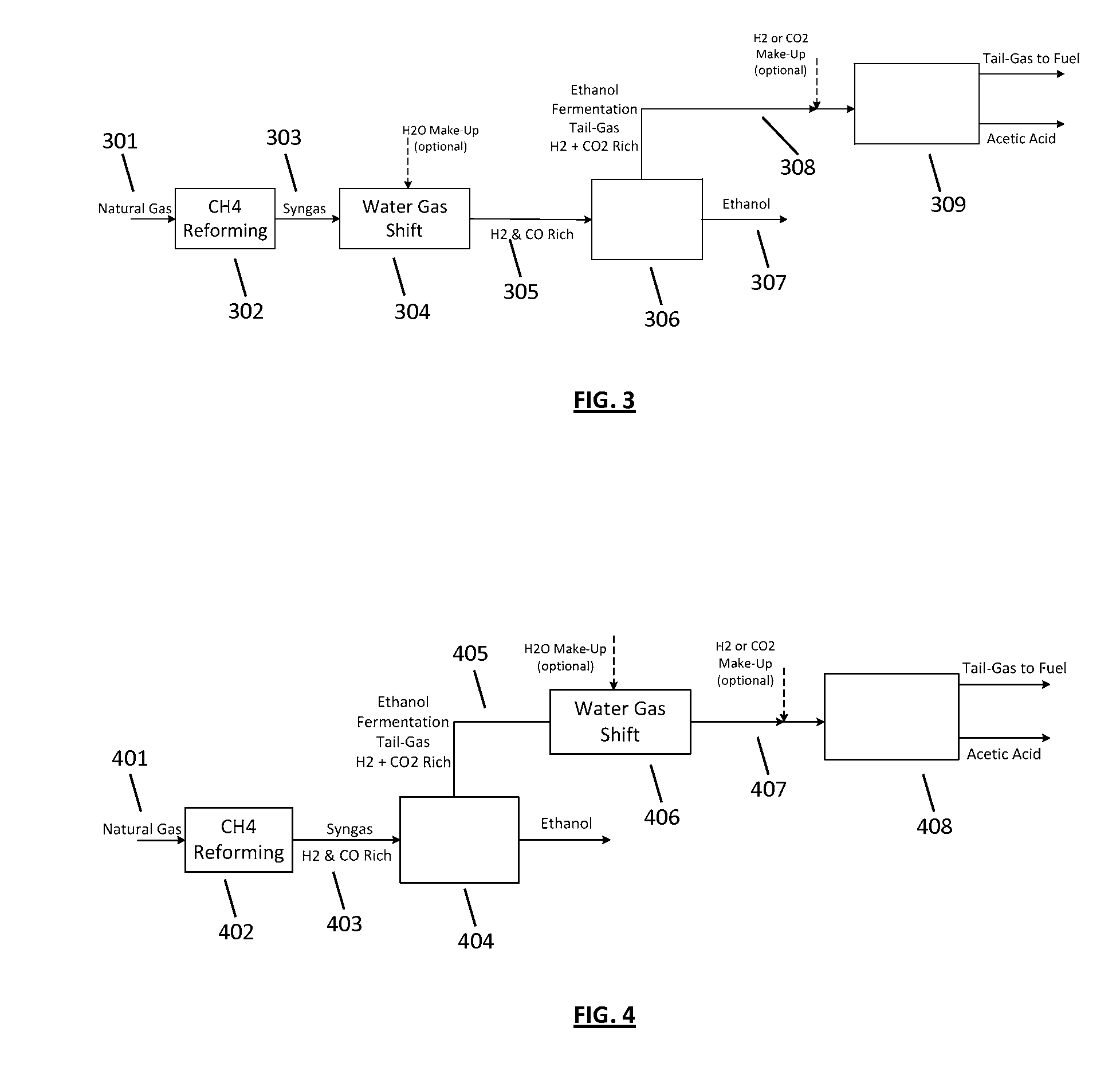

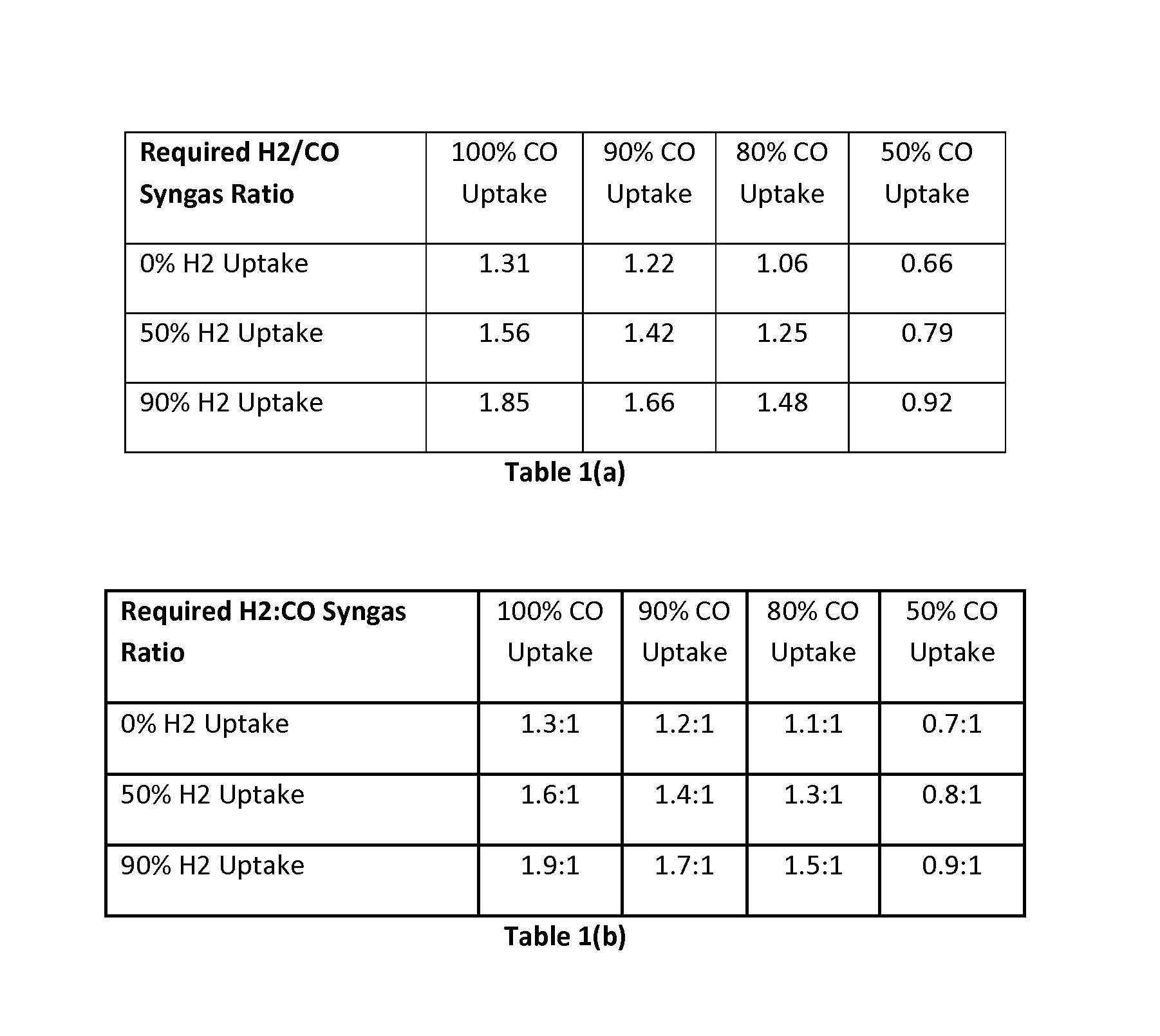

Carbon Capture in Fermentation

InactiveUS20150247171A1Easy to captureUptake of hydrogen by the culture is minimisedBiofuelsFermentationSyngasAlcohol

The present invention provides methods and systems for improving carbon capture from a gas stream comprising methane. Further, the invention provides a method for the production of at least one alcohol, and at least one acid from a gas stream comprising methane, the method comprising reforming a gas stream comprising methane to provide a syngas, in a first bioreactor fermenting the syngas to produce at least one acid and a tail gas comprising CO2 and H2, and, in a second bioreactor fermenting the tail gas to produce at least one acid.

Owner:LANZATECH NZ INC

Process for producing propylene from syngas via fermentative propanol production and dehydration

A process for making propylene by dehydration of propanol can include gasifying a carbonaceous solid or liquid feedstock, or reforming a gaseous carbonaceous feedstock into synthesis gas. The synthesis gas can be fermented or co-fermented by means of a microorganism into propanol. The microorganism can be a wild strain having the natural capability to ferment synthesis gas into propanol. The microorganism can be a microorganism possessing the required nucleic acid sequence information to express the enzymes for the biosynthesis of C3-oxygenates modified with the required nucleic acid sequence information to express the enzymes of the Wood-Ljungdahl pathway. The microorganism can be a microorganism possessing the required nucleic acid sequence information to express the enzymes of the Wood-Ljungdahl pathway, modified with the required nucleic acid sequence information to express the enzymes for the biosynthesis of C3-oxygenates. The stream can be fractionated, purified, and then dehydrated at conditions effective to make propylene.

Owner:TOTAL RES & TECH FELUY

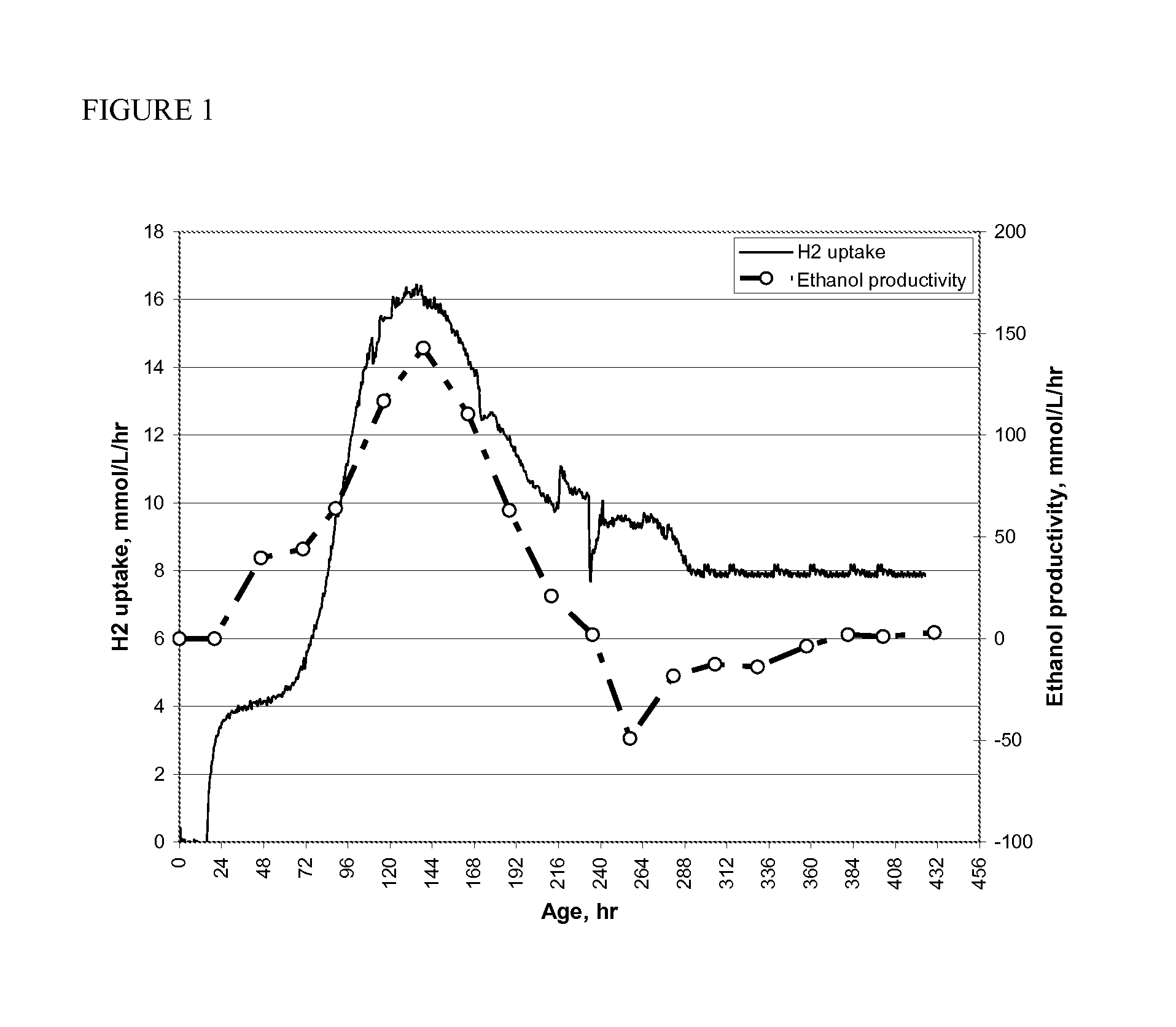

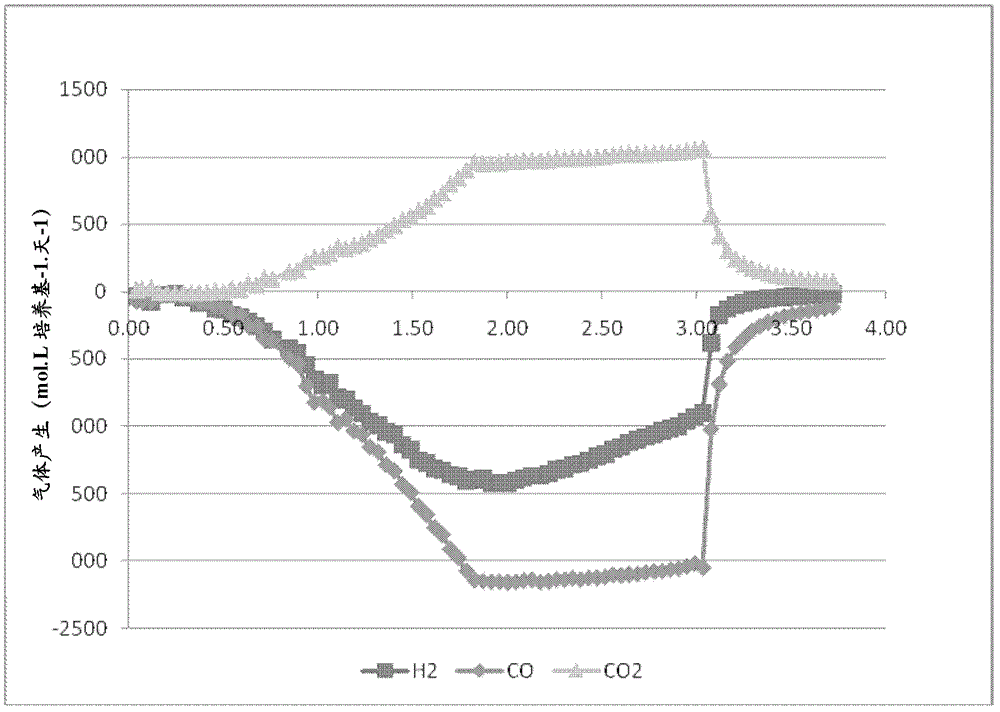

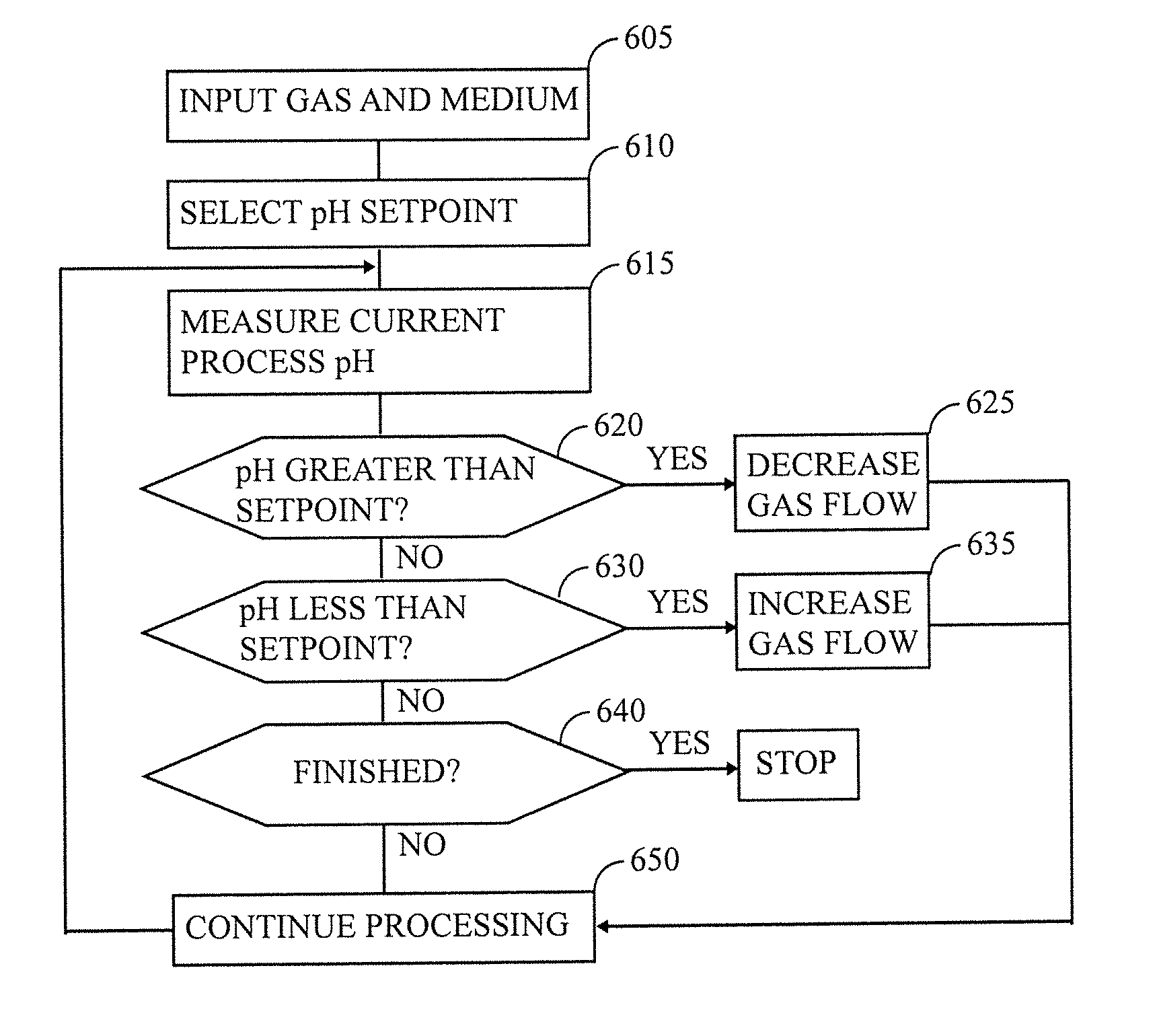

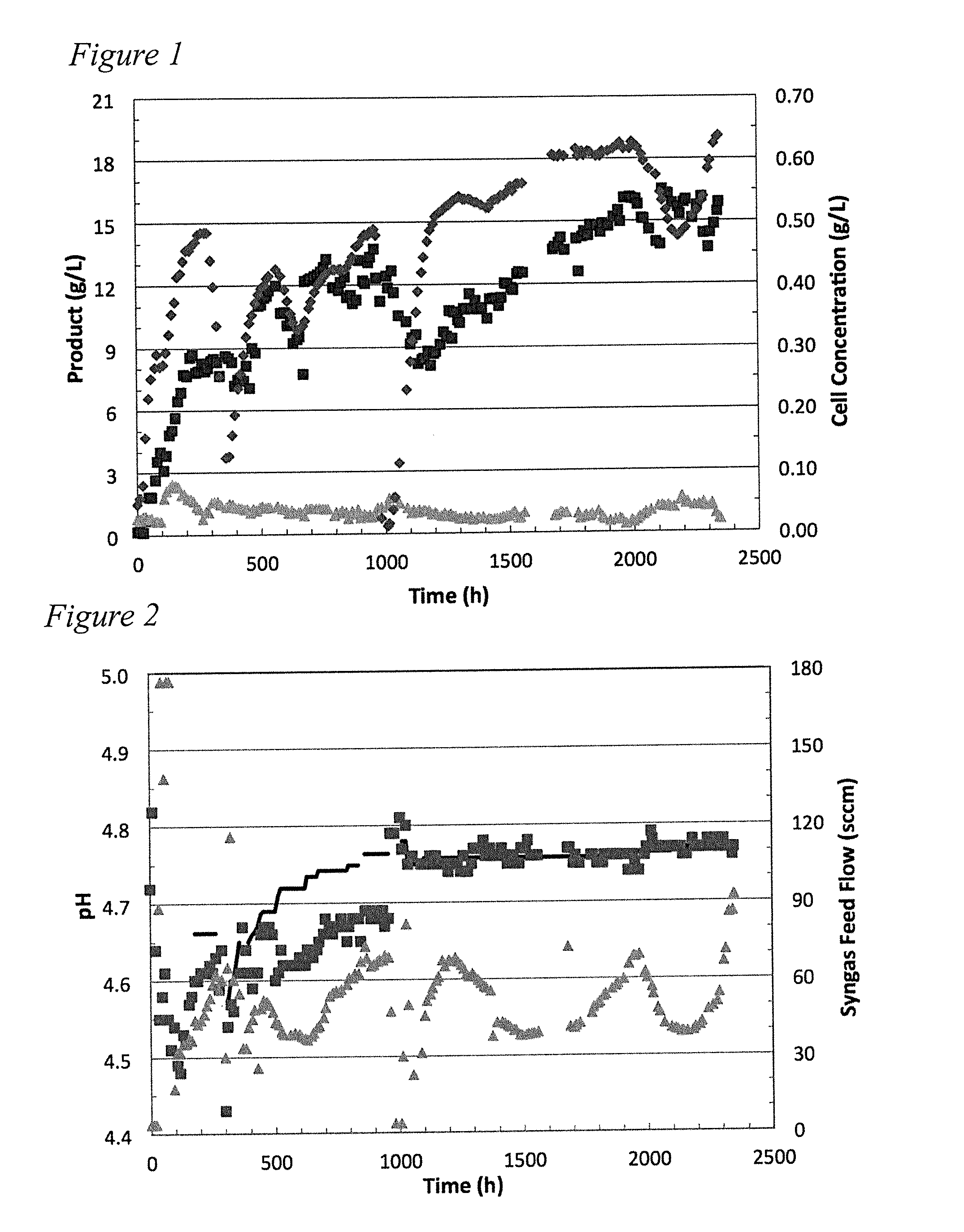

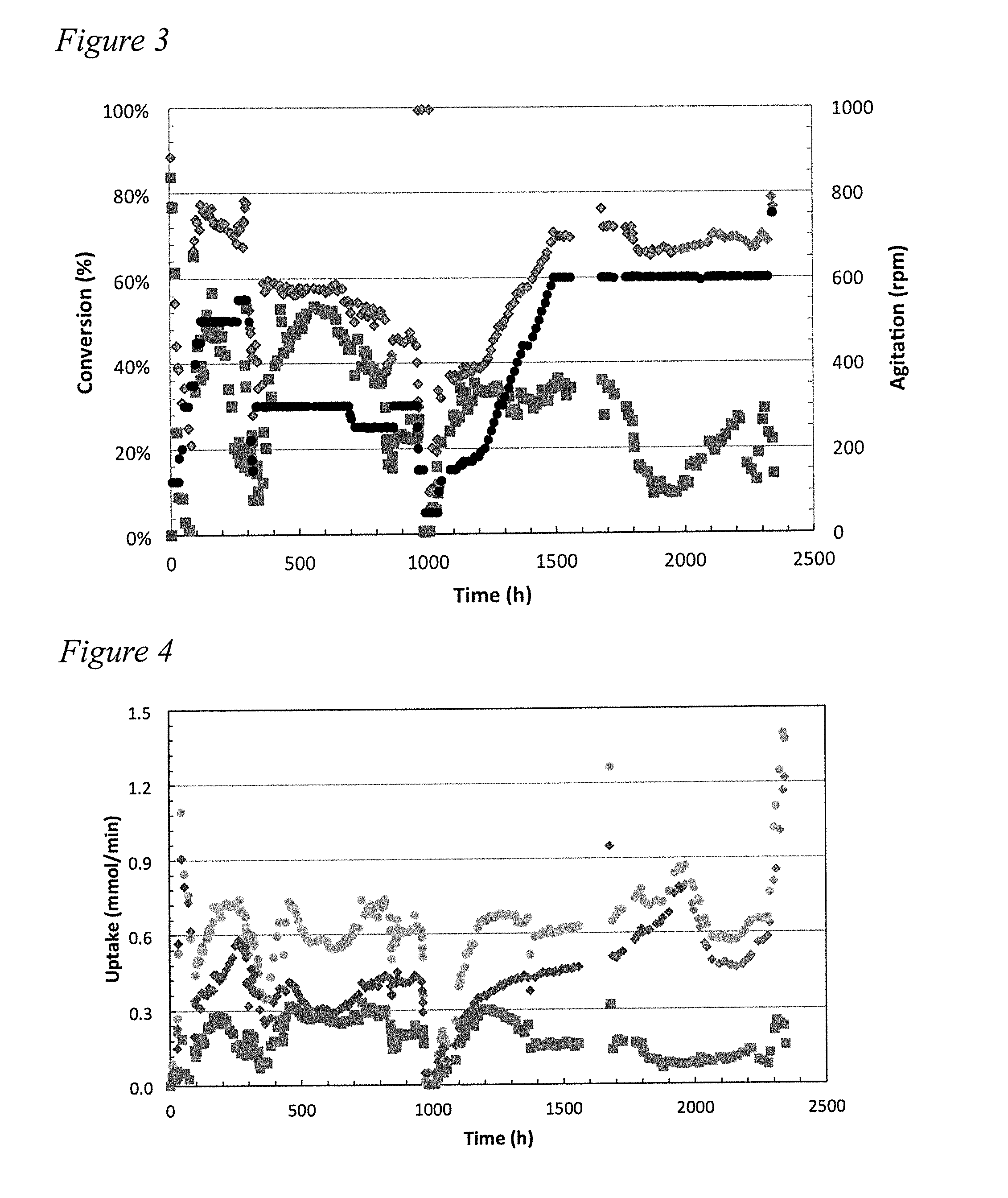

SYSTEM AND METHOD FOR FEEDBACK CONTROL OF GAS SUPPLY FOR ETHANOL PRODUCTION VIA SYNGAS FERMENTATION USING pH AS A KEY CONTROL INDICATOR

ActiveUS20160281114A1Reduce fermentationUseful strengthBioreactor/fermenter combinationsBiological substance pretreatmentsSyngasContinuous fermentation

According to an embodiment, there is provided herein a system and method wherein knowledge of the syngas fermentation is combined with standard instrumentation to provide a stable control of gas supply to automatically poise the fermentation to provide both high conversion of CO and H2, and high selectivity for production of ethanol. The control is based on an automatic feedback loop that corrects for operational imbalance and maintains a stable continuous fermentation required for commercial operation. In a further embodiment, feed of syngas to ethanol fermentation can be optimally controlled using the pH of the broth as the input variable for flow control of the gas. This concept will automatically maintain the correct supply of syngas to the fermentation, and provide stable operation at optimal rates.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

Ammonium recovery methods

ActiveUS8580219B2Effective recoveryImprove solubilitySludge treatmentMicroorganismsLiquid productSyngas

The methods are utilized to recover ammonium from waste water using CO2 acidified absorption water. The process is particularly suited for utilization of cellular matter and a CO2 rich tail gas from a syngas fermentation process and derives significant benefit from the recovery of ammonium bicarbonate and ammonium carbonate. Ammonia and ammonium are recovered from the treatment of the syngas as an ammonium rich solution, at least a portion of which is recycled to the fermentation zone to aid in the production of liquid products. A carbon dioxide rich gas produced by fermentation is used to capture the ammonia and ammonium, forming the ammonium rich solution.

Owner:SYNATA BIO INC

Sulfide generation process and system for syngas fermentation

InactiveUS8609380B2Simple deliveryCost effectiveBioreactor/fermenter combinationsBiological substance pretreatmentsSulfide generationLiquid product

Owner:SYNATA BIO INC

Integrated processes for bioconverting syngas to oxygenated organic compound with sulfur supply

Owner:SYNATA BIO INC

Method for preparing medium-chain fatty acid on hollow fiber membrane by utilizing fermentation of synthesis gas

InactiveCN109055443AGuaranteed long-term operationRealize integrated applicationBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeReaction temperature

The invention relates to a method for preparing medium-chain fatty acid on a hollow fiber membrane by utilizing fermentation of synthesis gas. The hollow fiber membrane is adhered to the interior of areactor, sludge, a medium needed by growth of microorganisms and a methane inhibitor are added into the reactor, the synthesis gas is injected into the reactor continuously, the reaction temperatureis controlled, so that substances in the reactor flows cyclically to react stably, and the medium-chain fatty acid is prepared. Compared with the prior art, the method solves the problem that competitiveness exists between the plant oil generated from the grain crop needed by preparing the medium-chain fatty acid and the grain needed by adequate food of human beings, and meanwhile, solves the problems that organic solid wastes are difficult to treat, and energy consumption is high.

Owner:TONGJI UNIV

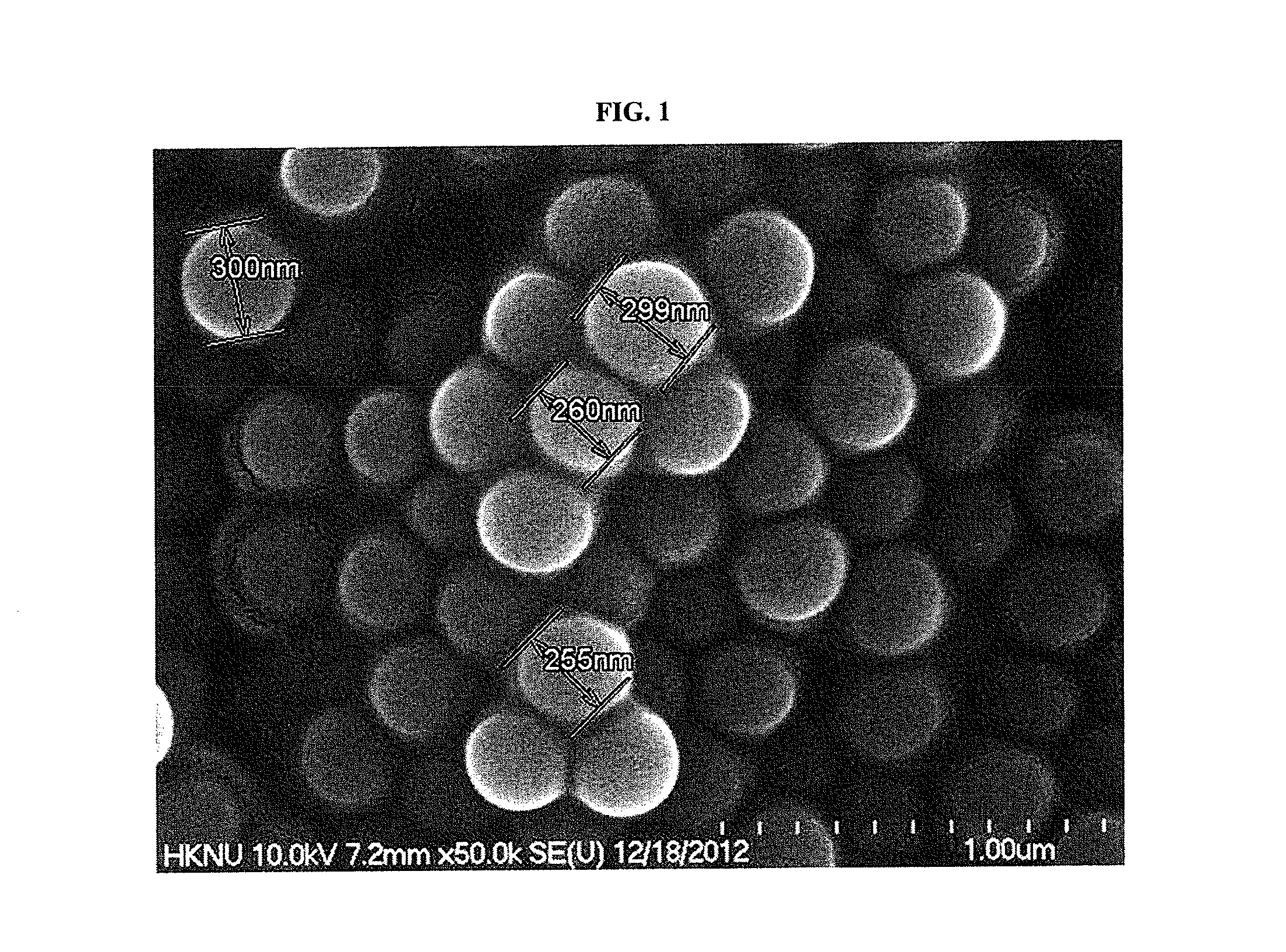

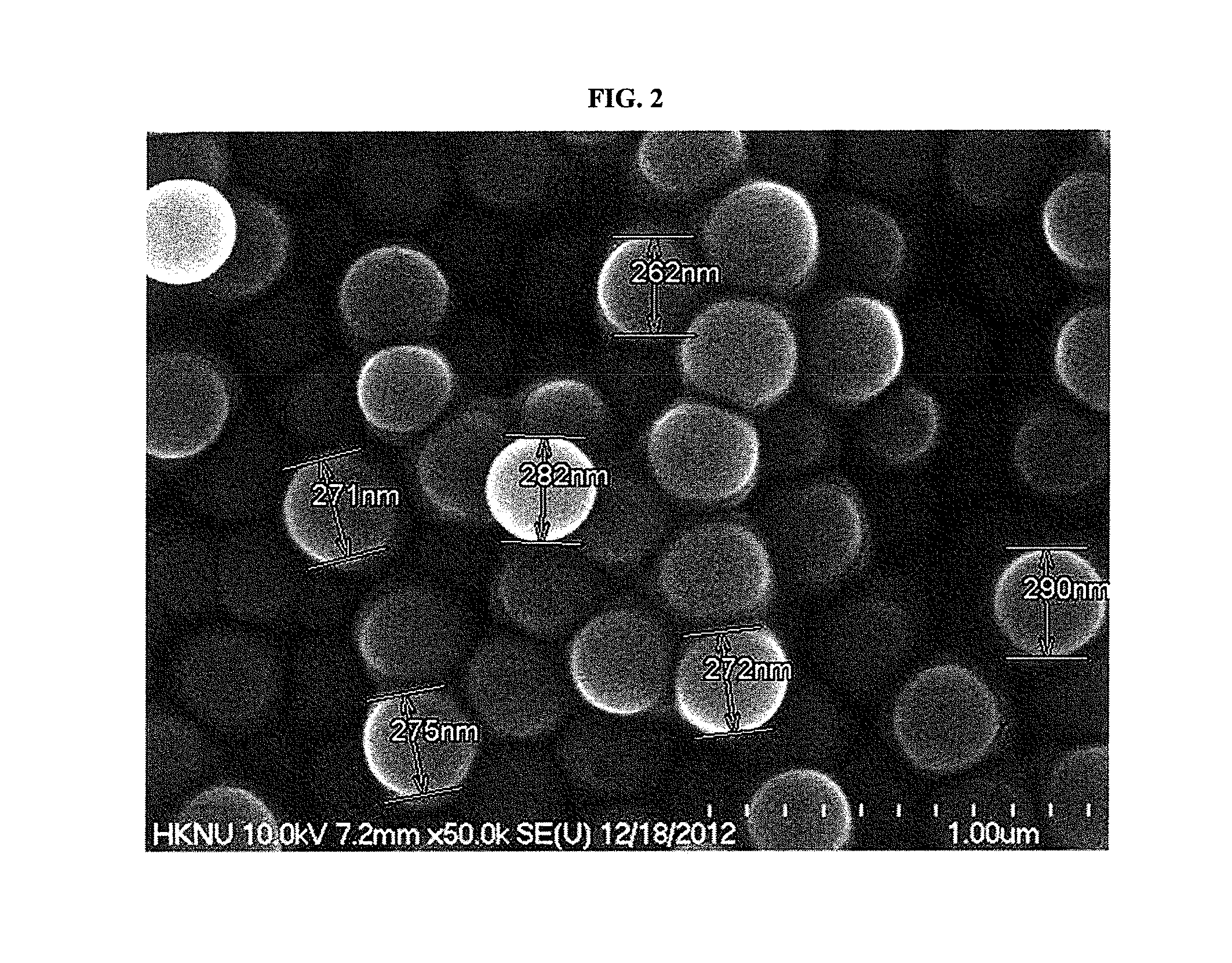

Method for producing bio-alcohol using nanoparticles

ActiveUS20140308722A1Enhanced mass transferIncrease productionSilicon organic compoundsBiofuelsSilica nanoparticlesSyngas

Disclosed is a method for producing a bioalcohol based on the fermentation of syngas. The method includes adding hydrophilic nanoparticles surface modified with hydrophobic groups to a culture medium for fermentation. Also disclosed are hydrophilic nanoparticles surface modified with hydrophobic groups for enhancing bioalcohol yield. The hydrophilic nanoparticles may be, for example, silica nanoparticles.

Owner:HANKYONG IND ACADEMIC COOPERATION CENT

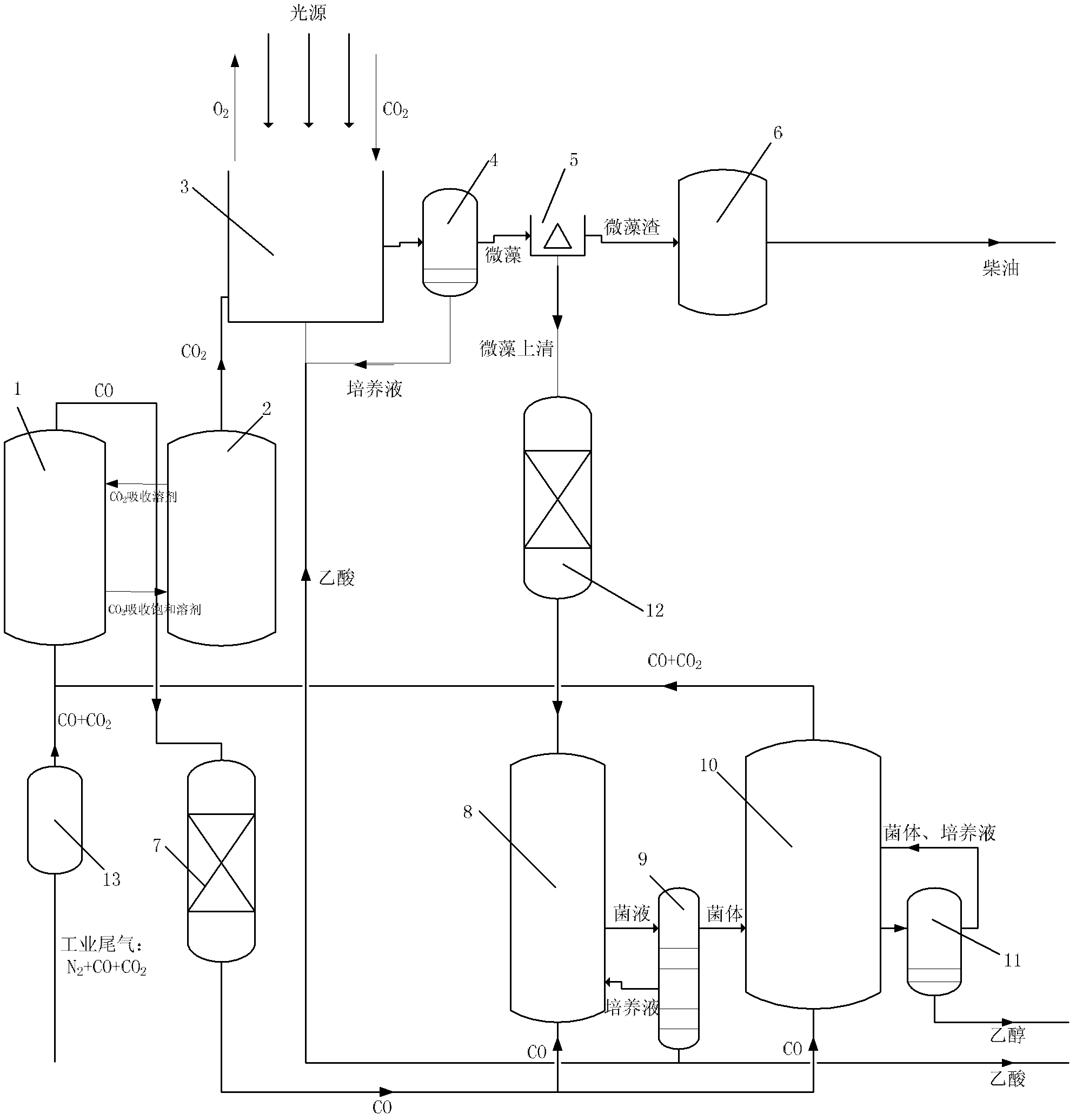

Industrial tail gas recycling system

ActiveCN102266719BSolving the problem of discontinuous supplyStable biological reaction environmentBiofuelsMicroorganism based processesOil productionClean energy

The invention discloses an industrial tail gas recycling system. In the industrial tail gas recycling system, a microalgae oil production device is organically coupled with a synthesis gas fermentation strain growth tank and a synthesis gas fermentation strain fermentation tank. By the industrial tail gas recycling system, CO2 and CO in the tail gas can be recycled effectively, so that two types of clean energy, namely ethanol and diesel, and a few of acetic acid by-products can be obtained. Thus, components of the industrial tail gas can be treated fully through a biologic mode, energy is recycled; therefore, pollution of industrial tail gas emission to the environment can be relieved; and the industrial tail gas energy recycling system has significant use value.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Methods and apparatus for recycling tail gas in syngas fermentation to ethanol

ActiveUS10603632B2Enhanced mass transferIncrease pressureProductsGas treatmentSyngasProcess engineering

The invention present provides a method (and suitable apparatus) to convert biomass to ethanol, comprising gasifying the biomass to produce raw syngas; feeding the raw syngas to an acid-gas removal unit to remove at least some CO2 and produce a conditioned syngas stream; feeding the conditioned syngas stream to a fermentor to biologically convert the syngas to ethanol; capturing a tail gas from an exit of the fermentor, wherein the tail gas comprises at least CO2 and unconverted CO or H2; and recycling a first portion of the tail gas to the fermentor and / or a second portion of the tail gas to the acid-gas removal unit. This invention allows for increased syngas conversion to ethanol, improved process efficiency, and better overall biorefinery economics for conversion of biomass to ethanol.

Owner:LANZATECH INC

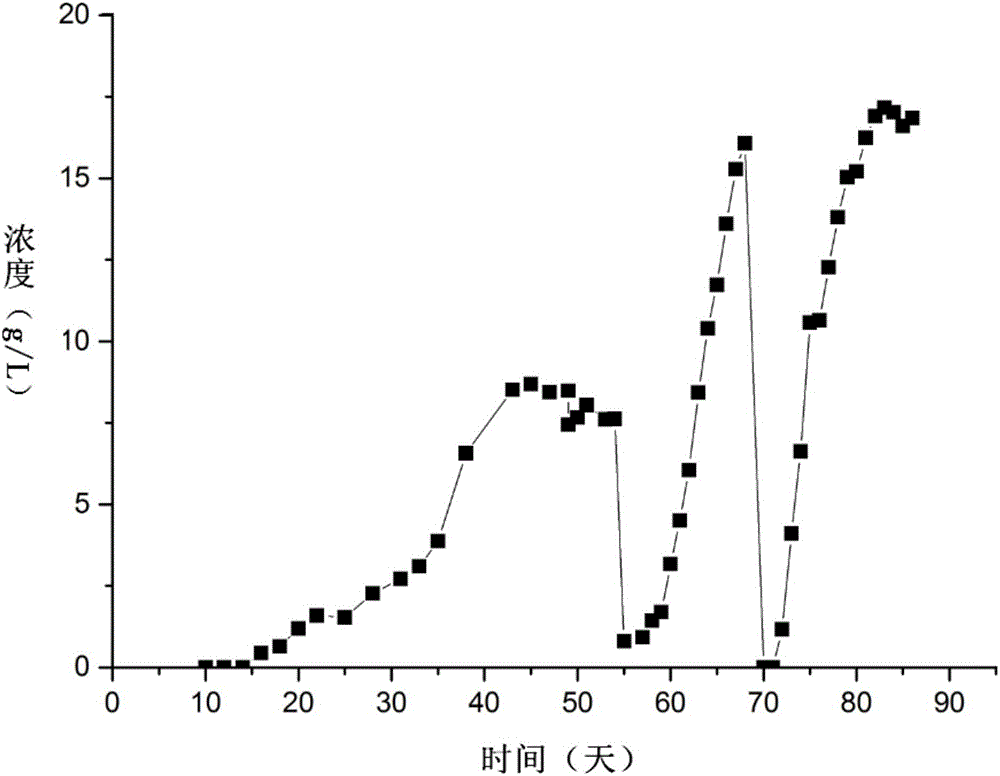

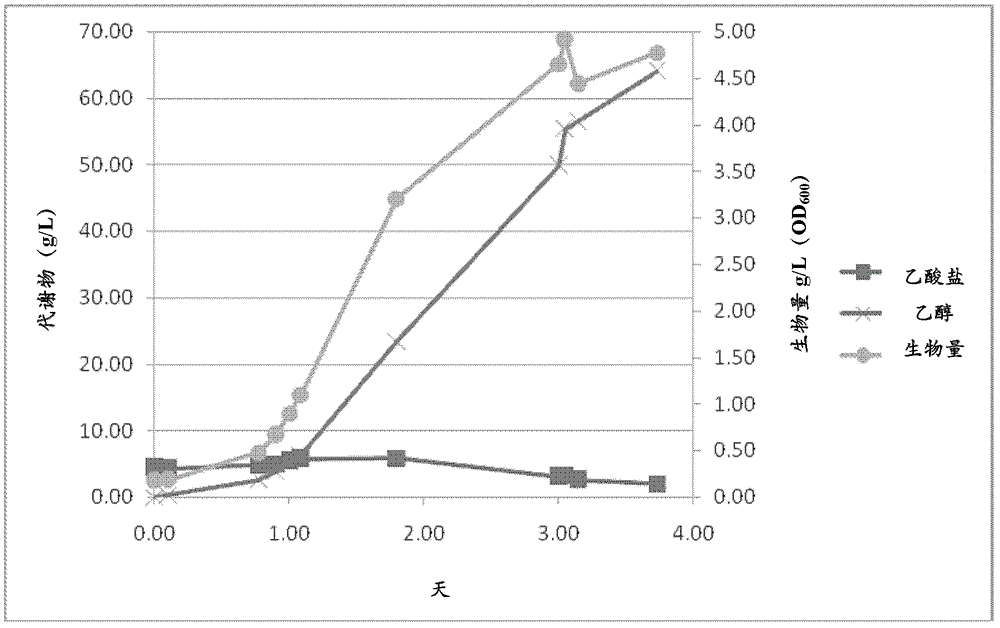

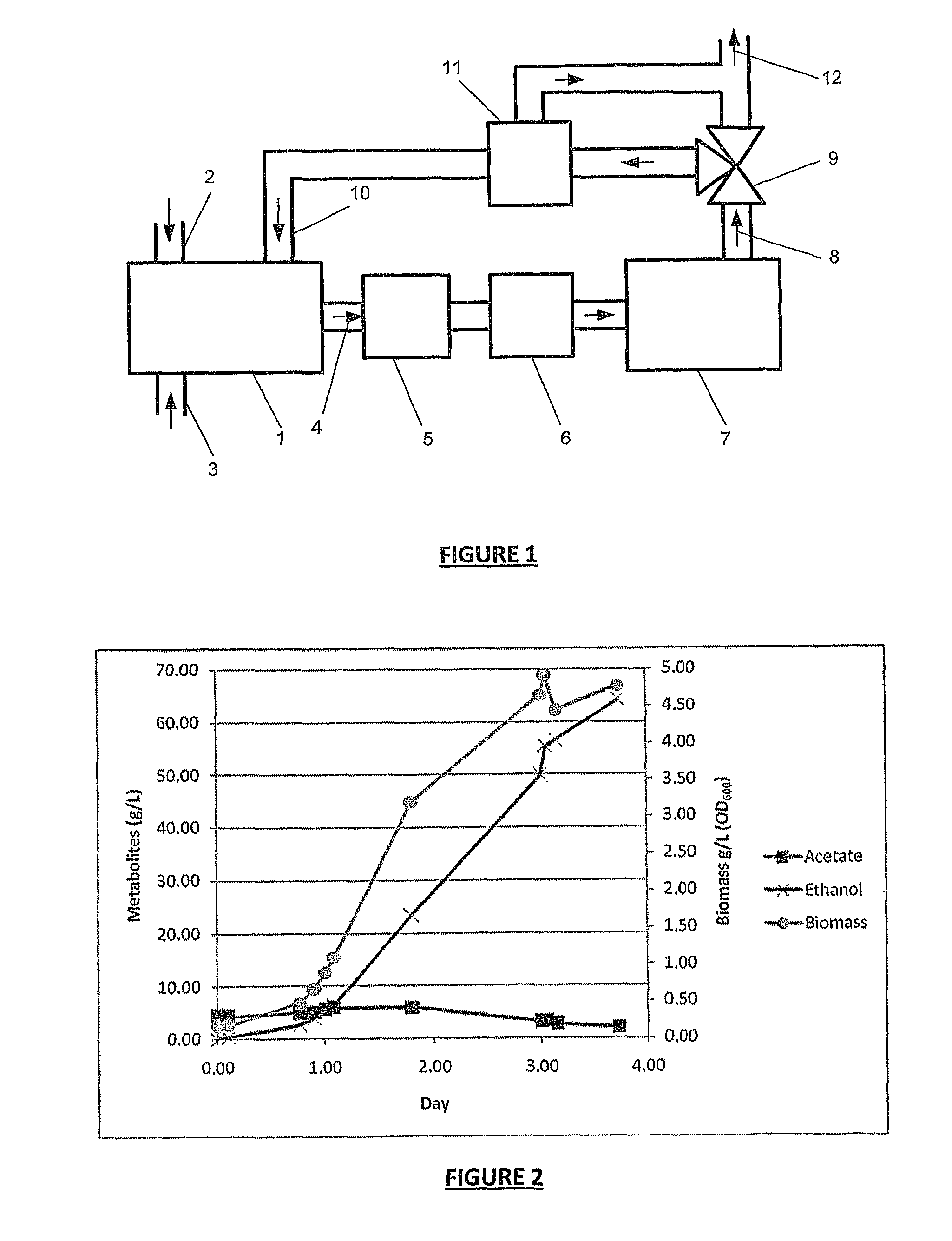

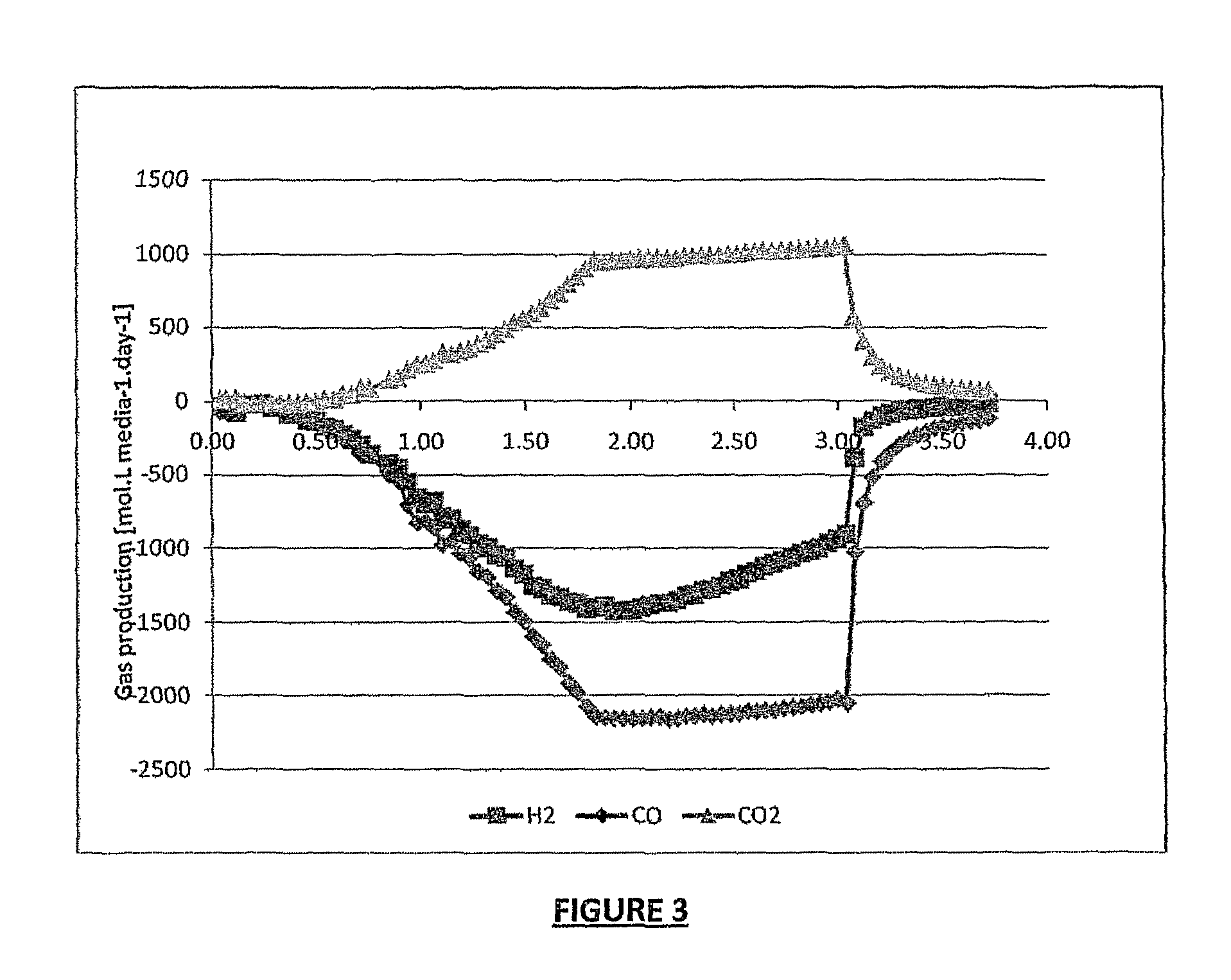

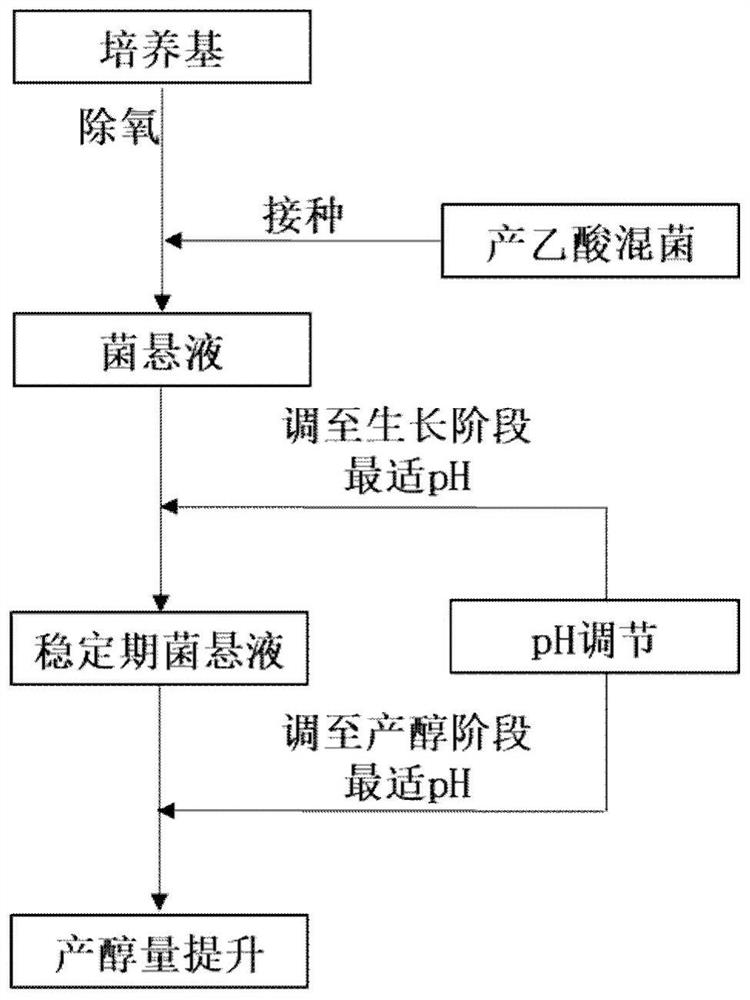

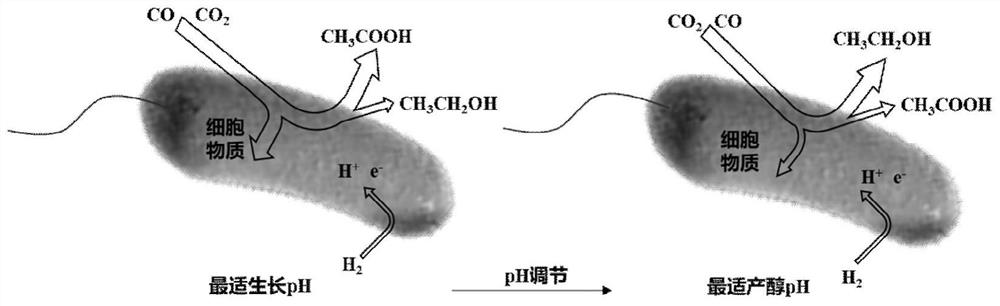

Two-step pH regulation method for producing ethanol through fermentation of synthesis gas

The invention discloses a two-step pH regulation method for producing ethanol by fermentation of synthesis gas, which is characterized by comprising the following steps: strictly deoxidizing a culture medium in an anaerobic fermentation bottle, and inoculating acetic acid-producing mixed strains into the strictly deoxidized anaerobic fermentation bottle containing the culture medium according to a certain volume ratio; setting the pH value of a culture solution in an anaerobic fermentation bottle according to the requirement of the acetic acid-producing mixed bacteria on pH in rapid growth, and adjusting and keeping the constant pH value through a pH value real-time measurement and feedback device so as to promote the growth of the acetic acid-producing bacteria and enable the acetic acid-producing bacteria to enter a rapid biomass enrichment stage; continuously introducing synthesis gas containing CO, CO2 and H2 into an anaerobic fermentation bottle as a gas substrate for fermentation, regulating the pH value of a culture solution in the anaerobic fermentation bottle to a proper range and keeping the pH value constant according to the pH value requirement of the strain for rapid ethanol production after the strain grows to a stable phase and is enriched with enough biomass, so that acetic acid-producing mixed bacteria enter a rapid ethanol production stage, and the method can be widely applied to the fields of energy conservation and emission reduction, environmental improvement, clean energy and the like.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com