Bubble-free air supply and solid-liquid separation integrated membrane biomembrane reactor taking indissoluble gases as fermentation raw materials

A solid-liquid separation, membrane reactor technology, applied in gas production bioreactors, methods of supporting/immobilizing microorganisms, biochemical instruments, etc., can solve the problem of low microbial cell concentration, low gas utilization efficiency, and low gas-liquid mass transfer rate and other problems, to achieve the effect of improving the fermentation reaction rate and avoiding the gas-liquid mass transfer step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the present invention is not limited to the following implementation examples, and many modifications can also be made. All modifications that can be directly derived or associated by those skilled in the art from the content disclosed in the present invention should be considered as protection of the present invention. scope.

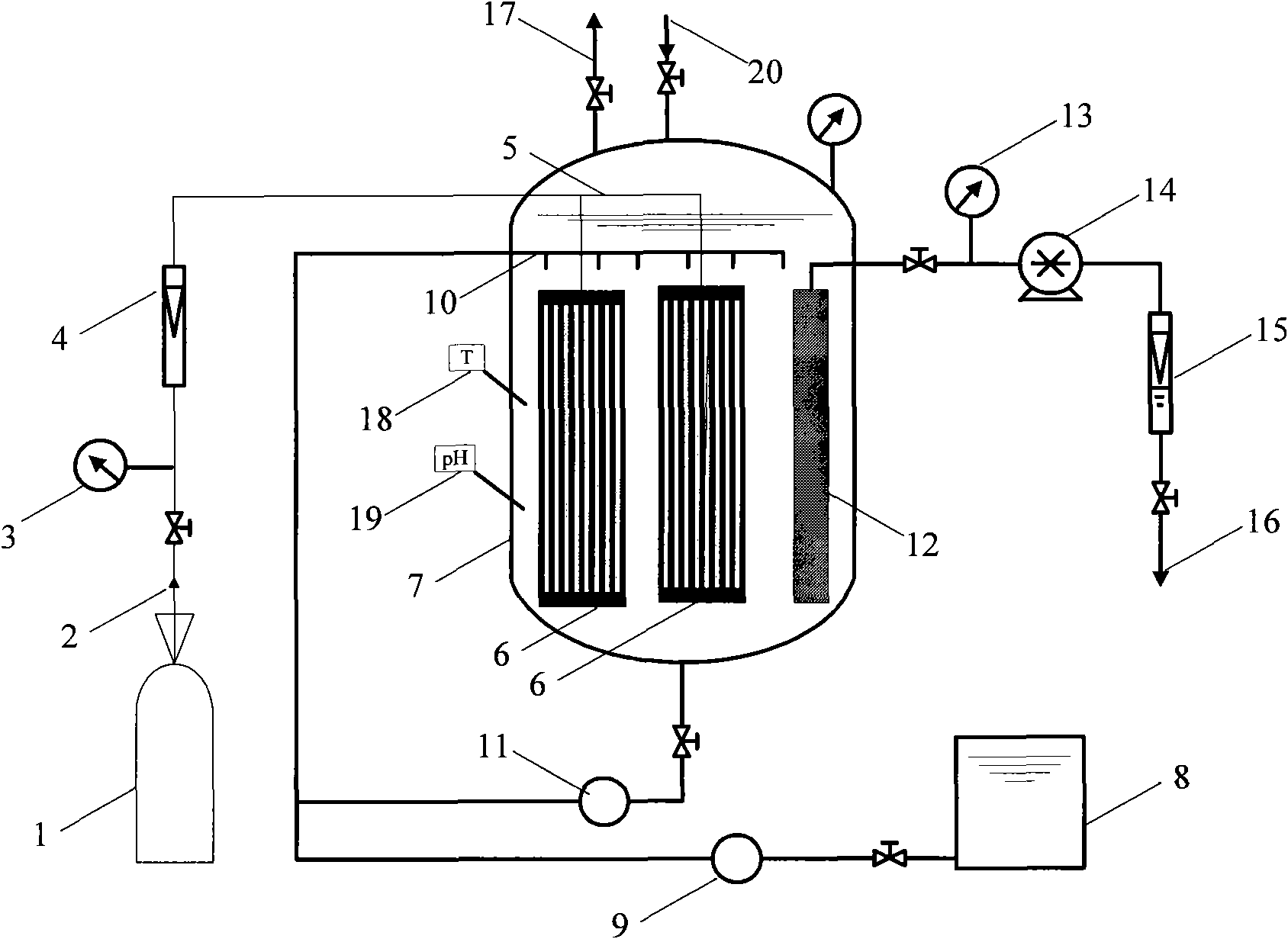

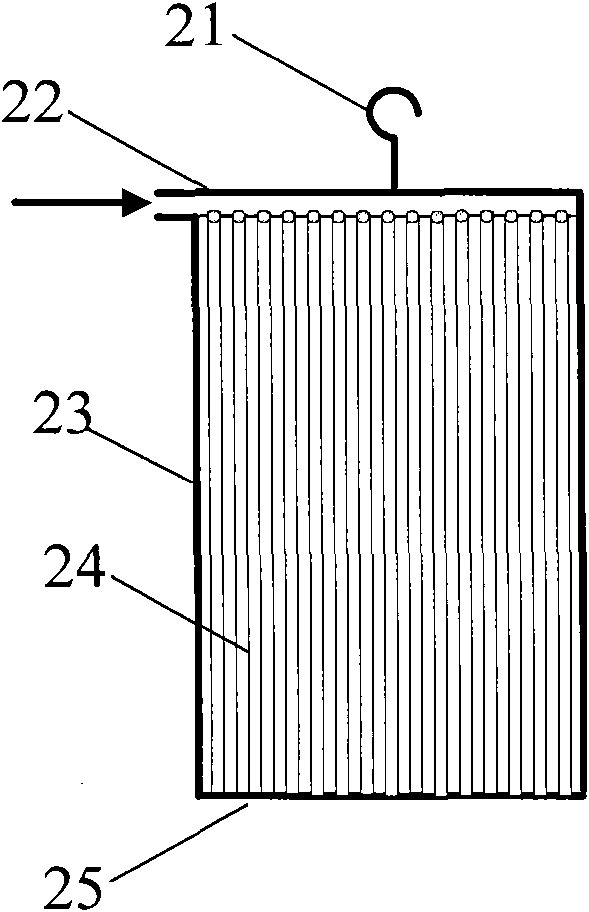

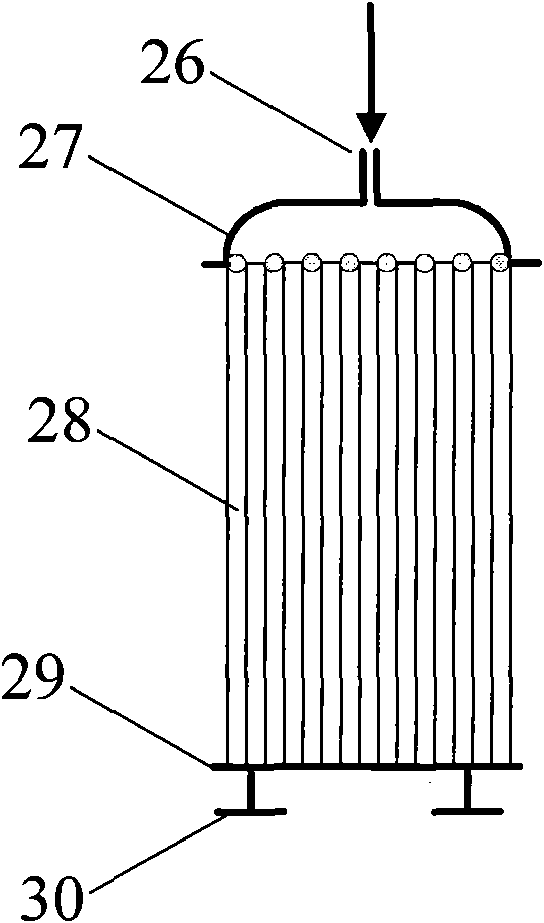

[0048] The bubble-free gas supply-solid-liquid separation integrated membrane biofilm reactor in this embodiment (see figure 1 ), including the reactor tank 7, the air distribution pipe 5, the air supply hollow fiber membrane module 6 without bubbles, the water distribution pipe 10, and the solid-liquid separation membrane module 12 placed in the reactor tank 7, and the air supply hollow fiber membrane without bubbles The top of the module 6 and the solid-liquid separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com