Atomization bioreactor based on synthesis gas fermented ethanol or butanol

A bioreactor, a technology for fermenting ethanol, applied in gas production bioreactors, specific-purpose bioreactors/fermenters, liquid production bioreactors, etc., can solve the energy input requirements and labor requirements. Bacterial growth and ethanol or butanol production, low gas-liquid mass transfer efficiency, etc., to improve the gas-liquid-solid mass transfer rate, overcome the problems of atomized nutrient solution escape and bacterial contamination, and facilitate separation and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

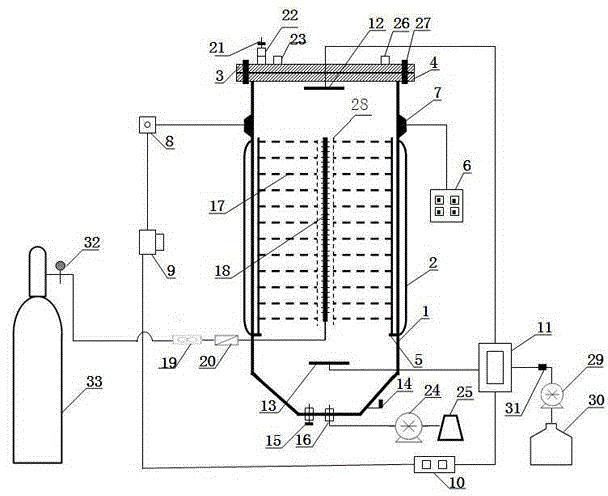

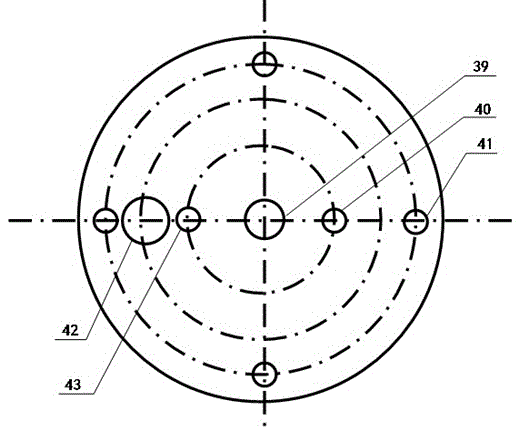

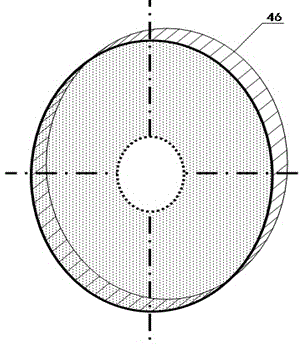

[0021] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a transparent bacteria culture tank 1, a medium atomization reaction tank system, an automatic atomization control system, a syngas gas control system and a mash recovery pipeline system. The bacteria culture tank 1 is made of a transparent material, It is convenient for the experimenter to observe the fermentation situation. A sealing flange 4 is arranged on the top of the cell culture tank 1, and a fixing flange 3 is connected to the upper end of the sealing flange 4, and the sealing flange 4 seals the whole cell culture tank 1 through the fixing flange 3, and can be fixed Flange 3 opens thalli culture tank 1. Bracket 5 is provided on the inner wall of thalli culture tank 1, and a plurality of disk-type mesh culture layers 17 are set up on the bracket 5, and immobilized fermentation cells are uniformly distributed on the mesh culture layer 17, and the center of mesh culture layer 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com