Two-step pH regulation method for producing ethanol through fermentation of synthesis gas

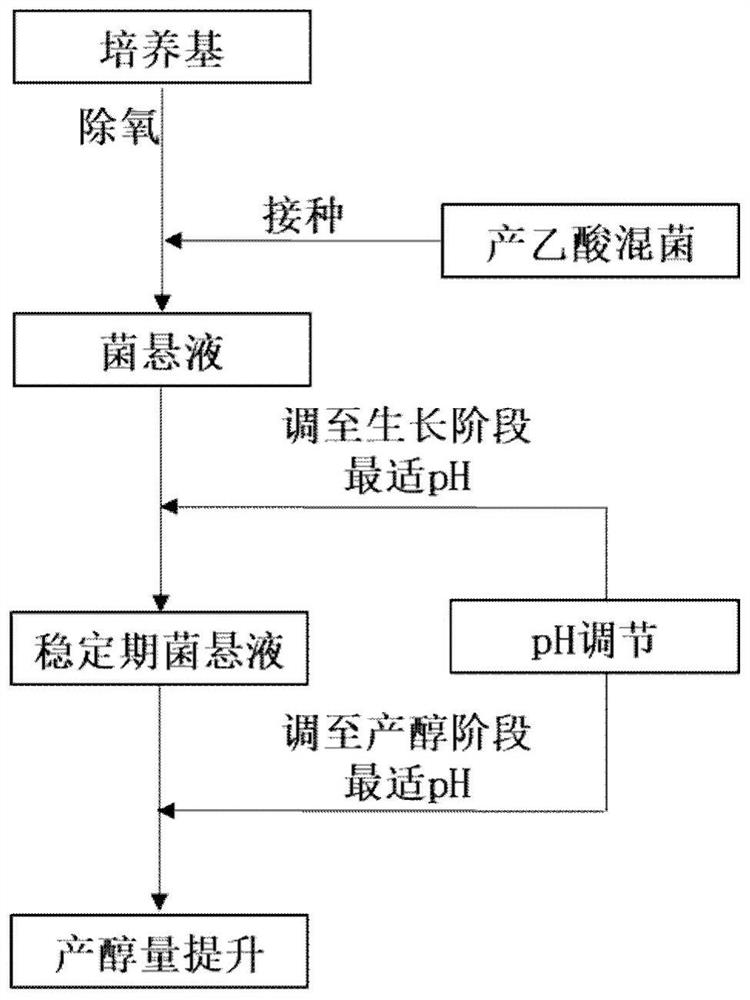

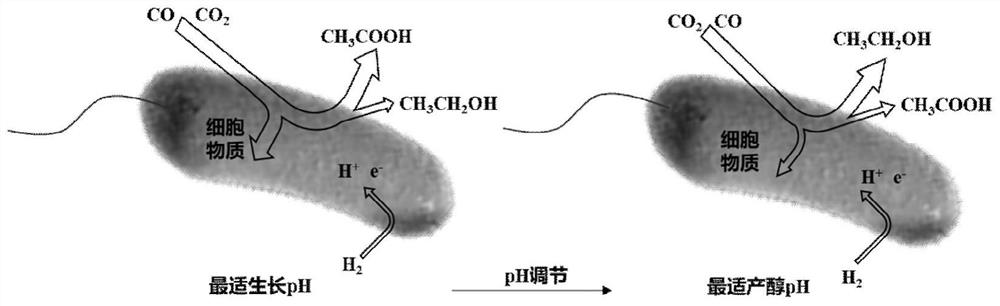

A technology for producing ethanol and syngas, applied in fermentation, biofuel, etc., can solve the problems of unsuitability for bacterial growth, low alcohol production, and decreased bacterial density, so as to achieve rapid enrichment of biomass, increase ethanol production, increase Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Two-step pH regulation with CO / CO 2 A method for producing ethanol by gas fermentation, comprising the steps of:

[0028] Step 1: Add 0.6g / L cysteine to the PBM medium to exclude dissolved oxygen in the medium, and inoculate the acetogenic mixed strain enriched from rabbit manure into the PBM containing PBM at a volume ratio of 10%. Anaerobic fermentation of culture medium in flasks.

[0029] Step 2: Connect the anaerobic fermentation bottle to the multi-channel pH online measurement and feedback adjustment automatic controller, set the initial pH of the fermentation bottle to 7.0 and use the NaOH solution with a concentration of 1mol / L and the HCl solution with a concentration of 1mol / L as the automatic pH adjustment For the acid-base solution, adjust it every 10 minutes to ensure that the pH value of the solution is always within the range of ±0.1 from the target value.

[0030] Step 3: Continuously feed 20% CO into the anaerobic fermentation bottle 2 , 15%CO, 40...

Embodiment 2

[0033] Two-step pH regulation with CO / CO 2 A method for producing ethanol by gas fermentation, comprising the steps of:

[0034] Step 1: Add 0.6g / L cysteine to the PBM medium to exclude dissolved oxygen in the medium, and inoculate the acetogenic mixed strain enriched from rabbit manure into the PBM containing PBM at a volume ratio of 10%. Anaerobic fermentation of culture medium in flasks.

[0035] Step 2: Connect the anaerobic fermentation bottle to the multi-channel pH online measurement and feedback adjustment automatic controller, set the initial pH of the fermentation bottle to 7.0 and use the NaOH solution with a concentration of 1mol / L and the HCl solution with a concentration of 1mol / L as the automatic pH adjustment For the acid-base solution, adjust it every 10 minutes to ensure that the pH value of the solution is always within the range of ±0.1 from the target value.

[0036] Step 3: Continuously feed 20% CO into the anaerobic fermentation bottle 2 , 15%CO, 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com