Complex microbial community and application thereof in alcohol production by syngas fermentation

A technology of compound flora and syngas, applied in the fields of fermentation, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc. Pollution and other problems, to achieve the effect of wide source of raw materials and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

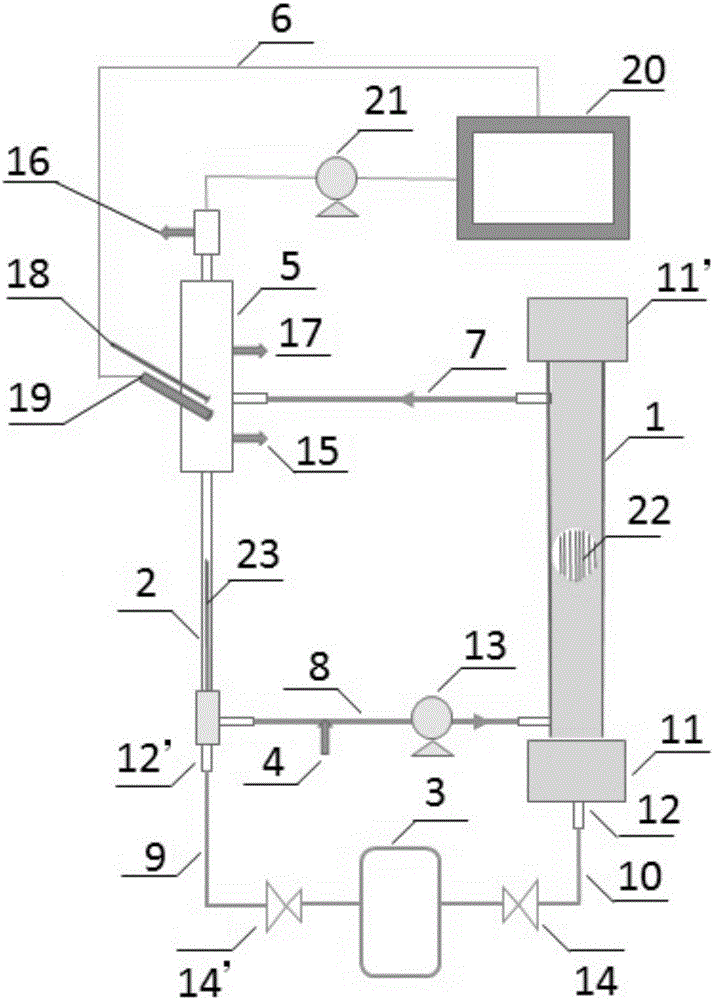

[0087] Embodiment 1 The device provided by the present invention

[0088] The device provided by the present invention is as figure 1 , comprising: a main reactor (1), a branch reactor (2), a syngas supply device (3), a culture medium supply device (4), a reactant recovery device (5) and a reaction system pH automatic control device (6 );

[0089] The main reactor (1) and the branch reactor (2) communicate through the first pipeline (7) and the second pipeline (8); the culture medium supply device (4) is set on the first pipeline; the second A reactant recovery device (5) and a reaction system pH automatic control device (6) are arranged on the pipeline; the synthesis gas supply device (3) communicates with the main reactor (1) through the third pipeline (9) and passes through the fourth pipeline (10) communicates with branch reactor (2).

[0090] In order to facilitate the observation of fermentation conditions, the shell of the branch reactor is made of glass, and the she...

Embodiment 2

[0099] Embodiment 2 flora screening

[0100] The composition of the medium used in this embodiment is: NH 4 Cl530mg / L; KH 2 PO 4 200mg / L; Na 2 SO 4 50mg / L; KCl50mg / L; CaCl 2 10mg / L; MgCl 2 . 6H 2 O70mg / L; MnCl 2 . 4H 2 O0.8mg / L; CoCl 2 . 2H 2 O1.2mg / L; FeSO 4 . 7H 2 O3.2mg / L; AlCl 3 0.5mg / L; NaMO 4 . 2H 2 O0.1mg / L; H 3 BO 3 0.2mg / L; NiCl 2 . 6H 2 O0.5mg / L; CuCl 2 . 2H 2 O1.1mg / L; ZnSO 4 . 2H 2 O3.2mg / L; EDTA-2Na3.0mg / L; biotin 2.0mg / L; folic acid 2.0mg / L; vitamin B610mg / L; riboflavin 5.0mg / L; vitamin B15.0mg / L; niacin 5.0 mg / L; pantothenic acid 5.0mg / L; vitamin B120.1mg / L; p-aminobenzoic acid 5.0mg / L; lipoic acid 5.0mg / L.

[0101] Using the device of Example 1, mix the anaerobic sludge with the culture medium (the mass ratio of the sludge to the culture medium is 5:95), inject it into the fermentation device to make the liquid reach the water outlet, and open the pressure stabilizing valve to adjust the air pressure to 0.01 MPa~0.02Mpa, open al...

Embodiment 3

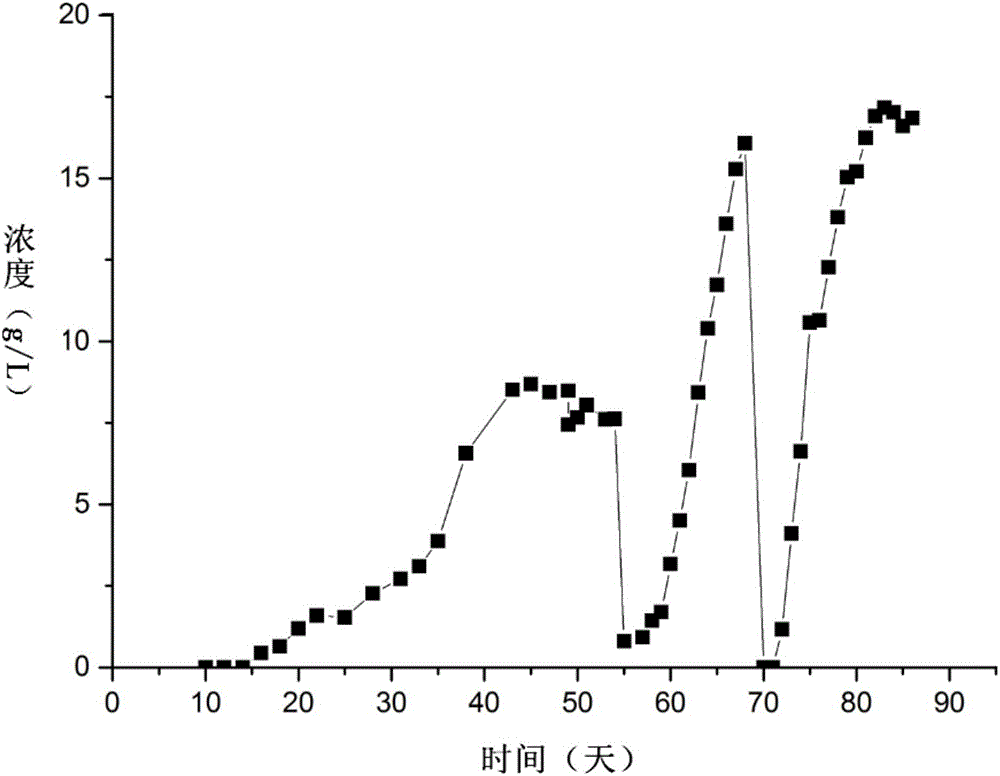

[0107] Embodiment 3 syngas fermentation

[0108] The composition of the medium used in this embodiment is: NH 4 Cl530mg / L; KH 2 PO 4 200mg / L; Na 2 SO 450mg / L; KCl50mg / L; CaCl 2 10mg / L; MgCl 2 . 6H 2 O70mg / L; MnCl 2 . 4H 2 O0.8mg / L; CoCl 2 . 2H 2 O1.2mg / L; FeSO 4 . 7H 2 O3.2mg / L; AlCl 3 0.5mg / L; NaMO 4 . 2H 2 O0.1mg / L; H 3 BO 3 0.2mg / L; NiCl 2 . 6H 2 O0.5mg / L; CuCl 2 . 2H 2 O1.1mg / L; ZnSO 4 . 2H 2 O3.2mg / L; EDTA-2Na3.0mg / L; biotin 2.0mg / L; folic acid 2.0mg / L; vitamin B610mg / L; riboflavin 5.0mg / L; vitamin B15.0mg / L; niacin 5.0 mg / L; pantothenic acid 5.0mg / L; vitamin B120.1mg / L; p-aminobenzoic acid 5.0mg / L; lipoic acid 5.0mg / L.

[0109] Using the device provided in Example 1, mix the flora screened in Example 2 with the culture medium (the mass ratio of the flora to the culture medium is 5:95), inject it into the fermentation device so that the liquid position reaches the water outlet, and open the pressure stabilizing valve Adjust the air pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com