Method for preparing medium-chain fatty acid on hollow fiber membrane by utilizing fermentation of synthesis gas

A medium-chain fatty acid and synthesis gas technology, which is applied in the field of environmental engineering, can solve the problems of ecological environment pollution, difficult disposal of organic waste, and large energy consumption of medium-chain fatty acids, so as to ensure long-term operation and realize the effect of engineering integrated application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

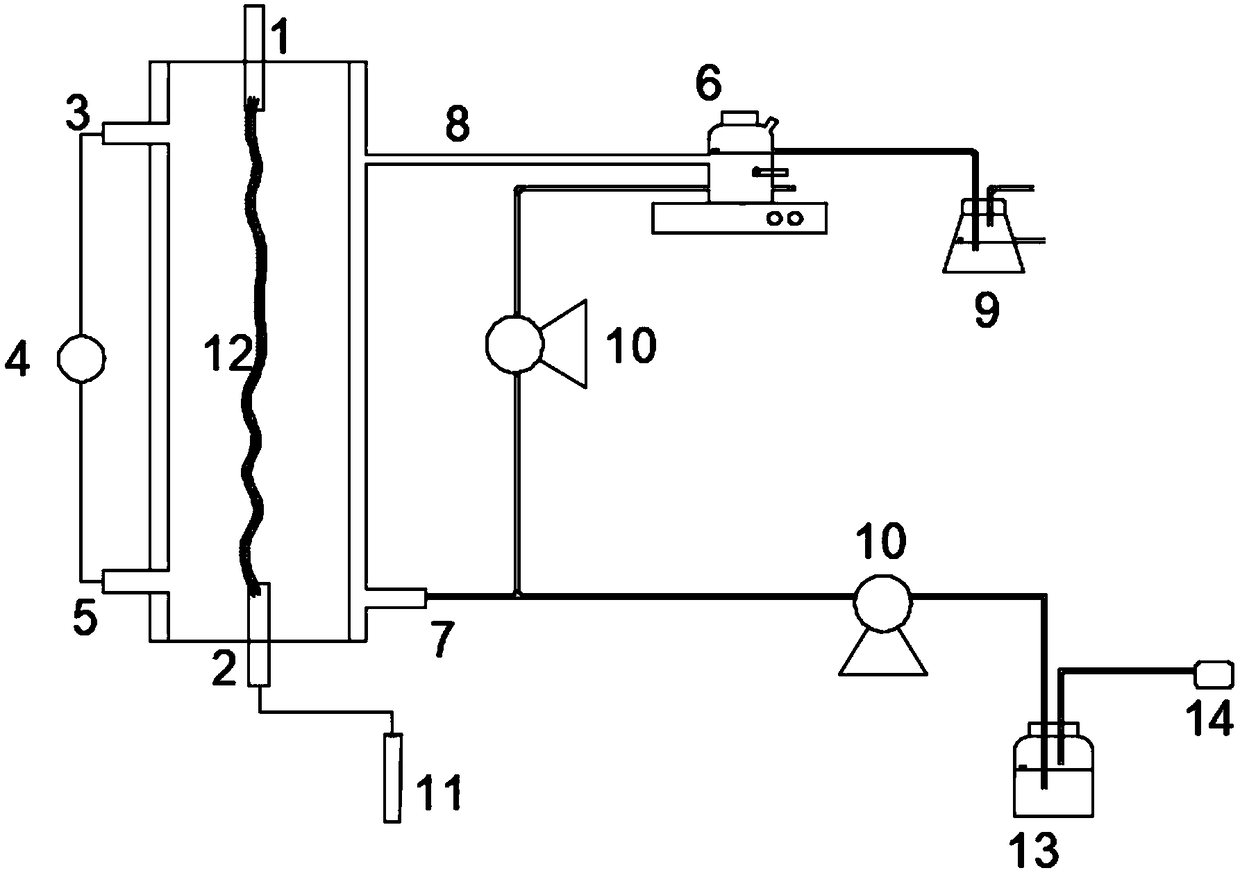

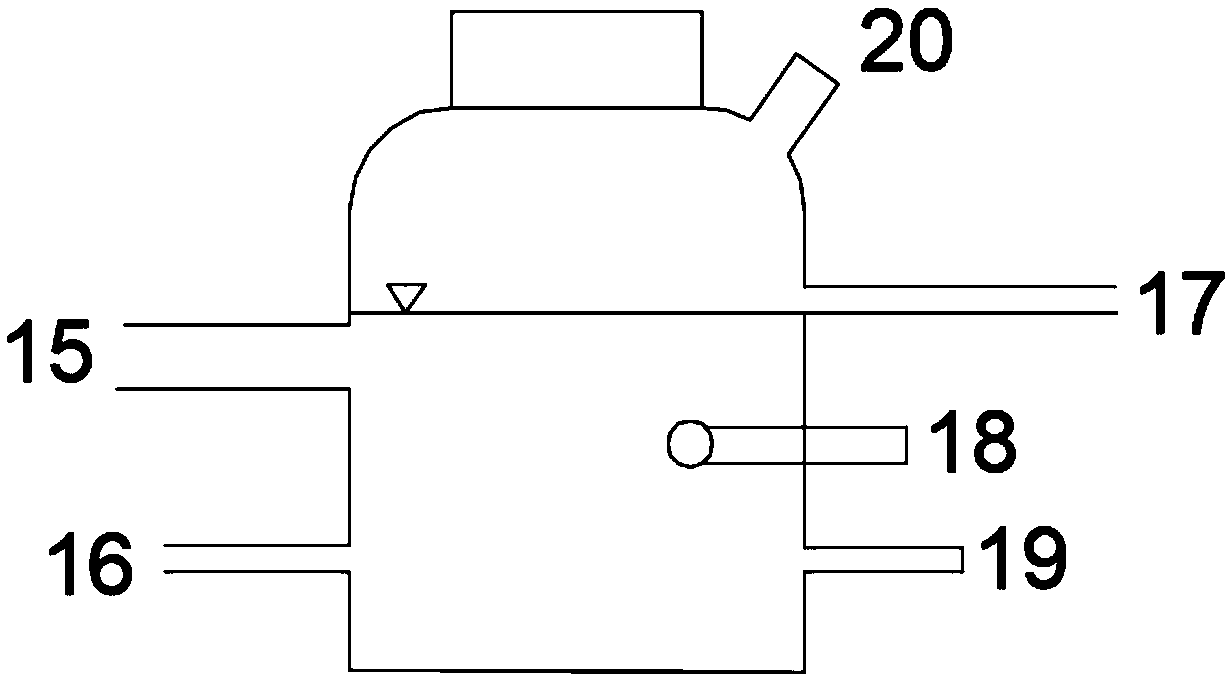

[0022] The reactor for preparing medium-chain fatty acids by fermentation of syngas is a continuous reactor with a double-layer glass structure, and its specific structure is as follows figure 1 Shown. The hollow fiber membrane 12 is bonded in the organic glass tube, inserted into the half-open cover at both ends of the reactor, and then sealed. The synthesis gas enters the reactor through the gas cylinder 11 through the air inlet at the bottom, and penetrates into the reactor through the hollow fiber membrane. The gas inlet volume is adjusted by the pressure reducing valve on the gas cylinder 11, and the aqueous solution circulates into the overflow through the pipeline. In the bottle 6, the peristaltic pump 10 circulates into the reactor. If there is air in the reactor, the gas enters the water-sealed bottle 9 from the overflow bottle 6 and then is discharged into the atmosphere. The outer glass of the reactor is a water bath heating layer, which is provided with a water bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com