Biochar finish machining method capable of improving anaerobic biological reaction efficiency

An anaerobic biology and reaction efficiency technology, applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of reducing anaerobic digestion efficiency and the effect is not very significant, and achieve the effect of accelerating leaching balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

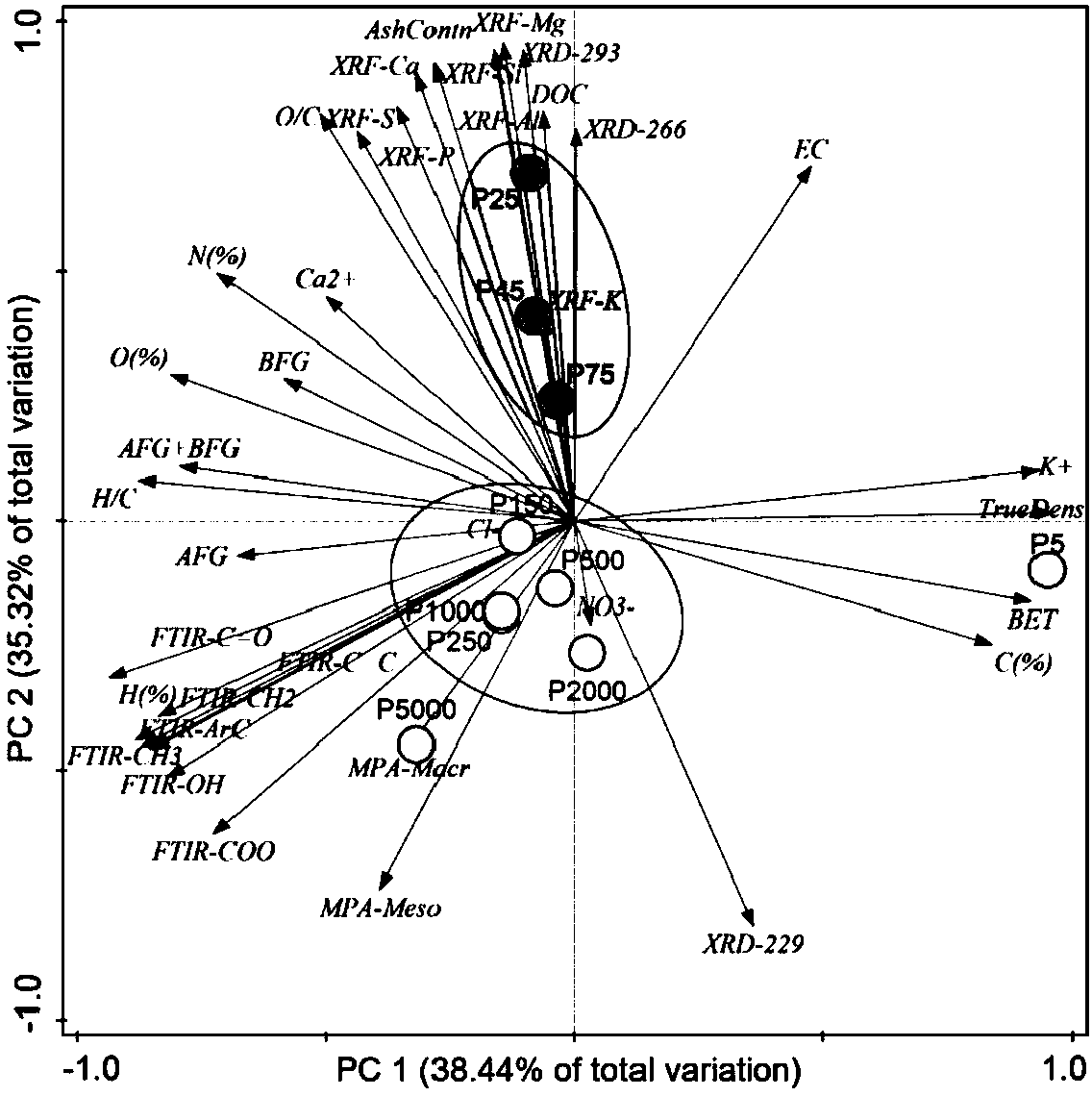

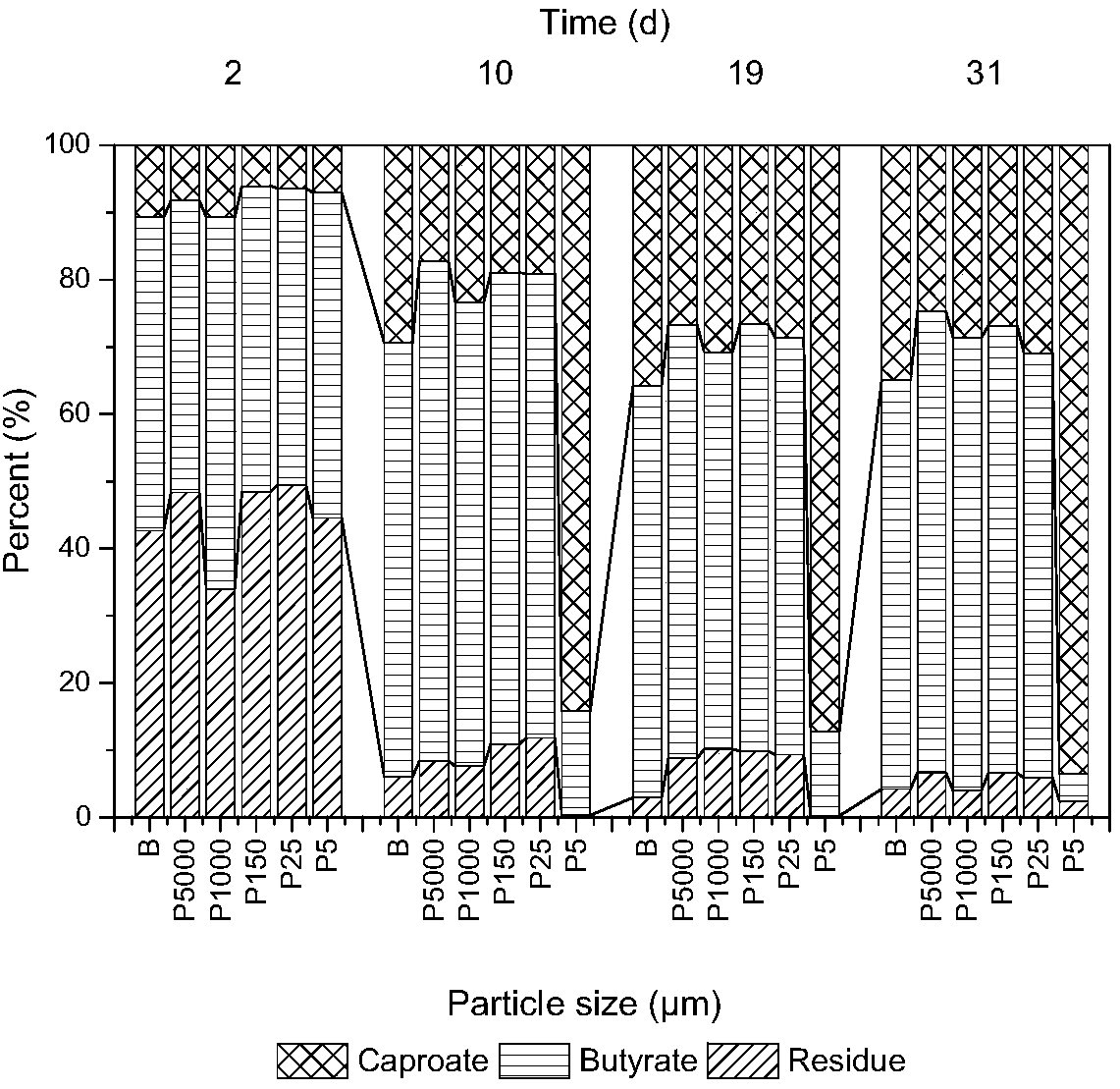

[0028] The crude biochar is derived from pyrolytic charcoal obtained by pyrolysis of fruit trees at 500°C for 2 hours, and the initial particle size ranges from 2-5mm. The coarse biochar was crushed into superfine biochar with a particle size of 1-5 μm by a jet mill. The ultrafine biochar was mixed with biochar from the same source but with different particle sizes (5000-2000, 2000-1000, 1000-500, 500-250, 250-150, 150-75, 75-45, 45-25, 25 ~16μm) for property analysis and comparison, including: C / H / O / N element analysis, X-ray fluorescence spectrum XRF, X-ray diffraction XRD, Fourier transform infrared spectrum FTIR, scanning electron microscope SEM, specific surface area, pore size distribution, Oxygen-containing functional groups, true density, dissolved organic carbon compounds in water immersion liquid, electrical conductivity, anion and cation concentrations, etc.; then, based on the test results of the above indicators, the principal component multidimensional statistical...

Embodiment 2

[0032] The finishing condition of biochar is identical with embodiment 1. The biochar obtained through the above finishing process is applied to the anaerobic digestion treatment of the initial leachate of the landfill, the dosage of biochar is 16g / L, and the COD concentration of the leachate is 28000mg / L. The maximum methanogenesis rate of the blank group without adding biochar was 18mL-CH 4 / g-COD / d, and the maximum methane production rate of the experimental group added with the biochar obtained by the method of the present invention is 51mL-CH 4 / g-COD / d. As a control, the maximum methane production rate of the control group added biochar with a particle size of 75-150 μm and biochar with a particle size of 2-5 mm was 36 mL-CH 4 / g-COD / d and 34mL-CH 4 / g-COD / d.

Embodiment 3

[0034] The finishing condition of biochar is identical with embodiment 1. The biochar obtained through the above finishing process is applied to the anaerobic digestion treatment of the kitchen waste slurry, the dosage of biochar is 16g / L, and the COD concentration of the slurry is 82000mg / L. Because the organic load of the slurry is too high, the vigor of methanogens is seriously inhibited. As a result, for the blank group without adding biochar, the lag period is as long as 28 days, while the experimental group added the biochar obtained by the method of the present invention. , its lagging period is shortened to 9 days. As a control, the lag period of the control group added biochar with a particle size of 75-150 μm and biochar with a particle size of 2-5 mm was 15 days and 18 days, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com