A kind of sugar-free tea-flavored purple sweet potato dumpling and its processing method

A processing method and technology of sugar-free tea, applied in the functions of food ingredients, food ingredients as taste improvers, food ingredients as antioxidants, etc., can solve the problems of single function, short shelf life, single taste, etc. The effect of ruddy color and unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

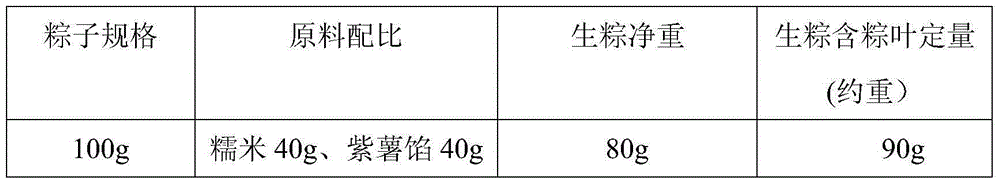

Embodiment 1

[0029] 1.1 Glutinous rice treatment

[0030] 1.1.1 Washing glutinous rice:

[0031] Wash the glutinous rice 2-3 times with clean water, and soak it in water for 50-60 minutes. It is advisable to use the glutinous rice to absorb and swell, and it is better to crush it with your hands.

[0032] 1.1.2 Drain:

[0033] Pour the soaked glutinous rice into a plastic basket with holes to drain. The draining time is controlled at 15-20 minutes, and the surface of the rice grains is white.

[0034] 1.1.3 Mixing material

[0035] Use a drum type rice mixer to mix materials, weigh the glutinous rice after draining, mix 100kg of glutinous rice per machine, weigh 3% of blending oil and 1.5% of black tea powder according to the weight of glutinous rice, and add them together to the glutinous rice and reverse stirring for 5 Minutes, when the color of the glutinous rice is uniform and the material liquid has no agglomeration, turn forward to discharge.

[0036] 1.1.4 Placement of rice mate...

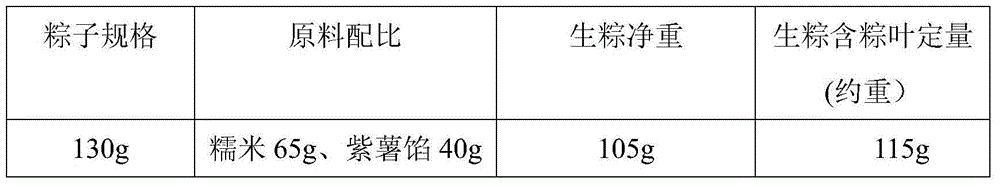

Embodiment 2

[0069] 2.1 Glutinous rice treatment

[0070] 2.1.1 Washing glutinous rice:

[0071] Wash the glutinous rice 2-3 times with clean water, and soak it in water for 50-60 minutes. It is advisable to use the glutinous rice to absorb and swell, and it is better to crush it with your hands.

[0072] 2.1.2 Drain:

[0073] Pour the soaked glutinous rice into a plastic basket with holes to drain. The draining time is controlled at 15-20 minutes, and the surface of the rice grains is white.

[0074] 2.1.3 Mixing material

[0075] Use a drum-type rice mixer to mix materials, weigh the glutinous rice after draining, mix 100kg of glutinous rice per machine, weigh 1% of blending oil, 0.5% of black tea powder, and add them together to the glutinous rice and reverse the stirring for 5 Minutes, when the color of the glutinous rice is uniform and the material liquid has no agglomeration, turn forward to discharge.

[0076] 2.1.4 Placement of rice materials

[0077] After the glutinous rice ...

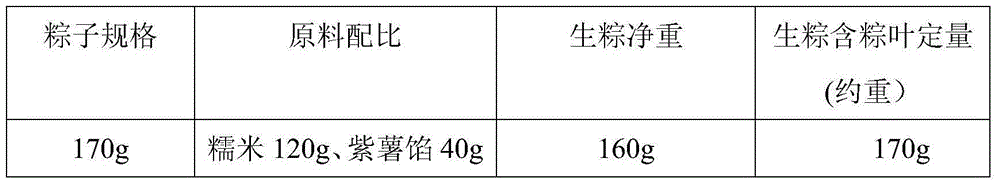

Embodiment 3

[0109] 3.1 Glutinous rice treatment

[0110] 3.1.1 Washing glutinous rice:

[0111] Wash the glutinous rice 2-3 times with clean water, and soak it in water for 50-60 minutes. It is advisable to use the glutinous rice to absorb and swell, and it is better to crush it with your hands.

[0112] 3.1.2 Drain:

[0113] Pour the soaked glutinous rice into a plastic basket with holes to drain. The draining time is controlled at 15-20 minutes, and the surface of the rice grains is white.

[0114] 3.1.3 Mixing material

[0115] Use a drum type rice mixer to mix materials, weigh the glutinous rice after draining, mix 100kg of glutinous rice per machine, weigh 5% of blending oil and 3% of black tea powder according to the weight of glutinous rice, and add them together to the glutinous rice. Minutes, when the color of the glutinous rice is uniform and the material liquid has no agglomeration, turn forward to discharge.

[0116] 3.1.4 Placement of rice materials

[0117] After the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com