Self-guide welding machine

A welding machine and self-guided technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of welding head alignment seam, welding difference, etc., and achieve the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

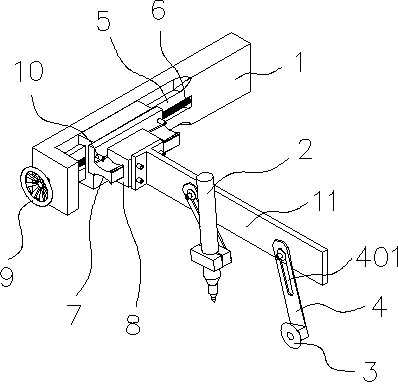

[0024] A self-guided welding machine, comprising a frame 1, a welding torch 2 arranged on the frame 1, characterized in that: the frame 1 includes a slide rail 7 arranged laterally, and the slide rail 7 is provided with a The moving slider 8 and the welding torch 2 are fixedly arranged on the slider 8 ; a detection device that can drive the slider 8 to move laterally along the slide rail 7 is also fixedly installed on the slider 8 .

[0025] Frame 1 is provided with limit guide rail 5, and limit guide rail 5 is provided with limit screw mandrel 6, and limit screw mandrel 6 is connected with rotating handle 9, and slide rail 7 is installed on the limit guide rail 5 and can be on the limit screw mandrel 6 Driven to slide laterally along the limit guide rail 5; the slider 8 is horizontally provided with a longitudinal beam 11 perpendicular to the sliding direction of the slider 8; the longitudinal beam 11 is sequentially installed with at least two connecting pieces 4 , the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com