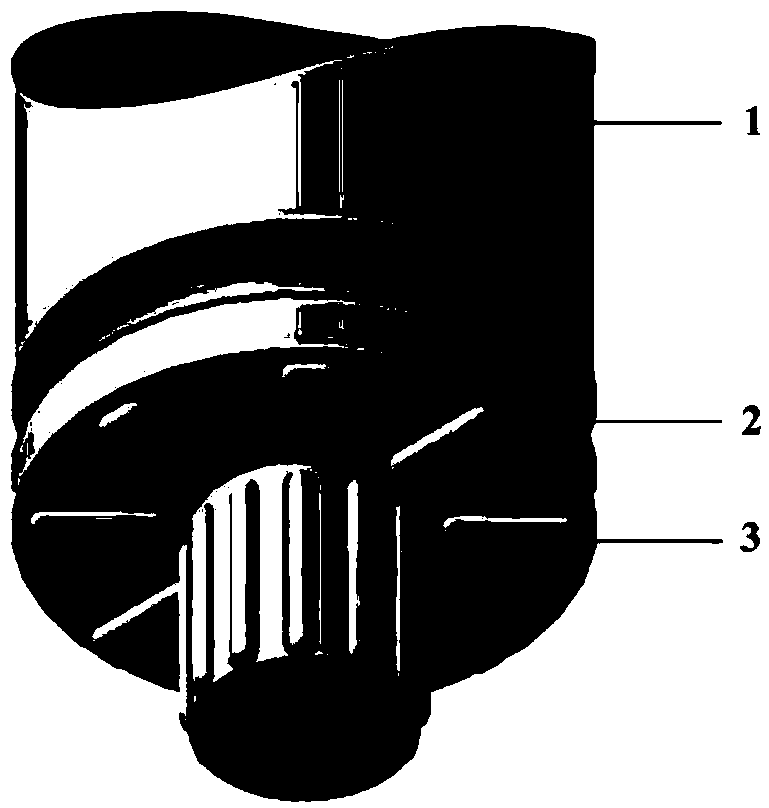

Method for improving abrasion resistance of stir head for stir-friction welding of high-strength aluminum alloy

A friction stir and stirring head technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of not taking into account the shoulder effect and wear resistance, low wear resistance, and poor impact resistance of joints question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

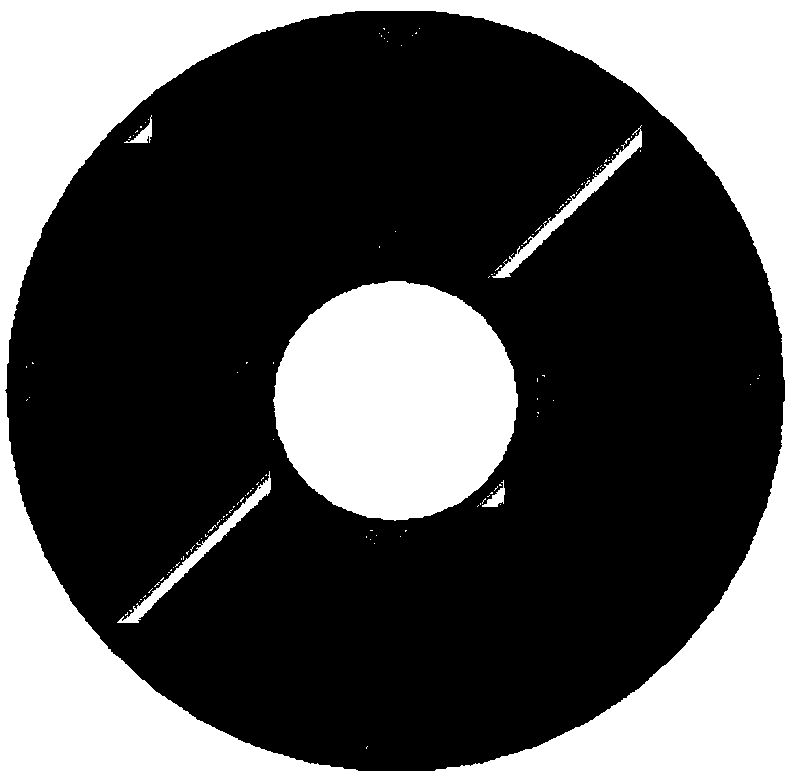

Method used

Image

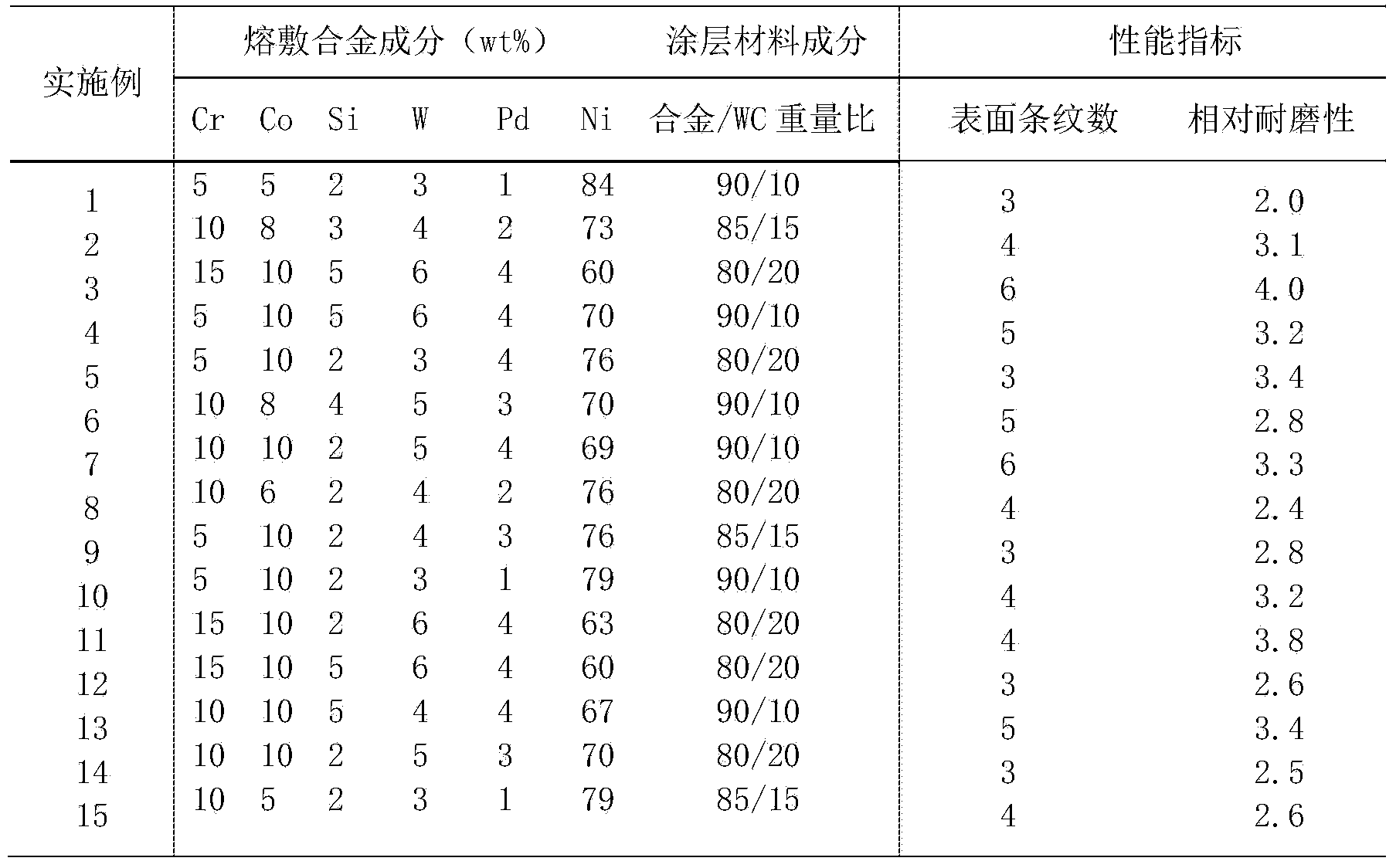

Examples

specific Embodiment approach

[0023] 1. The laser cladding method adopted in the present invention is to add cladding alloy materials on the surface of the substrate, and use a high-energy-density laser beam to melt the added cladding alloy materials and the surface layer of the substrate simultaneously, and form a composite material with the substrate after rapid solidification. Metallurgically bonded surface wear resistant coating. A wear-resistant coating with a certain wear resistance can be obtained by adjusting the cladding alloy composition, particle size and reinforcement phase content. The determination of laser cladding alloy composition is very important. Heat-treated alloy tool steel has a high carbon content and contains alloying elements such as Cr, Si, Mn, W, Ni, Mo, V, etc., to improve the hardenability, tempering resistance, hot hardness and wear resistance of the steel . The surface of the base material after laser cladding treatment is prone to brittle phases, which leads to a decrease...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com