Full-automatic spot welding device for rivet

A spot welding equipment, fully automatic technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of inability to guarantee processing quality, large labor costs, company increase, etc., to achieve accurate product inspection, fast welding speed , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

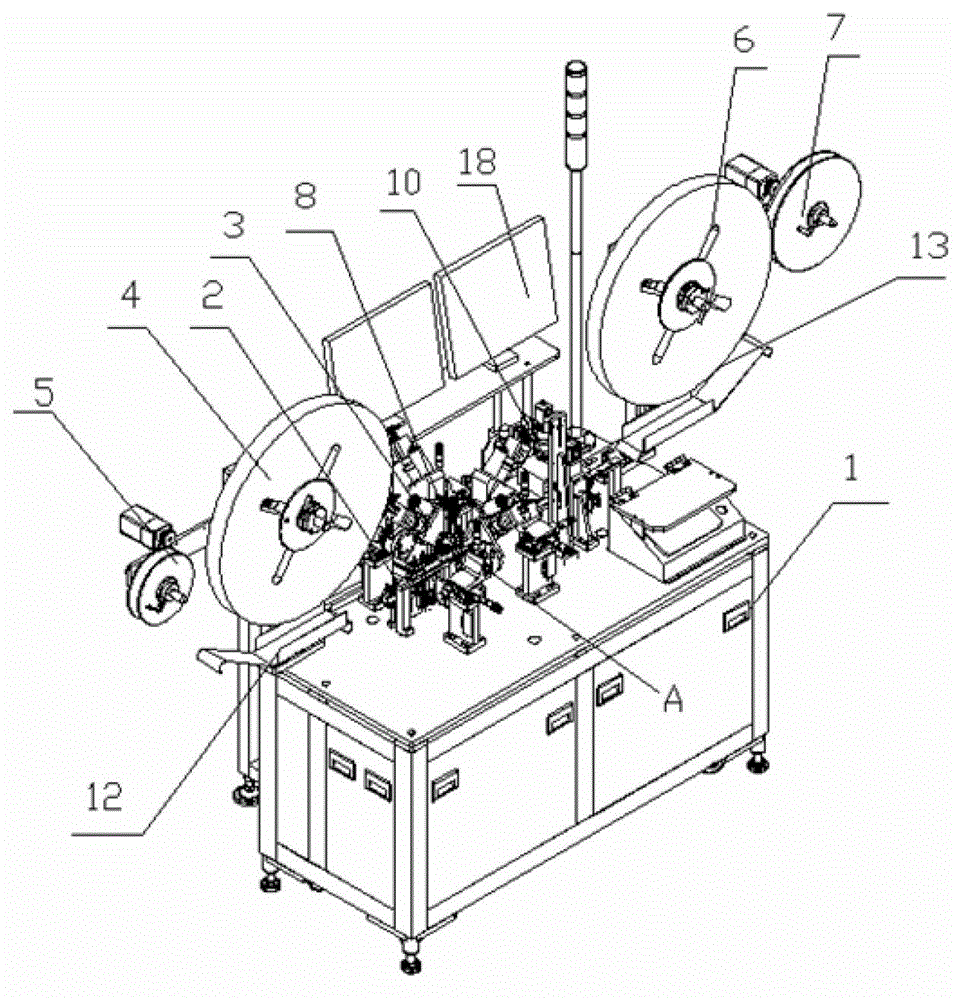

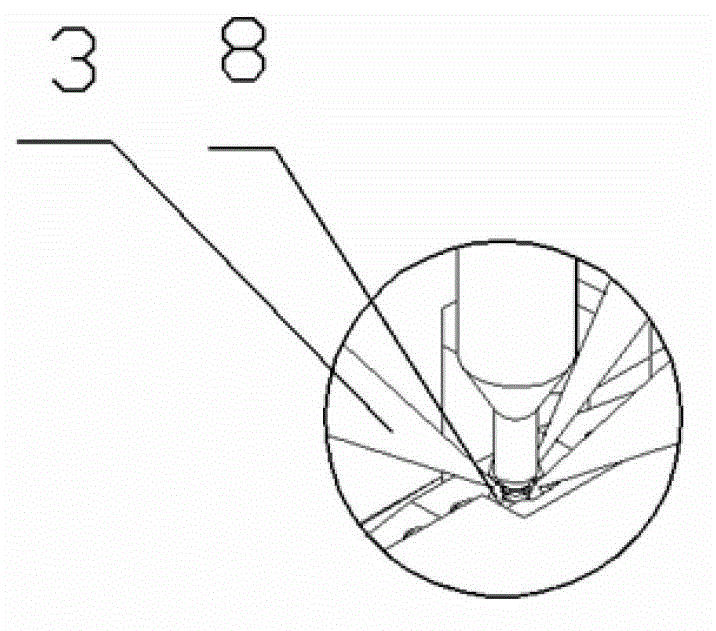

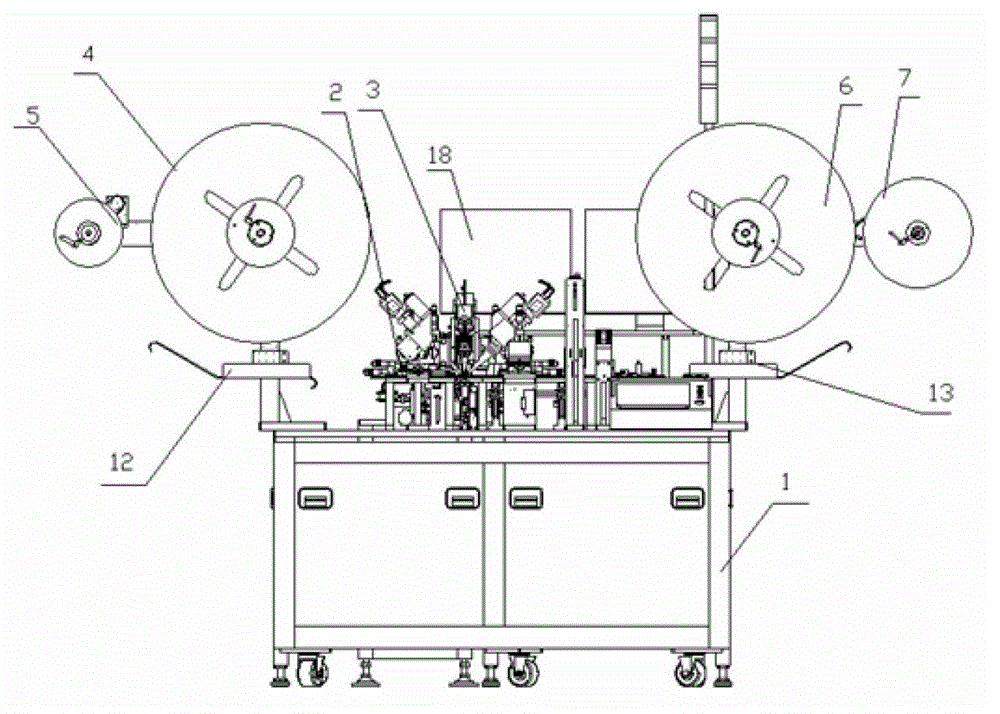

[0028] Embodiment: a kind of fully automatic rivet spot welding equipment, comprising frame 1, material belt conveying track 2, retractable material device, rivet automatic feeding device, automatic spot welding device 3, spot welding quality automatic detection device and controller, with The actual use direction is the reference, where:

[0029] The feeding and discharging device includes feeding tape reel 4, feeding paper tape reel 5, receiving material tape reel 6, receiving paper tape reel 7, first, second, third and fourth driving devices and receiving and discharging sensing devices The feeding tape reel 4 and the discharging paper tape reel 5 can be rotated and positioned on one side of the frame 1, and the receiving material tape reel 6 and the receiving paper tape reel 7 can be rotated and positioned on the other side of the frame 1. The discharging sensing device is respectively fixed on both sides of the frame 1, and the receiving and discharging sensing devices ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com