Controllable adjusting and measuring device of ball screw pretightening force and pretensioning amount

A pre-tightening force adjustment, ball screw technology, used in feeding devices, measuring/indicating equipment, maintenance and safety accessories, etc. Convenience and reliability, guaranteeing the effect of running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes in detail a ball screw pretension and pretension adjustment and measurement device proposed by the present invention with reference to the drawings and specific embodiments.

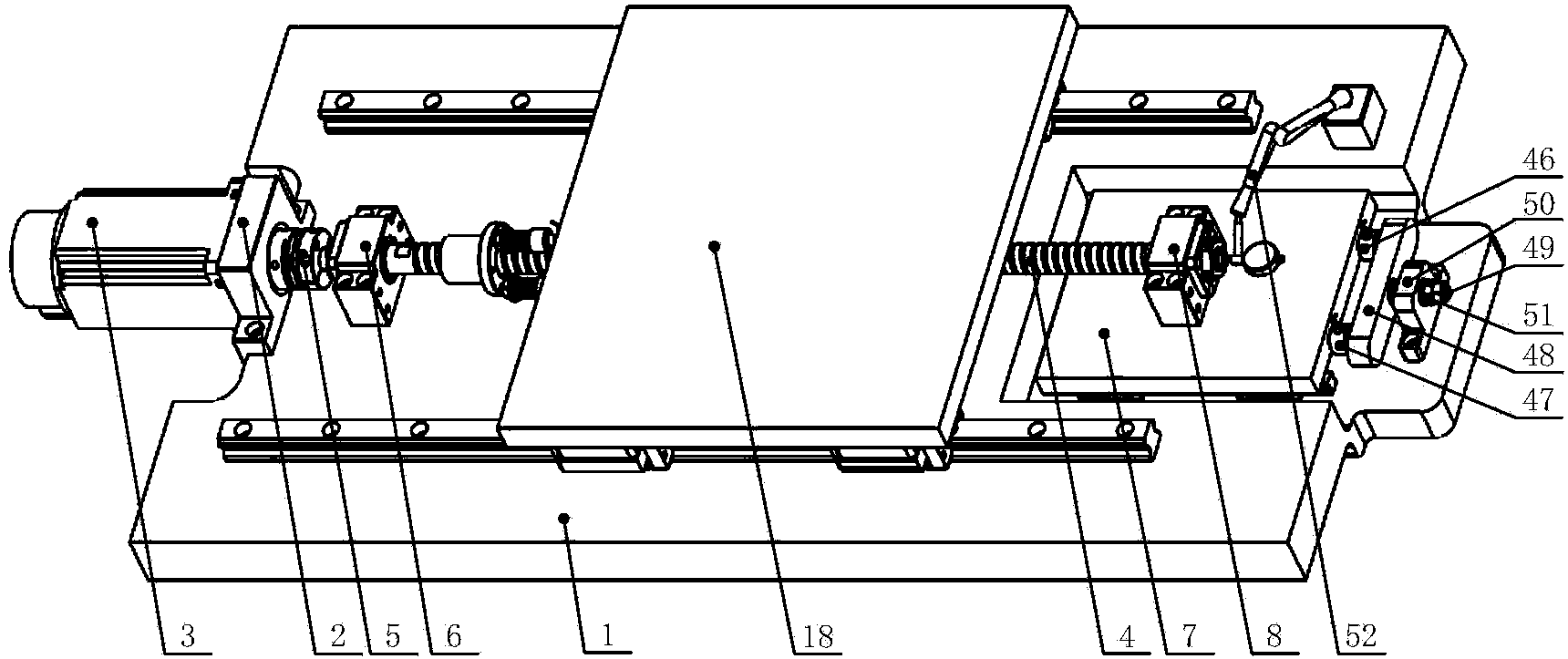

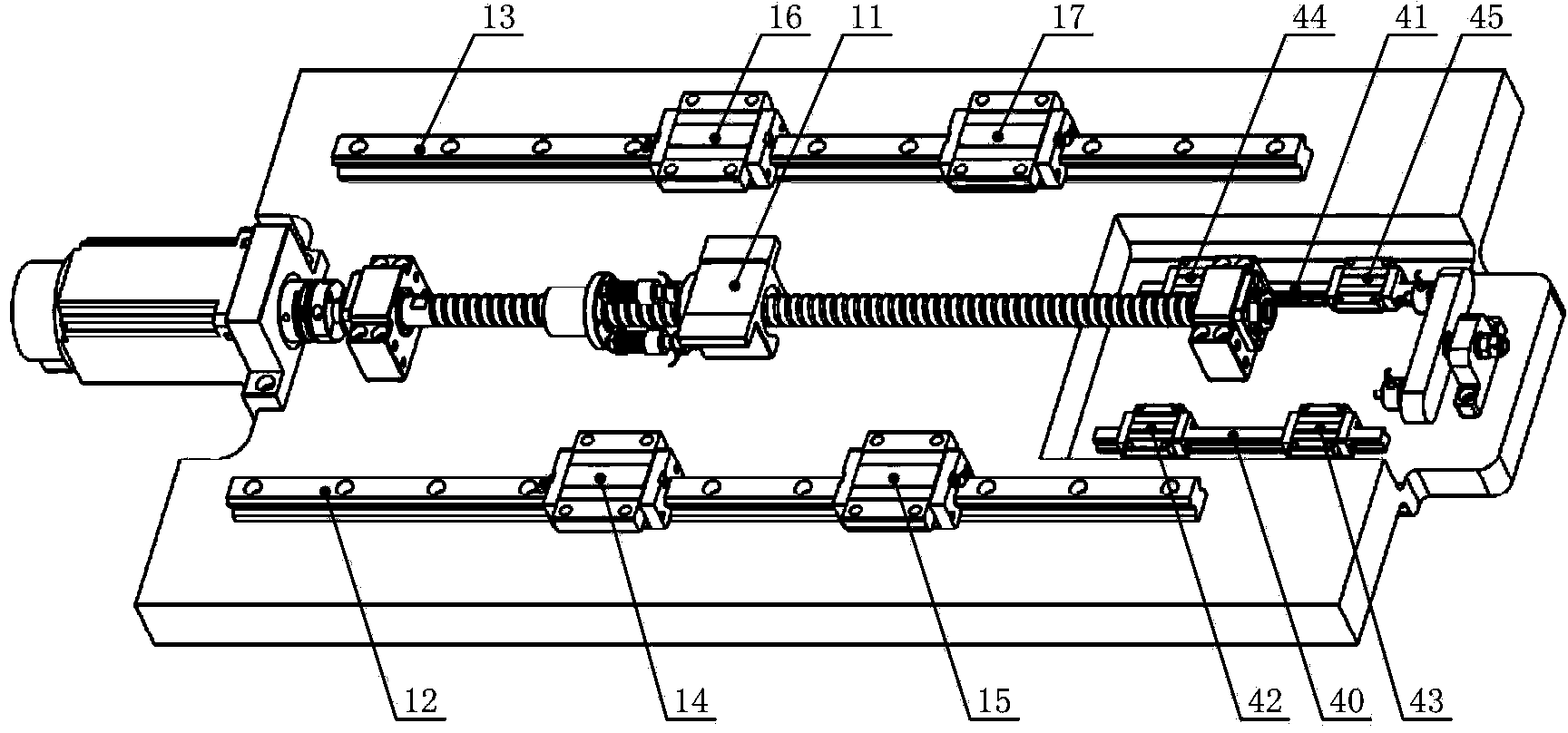

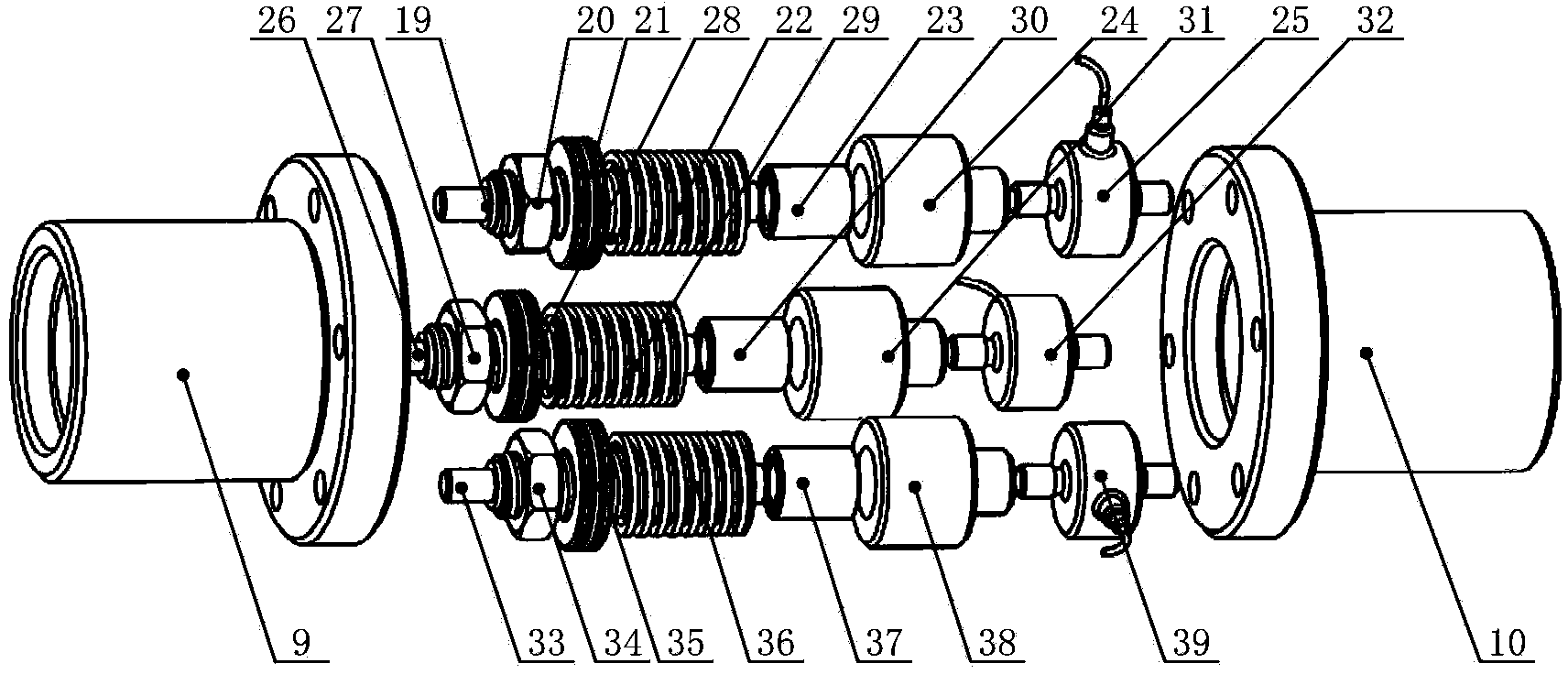

[0026] Such as figure 1 with 2 As shown, the structure of the linear feed system is: a motor support base 2 is fixed at one end of the bottom plate 1, and the servo motor 3 is fixed on the motor support base 2; the ball screw 4 passes through the coupling 5 and the servo motor 3 The shaft is connected; the ball screw 4 is at one end close to the coupling 5, and is supported and rotated by the first ball screw fixed support end 6 fixed on the bottom plate 1, and the other end is supported by the second ball fixed on the moving platform 7 The fixed support end 8 of the screw is supported and rotated; the ball screw 4 is sleeved with two flanges with opposite rotation directions, a first screw nut 9 and a second screw nut 10; on the second screw nut 10 The screw nut seat 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com