Protection film with blue-ray-resistant and full-ultraviolet-preventing adhesive layer

An anti-ultraviolet and anti-blue light technology, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve problems that no one has studied, achieve good light transmittance, high hardness, and delay skin aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

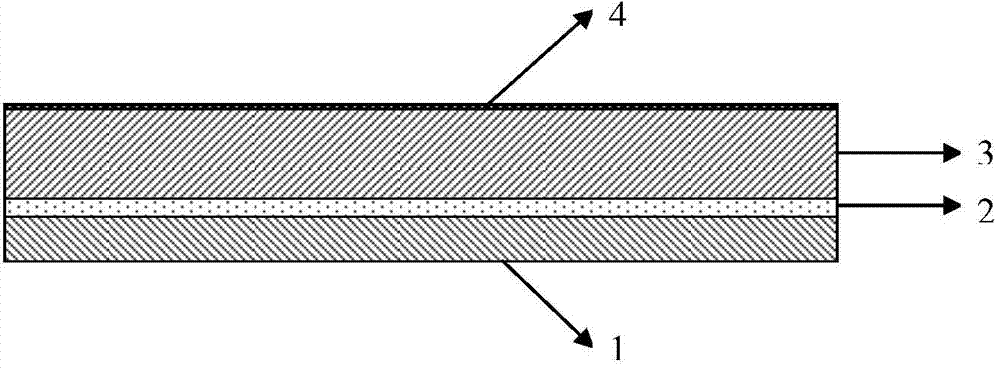

[0037] An adhesive layer anti-blue light full anti-ultraviolet protective film, which comprises: a peeling layer 1 with a thickness of 50 μm, an anti-blue light full anti-ultraviolet adhesive layer 2 with a thickness of 10 μm, a main film layer 3 with a thickness of 150 μm, and an anti-ultraviolet film with a thickness of 5 μm. Scratch coating4.

[0038] In this embodiment, the peeling layer is a PET release film; the adhesive used for the anti-blue light full UV protection adhesive layer is PU glue, and the selected blue light absorber is black essence and yellow fluorescent powder, and the contents are respectively 1% of the weight of the adhesive. % and 1%, the selected ultraviolet shielding agent is fluorescent whitening agent OB powder and ultraviolet absorber UV-P, the content is 1% and 1% of the adhesive weight respectively; the main film layer is made of PET film; anti-scratch coating The selected coating solution is epoxy acrylic resin coating solution with a solid co...

Embodiment 2

[0044] An adhesive layer anti-blue light full anti-ultraviolet protective film, which comprises: a peeling layer 1 with a thickness of 75 μm, an anti-blue light full anti-ultraviolet adhesive layer 2 with a thickness of 10 μm, a main film layer 3 with a thickness of 100 μm, and an anti-ultraviolet protective film with a thickness of 5 μm. Scratch coating4.

[0045] In this embodiment, the peeling layer is a PET release film; the adhesive selected for the anti-blue light full UV-resistant adhesive layer is PU glue, and the selected blue light absorbers are black essence and yellow essence, the contents of which are respectively 1% of the weight of the adhesive and 0.5%, the selected ultraviolet shielding agent is fluorescent whitening agent OB powder and pearl powder, and the content is 1% and 0.5% of the adhesive weight respectively; the main film layer is PC film; the coating liquid selected for the scratch-resistant coating is An epoxy acrylic resin coating solution with a s...

Embodiment 3

[0051] A kind of adhesive layer anti-blue light full anti-ultraviolet protective film, it comprises: the peeling layer 1 that thickness is 50 μm, the anti-blue light full anti-ultraviolet adhesive layer 2 that thickness is 15 μm, the main film layer 3 that thickness is 100 μm, the anti-ultraviolet layer that thickness is 3 μm Scratch coating4.

[0052] In this embodiment, the peeling layer is a PET release film; the adhesive used for the anti-blue light full UV-resistant adhesive layer (2) is acrylic adhesive, and the selected blue light absorbers are black essence and green fluorescent powder, the contents of which are respectively 1% and 1% of the weight, the selected ultraviolet shielding agent is nano-titanium dioxide and photochromic OP powder, the content is respectively 1% and 1% of the adhesive weight; the main film layer is TAC film; the anti-scratch coating is selected The liquid is a polyurethane coating liquid with a solid content of 50%.

[0053] The specific ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com