Antiskid film coating woven bag

A woven bag and film coating technology, which is applied in the field of woven bags, can solve the problems of increasing the bag turning process, low efficiency, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

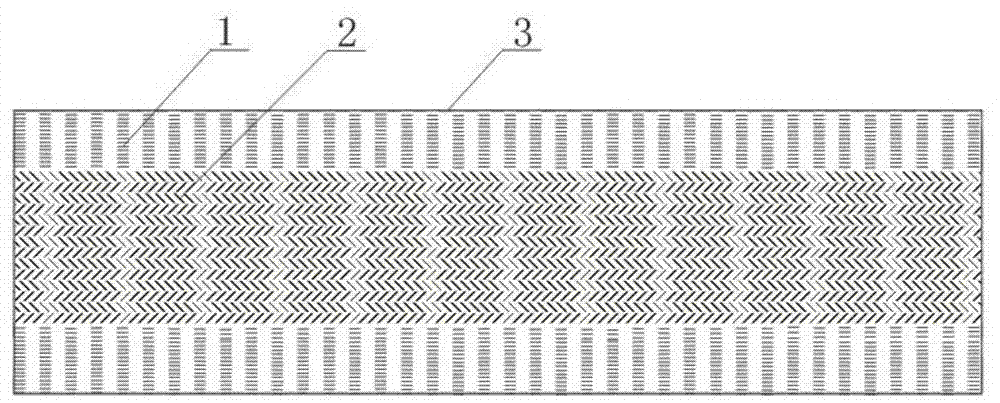

[0011] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0012] Such as figure 1 As shown, the non-slip coated film woven bag is formed by cutting and sewing plastic woven cloth, the outer surface of the plastic woven cloth is coated with a plastic film layer, and the surface of the plastic film layer has pattern-like protrusions formed by extrusion. Among them, the pattern-shaped protrusions located in the middle of the plastic woven cloth 3 are composed of several twill lines 2 distributed along the width direction of the plastic woven cloth, and the directions of adjacent twill lines are opposite. The cloth width is 0.5-0.6, and the pattern-like protrusions located at both ends of the plastic woven cloth are composed of several straight grains 1 that are evenly spaced along the length direction of the plastic woven cloth.

[0013] In the pattern-like protrusions located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com