Electric control system of stacking industrial robot

A technology of industrial robots and electronic control systems, applied in manipulators, manufacturing tools, stacking of objects, etc., can solve the problems of unsatisfactory, low stability and reliability, and achieve simple structure, high cost performance, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

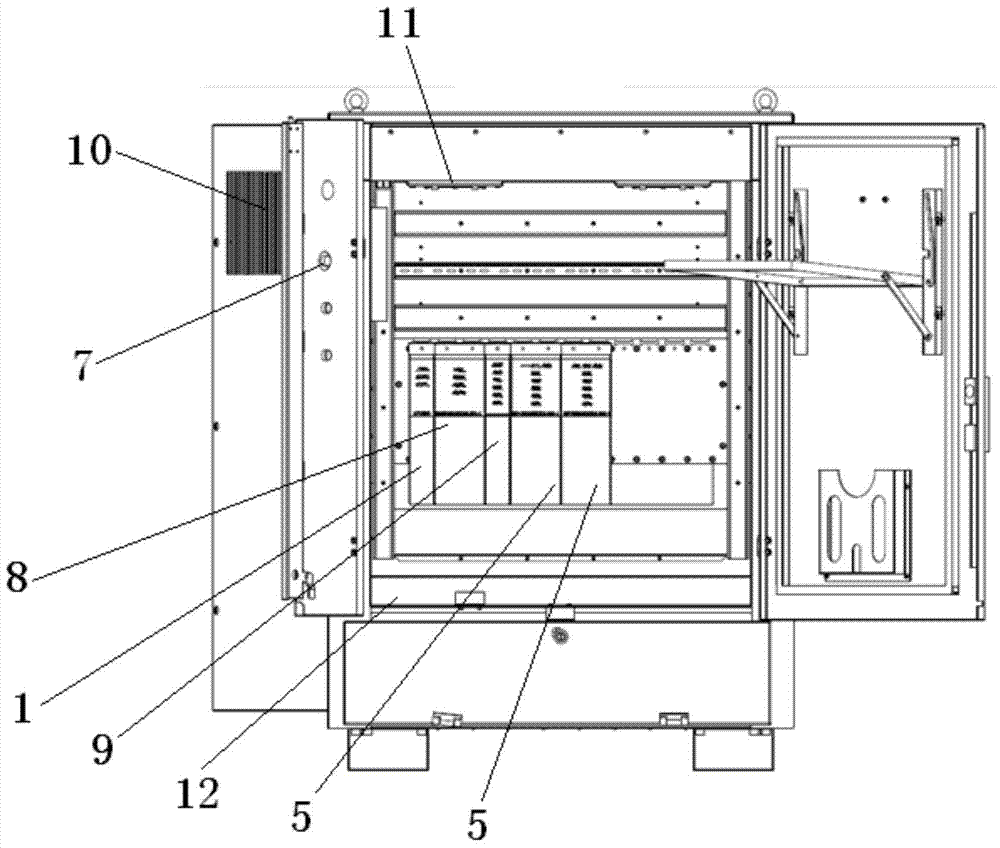

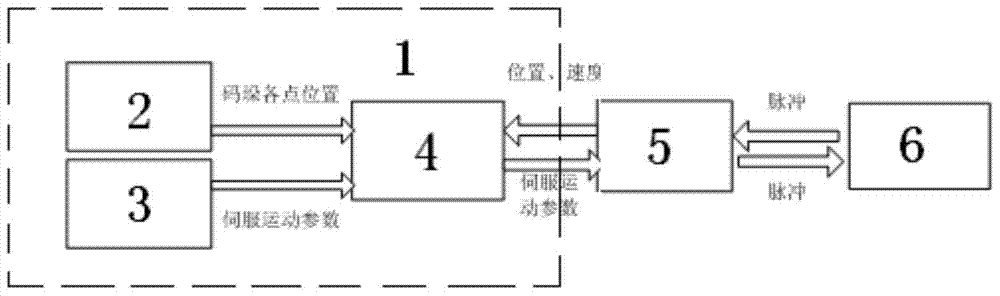

[0019] like Figure 1-2 As shown, the present invention adopts the PC-BASE framework form to build, that is, a power supply module 8 and an auxiliary power supply module 9 are provided in the cabinet 12 to connect the industrial computer 1 and the servo driver 5 respectively, and the industrial computer 1 and the servo driver 5 carry out two-way communication; The described industrial computer 1 is provided with a palletizing register module 2 , a variable acceleration PID register module 3 and an internal motion control module 4 . The cabinet 12 is provided with an operation panel 7 connected to the power module 8 . The cabinet 12 is provided with a heat sink 10 and a fan 11 .

[0020] Among them, the operation panel 7 is used to connect or disconnect the power supply voltage of the control unit, to power on the motor, and to remove the power; the heat sink 10 has a heat dissipation effect on the industrial computer, the driver and various electrical components; Ventilation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com