A method and system for preparing tailings filling slurry

A technology of tailings filling and tailings, which is applied in the direction of fillings, mining equipment, earth square drilling, etc., can solve the problems of high concentration of tailings overflow, low utilization rate of tailings, waste of resources, etc., and improve the utilization of tailings High efficiency, small footprint, and the effect of reducing resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

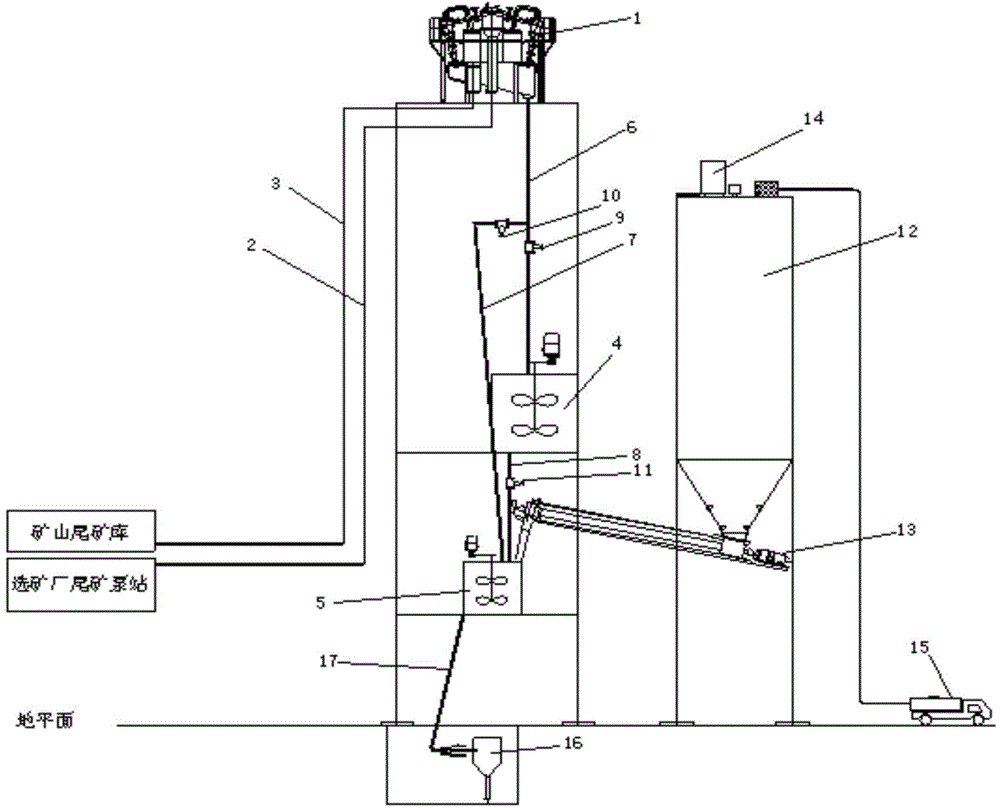

[0048] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

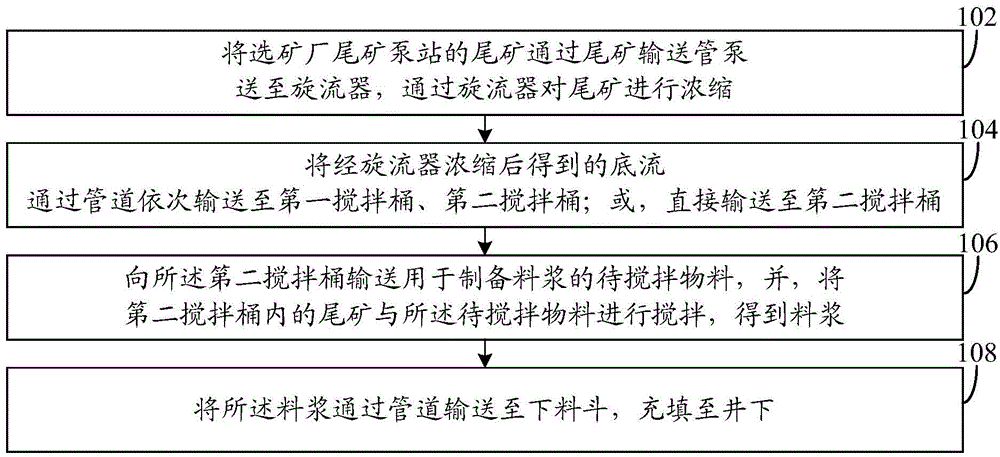

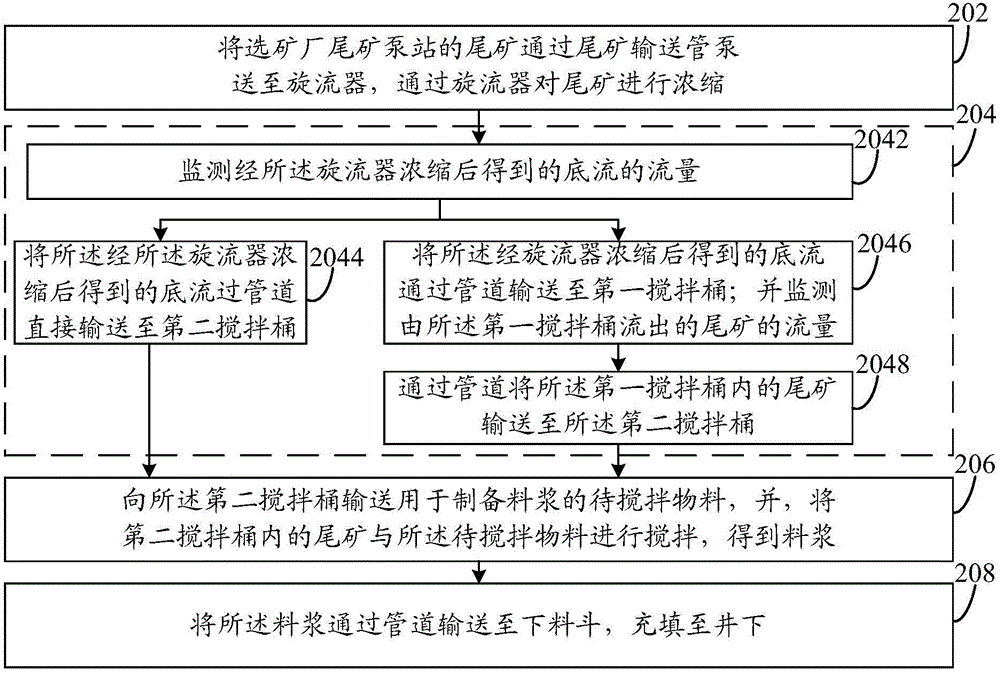

[0049] refer to figure 1, shows a flow chart of a method for preparing tailings filling slurry described in the first embodiment of the present application. In this embodiment, the method for preparing tailings filling slurry may specifically include the following steps:

[0050] Step 102, pump the tailings from the tailings pumping station of the mineral processing plant to the cyclone through the tailings delivery pipe, and concentrate the tailings through the cyclone.

[0051] At present, the main application of cyclones in industrial and mining enterprises is to physically classify tailings through cyclones. Its working principle is centrifugal sedimentation. When the two-phase (or three-phase) mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com