Modified anthraquinone coloring agent

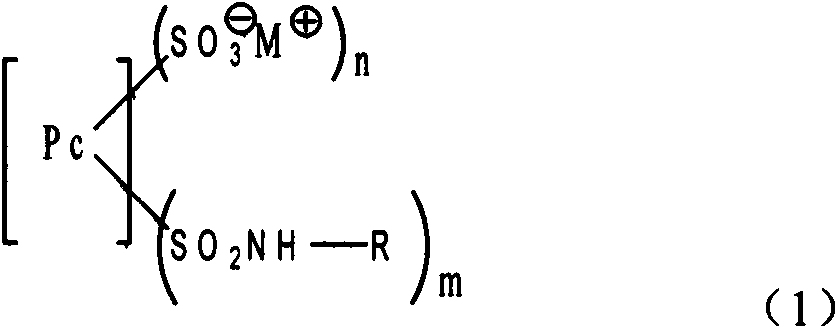

An anthraquinone dyeing agent and modification technology, which is applied in the direction of hydroxyanthraquinone dyes, anthracene dyes, organic dyes, etc., can solve the problems of insufficient dyeing fastness, affecting the dyeing performance of dyes, poor weather resistance, etc., and achieve bright color , easy to industrialized production, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

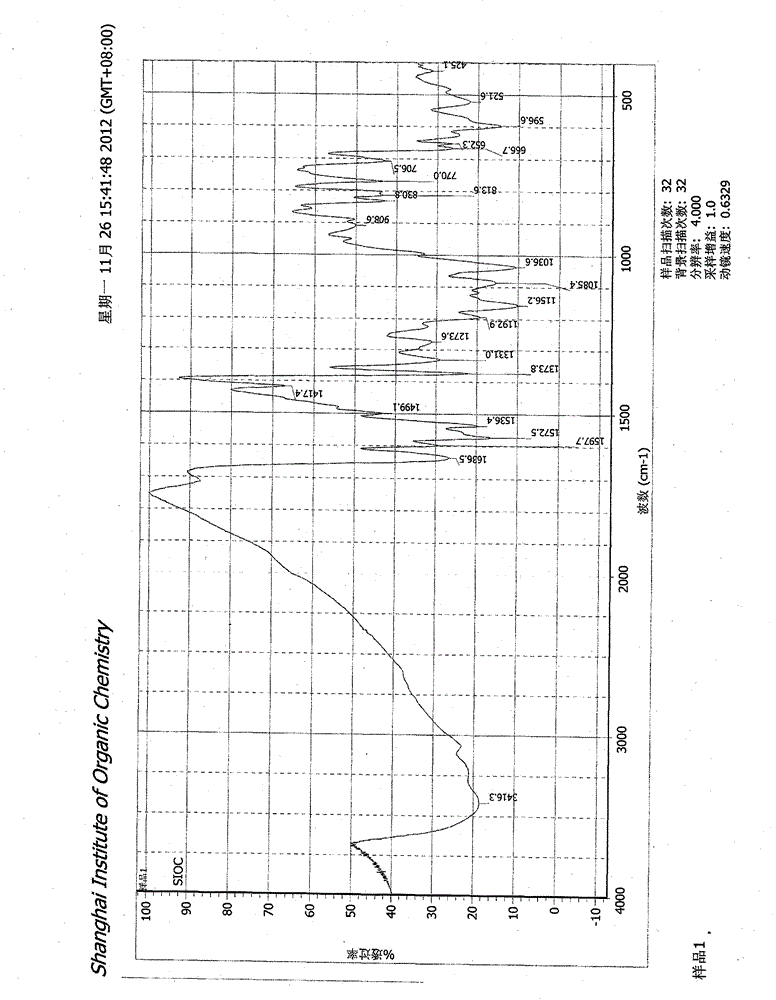

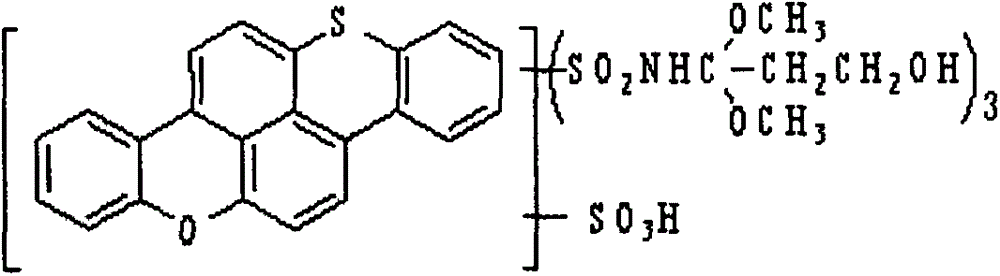

[0031] Add 40 parts of chlorosulfonic acid into the reaction vessel, slowly add 20 parts of solvent orange 63, and control the temperature between 25-40°C when feeding. After the addition, slowly raise the temperature to 90°C, and keep stirring at this temperature for 1h. After the heat preservation is over, the temperature is evenly raised to 100-120°C, and the temperature is kept at 100-120°C for 6 hours. After the heat preservation is over, add an appropriate amount of thionyl chloride, and continue the heat preservation for 1.0h. It was then poured into ice water, filtered to obtain anthraquinonesulfonyl chloride substituted with chlorosulfonic acid, and washed with 0.5% dilute hydrochloric acid ice water. Add the chlorosulfonate filter cake to 100 parts of water, cool to below 20°C, adjust the pH to 7.5 with an aqueous solution of 3,3-dimethoxypropanolamine, and stir at below 20°C for 2-4 hours. Raise the temperature to 20-30 degrees, add 30% hydrochloric acid, then sti...

Embodiment 2

[0038] Add 80 parts of chlorosulfonic acid into the reaction vessel, slowly add 20 parts of solvent orange 63, and control the temperature between 25-40°C when feeding. After the addition, slowly raise the temperature to 90°C, and keep stirring at this temperature for 1h. After the heat preservation is over, the temperature is evenly raised to 100-120°C, and the temperature is kept at 100-120°C for 6 hours. After the heat preservation is over, add an appropriate amount of thionyl chloride, and continue the heat preservation for 1.0h. It was then poured into ice water, filtered to obtain anthraquinonesulfonyl chloride substituted with chlorosulfonic acid, and washed with 0.5% dilute hydrochloric acid ice water. Add the chlorosulfonate filter cake to 100 parts of water, cool to below 20°C, adjust the pH to 7.5 with an aqueous solution of isopropanolamine, and stir at below 20°C for 2-4 hours. Raise the temperature to 20-30 degrees, add 30% hydrochloric acid, then stir and filt...

Embodiment 3

[0041] Add 60 parts of chlorosulfonic acid into the reaction vessel, slowly add 20 parts of solvent orange 63, and control the temperature between 25-40°C when feeding. After the addition, slowly raise the temperature to 90°C, and keep stirring at this temperature for 1h. After the heat preservation is over, the temperature is evenly raised to 100-120°C, and the temperature is kept at 100-120°C for 6 hours. After the heat preservation is over, add an appropriate amount of thionyl chloride, and continue the heat preservation for 1.0h. It was then poured into ice water, filtered to obtain anthraquinonesulfonyl chloride substituted with chlorosulfonic acid, and washed with 0.5% dilute hydrochloric acid ice water. Add the chlorosulfonate filter cake to 100 parts of water, cool to below 20°C, adjust the pH to 7.5 with 4-amino-2,2,6,6-tetramethylpiperidine solution, and stir at below 20°C for 2-4 Hour. Raise the temperature to 20-30 degrees, add 30% hydrochloric acid, then stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com