A device and method for leveling hairiness of ring spinning spun yarn

A technology of ring spinning and spun yarn, applied in the field of cotton textiles, which can solve the problems of reducing yarn hairiness index, increasing cost, increasing energy consumption, etc., so as to improve yarn production rate, increase spinning efficiency, and reduce yarn breakage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

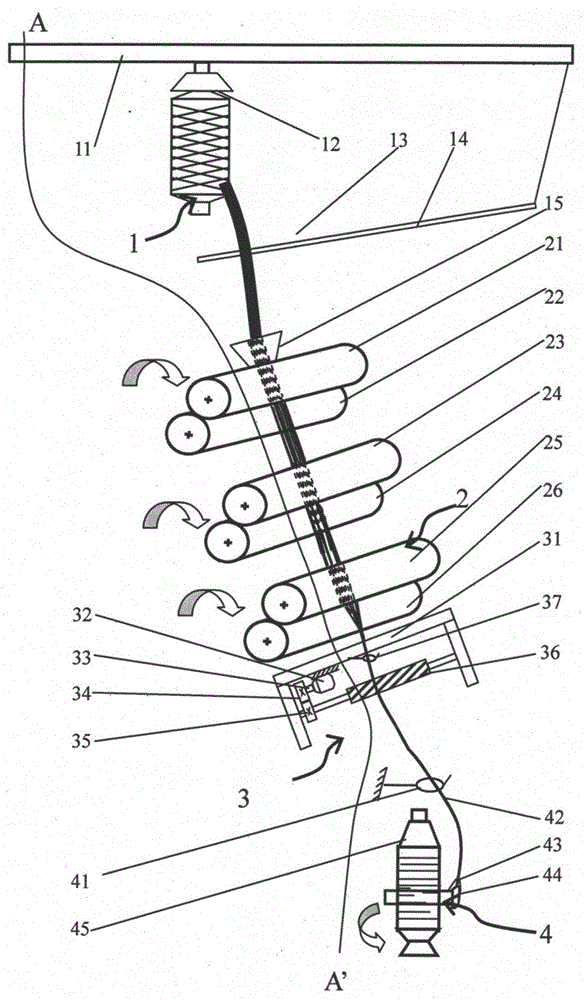

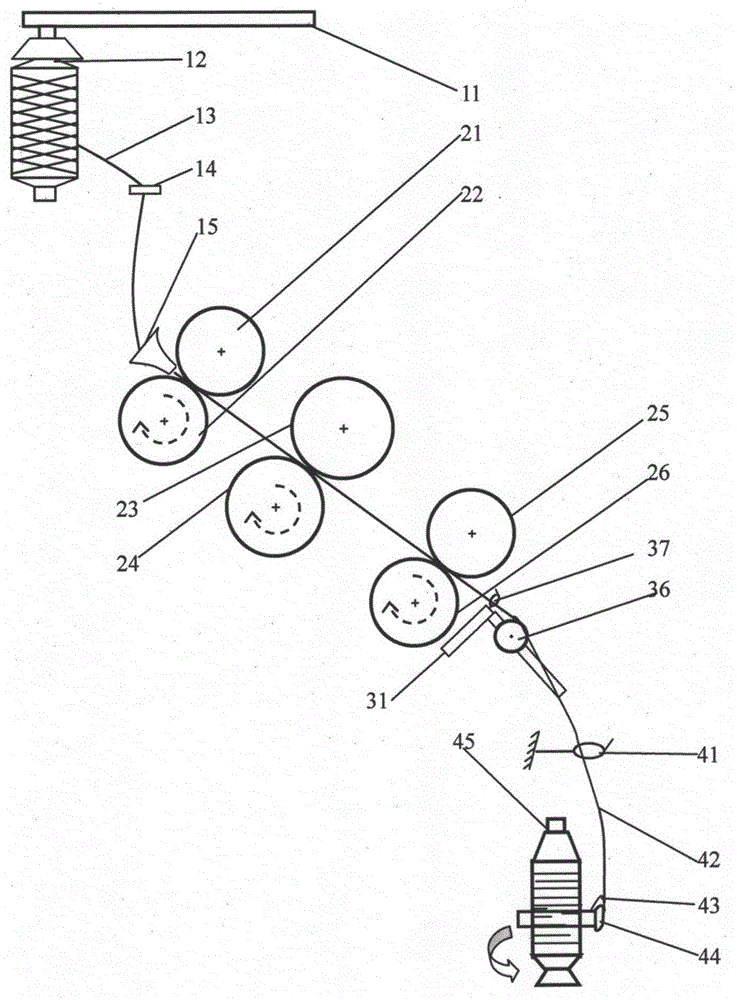

[0043] Such as figure 1 As shown, it is a front view of the device for leveling the hairiness of the ring spun spun yarn. The device for leveling the hairiness of the ring spun spun yarn includes a roving feeding mechanism 1, a drafting mechanism 2, a twisting and winding mechanism 4 and Hairiness leveling mechanism 3; described roving feeding mechanism 1, drafting mechanism 2, hairiness leveling mechanism 3 and twisting and winding mechanism 4 are arranged sequentially from top to bottom, as figure 2 As shown, described drafting mechanism 2 comprises the back roller pair that is made up of rear upper roller 21 and rear lower roller 22, the middle roller pair that is made up of middle upper roller 23 and middle lower roller 24 and is made up of front upper roller 25 and front roller pair. The pair of front rollers formed by the bottom roller 26; the rear bottom roller 22, the middle bottom roller 24 and the front bottom roller 26 can be driven to rotate, respectively driving ...

Embodiment 2

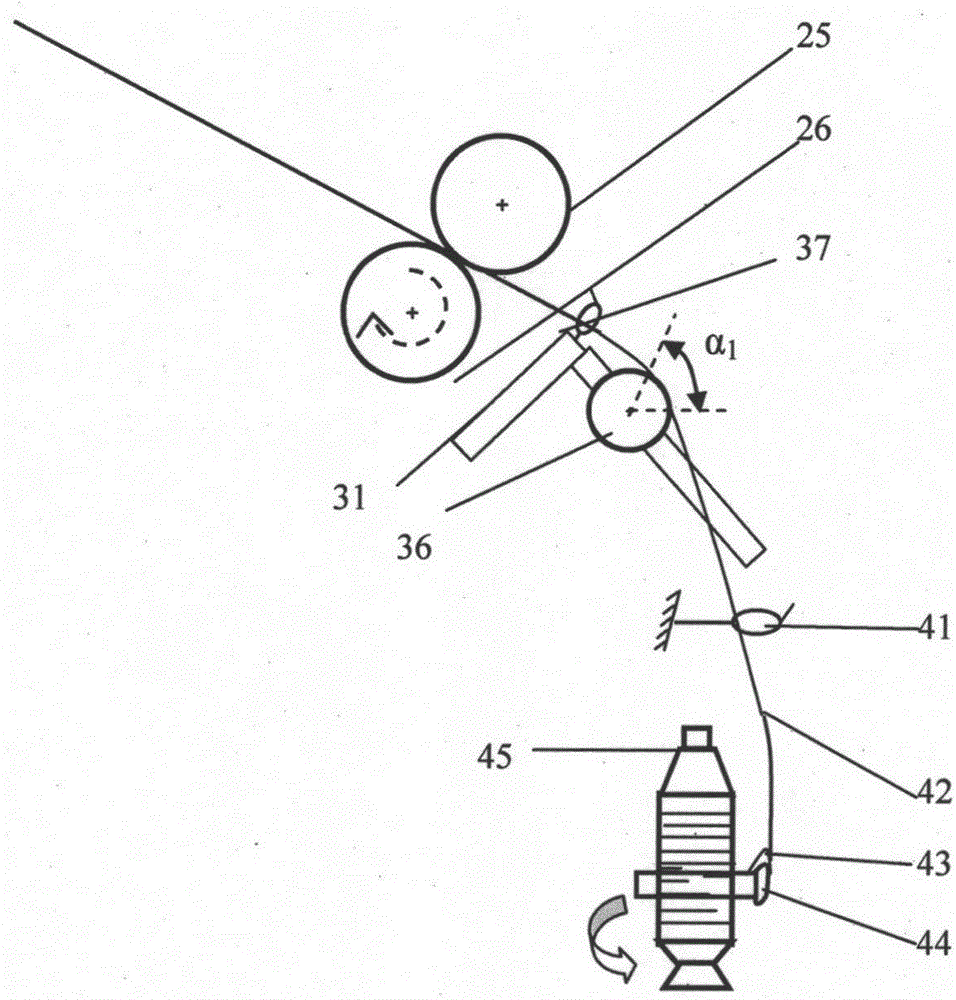

[0050] A device for leveling the hairiness of ring-spun spun yarn, similar to Example 1, the difference lies in the diameter of the leveling roll 36, the rotation speed of the leveling roll 36, and the wrapping angle α between the leveling roll 36 and the spun yarn 42 1 (Such as image 3 shown), the angle θ between the leveling lines 361 and the centerline of the leveling roller axis (such as Figure 4 As shown,), the logarithmic value of the roughness of the even lines 361, the coefficient of variation of the logarithmic values of the roughness of the even lines 361, the material of the even lines 361, the coefficient of friction of the even lines 361, and the distance between adjacent even lines 361 are different , see Table 1.

[0051] The device for leveling the hairiness of ring spinning spun yarn is applied to the attachment of yarn hairiness, and then the specific steps for preparing polyester-cotton 85 / 15 blended yarn with less hairiness, low energy consumption and ...

Embodiment 3

[0056] A device for leveling the hairiness of ring-spun spun yarn, similar to Example 1, the difference lies in the diameter of the leveling roll 36, the rotation speed of the leveling roll 36, and the wrapping angle α between the leveling roll 36 and the spun yarn 42 1 (Such as image 3 shown), the angle θ between the leveling lines 361 and the centerline of the leveling roller axis (such as Figure 4 As shown,), the logarithmic value of the roughness of the even lines 361, the coefficient of variation of the logarithmic values of the roughness of the even lines 361, the material of the even lines 361, the coefficient of friction of the even lines 361, and the distance between adjacent even lines 361 are different , see Table 1.

[0057] The device for leveling the hairiness of ring spinning spun yarn is applied to the attachment of yarn hairiness, and then the specific steps for preparing polyester-viscose 85 / 15 blended yarn with less hairiness, low energy consumption and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com