An electromagnetic induction heating device for corrugated paper and its application method

An electromagnetic induction heating and corrugated paper technology, applied in induction heating devices, induction heating, papermaking, etc., can solve the problems of slow start, difficult temperature control, unstable heating, etc., and achieve the effect of easy maintenance, automation, and balanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

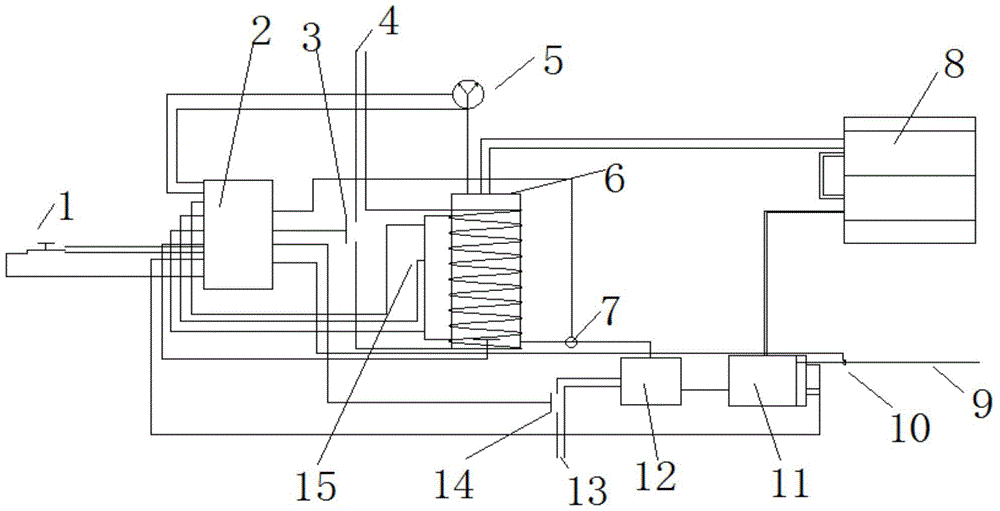

[0033] Such as figure 1 As shown, an electromagnetic induction heating device for corrugated paper includes a heating system 6, and also includes a control system 2, a pressure sensor 5, a radiator group 8, a water supply pipe 9, a water return system 11, a water adding system 12 and a water level sensor 15. System 6 consists of a heating coil and a heating cylinder. The heating coil is wound around the heating cylinder; the top of the heating cylinder is connected to one end of the radiator group 8 through a pipe. The inner shape of the heating cylinder is: 100mm in diameter, 450mm in height, and Smaller, quick start, the other end of the radiator group 8 communicates with the return water system 11, the water addition system 12 and the bottom of the heating cylinder in turn through the pipeline; the control system 2 is respectively connected with the heating system 6, the return water system 11 and the water addition system 12 The pressure sensor 5 and the water level sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com