Casting-free plastic-free large-adjustment-amount high-elasticity anti-theft rail fastener

A technology for rails and fasteners, which is applied in the directions of rails, fixed rails, roads, etc., can solve the problems of low strength of insulating gauge blocks, complicated production process of cast iron castings, complicated construction, etc., and achieve a large amount of rail position adjustment and lateral stability. The effect of good performance and less maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. For simplicity of description, the embodiments of the high-elastic rail fastener and the ordinary rail fastener are referred to as Example 1 and Example 2 respectively.

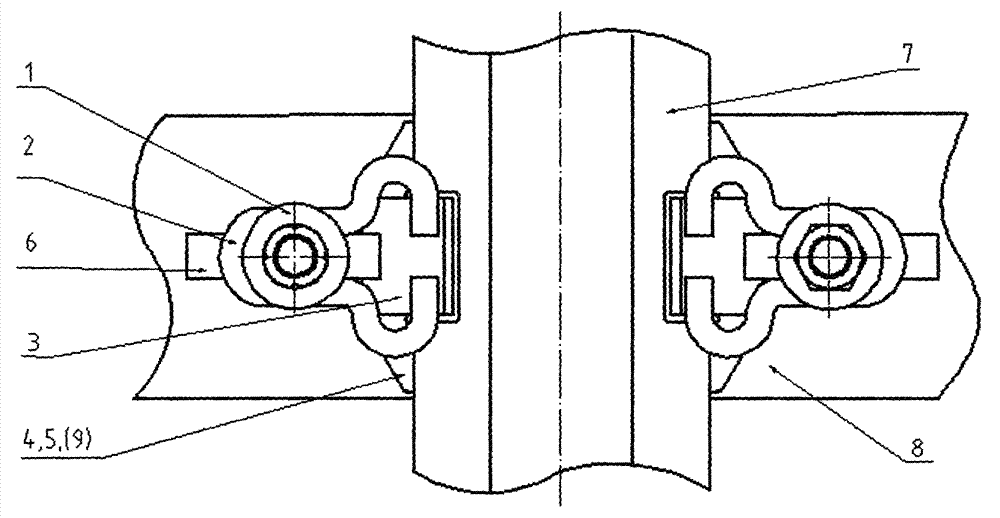

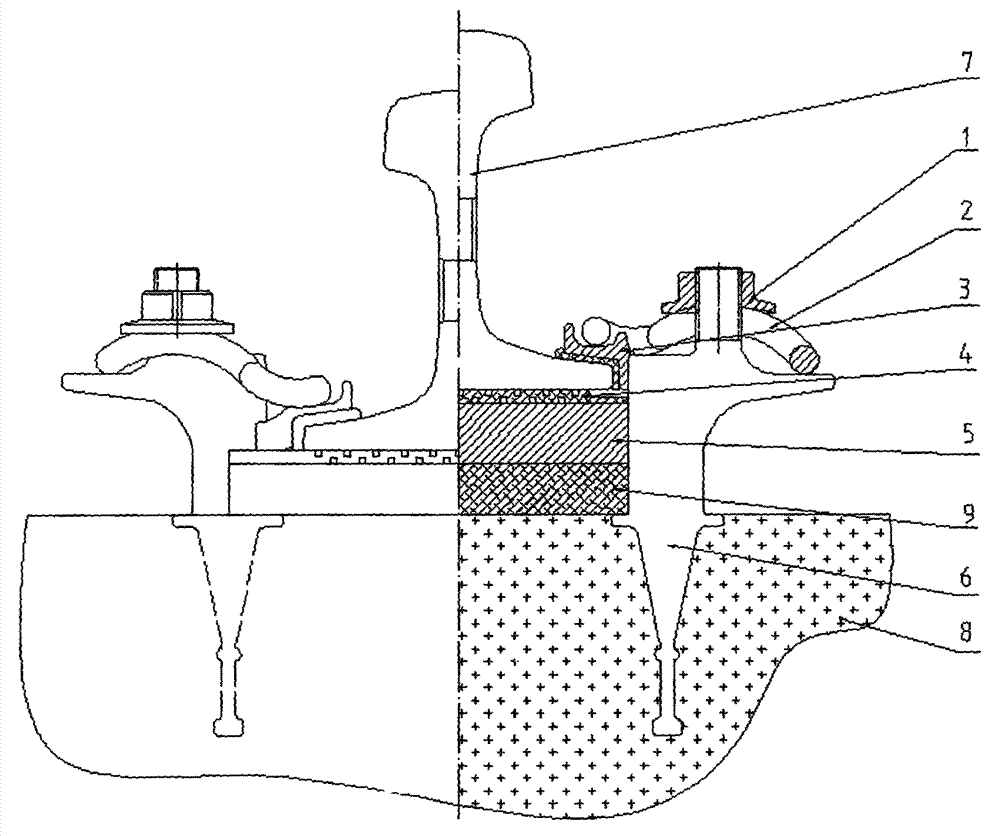

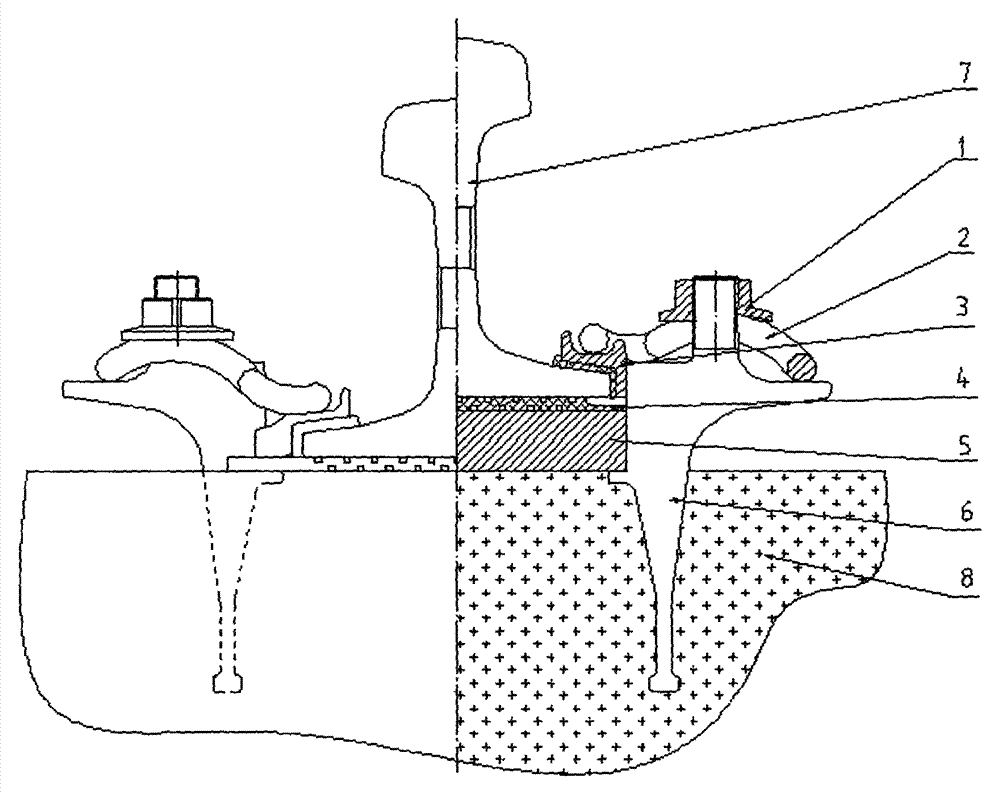

[0054] figure 1 Top view of Example 1 and Example 2. Because example 2 does not have shock pad 9, therefore figure 1 The shock pad 9 in (9) represents. figure 2 and image 3 They are the half-section front views of the rail fasteners of Example 1 and Example 2, respectively. The left half of the two figures is a front view without section, and the rail 7 is in the state of not adjusting the rail height; The left half in the above-mentioned 3 figures is an anti-theft type anti-loosening nut 1, and the right half is an ordinary hexagonal non-theft-proof anti-loosening nut 1. Compared figure 1 , figure 2 and image 3 It can be seen that the structures of the two embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com