Overpass bridge dismounting method

A flyover bridge and flyover technology, applied in construction, building maintenance, building construction, etc., can solve problems such as low efficiency, poor timeliness, shortening the normal operation time of railways and highways, etc., and achieve strong operability and construction plan Simple and convenient, reducing the effect of normal operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

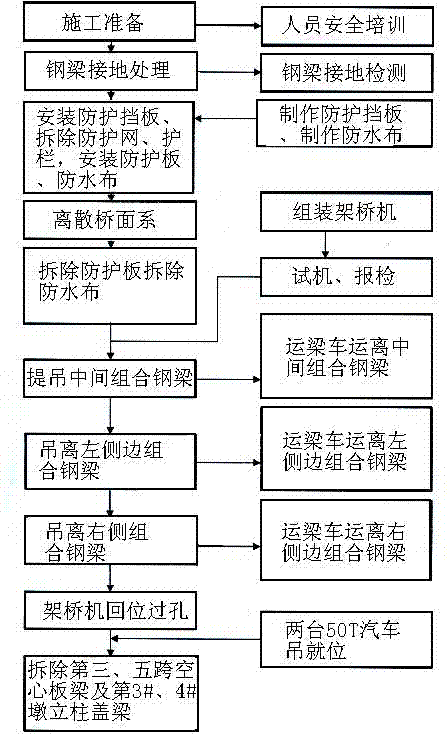

[0032] A method for dismantling a flyover, comprising the steps of:

[0033] Step 1: Carry out longitudinal cutting on the top plate of the main span bridge deck of the flyover bridge to form three Π-shaped steel beam units. For the first time, the 5-6cm thickness of the bottom of the bridge deck is not cut through without closing the traffic under the bridge;

[0034] Step 2: Carry out road closure under the bridge where the overpass bridge is demolished and constructed;

[0035] Step 3: Cut through the bridge deck with a thickness of 5-6cm at the bottom;

[0036] Step 4: Use lifting tools to clamp the cut steel beam;

[0037] Step 5: Use lifting tools to lift the overall clamped steel beams away.

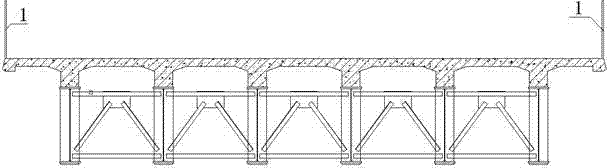

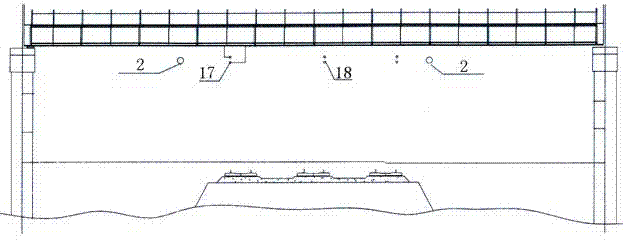

[0038] Such as figure 1 As shown, in step 1, before cutting the top plate of the main span bridge deck of the span bridge, an L-shaped protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com