Static Offset Push-By Rotary Steerable Drilling Tool

A technology of rotary steerable drilling and static offset, which is applied in directional drilling and other directions, can solve the problems of high oil circuit strength requirements and sealing requirements, poor system safety, and difficult installation, so as to avoid difficult selection, improve response speed, and ensure The effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

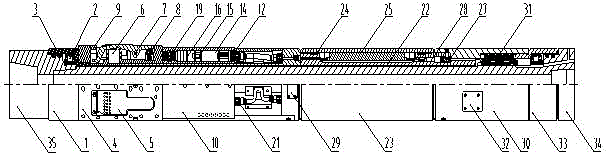

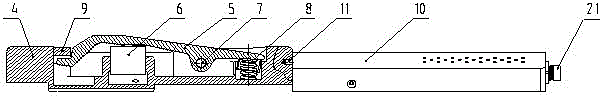

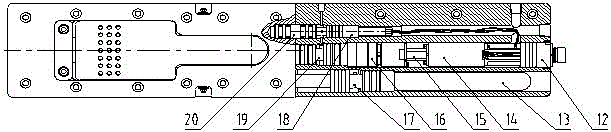

[0033] see Figure 1 to Figure 4, a static bias push-to-type rotary steerable drilling tool, including a rotating mandrel 34 and a non-rotating outer casing section, a circuit installation section and a coupler installation section installed on the rotating mandrel 34, wherein the rotating mandrel 34 is hollow Structure, the upper end (the left end in the figure) of the non-rotating jacket 34 is connected to the drill string, and the lower end (the right end in the figure) is connected to the drill bit through the lower joint 35, which mainly plays the role of transmitting drilling moment, drilling pressure and transporting drilling fluid; the non-rotating jacket section, circuit installation section and coupler installation section are connected sequentially from bottom to top, the non-rotating jacket section includes non-rotating jacket 1, non-rotating jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com