Continuously supplying device of liquefied carbon dioxide fluid

A liquid carbon dioxide and supply device technology, applied in the direction of gas/liquid distribution and storage, container discharge methods, equipment loaded into pressure vessels, etc., to achieve continuous and stable output, low energy consumption, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

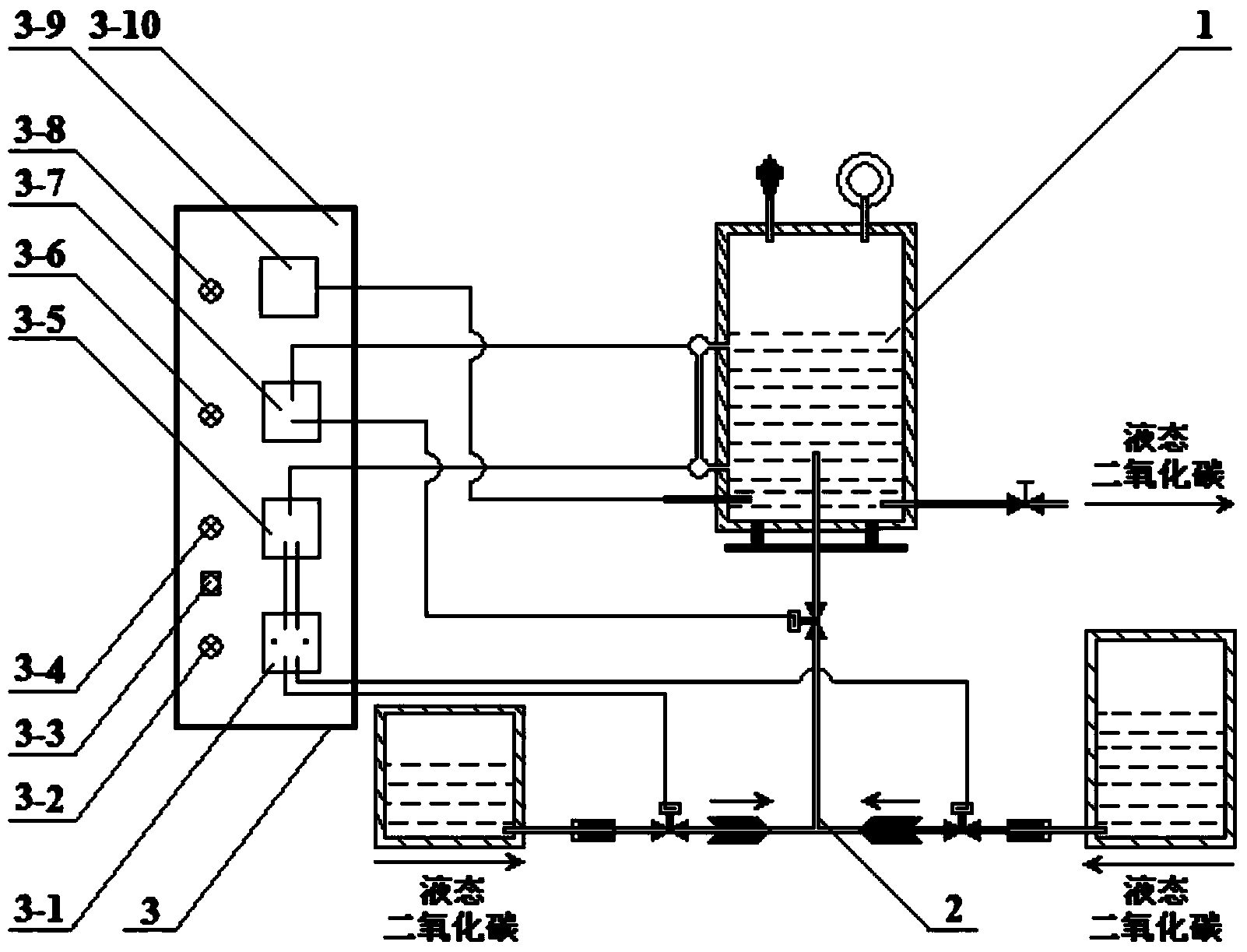

[0020] exist figure 1 Among them, the continuous supply device of the liquid carbon dioxide fluid in this embodiment is composed of a liquid carbon dioxide storage tank 1 , a liquid carbon dioxide bus 2 , and a controller 3 connected together.

[0021] A controller 3 is arranged on the left side, and a liquid carbon dioxide storage tank 1 and a liquid carbon dioxide busbar 2 are arranged on the right side. The liquid carbon dioxide storage tank 1 is connected to the controller through a wire, and the liquid carbon dioxide busbar 2 is connected to the controller through a wire. , communicate with the liquid carbon dioxide storage tank 1 through pipelines.

[0022] The controller 3 of this embodiment consists of a low liquid level controller 3-1, a right liquid carbon dioxide tank alarm 3-2, a reset switch 3-3, a left liquid carbon dioxide tank alarm 3-4, and a left and right road switcher 3-5 , liquid inlet solenoid valve indicator light 3-6, high liquid level controller 3-7, ...

Embodiment 2

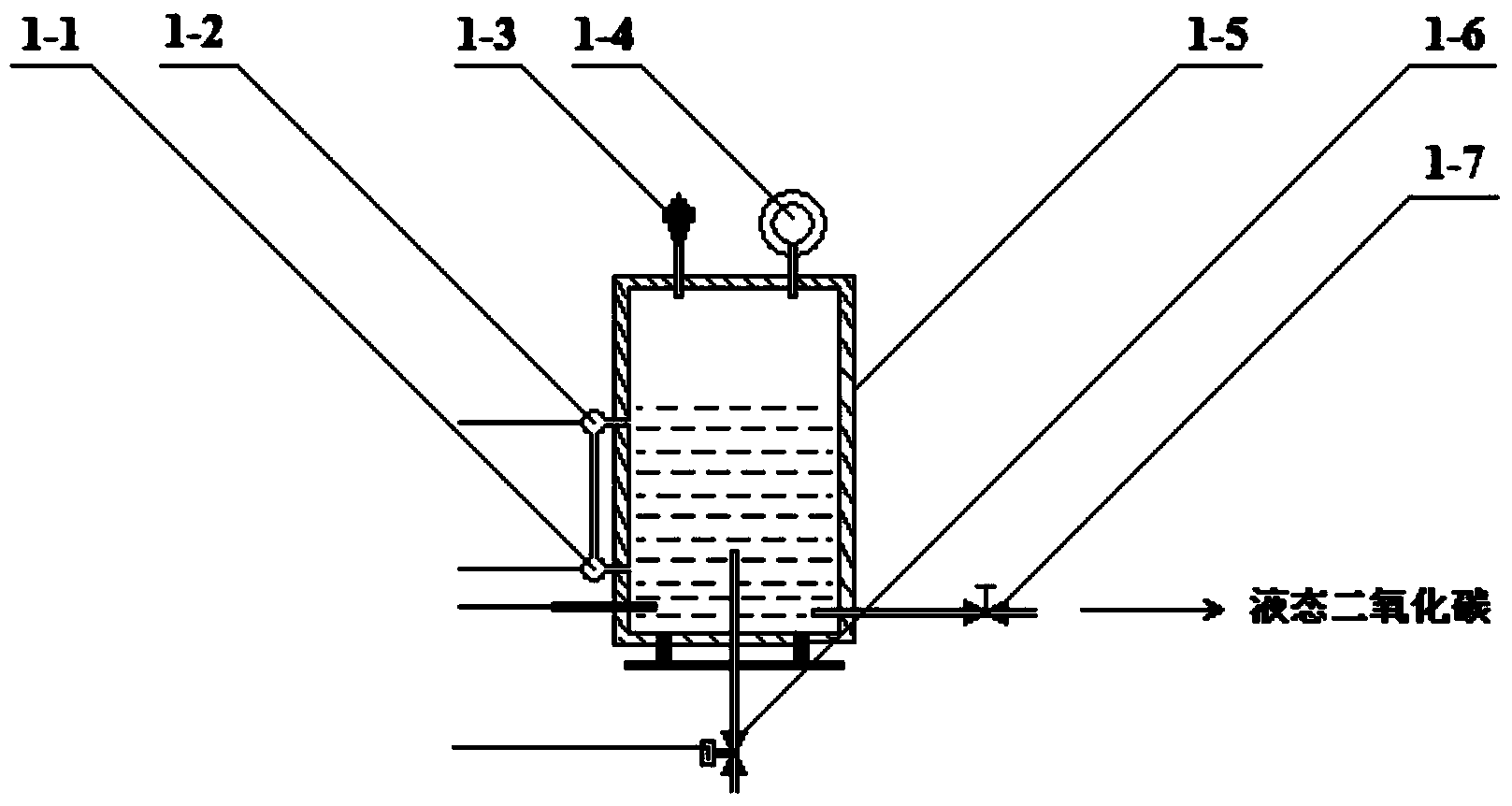

[0027] Figure 4 A schematic structural diagram of Embodiment 2 of the liquid carbon dioxide storage tank 1 is given. exist Figure 4 Among them, the liquid carbon dioxide storage tank 1 of this embodiment is composed of a temperature sensor 1-1, a liquid level sensor 1-2, a safety valve 1-3, a pressure gauge 1-4, a main tank body 1-5, and a liquid inlet solenoid valve 1 -6, the liquid outlet valve 1-7, the coolant inlet pipe 1-8, and the coolant outlet pipe 1-9 are connected to form. The main tank body 1-5 of the present embodiment is a sandwich tank body, and the cooling liquid inlet pipe 1-8 is installed by screw connection under the right side of the main tank body 1-5, and the cooling liquid inlet pipe 1-8 is connected with the main tank body. 1-5 interlayer is interconnected, and the right side of the main tank 1-5 is threadedly installed with a coolant outlet pipe 1-9, and the coolant outlet pipe 1-9 communicates with the main tank 1-5 interlayer. In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com