Air negative electrode for microbial fuel cell and preparation method for air negative electrode

A technology for fuel cells and air cathodes, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of large anode chamber, air cathode performance degradation, and falling off of catalytic layer materials, so as to improve reaction rate, continuous and stable output, shorten effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A microbial fuel cell cathode is composed of a protective layer, a catalytic layer and a diffusion layer.

[0029] The preparation method of the microbial fuel cell air cathode, the specific steps are as follows:

[0030] 1) First place the diffusion layer with a geometric area of 4.0cm×4.0cm and a weight of 2.15g on an electrospun polytetrafluoroethylene receiving plate, and the distance between the receiving plate and the nozzle is 15cm.

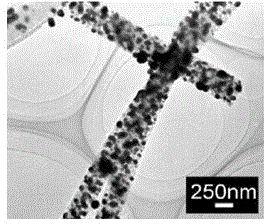

[0031] 2) Carbon-supported platinum (platinum content 10wt%), Nafion solution and polyacrylic acid (the three are in a mass ratio of 75:15:10) were mixed and ultrasonicated to make an ink.

[0032] 3) Input the ink into the 10mL syringe of the electrospinning device. By controlling the movement trajectory of the needle within the range of 4cm×4cm, apply a DC voltage of 15kV, and the supply rate of the catalyst ink is 2mL / h.

[0033] 4) Spinning, stop when the target catalyst load is reached, and then put into the oven 110 o C dr...

Embodiment 2

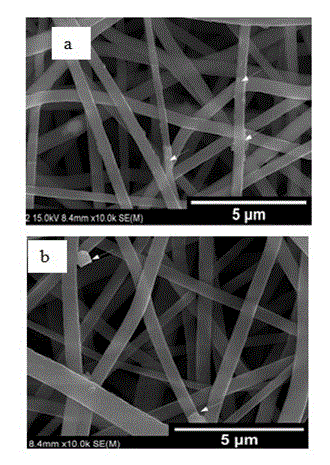

[0039] A microbial fuel cell cathode is composed of a protective layer, a catalytic layer and a diffusion layer. The specific implementation steps are basically the same as in Example 1, except that the protective layer is made of polysulfone organic polymer material and has no antibacterial functional material. image 3 a is the SEM image of the protective layer obtained after Example 2. The pore size ranges from 220nm to 3100nm, with an average of 720nm, the fiber diameter ranges from 250nm to 870nm, with an average of 460nm, the porosity is 91%, and the average thickness of the protective layer is 8μm. The test conditions are basically the same as in Example 1, except that the washing frequency is once every 30 minutes. image 3 b is the SEM image of the surface protective layer of the microbial fuel cell using the air cathode of Example 2 after running for one month, confirming that the polysulfone non-antibacterial material protective layer can prevent microbial contamina...

Embodiment 3

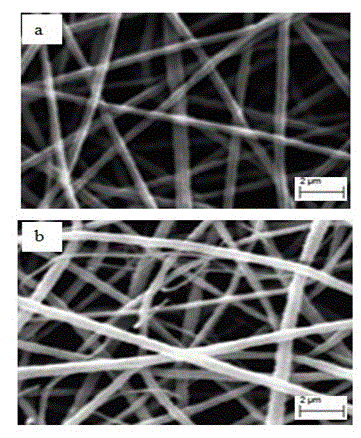

[0041] A microbial fuel cell cathode is composed of a protective layer, a catalytic layer and a diffusion layer. The specific implementation steps are basically the same as in Example 1, except that the protective layer uses a quaternized polysulfone organic polymer material (anion exchange material) and No antibacterial functional materials. Figure 4 a is the SEM image of the protective layer obtained after Example 3. The pore size ranges from 400nm to 6700nm, with an average of 1800nm, the fiber diameter ranges from 340nm to 910nm, with an average of 440nm, the porosity is 81%, and the average thickness of the protective layer is 13μm. The test conditions are basically the same as in Example 1, except that the washing frequency is once every 30 minutes. Figure 4 B is the SEM image of the surface protective layer of the microbial fuel cell that adopts the air cathode of embodiment 2 after running for 1 month, confirms that the quaternized polysulfone anion exchange materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com