Diesel-engine air valve and cylinder head seat retainer leakage detecting and repairing method

A leak detection, diesel engine technology, applied in the direction of detecting the appearance of fluid at the leak point, measuring the acceleration and deceleration rate of the fluid, and using the liquid/vacuum degree for liquid tightness measurement, etc., can solve the waste of production cost and production takt, The detection process cannot accurately and sensitively reflect the assembly quality of the valve seat, and there is no plan to check the valve seat assembly failure, so as to avoid the waste of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

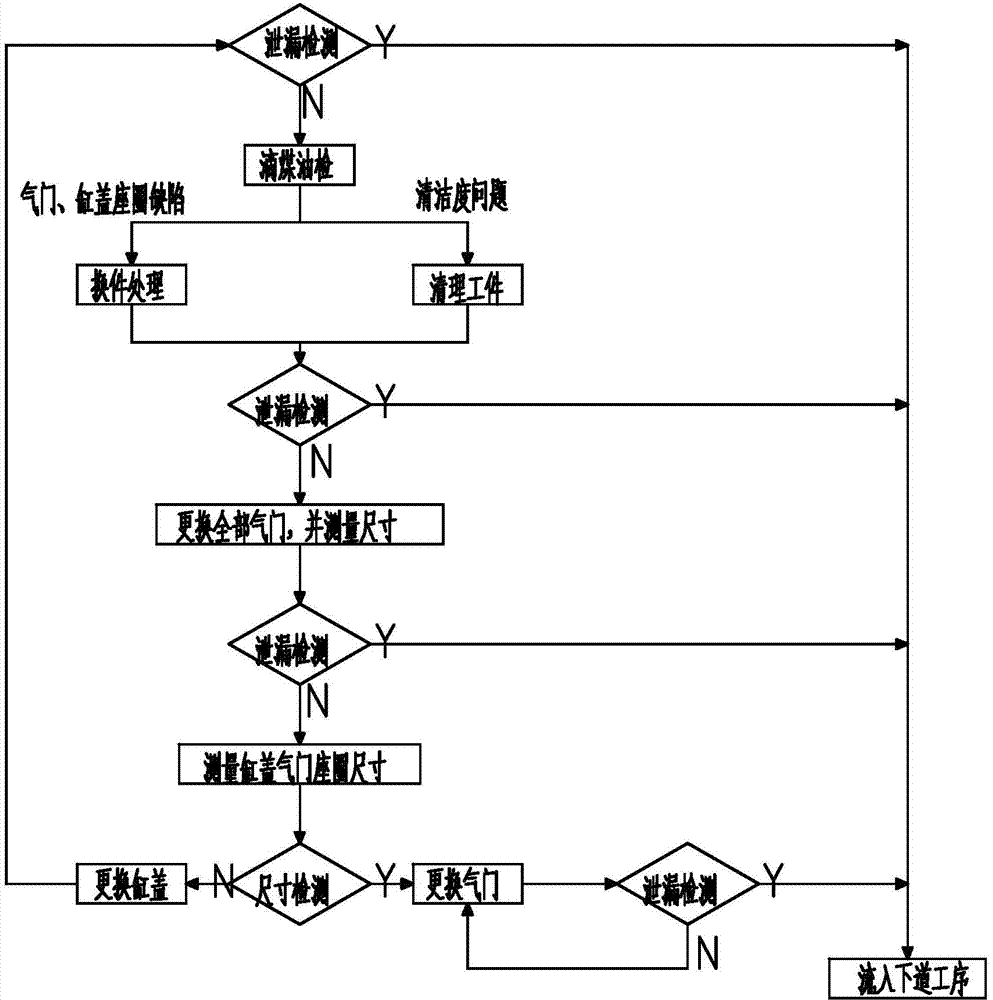

Image

Examples

Embodiment 1

[0021] A diesel engine valve and cylinder head seat leakage detection and repair method, comprising the following steps:

[0022] (1) Plugging: Take a diesel engine, each diesel engine has 6 cylinders, and each cylinder has 4 valves; use the plugging head to automatically seal the joint surface between the valve of the first cylinder of the diesel engine and the cylinder head seat;

[0023] (2) Inflation: Inflate the joint surface of the valve and the cylinder head seat, the inflation pressure is 50KPa, and the inflation time is 7s;

[0024] (3) Measure the leakage rate: measure the leakage rate of the first cylinder valve and the cylinder head seat, the measurement pressure is 50KPa, the measurement time is 4s, and the leakage rate is 3.5cm 3 / min;

[0025] (4) Repeat: Repeat steps (1)-(3) to complete the leakage detection of the joint surface between the valve and the cylinder head seat of the second cylinder - the sixth cylinder. The measured pressure and leakage rate of e...

Embodiment 2

[0030] A diesel engine valve and cylinder head seat leakage detection and repair method, comprising the following steps:

[0031] (1) Plugging: Take a diesel engine, each diesel engine has 6 cylinders, and each cylinder has 4 valves; use the plugging head to automatically seal the joint surface between the valve of the first cylinder of the diesel engine and the cylinder head seat;

[0032] (2) Inflation: Inflate the joint surface of the valve and the cylinder head seat, the inflation pressure is 55KPa, and the inflation time is 5s;

[0033] (3) Leakage rate measurement: measure the leakage rate of the first cylinder valve and the cylinder head seat, the measurement pressure is 0.45Bar, the measurement time is 4s, and the leakage rate is 900.5cm 3 / min;

[0034] (4) Repeat: Repeat steps (1)-(3) to complete the leakage detection of the joint surface between the valve and the cylinder head seat of the second cylinder - the sixth cylinder. The measured pressure and leakage rate ...

Embodiment 3

[0043] A diesel engine valve and cylinder head seat leakage detection and repair method, the steps are as follows:

[0044] (1) Plugging: take a diesel engine, each diesel engine has 6 cylinders, and each cylinder has 4 valves; use the plugging head to automatically seal and seal the joint surface between the valve of the first cylinder of the diesel engine and the cylinder head seat;

[0045] (2) Inflation: Inflate the joint surface of the valve and the cylinder head seat, the inflation pressure is 51KPa, and the inflation time is 6s;

[0046] (3) Measure the leakage rate: measure the leakage rate of the first cylinder valve and the cylinder head seat, the measurement pressure is 50Kpa, the measurement time is 5s, and the leakage rate is 3.5cm 3 / min;

[0047] (4) Repeat: Repeat steps (1)-(3) to complete the leak detection of the joint surface between the valve and the cylinder head seat of the second cylinder to the sixth cylinder of the diesel engine;

[0048] Table 3 Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com