Formaldehyde remover, and preparation method and application thereof

The technology of a formaldehyde remover and chitin derivatives, which is applied in the field of formaldehyde remover and its preparation, can solve the problems of incomplete air purification, easy rebound release of formaldehyde, unstable substances, etc., and achieves stable properties, simple preparation methods, and easy reaction. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Weigh 80kg deionized water, 1kg lactic acid, 2kg chitin and 1kg tea polyphenols respectively;

[0036] 2) Add 1kg of lactic acid to 50kg of deionized water and stir evenly to obtain a weak acid solution;

[0037] 3) Add 2kg of chitin (degree of deacetylation greater than or equal to 90%) to the weak acid solution of step 1), stir at 60°C until it is completely dissolved, and cool to room temperature to obtain a chitin derivative solution;

[0038] 4) Add 1 kg of tea polyphenols to 30 kg of deionized water, stir at room temperature until completely dissolved, to obtain a tea extract solution;

[0039] 5) The chitin derivative solution of step 3) and the tea extract solution of step 4) are mixed, stirred evenly to obtain a formaldehyde remover, and sealed and stored.

Embodiment 2

[0041] 1) Weigh 90kg of deionized water, 5kg of acetic acid, 10kg of graft-modified chitin, 1kg of theaflavin, 2kg of tea polysaccharide and 2kg of tea saponin;

[0042] 2) Add 5kg of acetic acid to 60kg of deionized water and stir evenly to obtain a weak acid solution;

[0043] 3) Add 10 kg of graft-modified chitin (biguanidyl-modified chitin) to the weak acid solution of step 1), stir at 60°C until it is completely dissolved, and cool to room temperature to obtain a chitin derivative solution;

[0044] 4) Add 1kg of theaflavins, 2kg of tea polysaccharides and 2kg of tea saponin to 30kg of deionized water, stir at room temperature until completely dissolved, to obtain a tea extract solution;

[0045] 5) The chitin derivative solution of step 3) and the tea extract solution of step 4) are mixed, stirred evenly to obtain a formaldehyde remover, and sealed and stored.

Embodiment 3

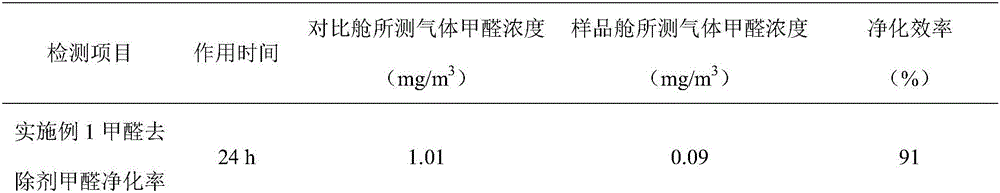

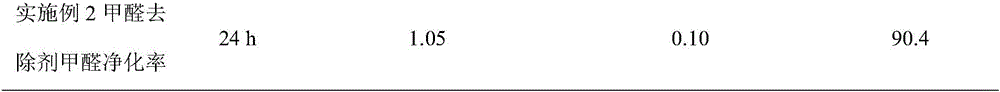

[0046] Example 3: Formaldehyde remover and formaldehyde reaction experiment (indoor temperature 25℃)

[0047] 1. Add 20 mL of the formaldehyde remover prepared in Examples 1 and 2 into a 50 mL beaker;

[0048] 2. Slowly drop 2 mL of 36% formaldehyde solution into the beaker of formaldehyde remover;

[0049] 3. Stir the mixture in the beaker evenly and let it stand for 15 minutes;

[0050] 4. The solution in the beaker formed a three-dimensional gel;

[0051] 5. The reason for the formation of jelly is that the amino group on the side chain of the chitin derivative in the formaldehyde remover has a cross-linking reaction with formaldehyde. The linear polymer is cross-linked and called a bulk polymer compound, and the bulk polymer compound does not dissolve It has strong properties, strong rigidity, and poor fluidity. After long-term observation, it has strong stability and will no longer degrade and rebound to release formaldehyde.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com