Three-port router based on planar optical waveguide technology and manufacturing method thereof

A planar optical waveguide and router technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of large chip size, large occupied area, increased control and process difficulty, etc., and achieve small size, high integration, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

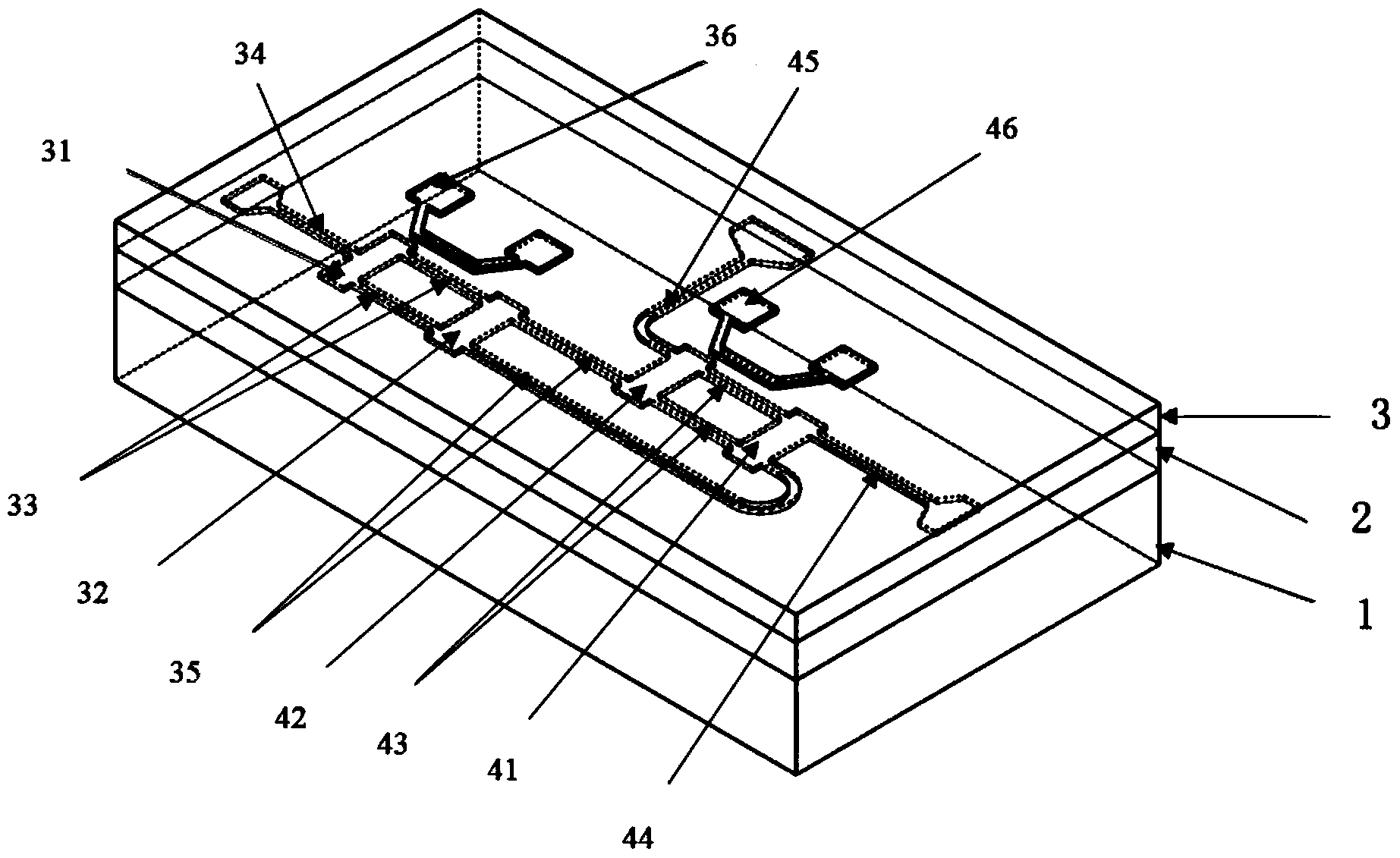

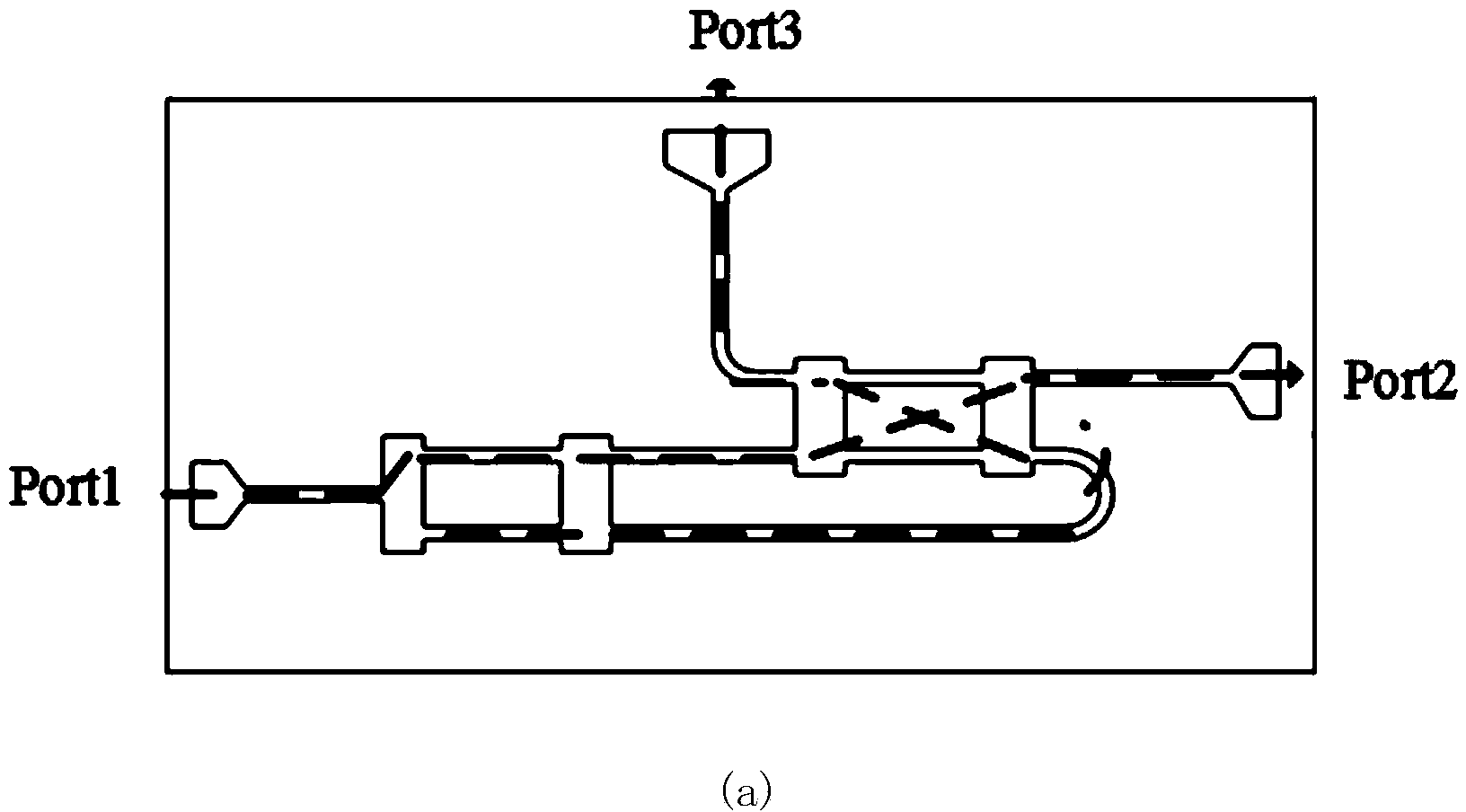

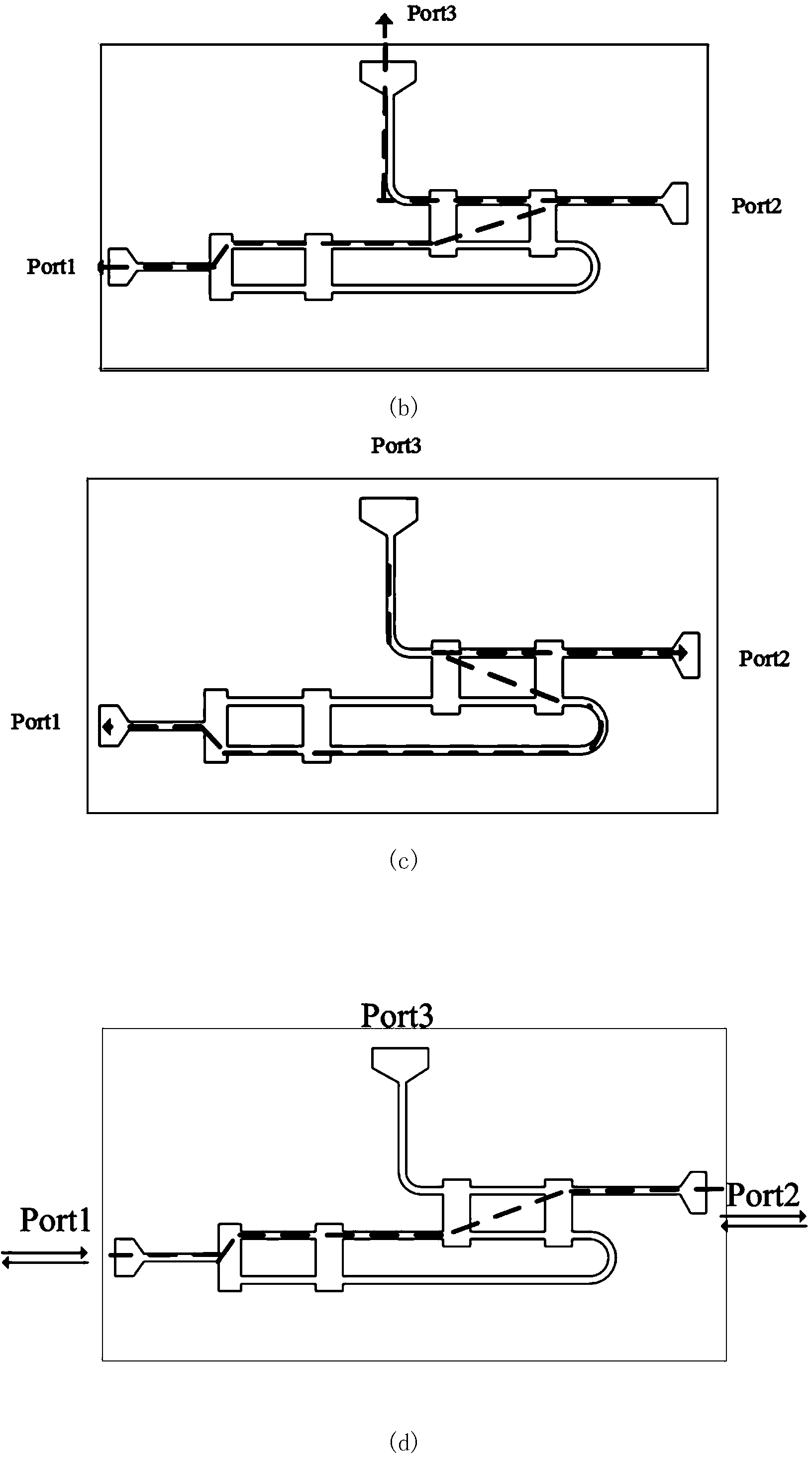

[0030] see figure 1 , a three-port router based on planar optical waveguide technology provided by the preferred embodiment of the present invention, includes a substrate layer 1, a core layer 2 and a cover layer 3 from bottom to top, and a 1X2 optical A switch and a 2X2 optical switch, the input port of the 1X2 optical switch is the first port Port1, and one of the input ports and one of the output ports of the 2X2 optical switch are the second port Port2 and the third port Port3 respectively. Preferably, the first port Port1, the second port Port2 and the third port Port3 are respectively located on three sides ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap