Helical-gear precise modeling method involving tooth alignment errors

A modeling method and a tooth-tooth error technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as complex modeling, low modeling accuracy, and inability to realize parametric modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

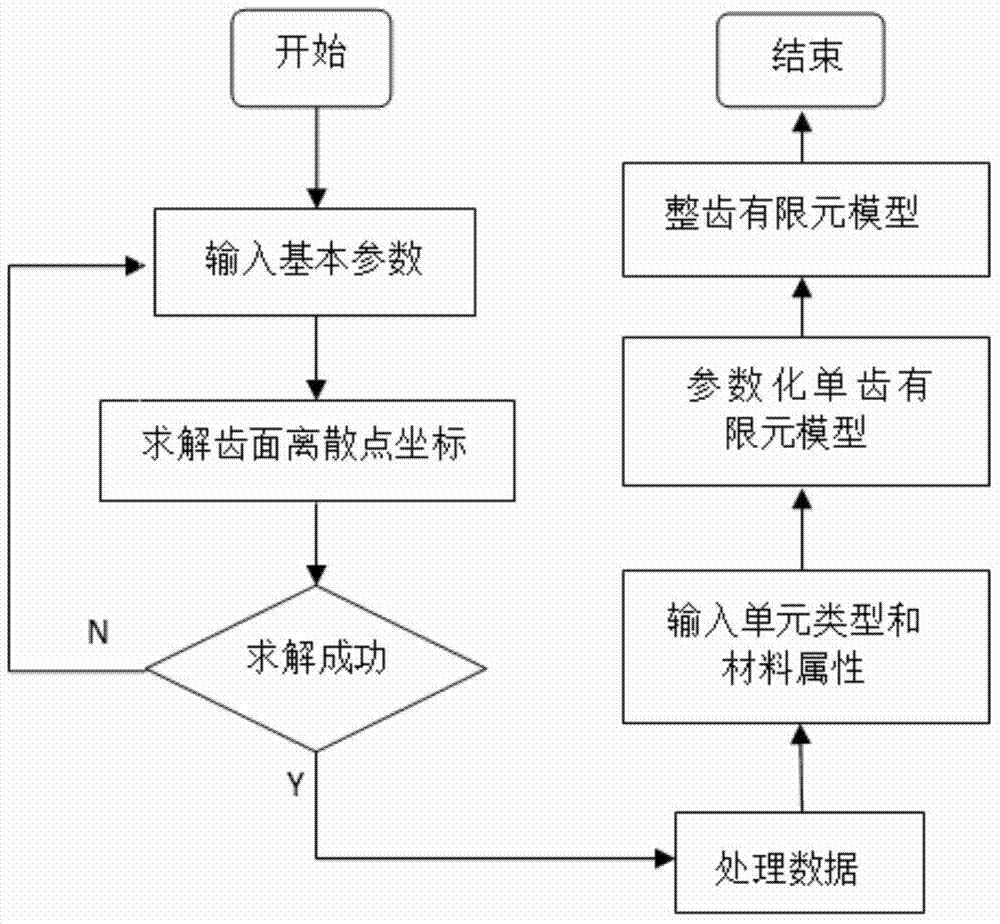

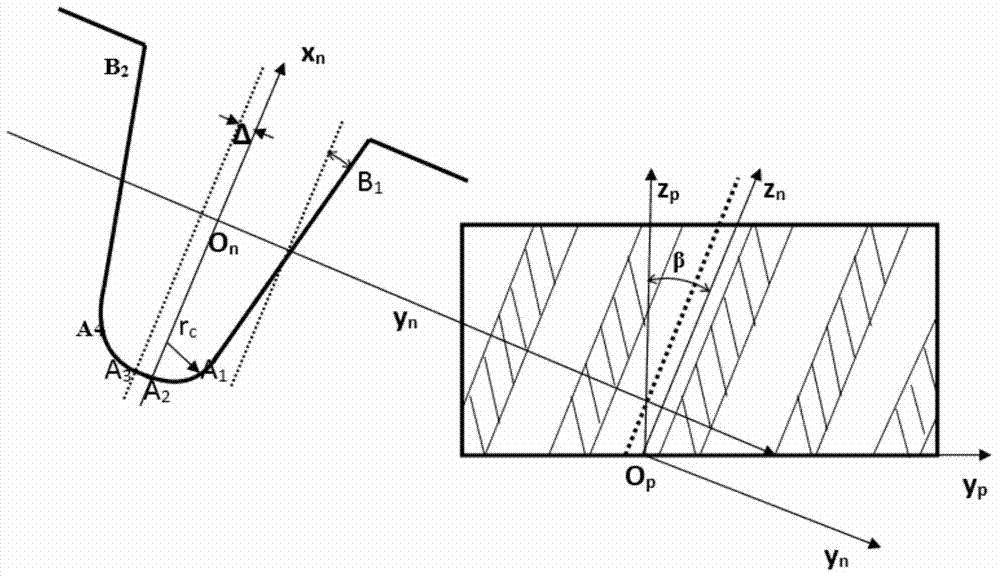

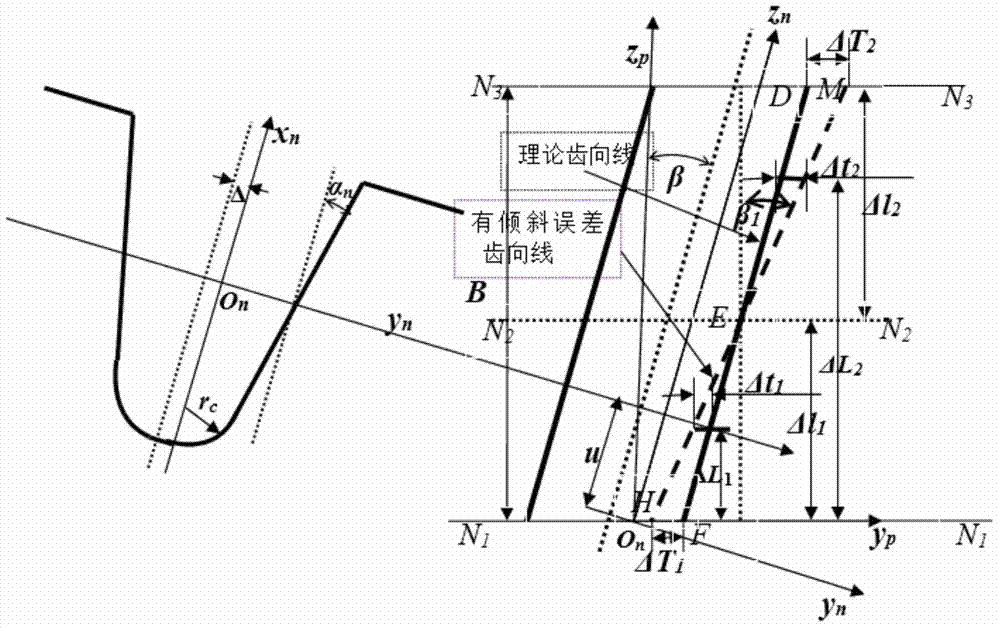

[0100] The invention relates to a helical gear modeling method with tooth direction error, comprising the following steps: (1) obtaining the tooth profile equation of the rack cutter according to the structure of the rack cutter; (2) combining the form of the error and combining the According to the law of motion, the equation of the tool tooth surface containing the helical tilt and shape error is obtained through coordinate transformation; (3) According to the error tool tooth surface equation and the gear meshing law, the rack and pinion meshing equation is obtained; (4) According to the meshing equation and the error tool Tooth surface equation, determine the tooth surface equation of the helix shape error including the helix tilt error and obeying the sine law. (5) According to the tooth surface equation, solve and process the discrete points of the tooth surface, so that they can be directly read into the finite element software, and number the discrete points of the toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com