A furnace group method for magnetic material production

A magnetic material and production work order group technology, applied in the information field, can solve problems such as heavy workload, difficult to give, and long time for furnace assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

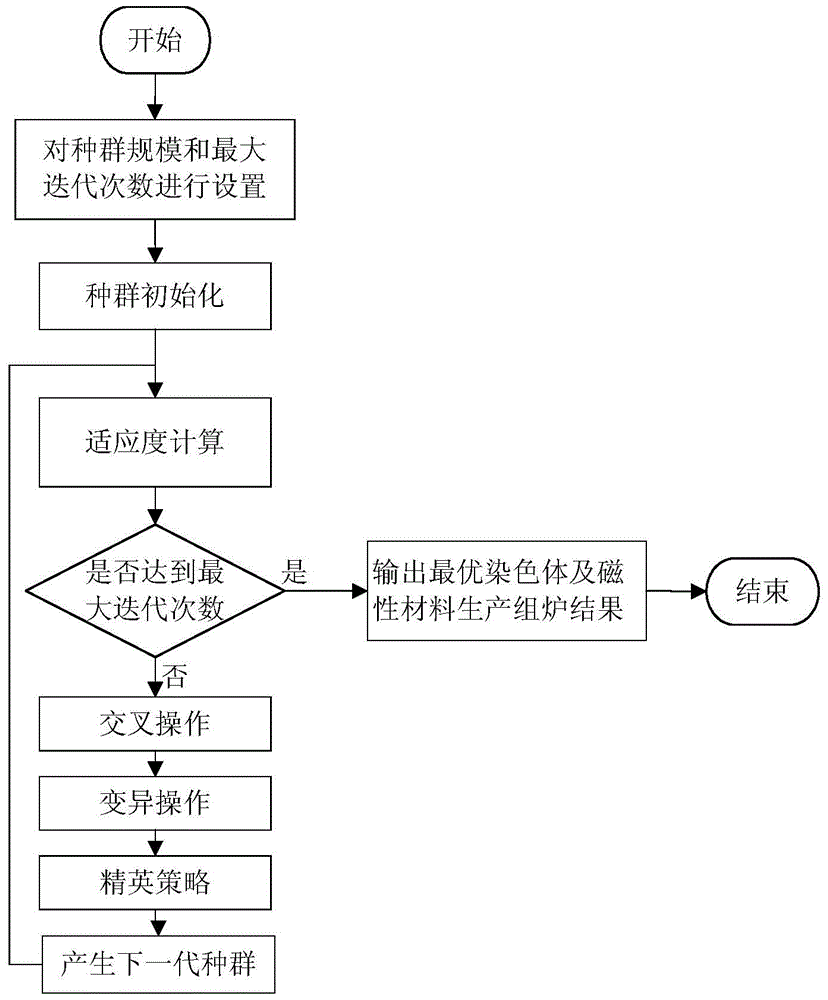

[0063] Taking the group furnace for magnetic material production of a magnetic material enterprise as an example, a furnace group method for magnetic material production according to the present invention will be further described in conjunction with the accompanying drawings.

[0064] The belt throwing furnace is the corresponding equipment for the production of sintered NdFeB magnetic materials. Swing belt furnace is composed of vacuum system, vacuum furnace shell, induction heater coil, crucible, tundish, runner and drum, etc. The length, width and height of the strip furnace used on site are 5*5*5m respectively. Its working principle is that the prepared raw materials are vacuumed and induction smelted to obtain a high-temperature metal solution with a temperature of about 1450°C. After refining for 3-5 minutes, it is poured in a cooling furnace of 2.42-2.77m / s On the roller, through the rotation of the roller, flakes with a thickness of 0.3-0.5mm are thrown out, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com