A permanent magnet movable medium and low voltage circuit breaker driving device

A low-voltage circuit breaker and driving device technology, which is applied in the field of permanent magnet movable medium and low-voltage circuit breaker driving devices, can solve the problem of not being able to fully utilize high-current circuit shutdown, increasing the complexity of circuit breaker driving devices, and increasing the risk of circuit breaker switching etc., to achieve the effects of reducing the probability of high temperature burnout, simple structure, and improving mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

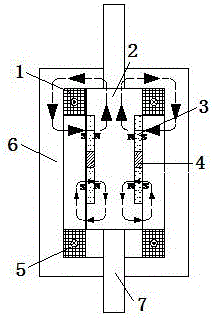

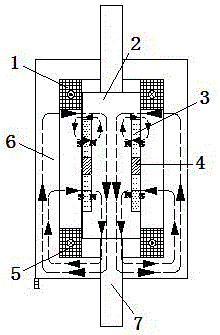

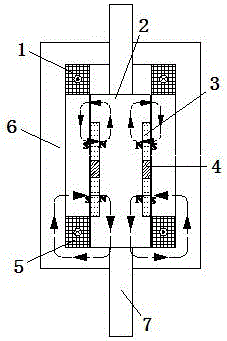

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] as attached Figures 1~5 As shown in the figure, a medium and low voltage permanent magnet movable circuit breaker driving device of the present invention includes an opening winding 1, a moving iron core 2, a permanent magnet 3, a fixing device 4, a closing winding 5, a static iron core 6, and a driving connecting rod 7 .

[0027] The opening and closing windings are respectively wound around the upper and lower parts of the static iron core 6.

[0028] The moving iron core 2 adopts the "I" shape structure design, the cross-sectional area of the moving iron core is circular, and the cross-sectional diameter of the two ends of the moving iron core is larger than the cross-sectional diameter of the middle of the moving iron core, such as Figure 5 As shown, the inner diameter of the aluminum ring or permanent magnet of the fixing device is the inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com