Patents

Literature

30results about How to "Short transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Active disturbance rejection control technology-based method for controlling synchronization of photovoltaic power generation system

InactiveCN101969210ARealize grid connection controlReduce shockSingle network parallel feeding arrangementsPhotovoltaic energy generationActive disturbance rejection controlPower grid

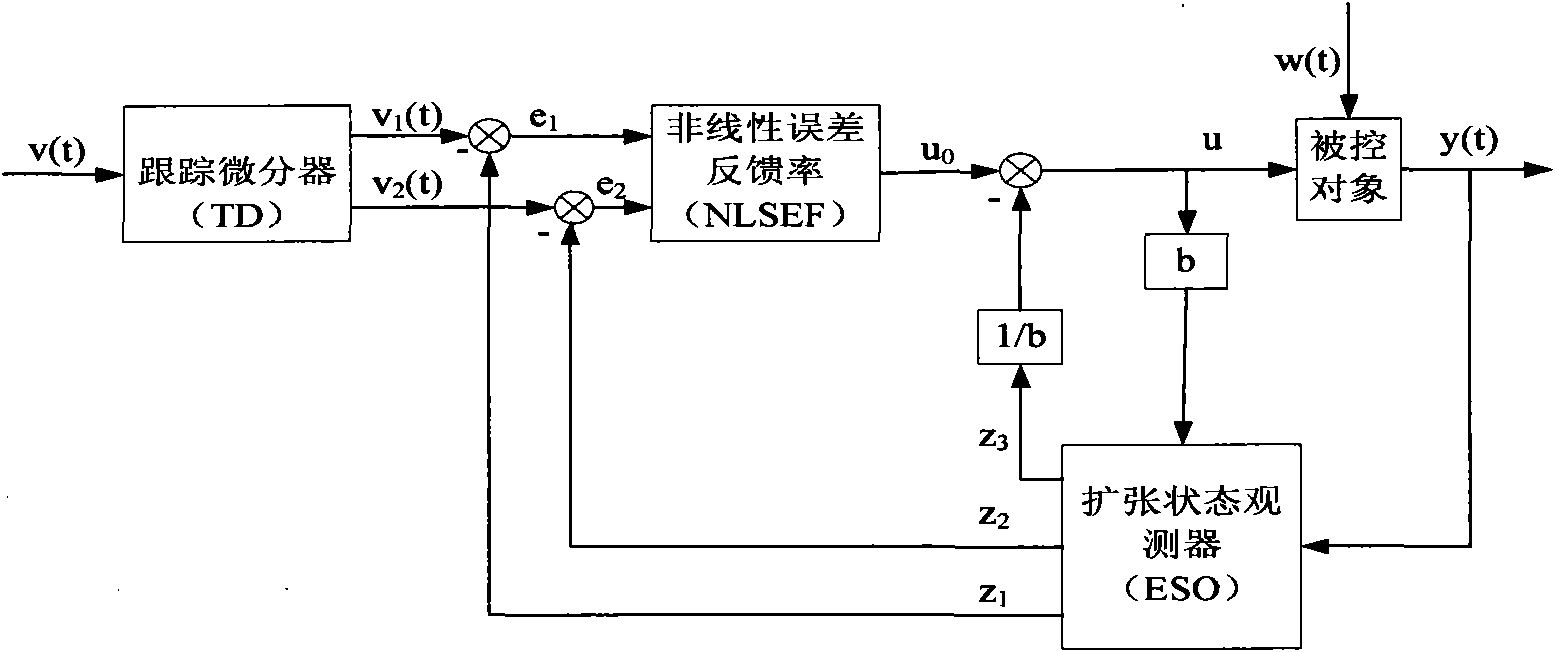

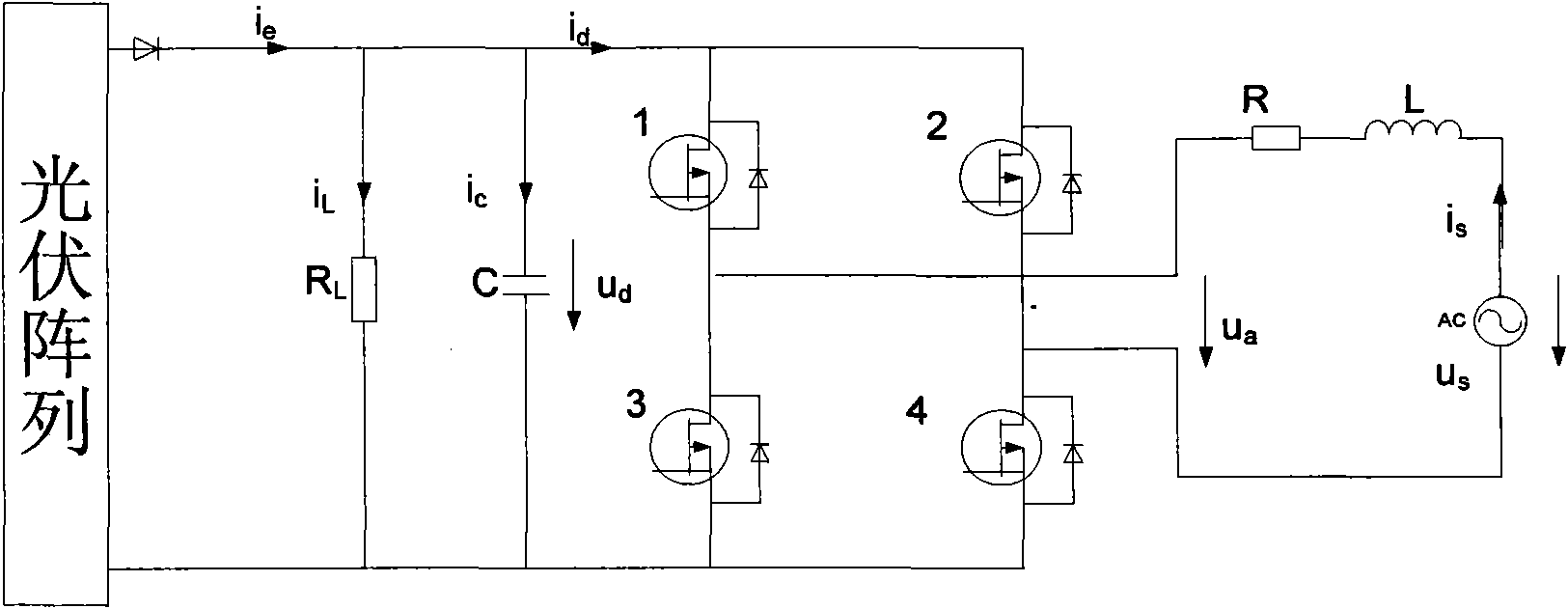

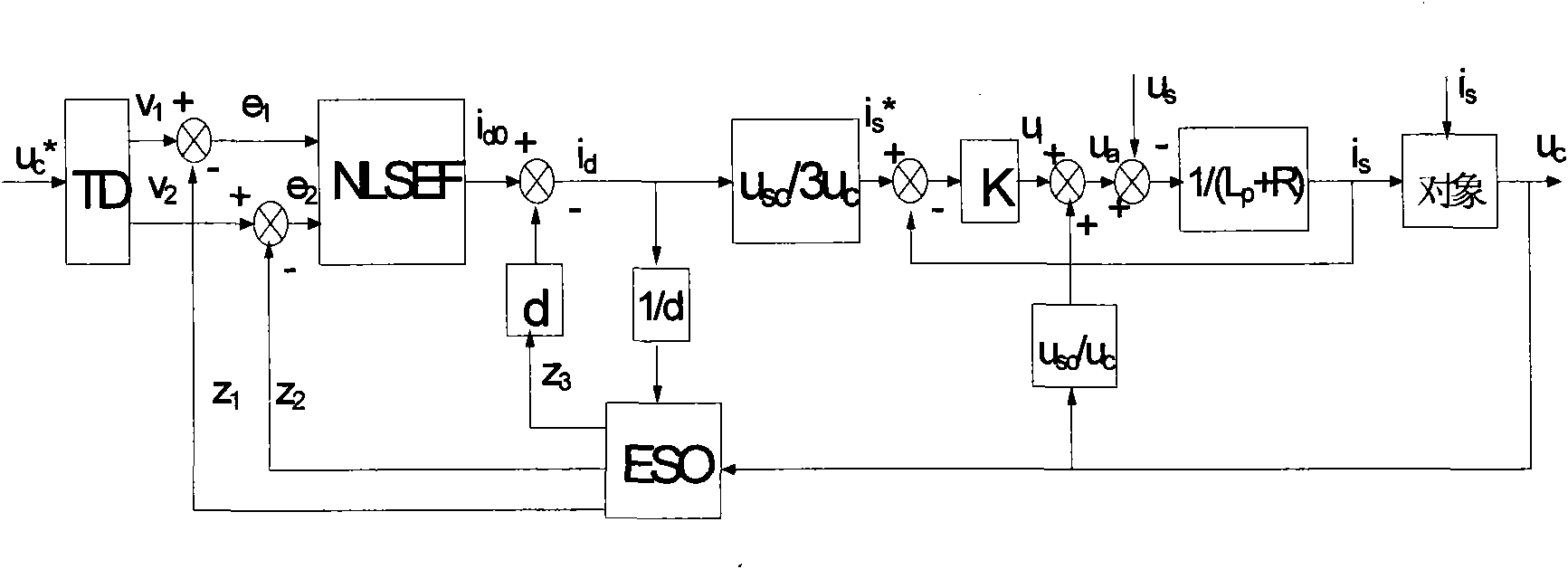

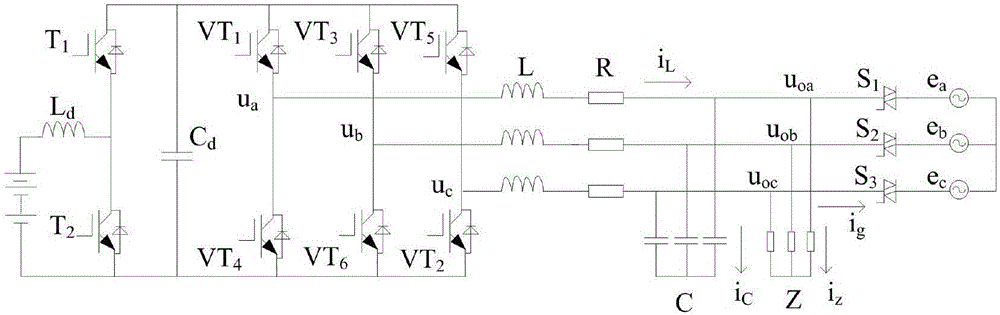

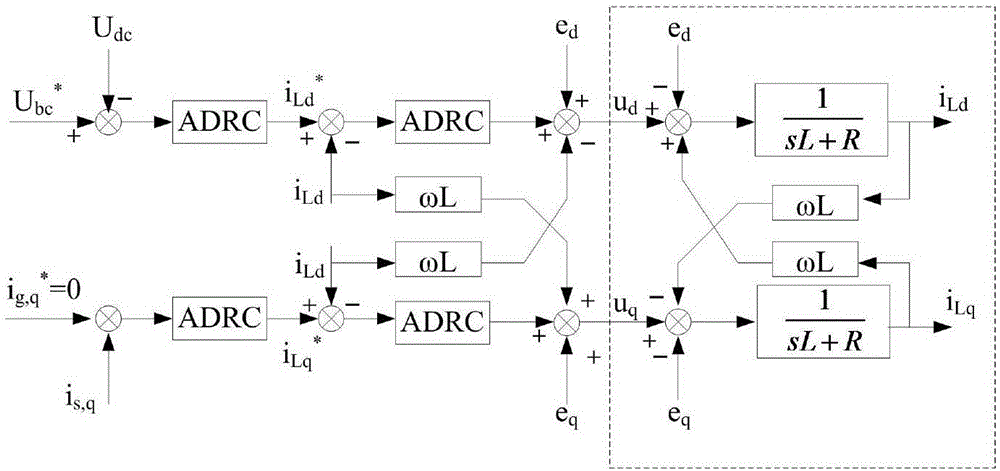

The invention provides an active disturbance rejection control-based method for controlling synchronization of a photovoltaic power generation system. The photovoltaic power generation system is a non-linear system, influenced by power grid and environment and strongly disturbed by the outside and has nonlinear uncertain factors. According to the work characteristics of the system, the active disturbance rejection control technology is adopted to realize effective control of the system. The system dynamically observes the uncertain factors in the system model and external disturbance by utilizing an extended state observer of an active disturbance rejection controller (ADRC) to ensure that the system has good adaptability to disturbance, can adapt to changes of an object model and the surrounding environment in a large range without influencing the control quality of the controller, and represents well robustness.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

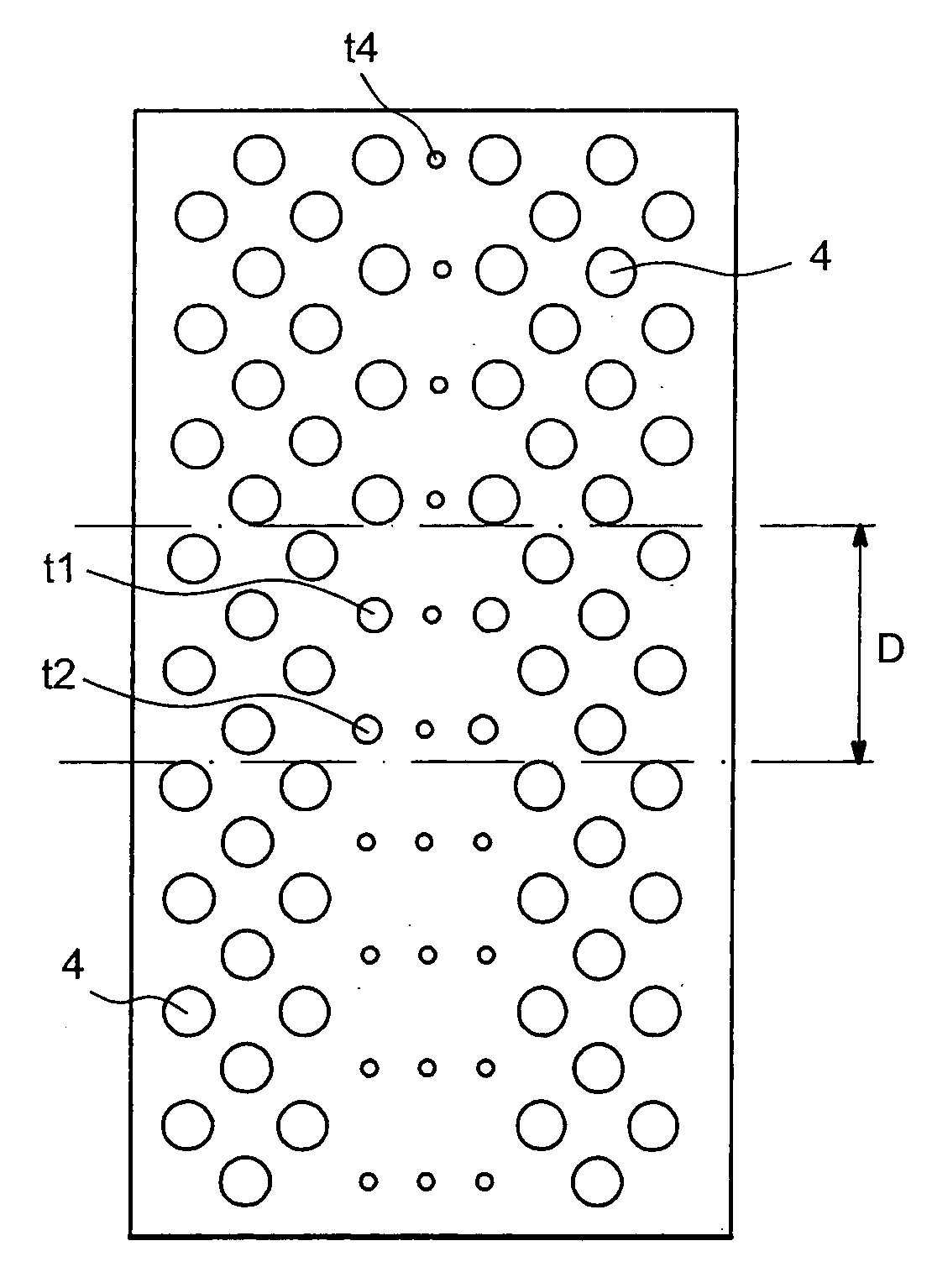

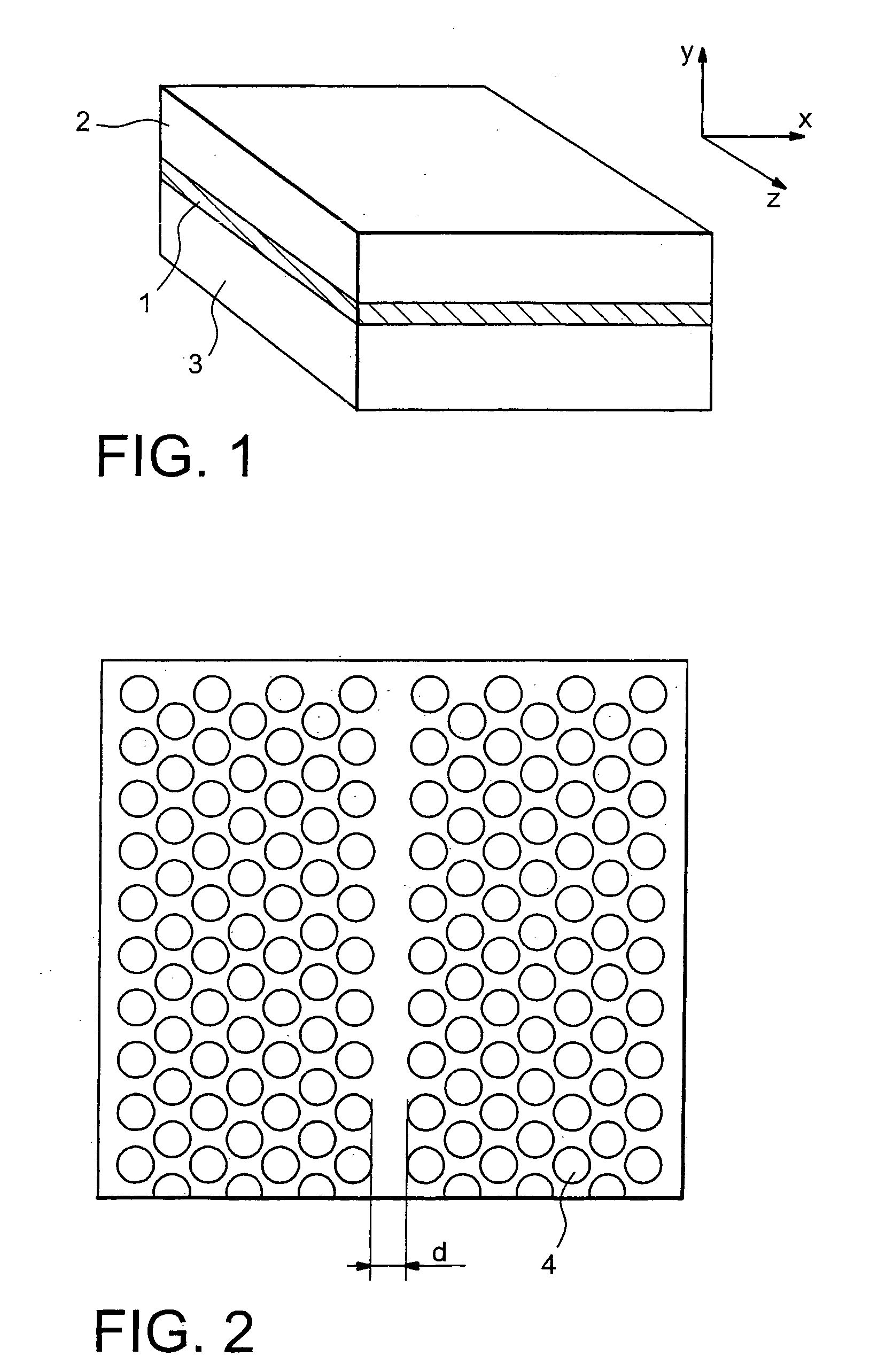

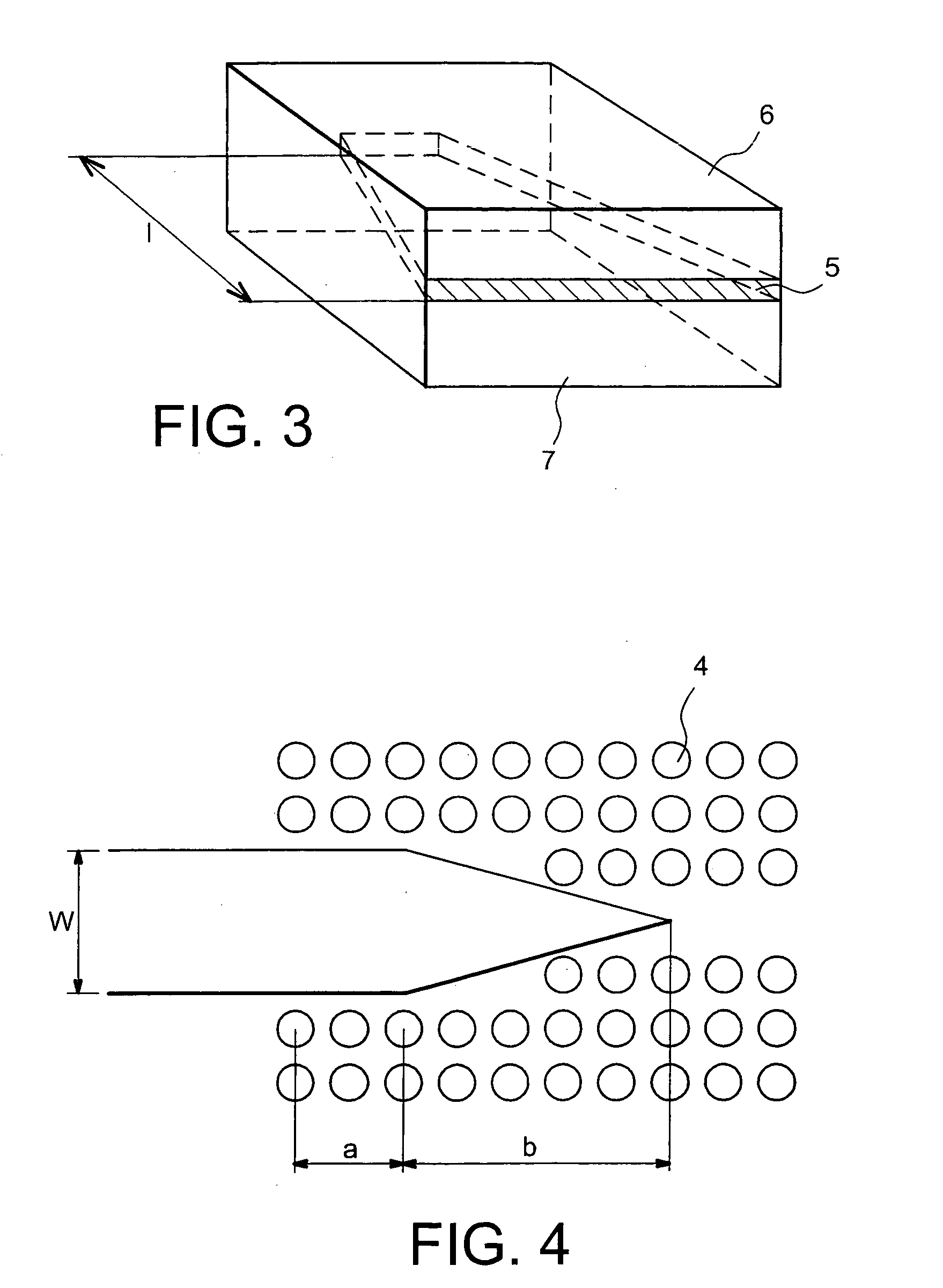

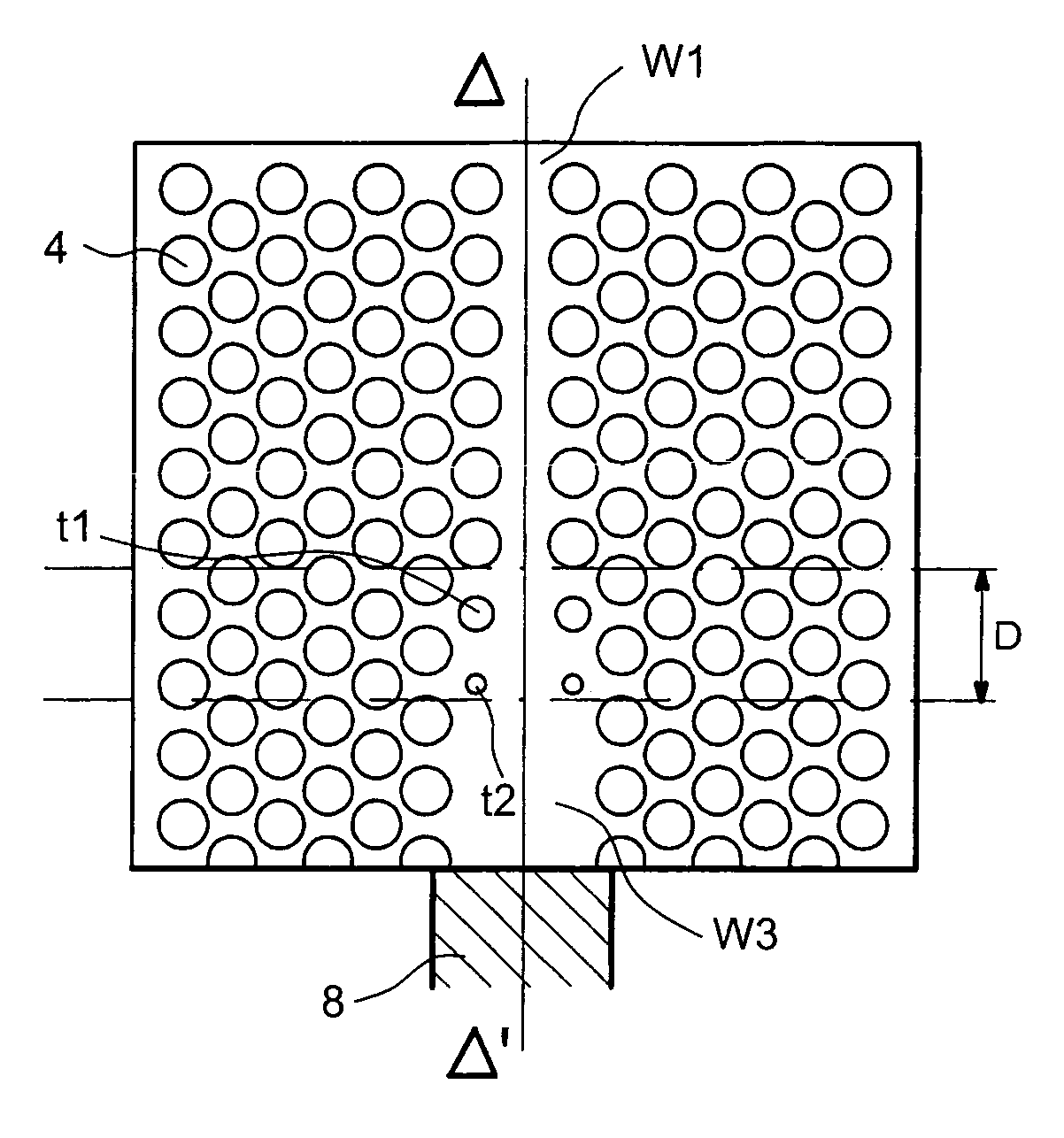

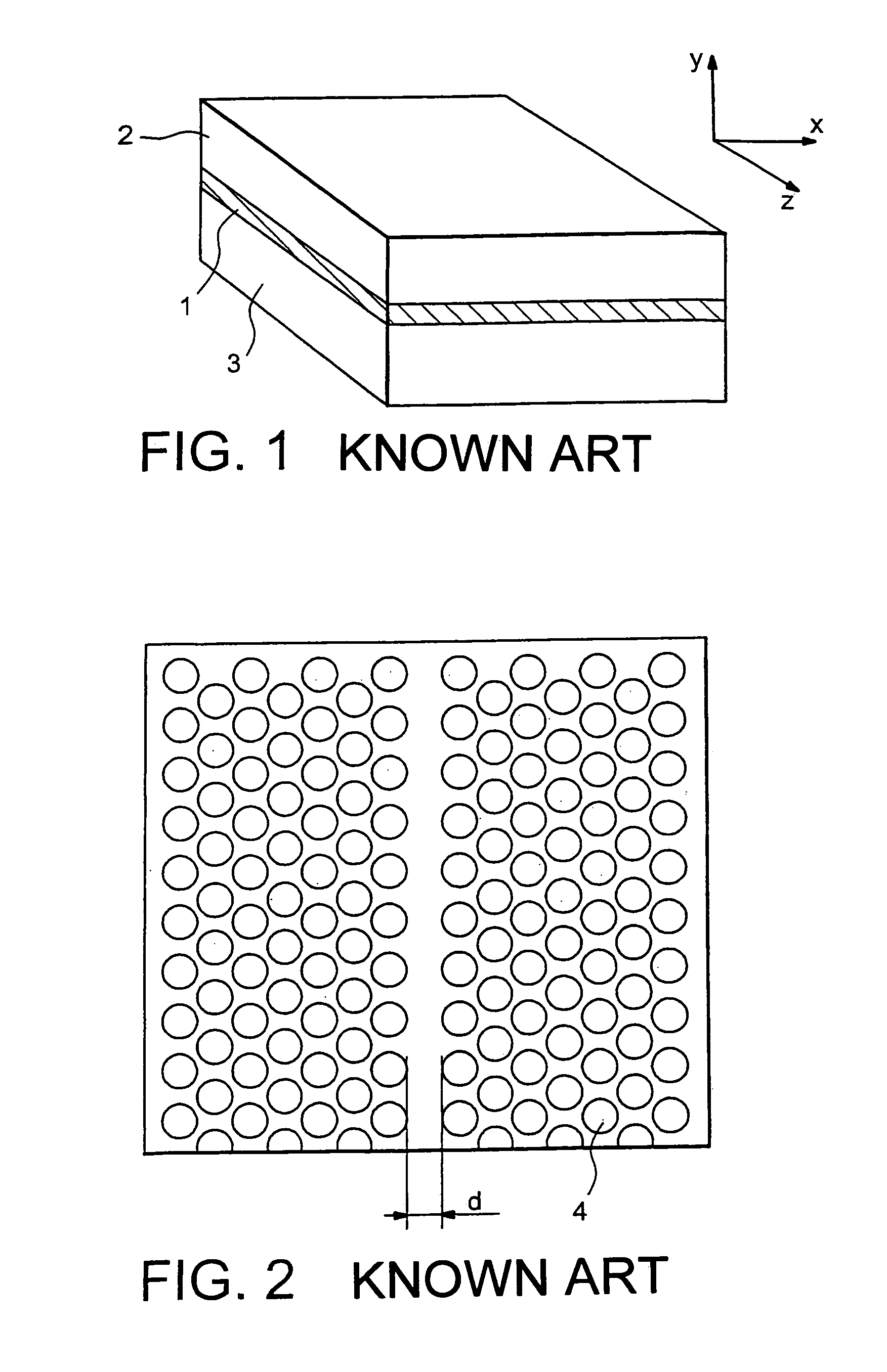

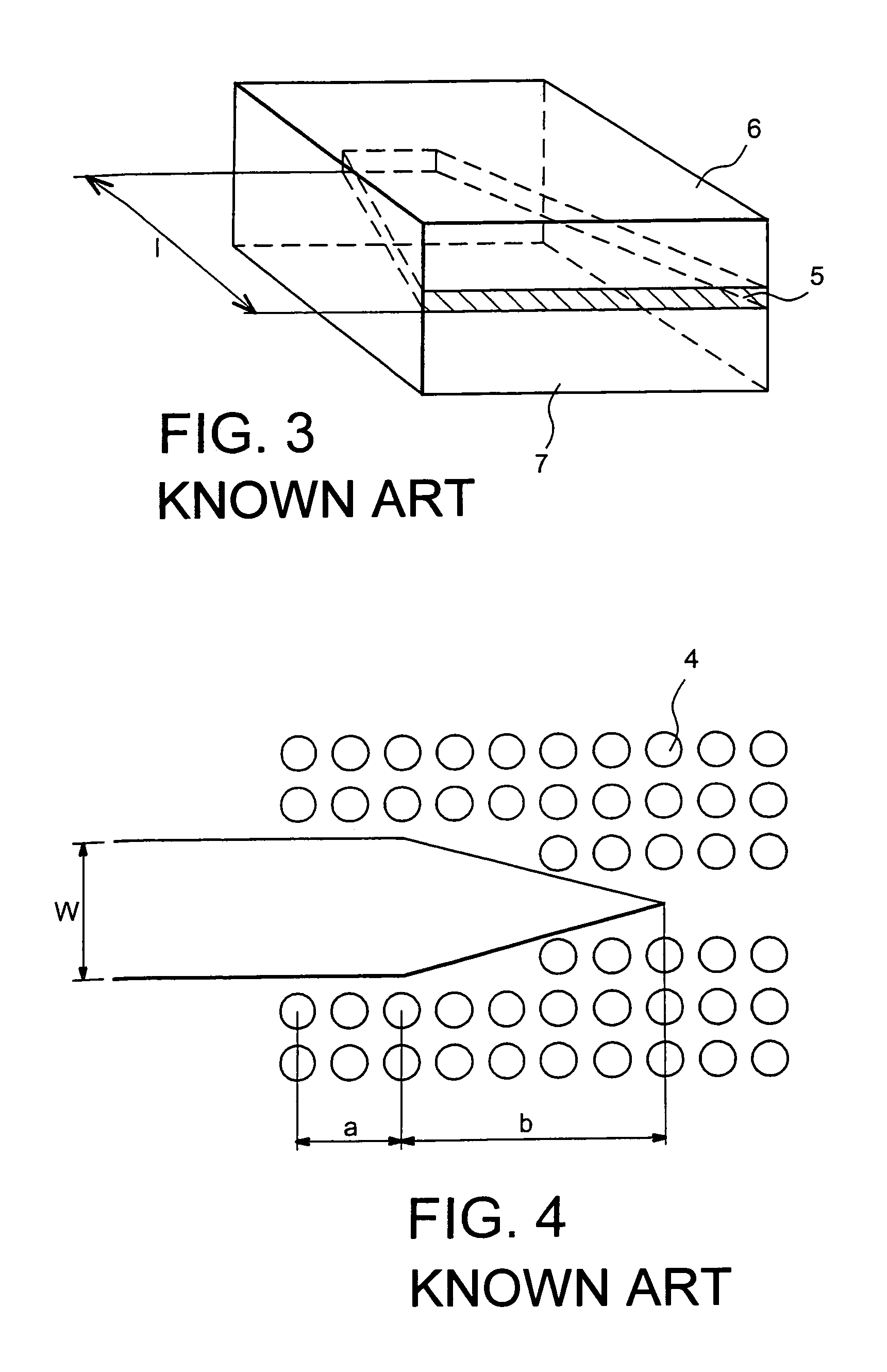

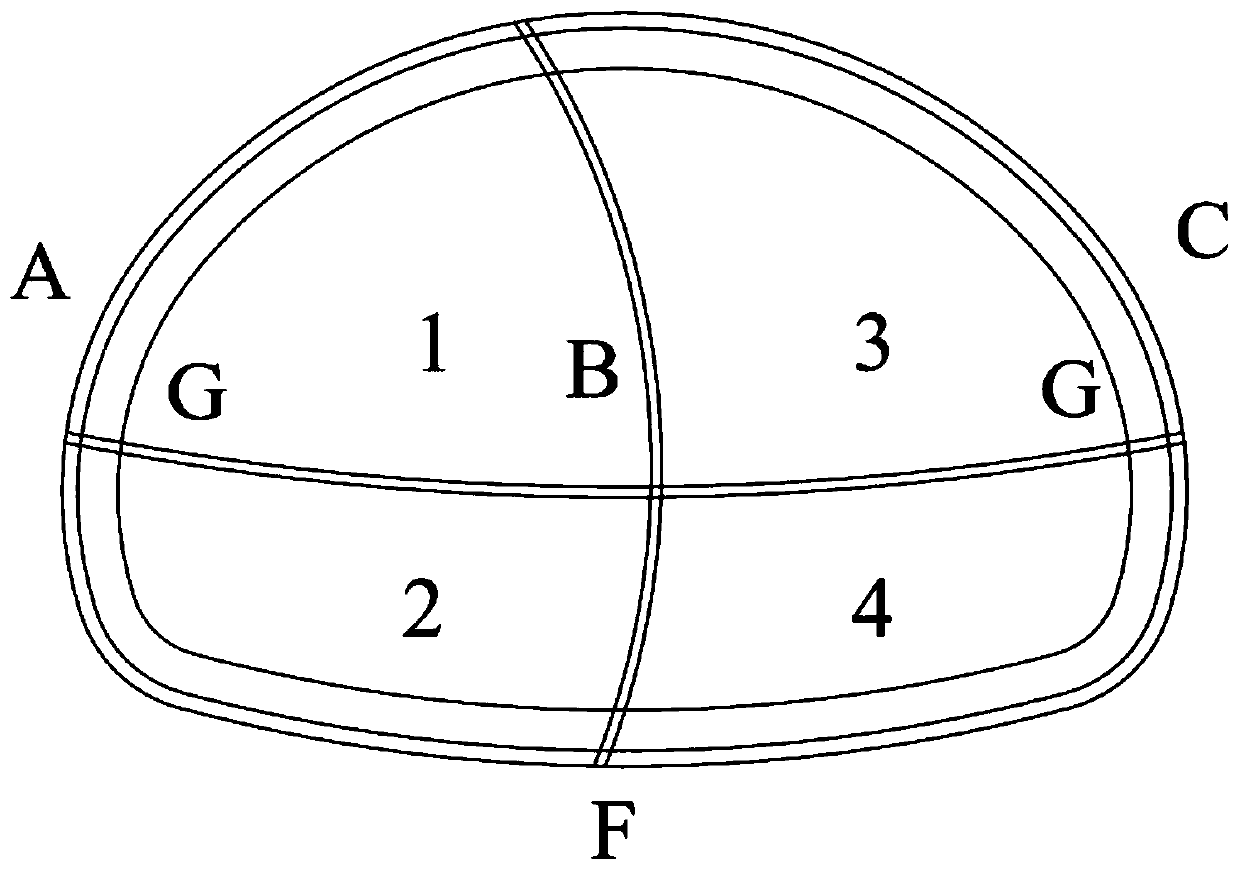

Photonic crystal structure for mode conversion

InactiveUS20050152656A1Short transitionReduce lossNanoopticsCoupling light guidesCrystal structurePhotonic crystal structure

A photonic crystal guided propagation structure. The structure includes a guide portion Wn, n being a positive real number or zero number, having a first configuration of rows of patterns, and a guide portion Wm, m being a real number, m>n, having a second configuration of rows of patterns, and a transition zone of distance D located between guide portion Wn and guide portion Wm, in which patterns aligned with at least one row of patterns in the first configuration decrease in size over distance D to allow progressive passing from the first configuration of rows of patterns to the second configuration of rows of patterns. The structures can be applied to the area of integrated optics (semiconductor lasers, laser modulators, filters, multiplexors, etc.).

Owner:CENT NAT DE LA RECHERCHE SCI

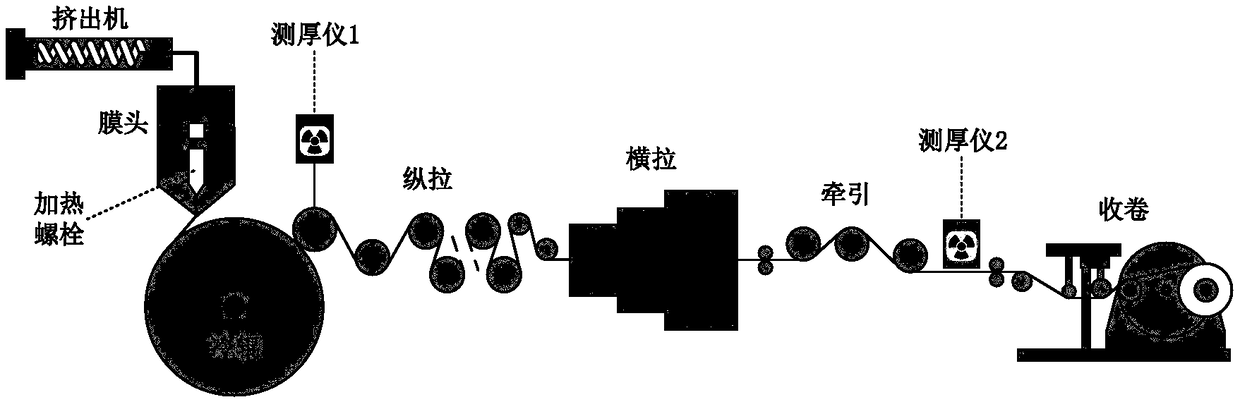

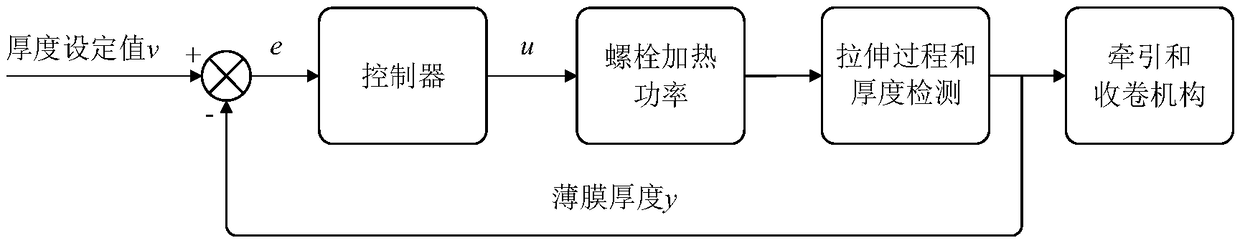

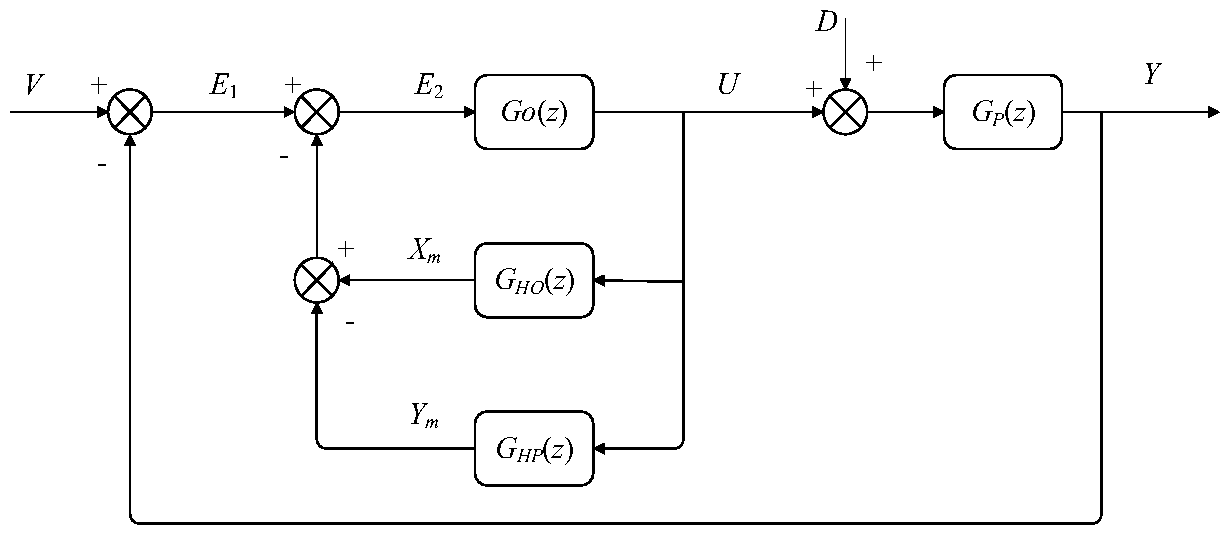

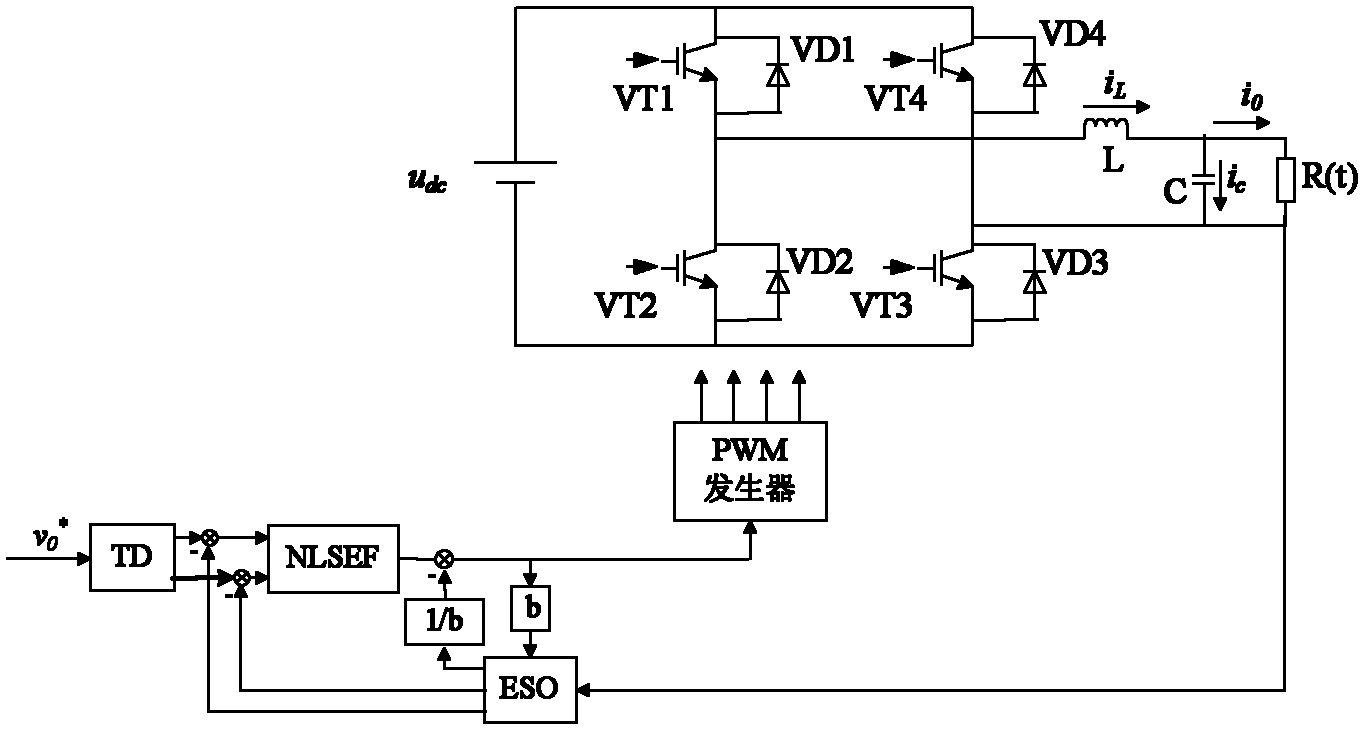

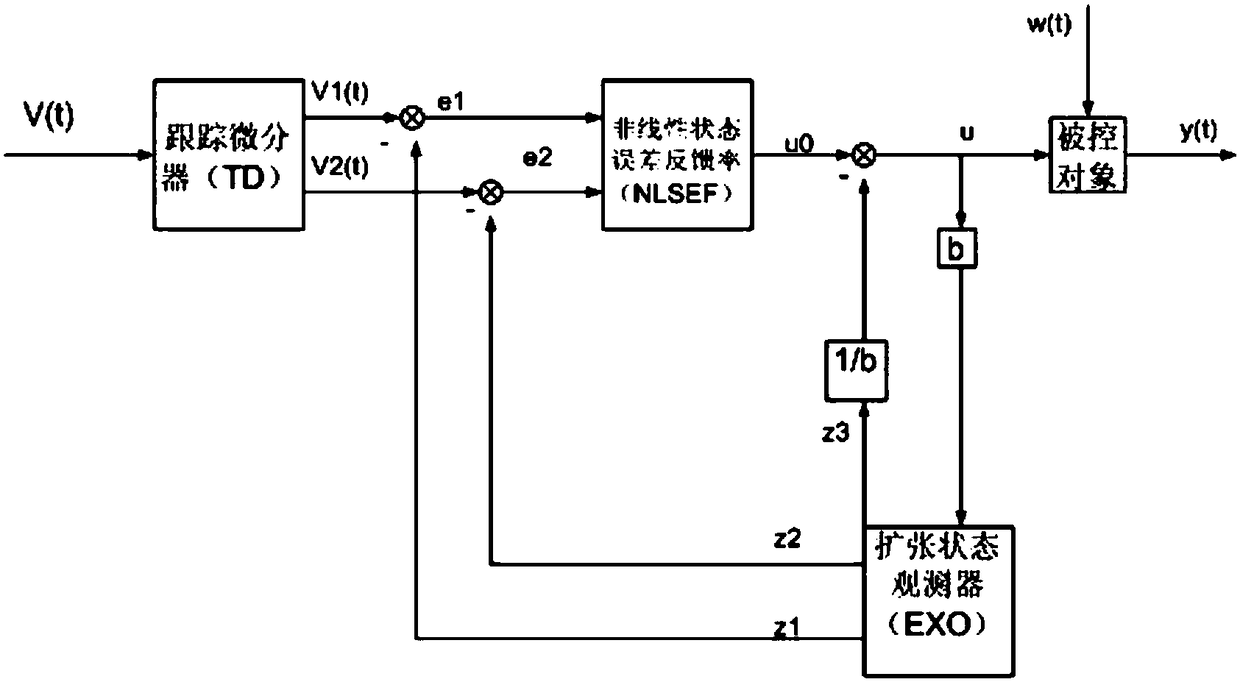

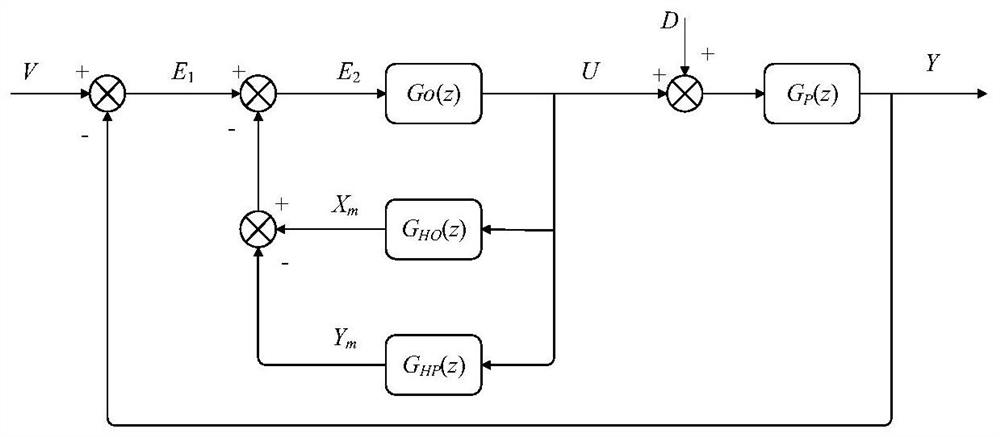

Fast self-learning improved ADRC control method for non-linear system

ActiveCN109143863AQuick responseImprove controlAdaptive controlDifferentiatorActive disturbance rejection control

The invention discloses a fast self-learning improved ADRC control method for a non-linear system, which comprises the following steps: S1, creating an active disturbance rejection controller (ADRC) which includes a tracking differentiator (TD) part, an extended state observer (ESO) part, a non-linear state error feedback (NLSEF) part and a disturbance compensation part, wherein S1 includes S11, establishing a tracking differentiator (TD) control model, S12, establishing an extended state observer (ESO) control model, S13, establishing a non-linear state error feedback (NLSEF) control model, and S14, establishing a disturbance compensation control model; S2, creating a self-learning active disturbance rejection controller (SADRC): applying a self-learning method to the non-linear state error feedback (NLSEF) control model to establish a self-learning non-linear active disturbance rejection control system model; and S3, creating a fast self-learning active disturbance rejection controller (FSADRC): designing a learning rate oriented adaptive mechanism by using an additional momentum term method and establishing a fast self-learning model based on dynamic adaptive learning rate.

Owner:WUHAN UNIV OF SCI & TECH

Photonic crystal structure for mode conversion

InactiveUS7242837B2Short transitionReduce lossNanoopticsCoupling light guidesPhotonic crystal structureCrystal structure

A photonic crystal guided propagation structure. The structure includes a guide portion Wn, n being a positive real number or zero number, having a first configuration of rows of patterns, and a guide portion Wm, m being a real number, m>n, having a second configuration of rows of patterns, and a transition zone of distance D located between guide portion Wn and guide portion Wm, in which patterns aligned with at least one row of patterns in the first configuration decrease in size over distance D to allow progressive passing from the first configuration of rows of patterns to the second configuration of rows of patterns. The structures can be applied to the area of integrated optics (semiconductor lasers, laser modulators, filters, multiplexors, etc.).

Owner:CENT NAT DE LA RECHERCHE SCI

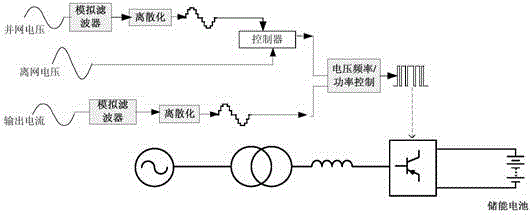

Grid-connection and off-grid seamless switching control method for energy storage inverter

InactiveCN106208147ASimple designAccelerated disengagementSingle network parallel feeding arrangementsMicrogridClosed loop

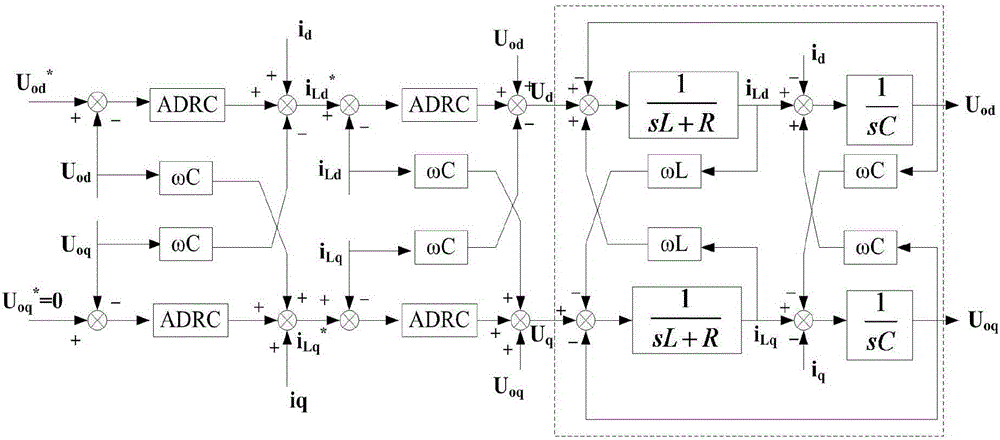

The invention discloses a grid-connection and off-grid seamless switching control method for an energy storage inverter, and relates to the field of a microgrid or a distributed type power generation system. A control system and an energy storage apparatus are included; when the inverter is in a grid-connection state, a dual-closed-loop feedforward decoupling control system (ADRC control) is adopted; when the inverter is in an off-grid state, a load end voltage is maintained by the inverter, and the dual-closed-loop feedforward decoupling control system (ADRC control) is adopted; and when the inverter is between the grid-connection state and the off-grid state, the switching process is performed in three stages, and automatic seamless switch between the grid-connection state and the off-grid state is performed. The grid-connection and off-grid seamless switching control method has the beneficial effects that the hardware apparatus is simple to design, and the software programming is popular and easy to understand; different ways are adopted for active off-grid switching, passive off-grid switching and grid-connection switching with initial phase difference, so that seamless and non-impact switching is realized; in addition, high-speed data calculation capacity and data handling capacity of a computer are utilized, thereby greatly improving the reliability of the control system.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

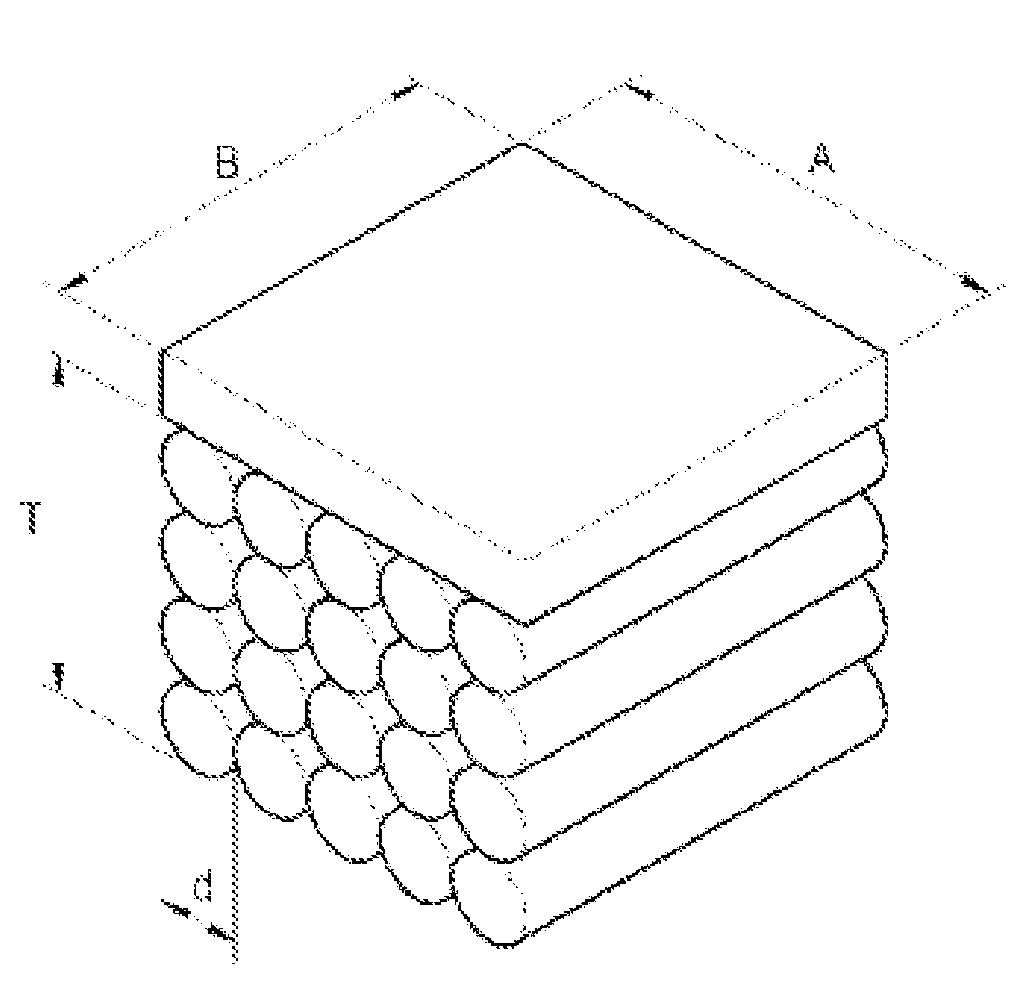

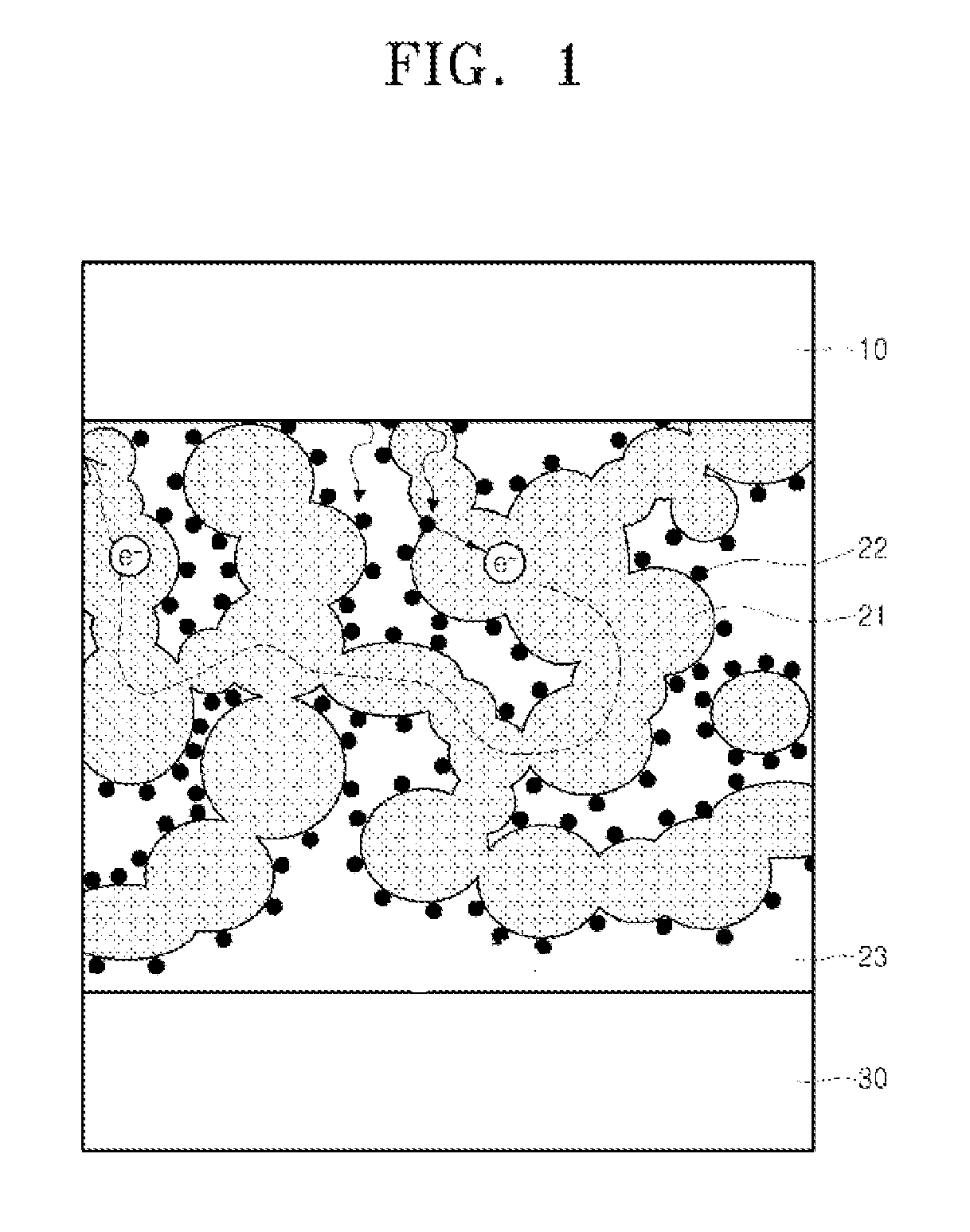

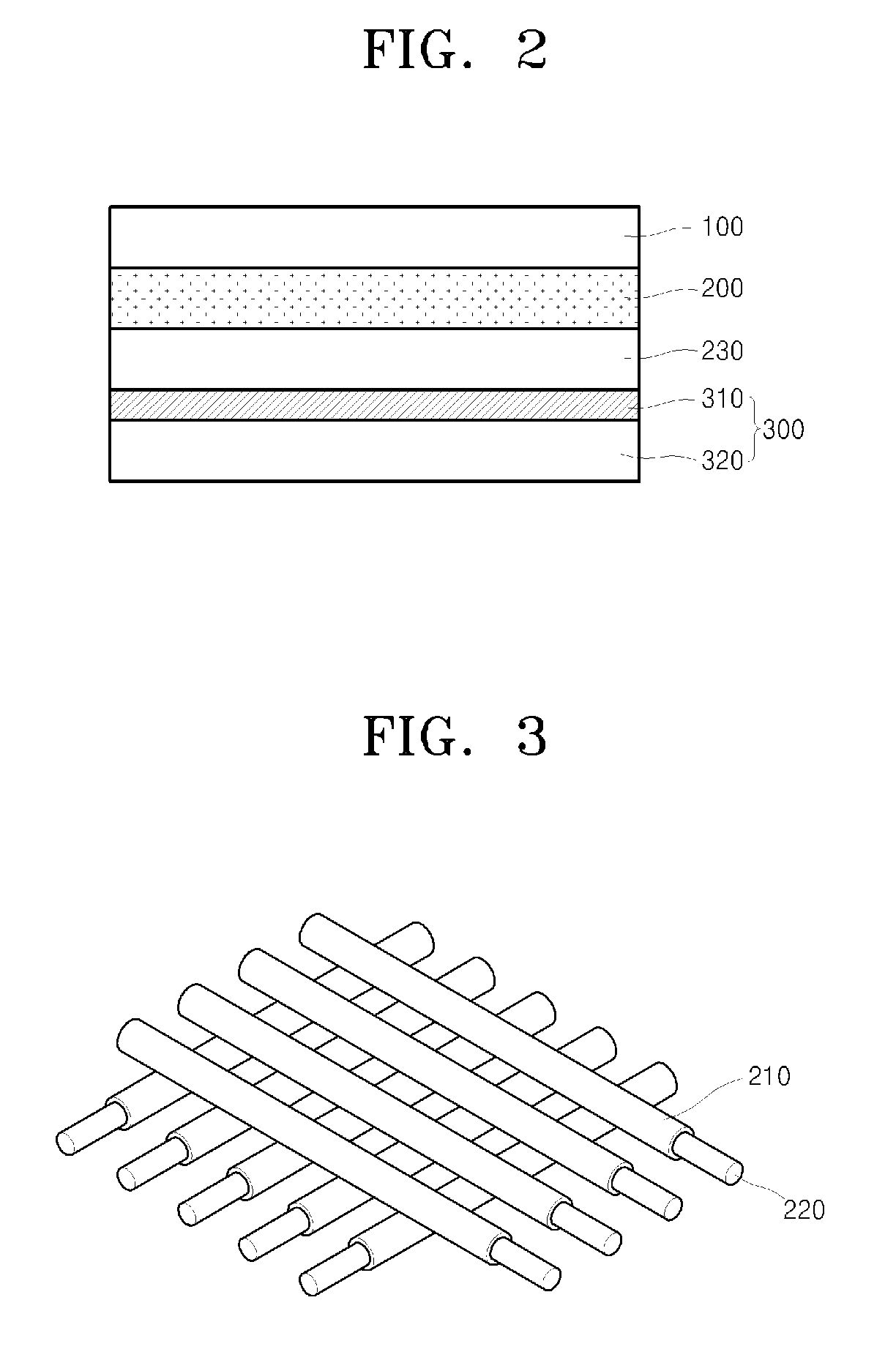

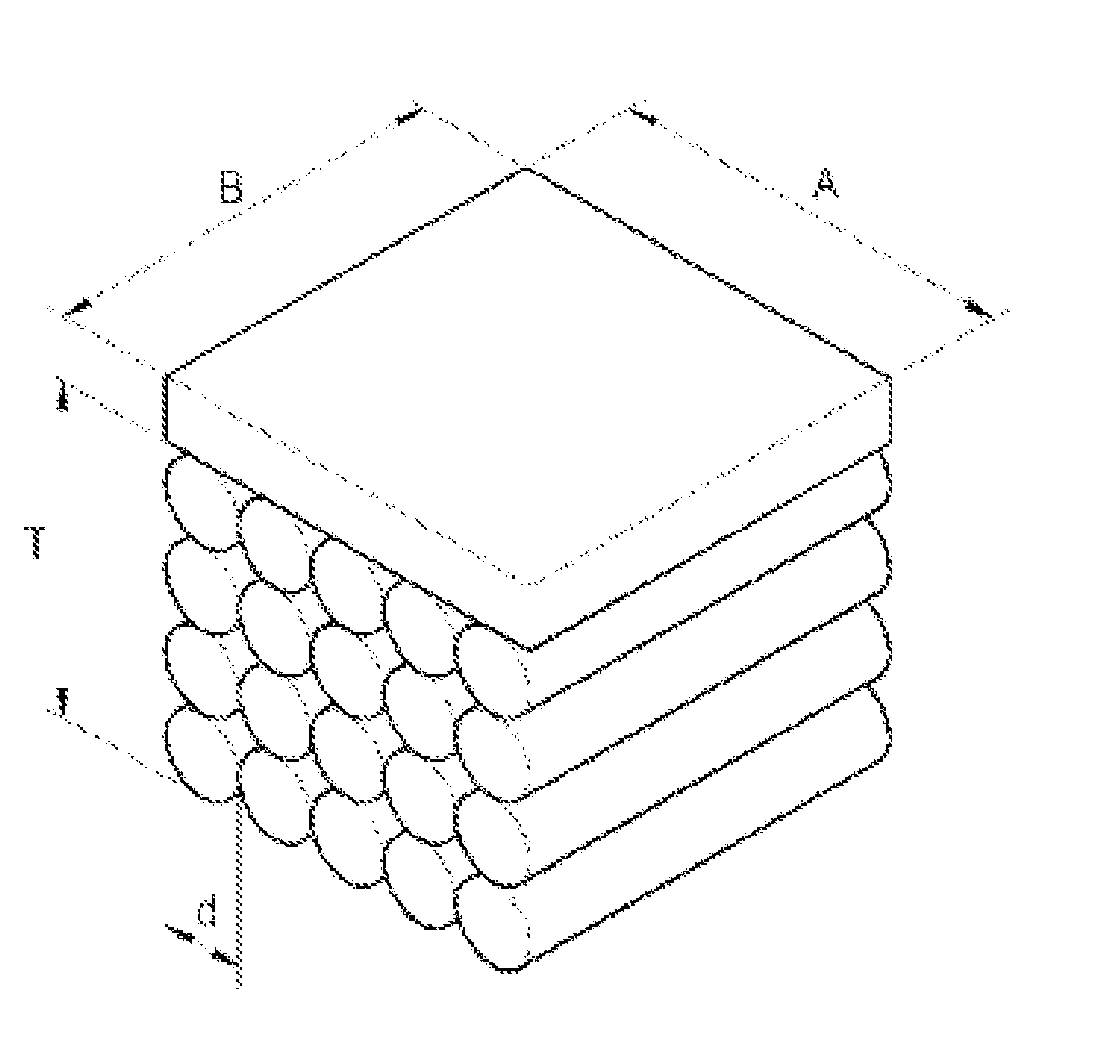

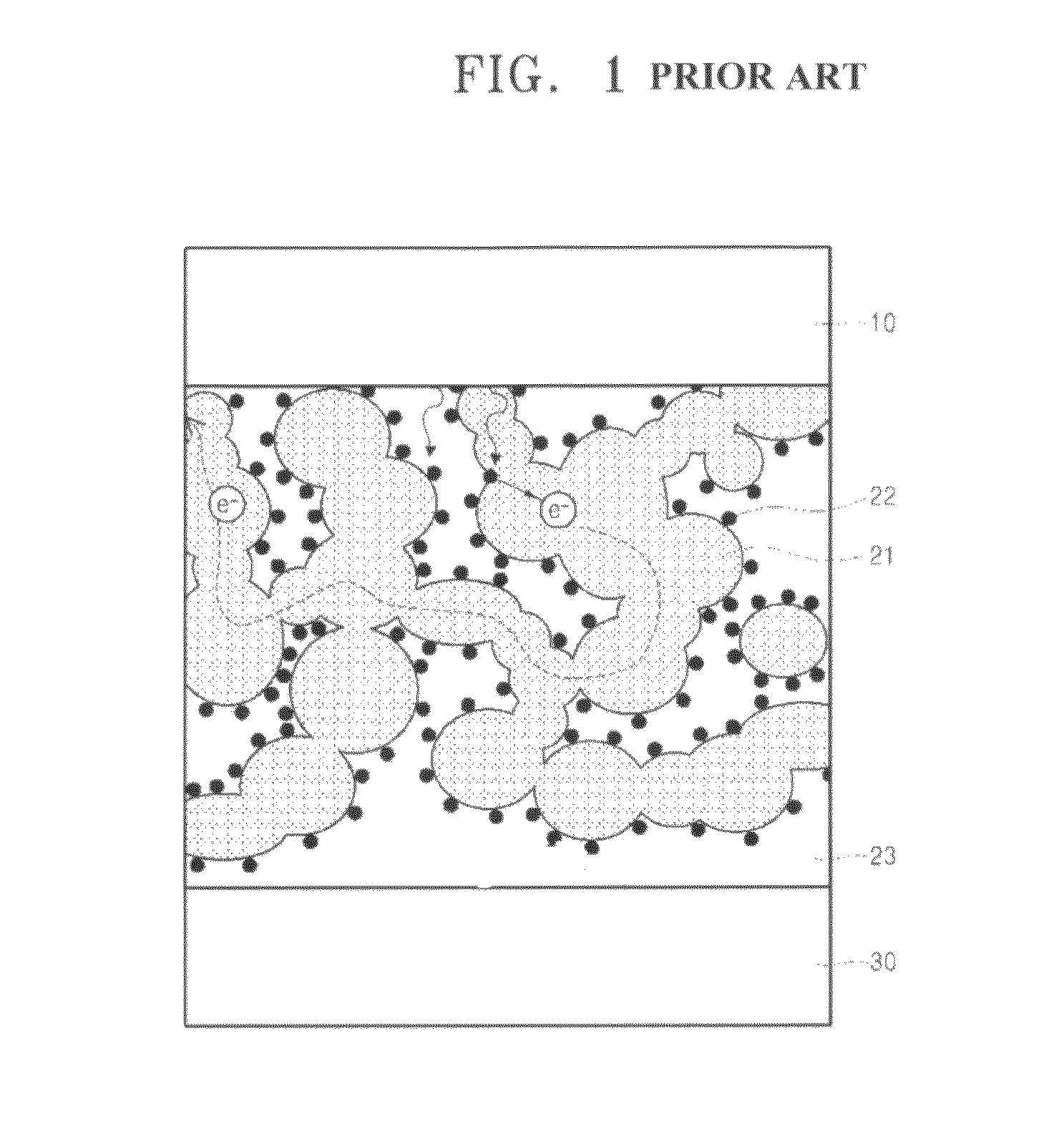

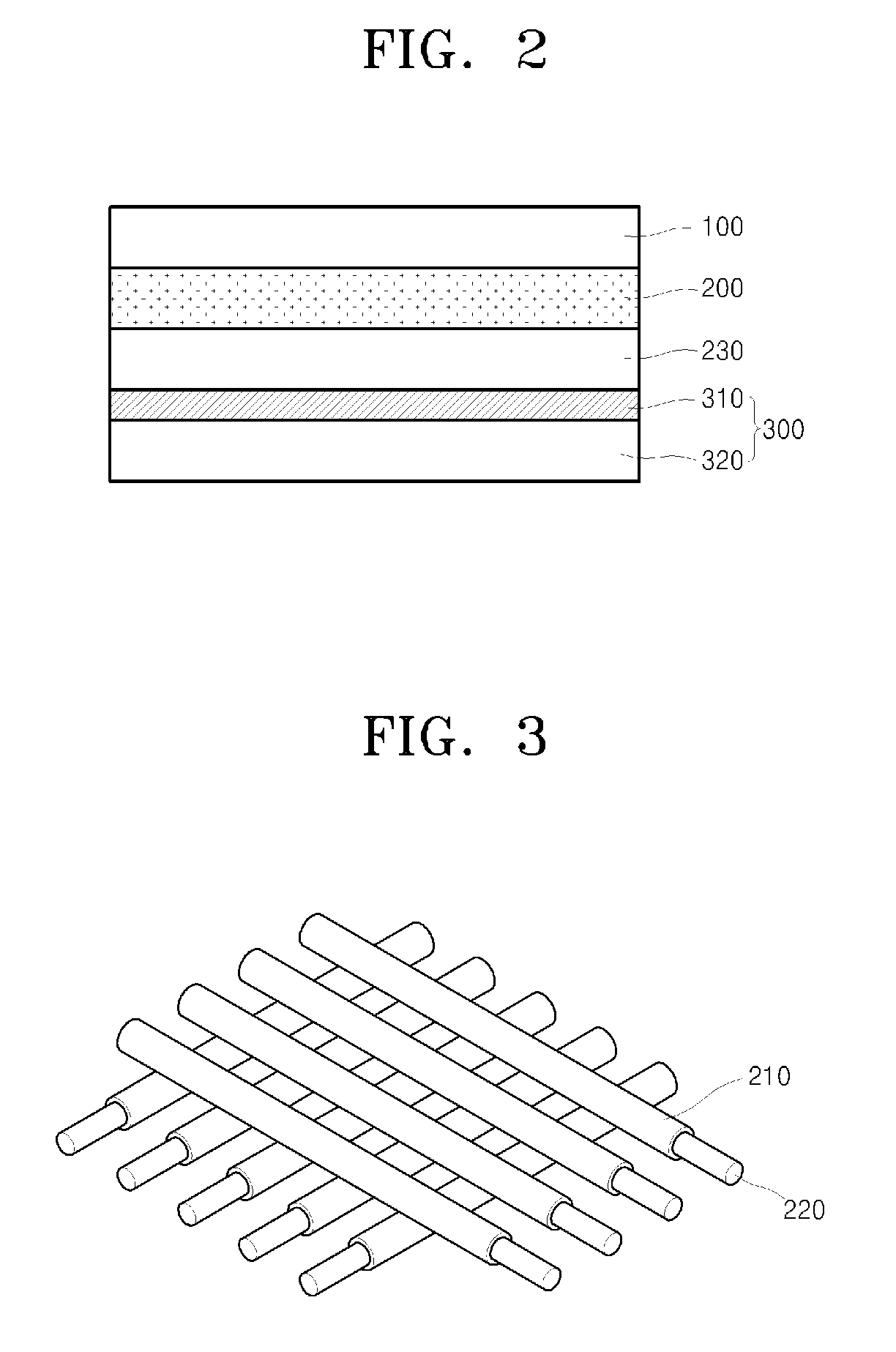

Dye-sensitized solar cell using conductive fiber electrode

InactiveUS20090126784A1Good energyIncrease flexibilityElectrolytic capacitorsFinal product manufactureFiberNanoparticle

Provided is a dye-sensitized solar cell including a flexible electrode. The dye-sensitized solar cell includes: first and second electrodes facing each other, and an electrolyte layer interposed between the first and second electrodes, wherein the first electrode comprises a structure formed of conductive fibers, a nano-particle semiconductor oxide layer formed on a surface of the structure of the conductive fibers, and dye molecules adsorbed in the nano-particle semiconductor oxide layer.

Owner:ELECTRONICS & TELECOMM RES INST

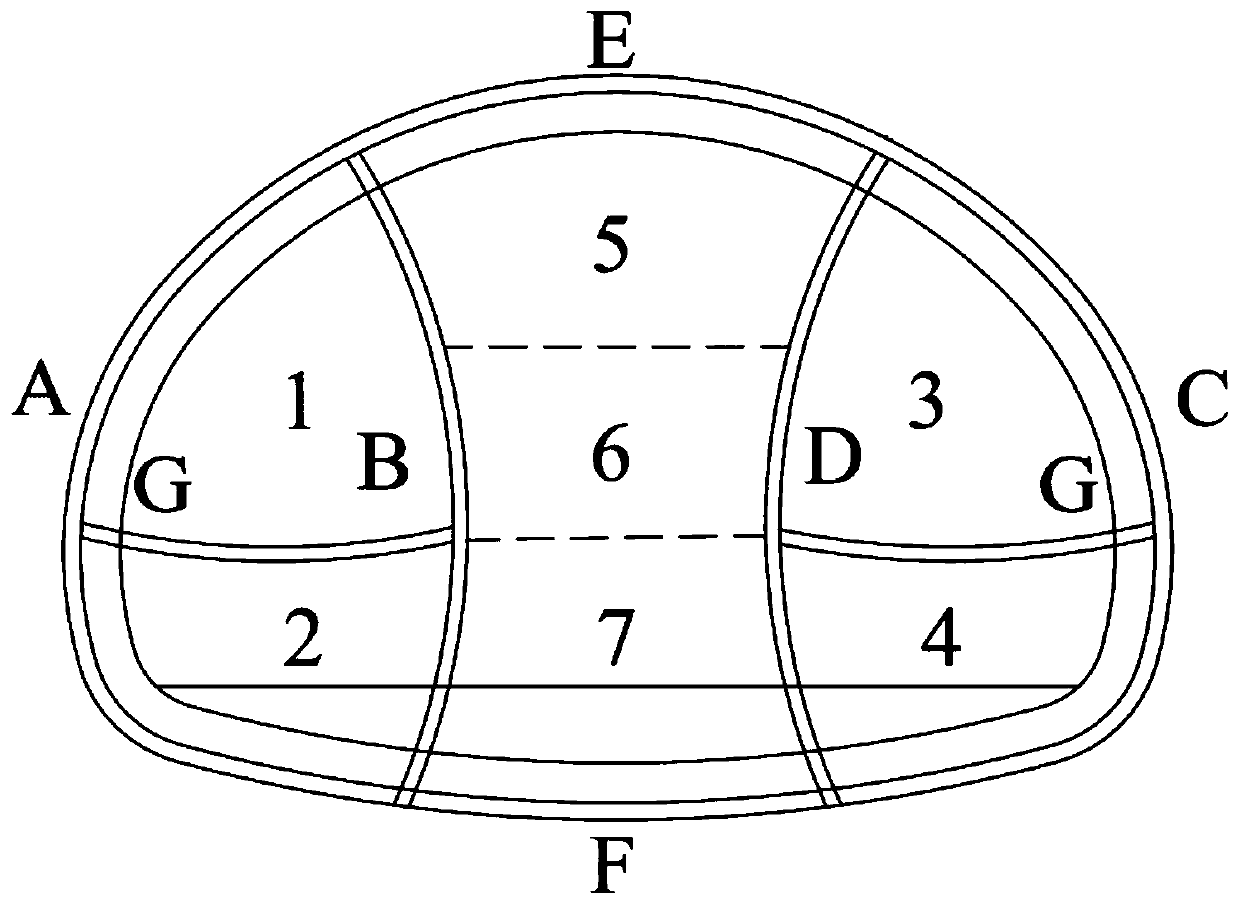

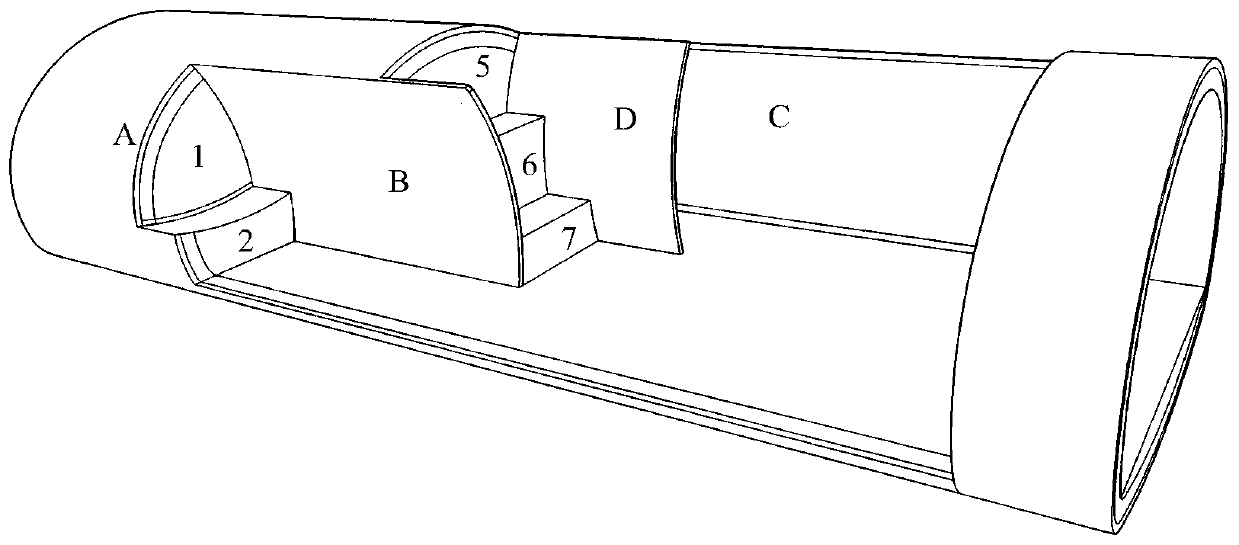

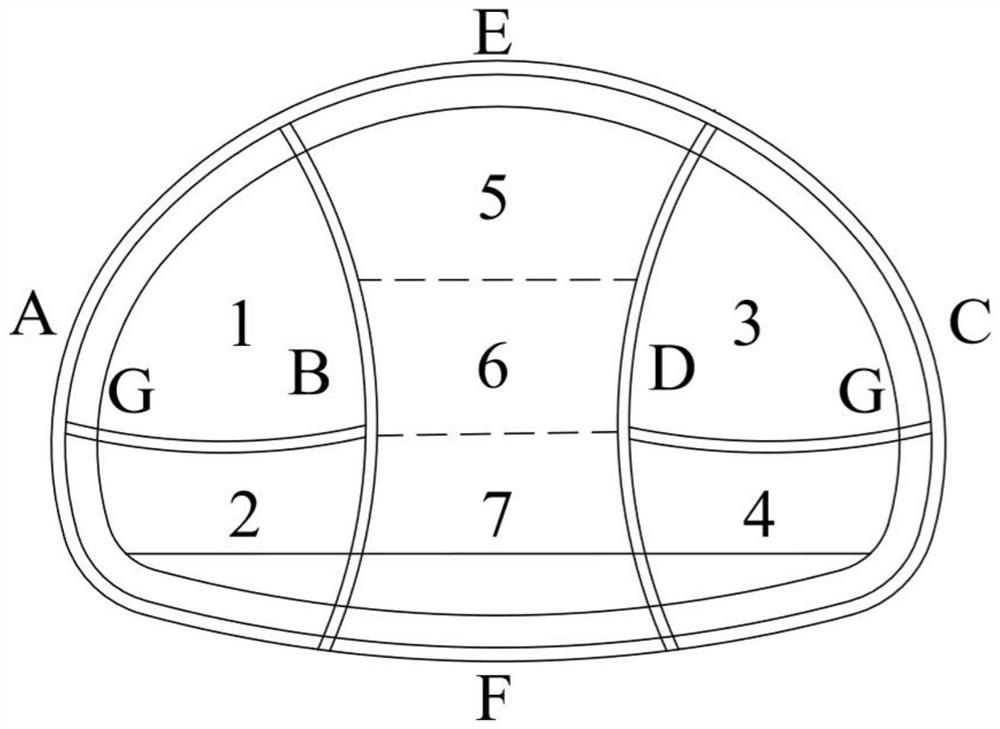

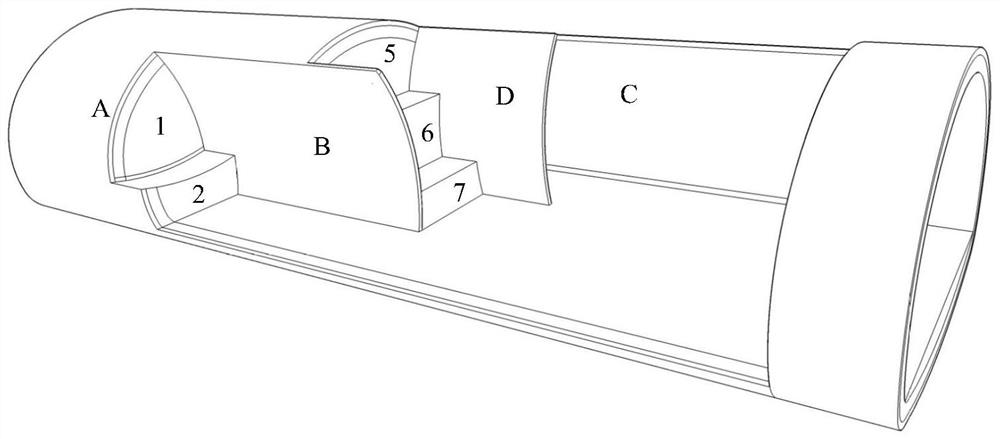

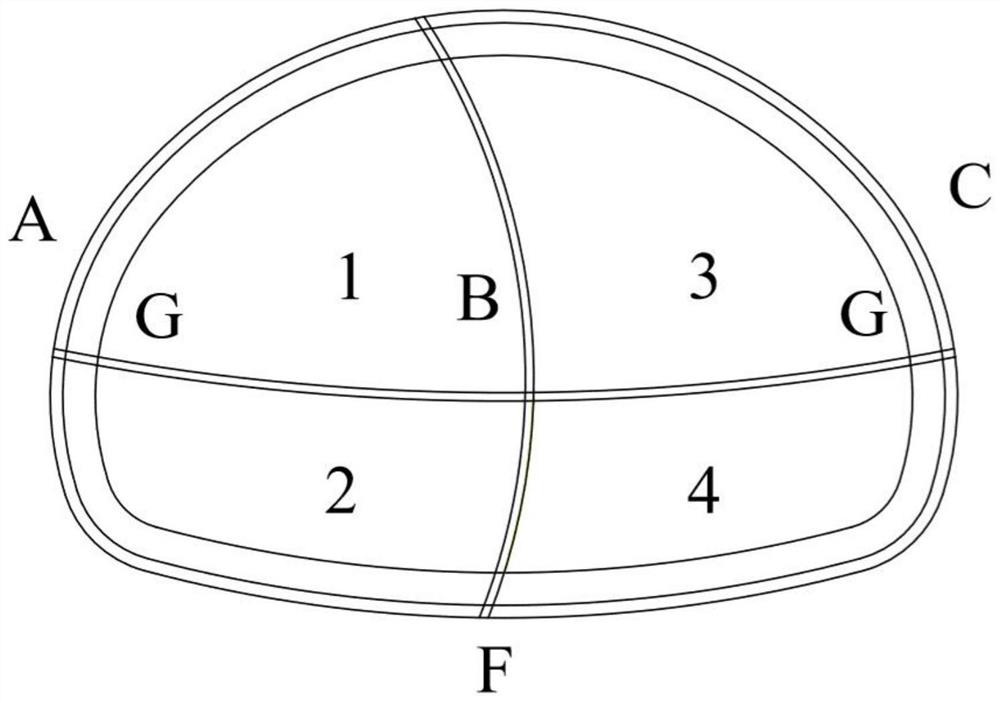

Construction method conversion construction method of super-large-span tunnel in V-level to IV-level surrounding rock section

ActiveCN109989757AReduce disturbanceAvoid intervalsUnderground chambersTunnel liningTunnel constructionBuilding construction

The invention discloses a construction method conversion construction method of a super-large-span tunnel in a V-level to IV-level surrounding rock section. The elevation of an excavation arching lineis controlled to be consistent; in transition section construction, a left pilot tunnel temporary middle wall and a right pilot tunnel temporary middle wall on the two sides of a pilot and a rear pilot in a surrounding rock double-side-wall pilot tunnel method simultaneously move towards the middle of the tunnel until the left pilot tunnel temporary middle wall is in contact with the right pilottunnel temporary middle wall, and foot locking anchor rods are applied to the two sides of a temporary inverted arch; and then the right pilot tunnel temporary middle wall is removed, and the left pilot tunnel temporary middle wall is reserved as a middle temporary middle wall of a CRD method. According to the method, a double-side-wall pilot tunnel method is transversely transited to the CRD method through a gradual change method, the time interval between construction method conversion is avoided, and disturbance of later removal of temporary supports of the double-side-wall pilot tunnel method to surrounding rock is reduced; and therefore the construction speed is increased, the construction period is shortened, enforced idleness due to poor organization of work is avoided, and economicbenefits of tunnel construction are improved.

Owner:CHANGAN UNIV

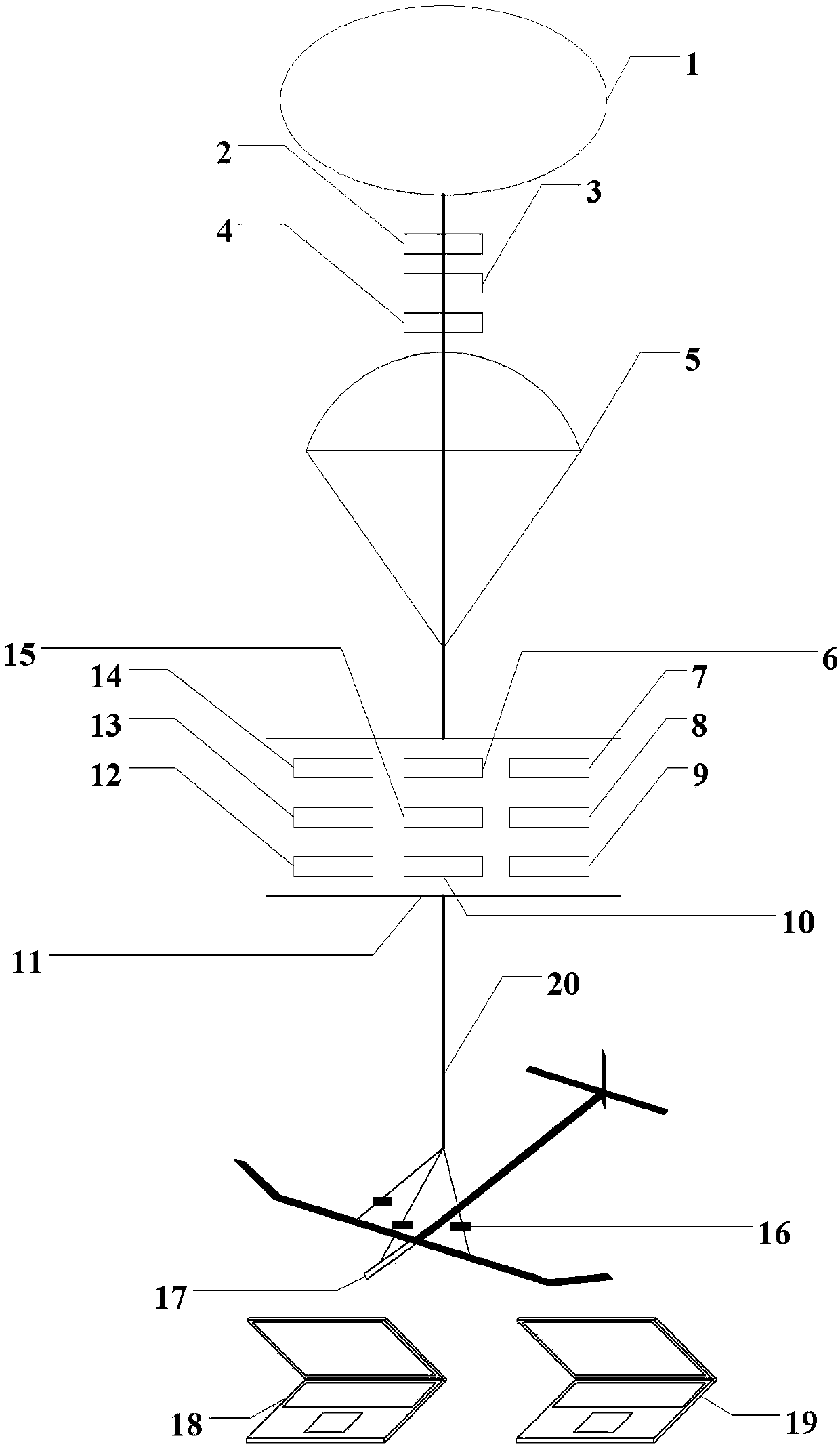

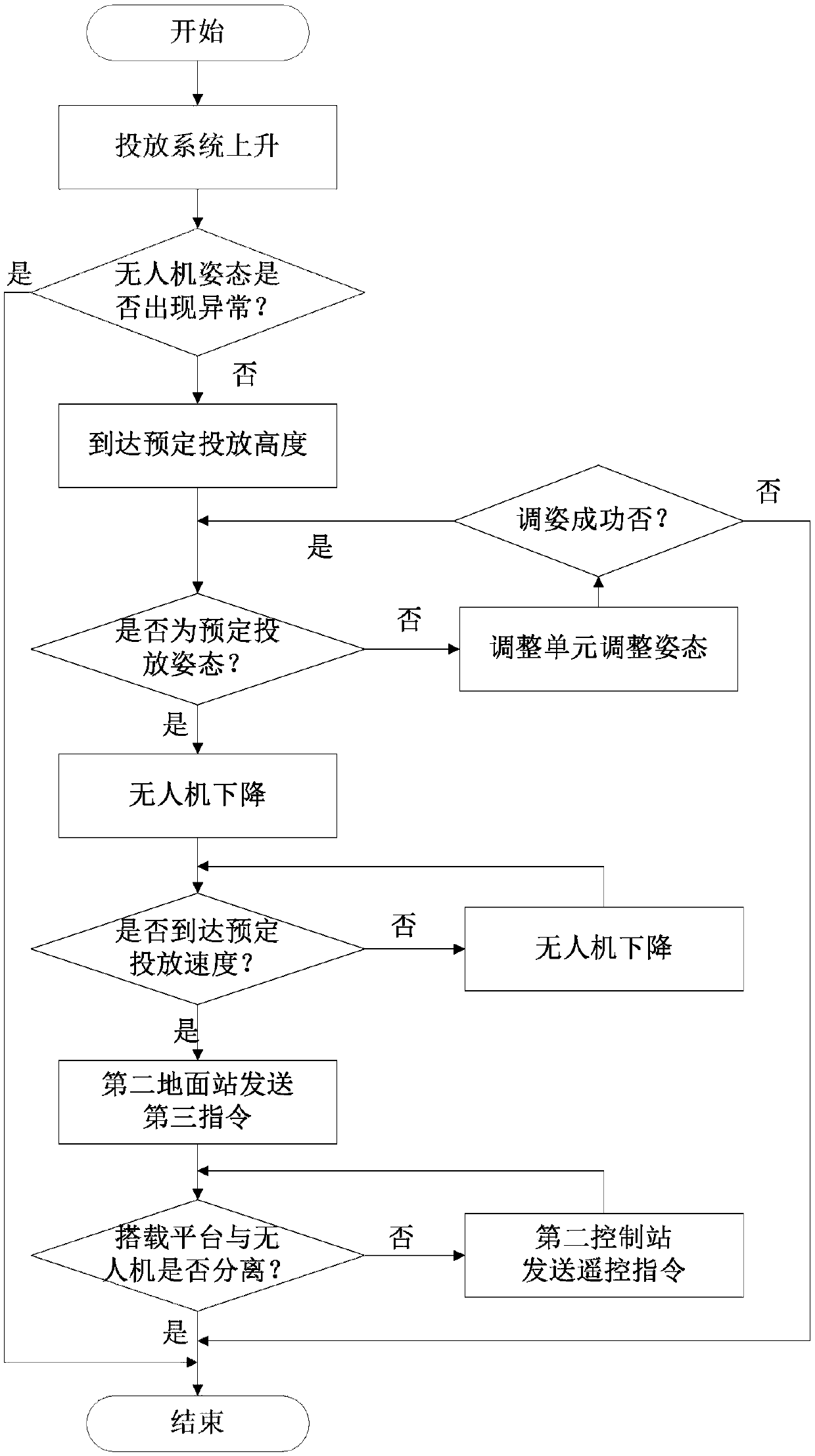

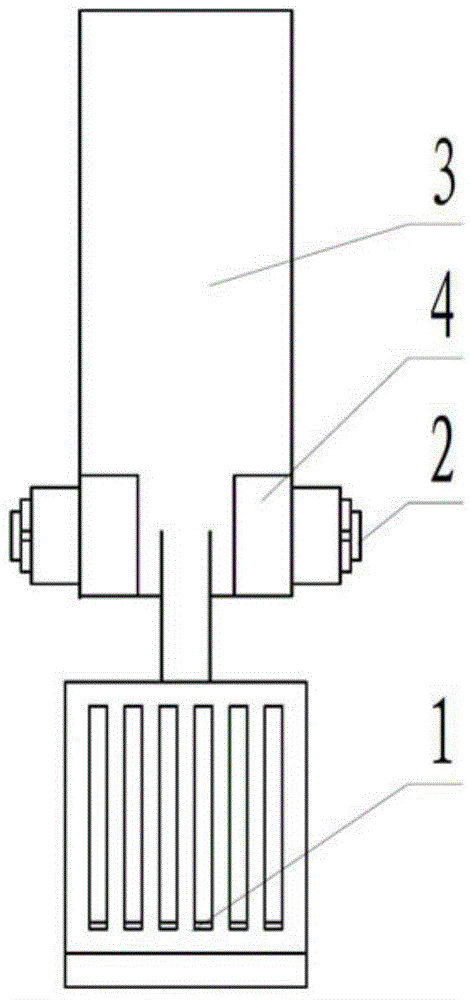

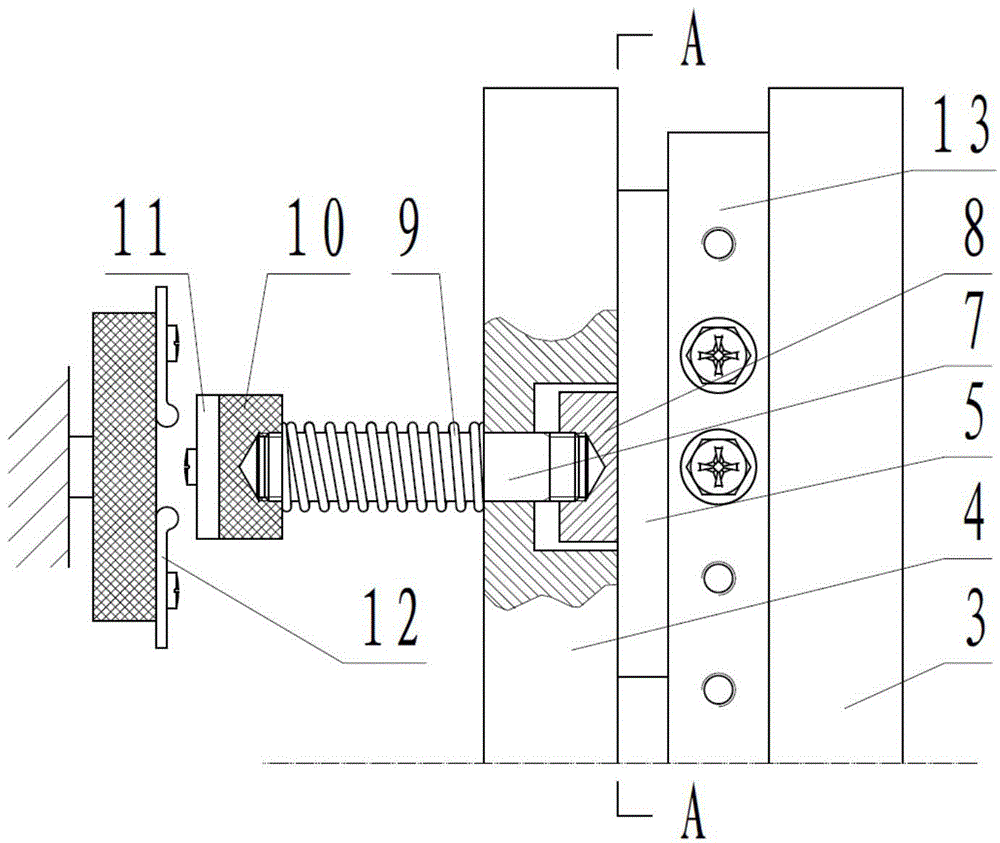

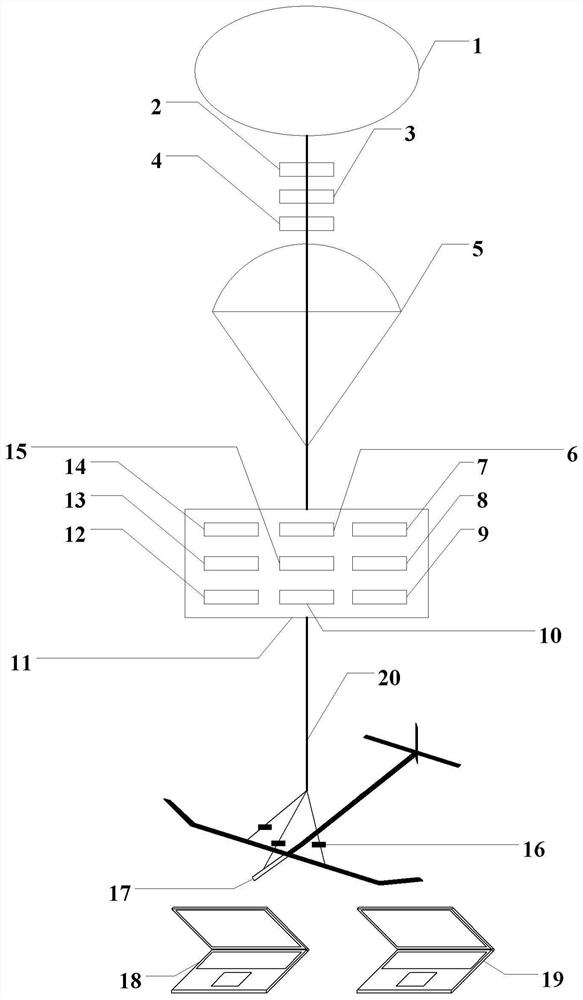

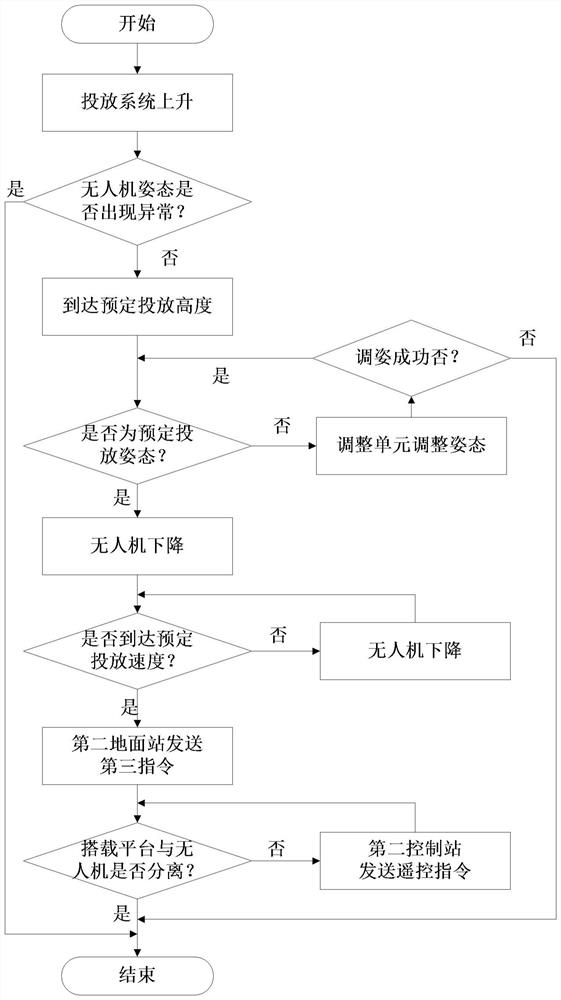

Launching system of unmanned aerial vehicle

ActiveCN108045543AHigh speedEnsure safetyAircraft componentsLighter-than-air aircraftUncrewed vehicleEngineering

The invention provides a launching system of an unmanned aerial vehicle. The launching system comprises a fixing assembly used for hanging fixing of a to-be-launched unmanned aerial vehicle. The unmanned aerial vehicle comprises a nose and two wings. Hanging fixing is conducted in the mode that the fixing assembly is connected with the nose and the two wings so as to form three-point type connection, the nose faces the ground, and a vehicle body is in a predetermined launching posture. The fixing assembly of the launching system and the to-be-launched unmanned aerial vehicle are in three-pointtype connection, and the unmanned aerial vehicle is in the predetermined launching posture when fixed so that the unmanned aerial vehicle can be in the predetermined launching posture more easily when launched, and the number of posture adjusting times is decreased; meanwhile, through the posture, the speed can be further obtained advantageously after the aerial vehicle is released, rapid flareout of the posture of the aerial vehicle is facilitated, the transition process is reduced, and the safety of the aerial vehicle is ensured; and in addition, the launching system is simple in structure,high in safety and reliability, and convenient to apply in engineering.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

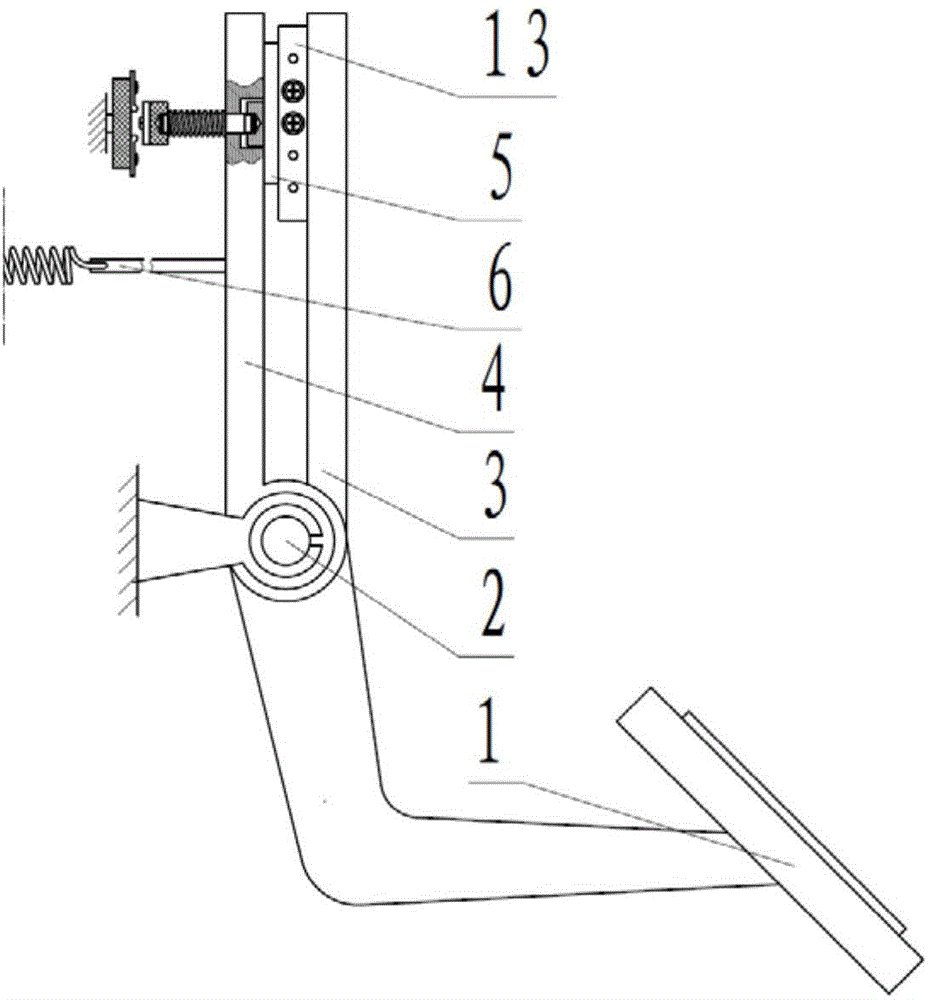

Vehicle safety control device for preventing accelerator from being stepped on mistakenly and application thereof

InactiveCN104057824AShort transitionAvoid pollutionAutomatic initiationsTractorsSafety controlFlameout

The invention relates to a vehicle safety control device for preventing an accelerator from being stepped on mistakenly. The vehicle safety control device is characterized in that a magnet is arranged on the lower surface of the other head of an accelerator control lever; a passive accelerator control lever is arranged below the magnet; the passive accelerator control lever and the accelerator control lever are coaxially hinged to a car body and are absorbed on the lower surface of the magnet in virtue of the attractive force of the magnet; the lower surface of the passive accelerator control lever is connected with an accelerator inhaul cable; a normally open push button switch for providing a braking signal and / or a flameout signal is further arranged on the passive accelerator control lever, and the normally open push button switch comprises a pair of electrical contacts and a button, wherein the button comprises a pull rod and a compression spring sleeving the pull rod, the upper end of the pull rod passes to approach the upper surface of the passive accelerator control lever, and the tension of the compression spring is overcome under the action of the attractive force of the magnet so that the pair of electrical contacts are at a normally open state. The vehicle safety control device not only ensures the safety when the accelerator is stepped on mistakenly but also does not influence high-speed running of vehicles under normal circumstances.

Owner:李明胜

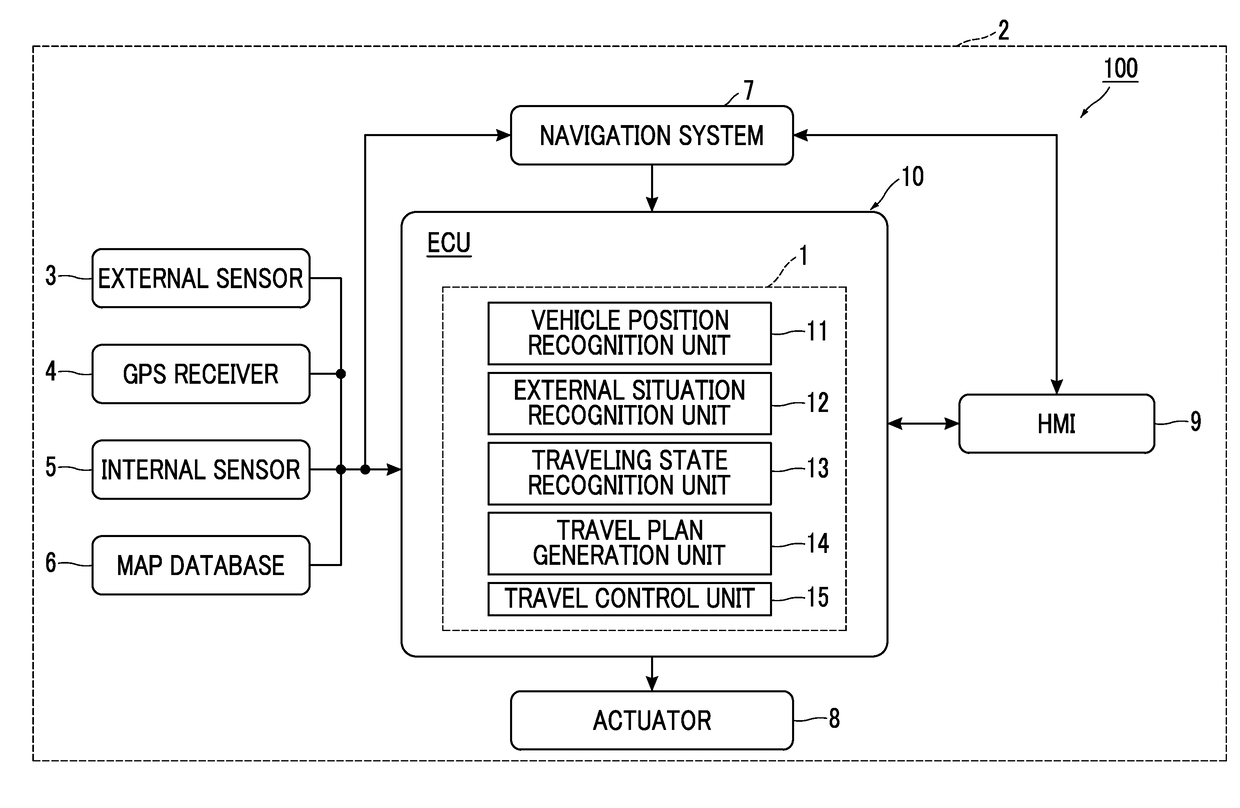

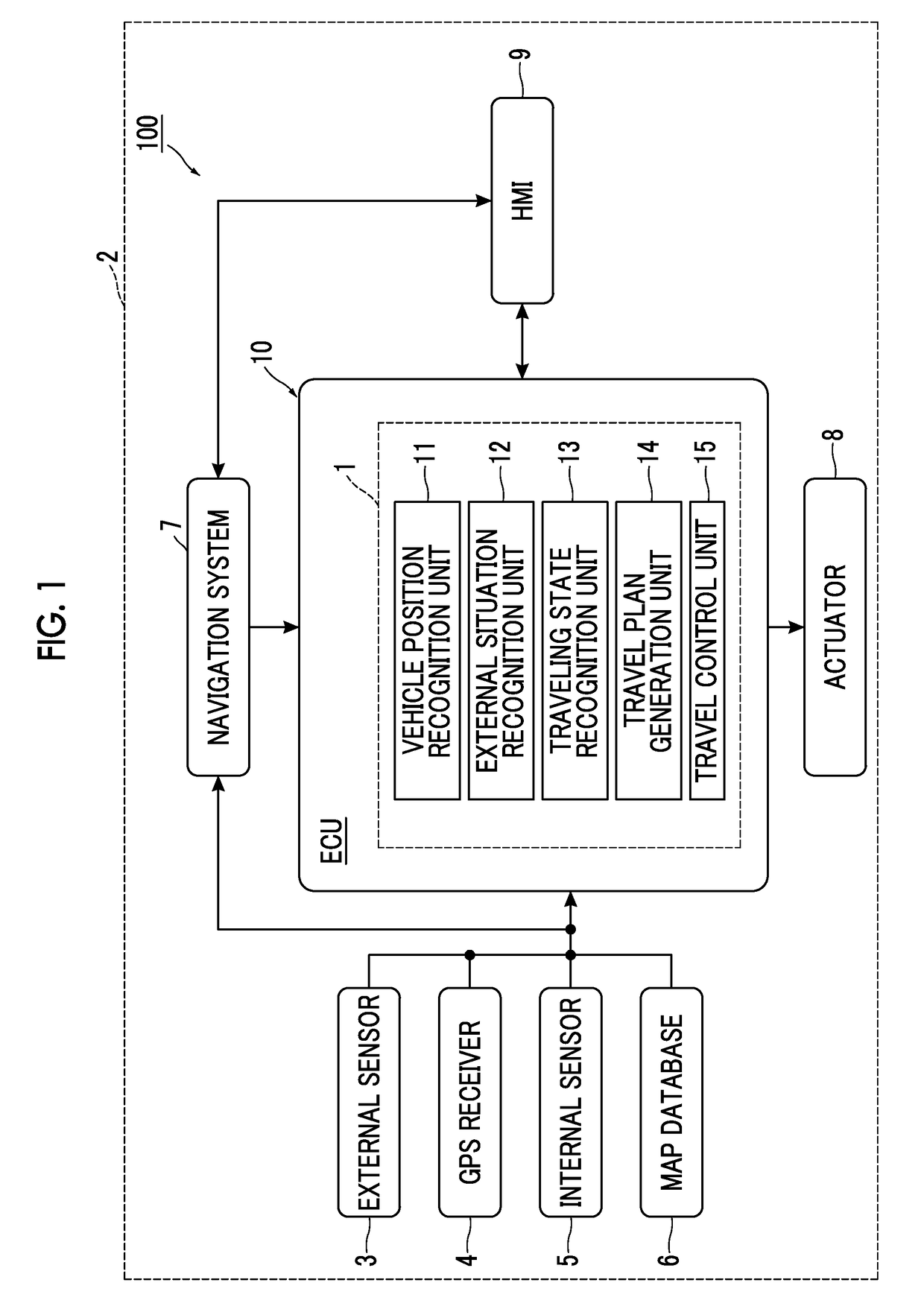

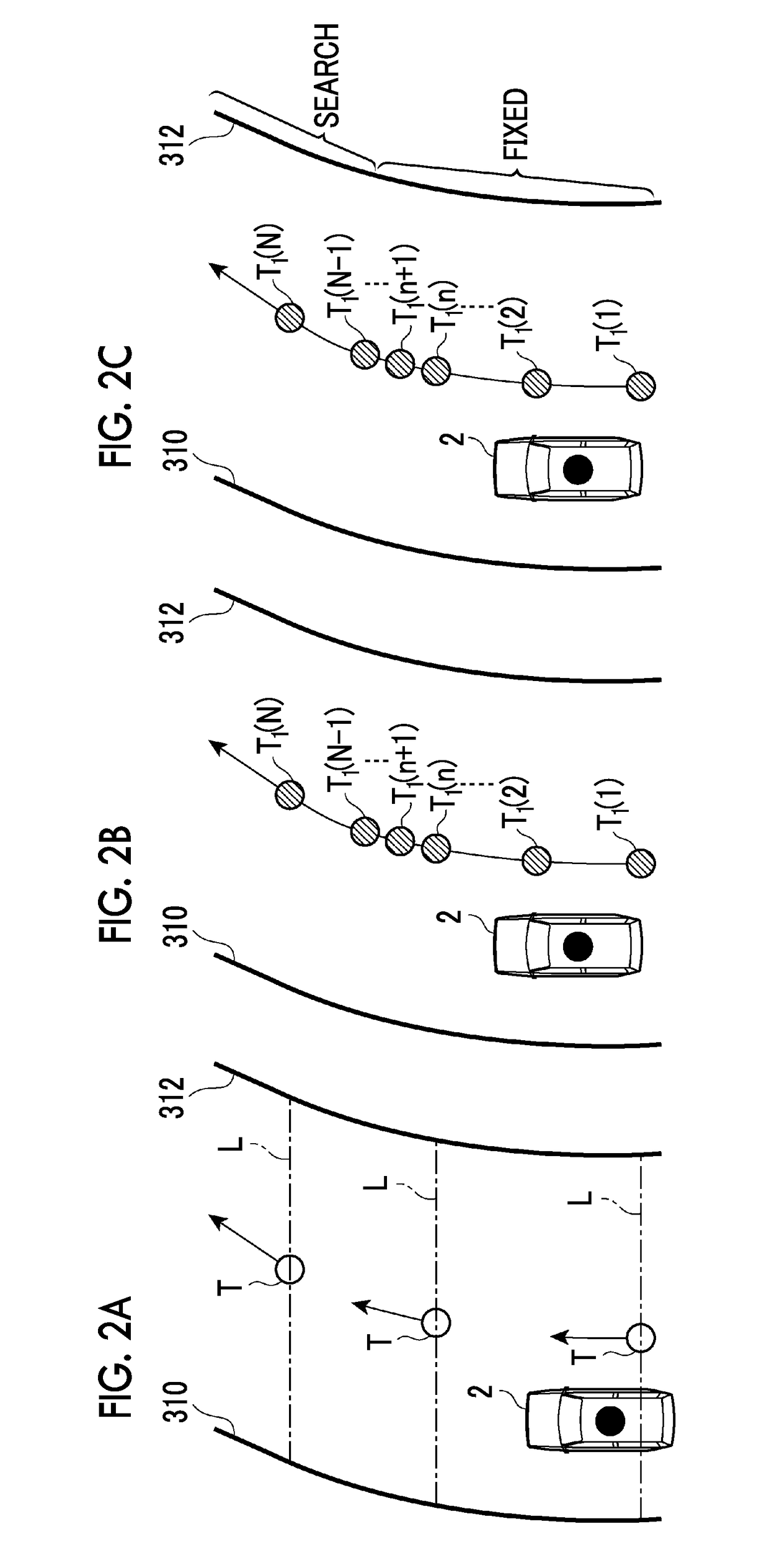

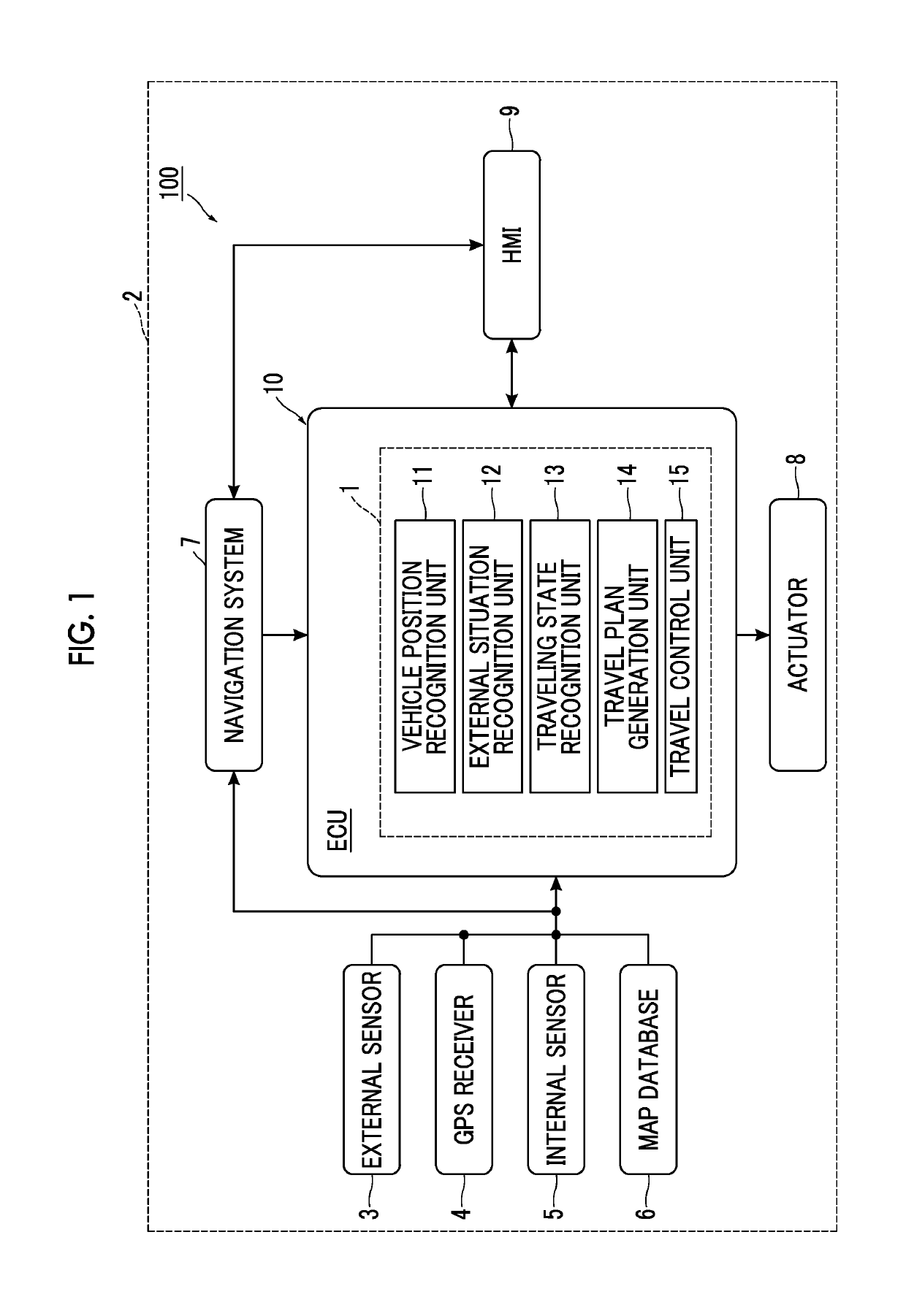

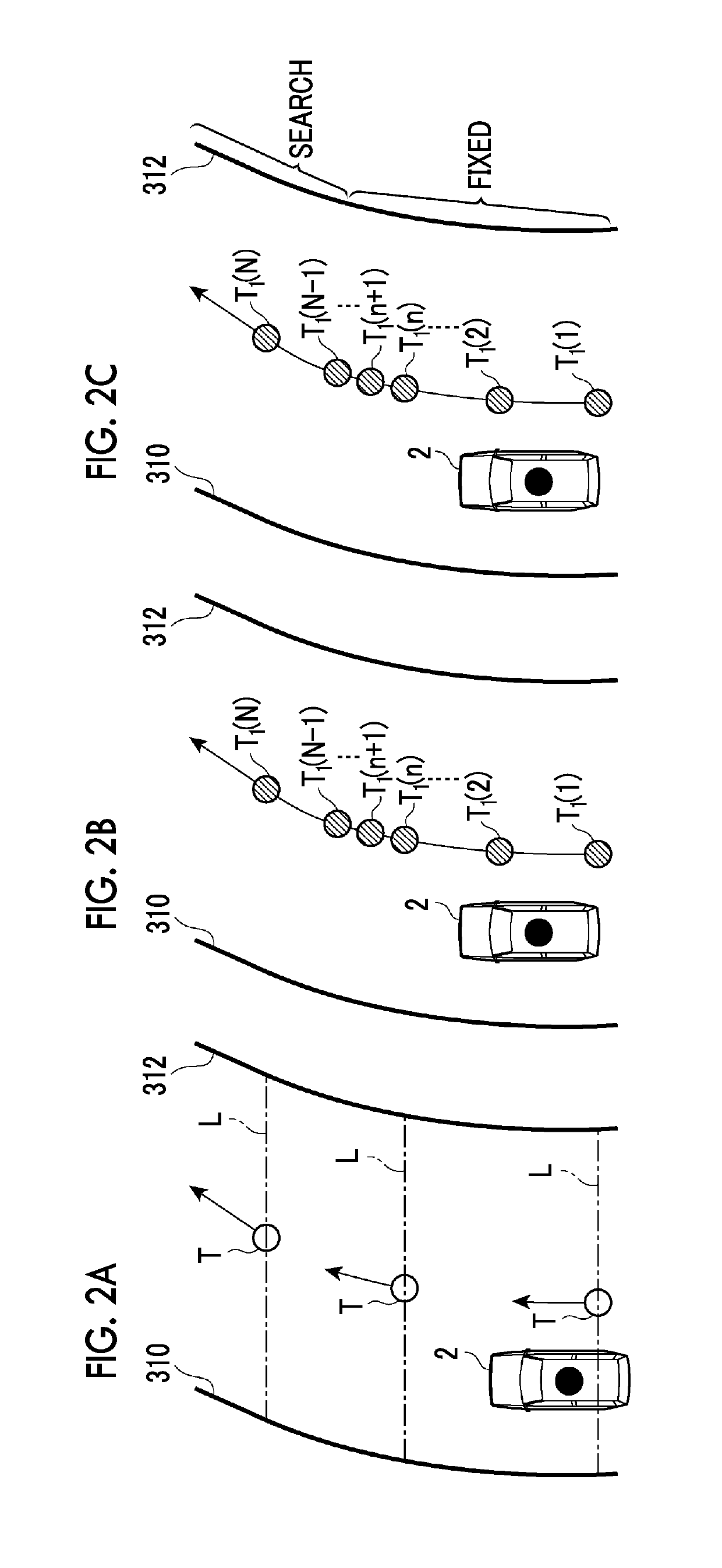

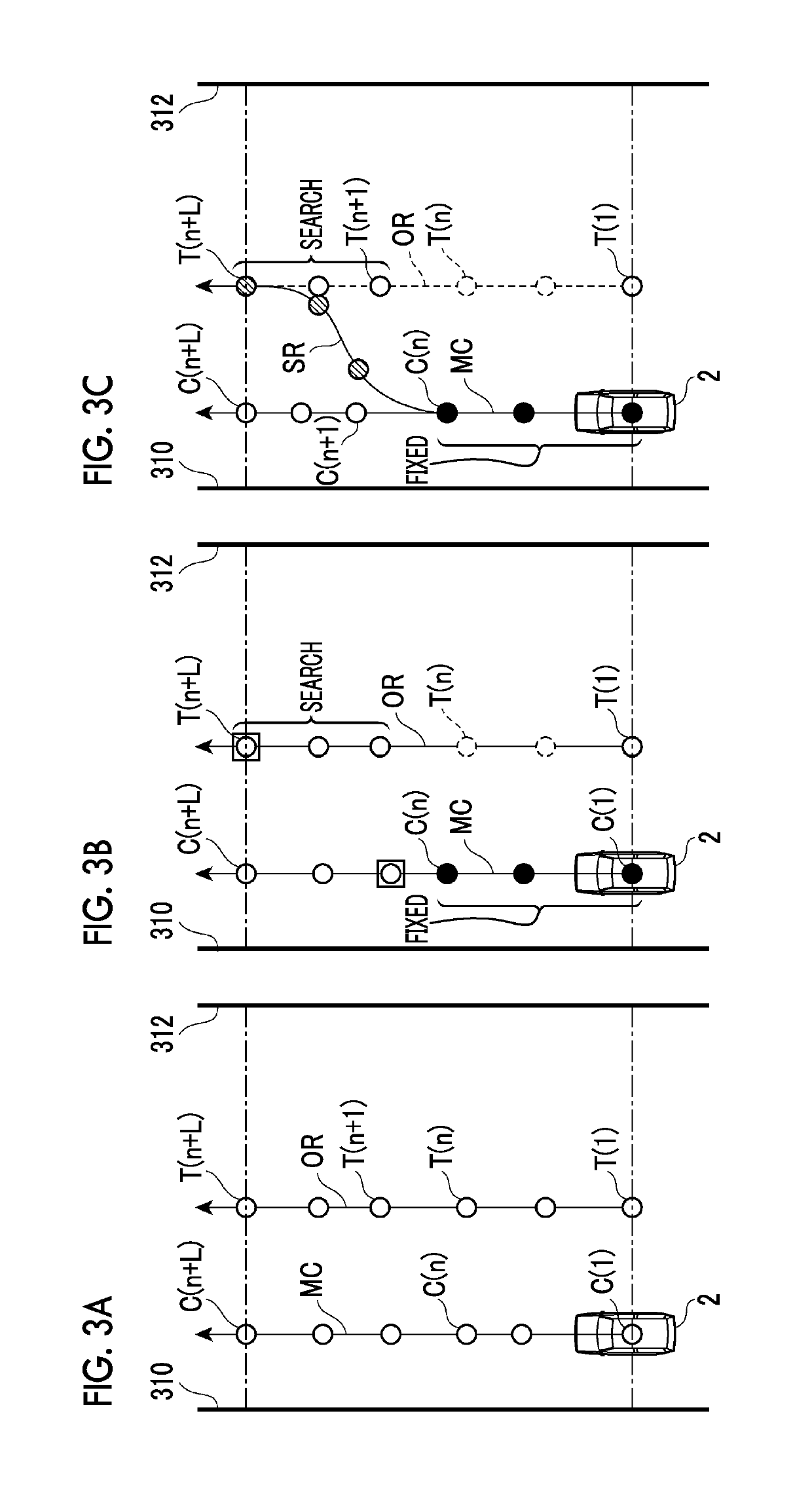

Vehicle control device

ActiveUS20180210453A1Reliable calculationLow reliabilityInstruments for road network navigationExternal condition input parametersEngineeringVehicle control

A vehicle control device includes a map database and at least one electronic control unit. The electronic control unit is configured to calculate a reference arrival position based on a target time or a target distance. The at least one electronic control unit is configured to determine, according to the map information or the external situation at the reference arrival position, as a target arrival position, a position where the vehicle arrives on the potential route in a time different from the target time or over a distance different from the target distance. The at least one electronic control unit is configured to calculate a transition route from the road position to the target arrival position, and generate the target route by connecting the transition route and the potential route following the target arrival position.

Owner:TOYOTA JIDOSHA KK

Direct-current magnetic bias calculation method for extra-high voltage transformer parallel winding series resistance compensation

PendingCN110991099AIncrease time constantShort transitionDesign optimisation/simulationElectrical connectionEngineering

The invention belongs to the technical field of safety guarantee of extra-high-voltage alternating-current power grid electrical equipment, and particularly to a direct-current magnetic bias real-timecalculation method for extra-high voltage transformer parallel winding series resistance compensation. The method comprises the following steps: constructing three-dimensional geometric models of three transformers and a direct-current magnetic bias calculation magnetic field model according to actual structural parameters of a main transformer, a voltage regulation transformer and a compensationtransformer of the extra-high voltage transformer; calculating a self-inductance value when different currents flow through each transformer winding and a mutual inductance value between the windings; in combination with an electrical connection relationship among the three transformers, establishing an overall direct-current magnetic bias equivalent circuit calculation model of the three transformers through series resistance compensation voltage; solving the direct-current magnetic bias circuit model by using a fourth-order Runge-Kutta method of inductance parameters; multiplying the instantaneous current value of the branch where the series resistor is located by the increased series resistor to perform voltage compensation; and calculating the voltage and current values of each transformer and carrying out FFT (Fast Fourier Transform) to obtain the voltage and current harmonic condition of each transformer under the direct current magnetic bias of the extra-high voltage transformer.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

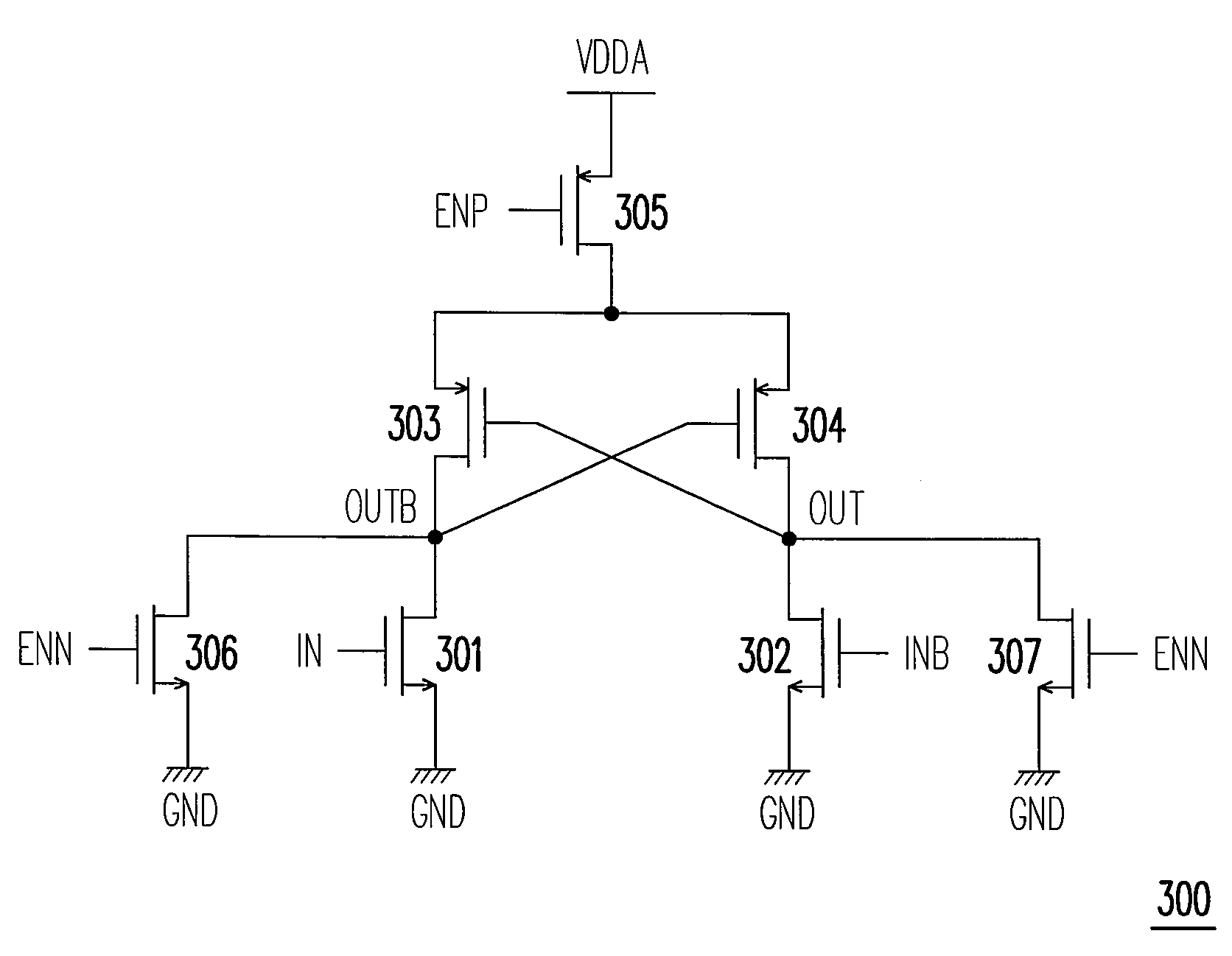

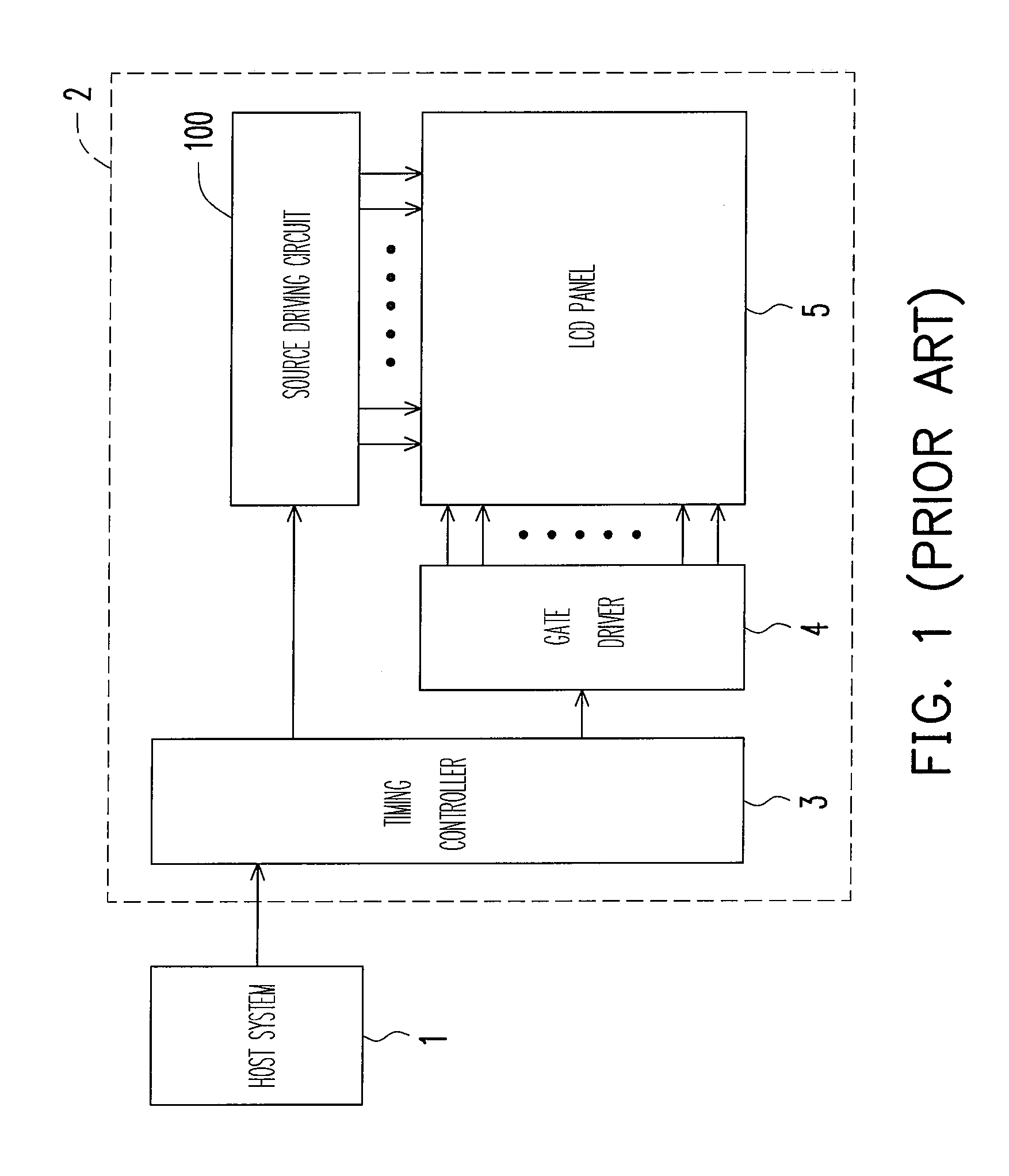

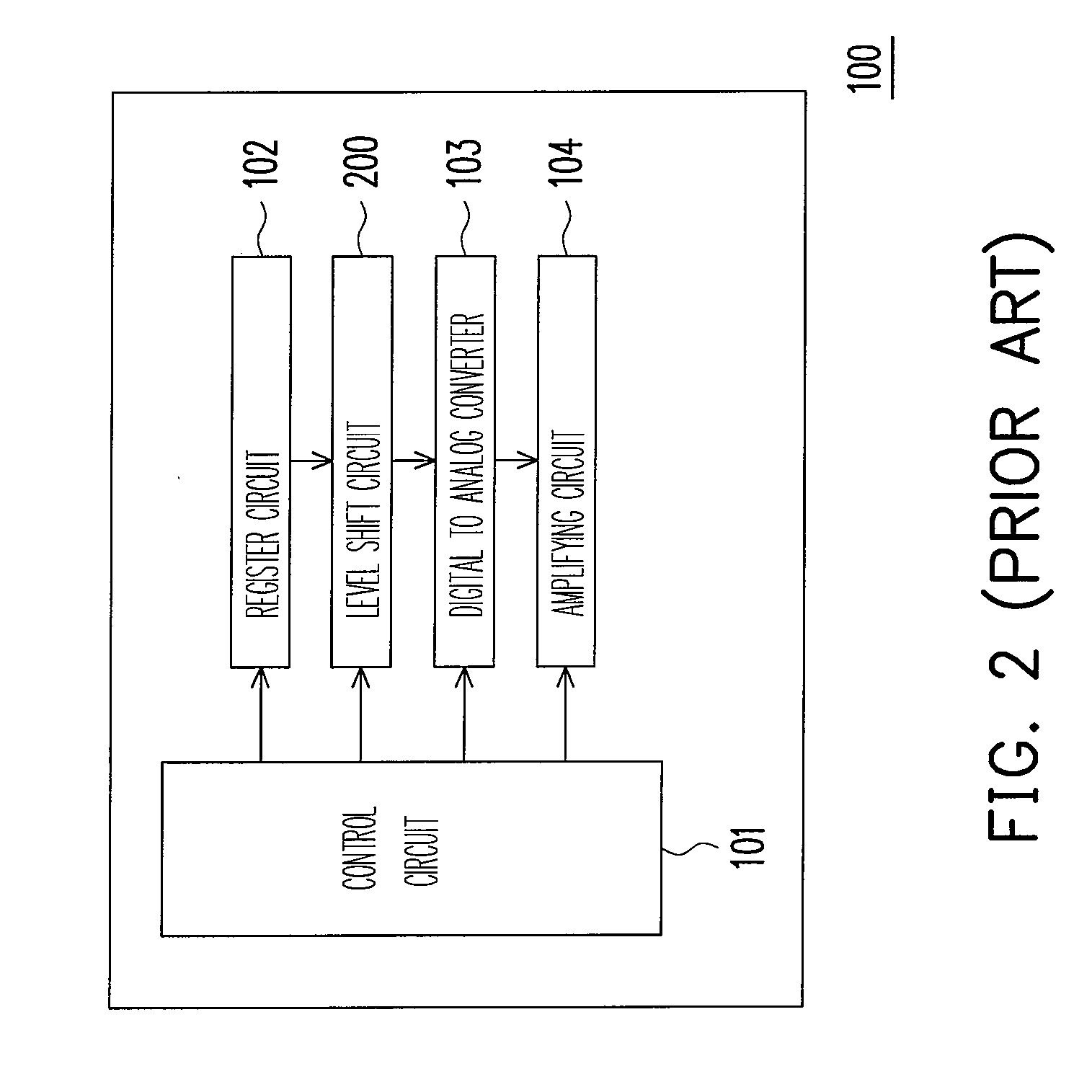

Level shift circuit for a driving circuit

InactiveUS20090206878A1Easy transitionPreventing short transitionPulse automatic controlElectric pulse generatorDriver circuitControl signal

Provided is a level shift circuit for a driving circuit. The level shift circuit includes: a cross-coupled transistor pair, for receiving a first input signal and a second input signal and for providing a first output signal and a second output signal; a first transistor, coupled to a first power supply and to the cross-coupled transistor pair, further receiving a first control signal; a second transistor, coupled to the cross-coupled transistor pair and for receiving a second control signal; and a third transistor, coupled to the cross-coupled transistor pair and for receiving the second control signal. The first control signal, the second control signal, the first output signal and the second output signal are all referenced to the first power supply, and the first input signal and the second input signal are referenced to a second power supply lower than the first power supply.

Owner:HIMAX TECH LTD

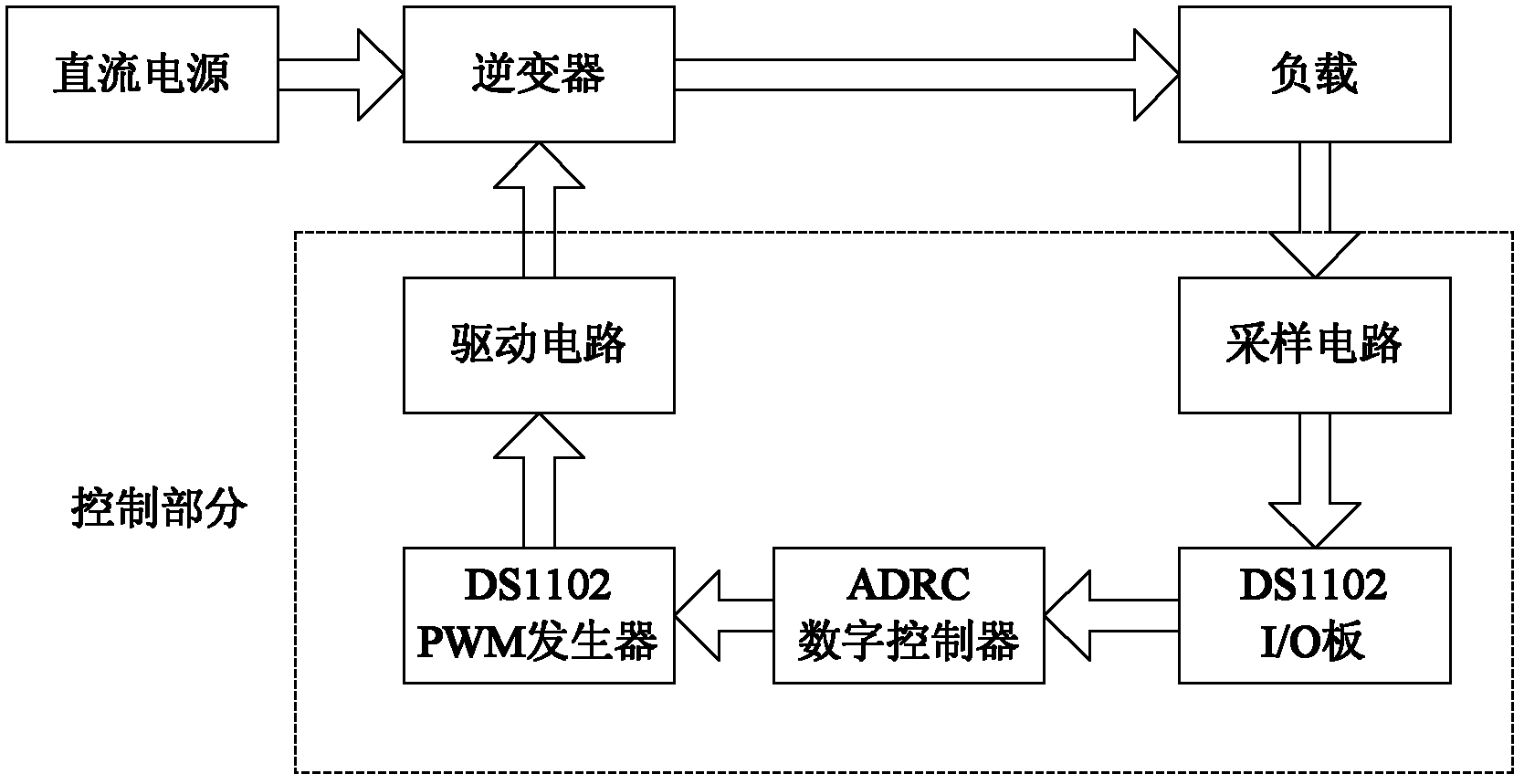

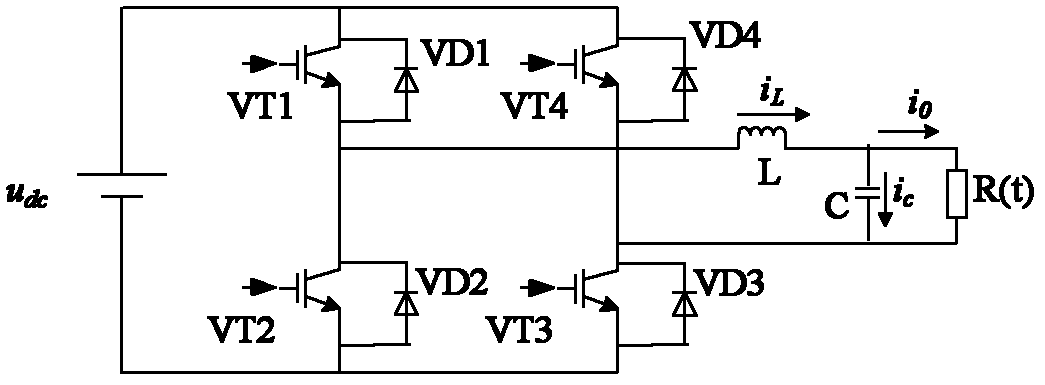

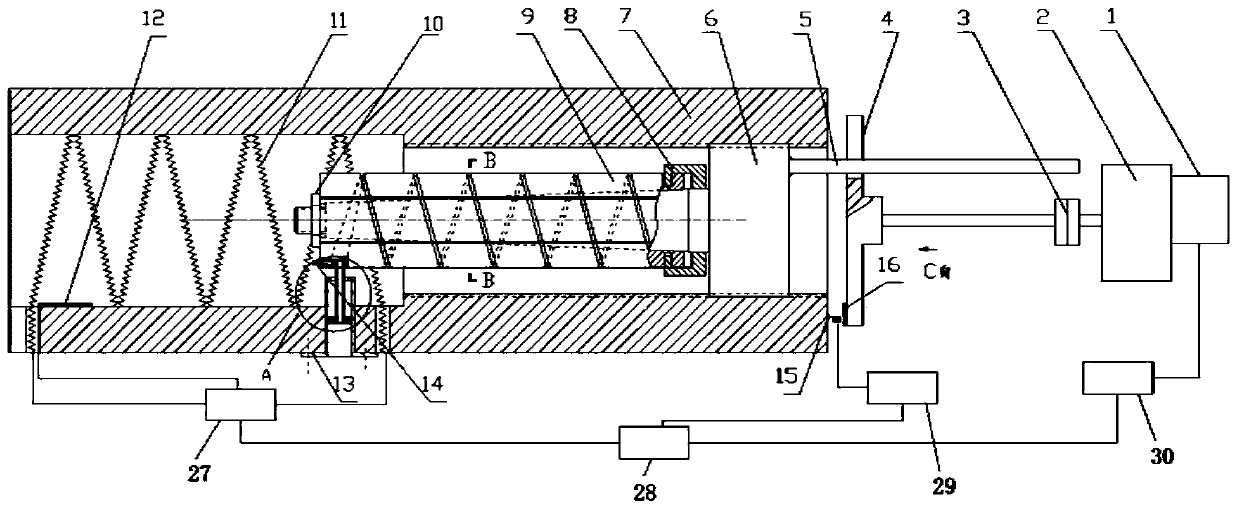

An inverter control system and control method based on active disturbance rejection control technology

InactiveCN102299656AImprove control qualityImprove robustnessDc-ac conversion without reversalControl signalActive disturbance rejection control

An inverter control system based on active disturbance rejection control theory, which is composed of a sampling circuit, a drive circuit, an ADRC controller, an I / O conversion module and a PWM generator; its control method is: establish a control quantity model, collect The signal is sent to the ADRC controller, the control law is obtained, and the control signal is output; its advantages are: 1. It has good control quality for nonlinear and complex systems, and has good anti-interference ability; 2. Small overshoot , The transition process is short, it can adapt to the changes of the object model and the surrounding environment in a wide range, and does not affect the control quality of the controller, and has good robustness.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

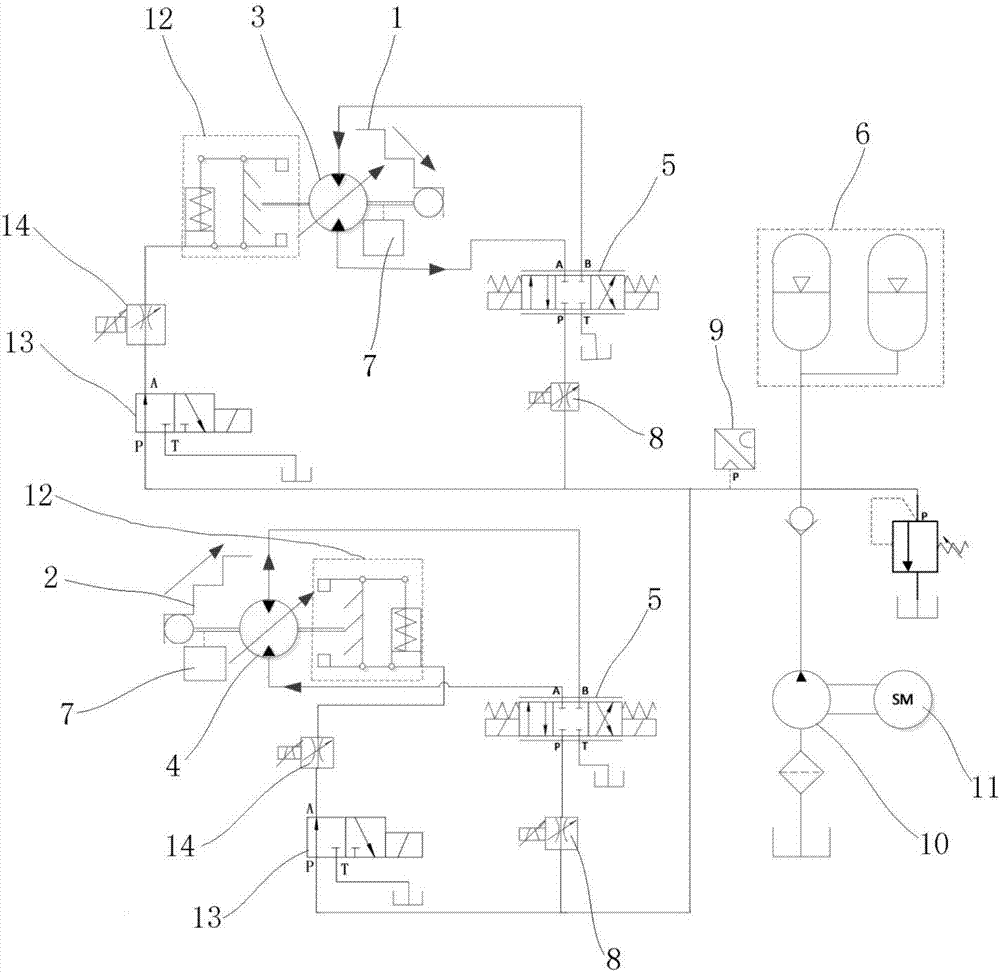

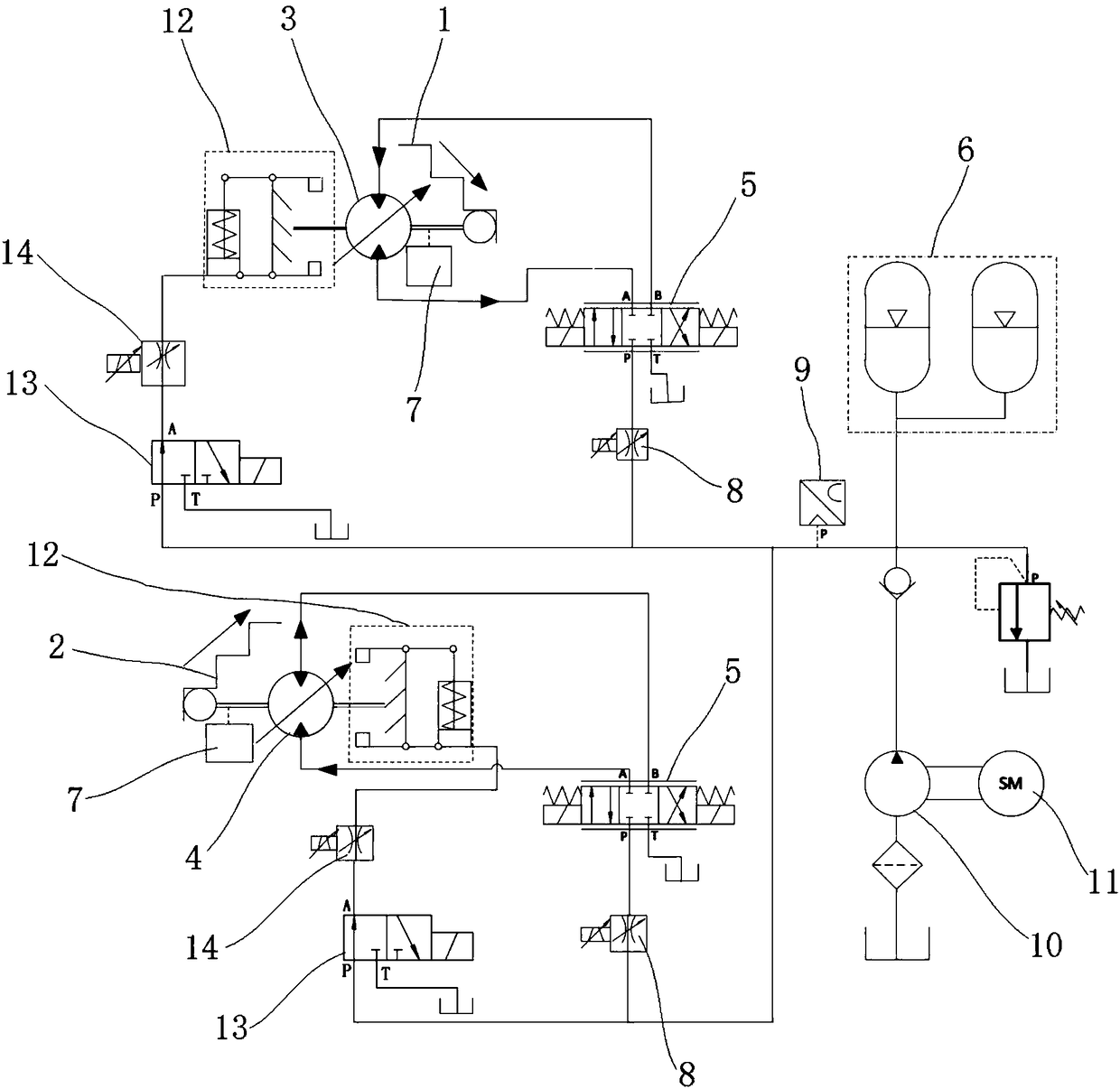

Energy-saving type hydraulic escalator

InactiveCN107140514ARealize energy savingImprove recycling ratesAccumulator installationsFluid-pressure actuator componentsDrive shaftHydraulic circuit

The invention discloses an energy-saving type hydraulic escalator which comprises a controller, a descending escalator part, an ascending escalator part, a first variable displacement motor, a second variable displacement motor and a reversing valve; the first variable displacement motor and the second variable displacement motor are each provided with a pump working condition and a motor working condition; the first variable displacement motor, the second variable displacement motor and the reversing valve form a hydraulic circuit; an output shaft of the first variable displacement motor is connected with a transmission shaft of the descending escalator part; an output shaft of the second variable displacement motor is connected with a transmission shaft of the ascending escalator part; when the descending speed of the descending escalator part is greater than a preset threshold, the reversing valve is positioned in a first station, an oil inlet of the reversing valve communicates with a pump working condition oil port of the first variable displacement motor, and an oil return port of the reversing valve communicates with a motor working condition oil port of the first variable displacement motor; and when the descending speed of the descending escalator part is less than a preset threshold, the reversing valve is positioned in a second station, the oil inlet of the reversing valve communicates with a motor working condition oil port of the first variable displacement motor, and the oil return port communicates with a pump working condition oil port of the first variable displacement motor. The gravitational potential energy of the descending escalator part is converted to pressure energy used for driving the ascending escalator part to operate, an energy conversion link is brief, the conversion efficiency is high, no additional space is occupied, and the cost is low.

Owner:GUANGDONG UNIV OF TECH

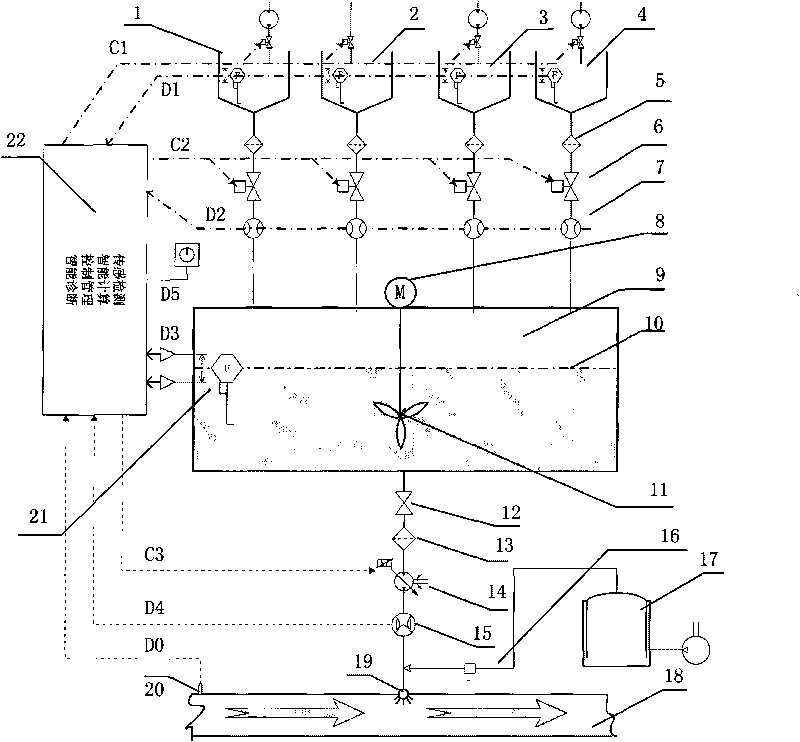

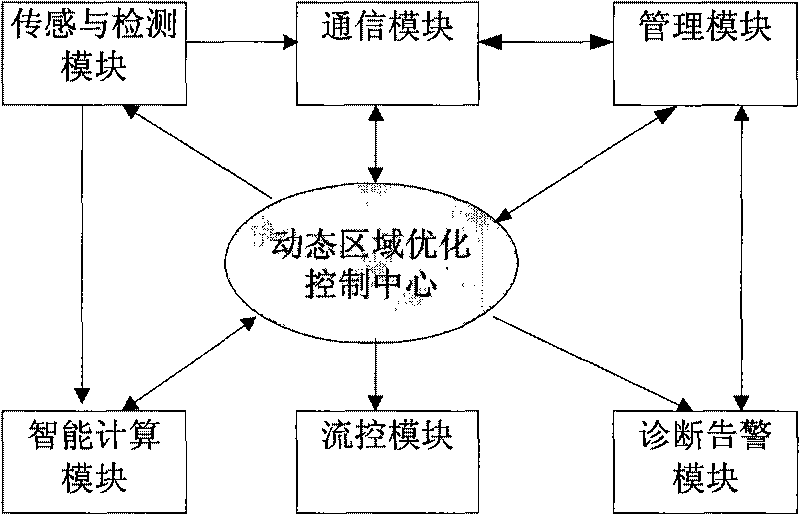

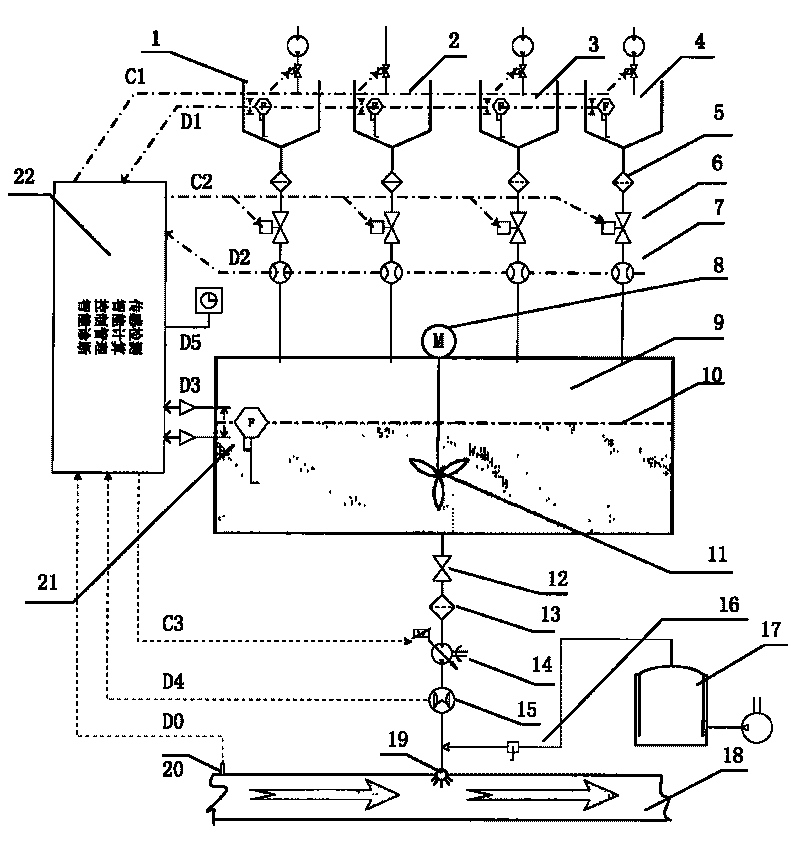

Dynamic area optimization and control system of glue mixing and applying of planed fiber artificial board

The invention provides a dynamic area optimization and control system of glue blending and applying process production of a planed fiber artificial board. The system realizes glue mixing by dynamic proportioning and dynamic glue applying process control in a constant proportion through specific value follow-up adjustment, dynamic area optimization and a high-precision fluid control technology, thereby improving the constant proportion glue applying precision and the glue mixing proportioning accuracy. The process control system comprises a parallel glue mixing mechanism consisting of a gas injector, a pipeline, a flowmeter, a pump valve, a pot group, and the like, an on-line glue applying mechanism and a fully-automatic glue mixing and applying control system consisting of a sensing and detecting module, an intelligent calculating module, a flow control module, a management module, a communication module, a diagnosis and alarm module, and the like. Control methods mainly comprise a dynamic specific value follow-up adjustment method, an area liquid level optimum control method and a pseudo-differential feedback flow control method. The invention improves the dynamic stability of the glue mixing and applying system and realizes the accuracy control of the glue mixing and applying process, thereby improving the product quality, reducing glue liquid and raw material loss and improving the automatic and continuous production and the productivity level of equipment.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

Dye-sensitized solar cell using conductive fiber electrode

InactiveUS8299352B2Good energyIncrease flexibilityElectrolytic capacitorsFinal product manufactureFiberNanoparticle

Provided is a dye-sensitized solar cell including a flexible electrode. The dye-sensitized solar cell includes: first and second electrodes facing each other, and an electrolyte layer interposed between the first and second electrodes, wherein the first electrode comprises a structure formed of conductive fibers, a nano-particle semiconductor oxide layer formed on a surface of the structure of the conductive fibers, and dye molecules adsorbed in the nano-particle semiconductor oxide layer.

Owner:ELECTRONICS & TELECOMM RES INST

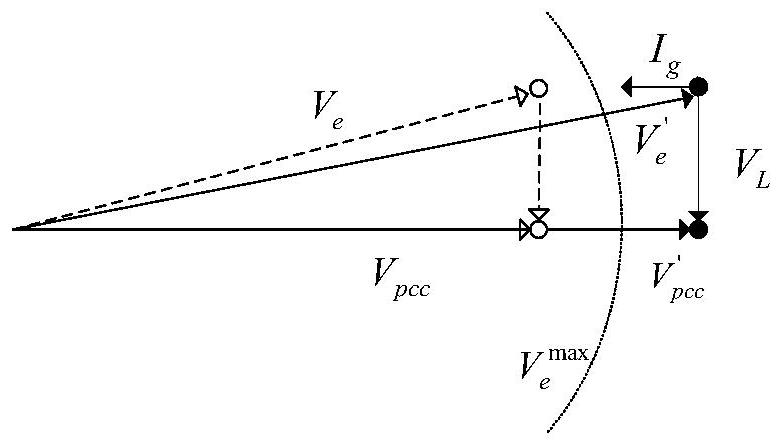

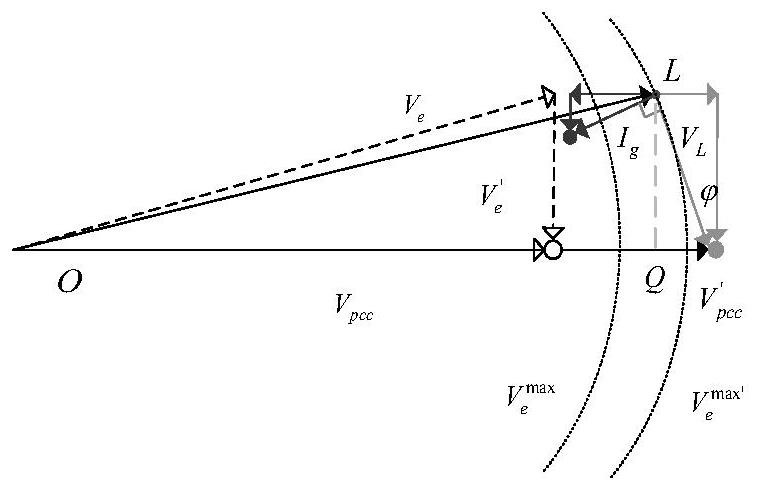

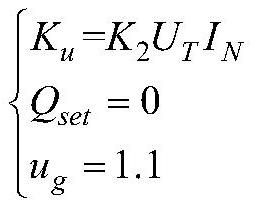

Direct-drive fan high-penetration improved control based on virtual synchronization technology

PendingCN114362194AStable power outputShort transitionSingle network parallel feeding arrangementsPower oscillations reduction/preventionPower gridControllability

The invention provides an improved control scheme for increasing the controllability of the GSC by dynamically adjusting the voltage of a DC bus during high voltage penetration, aiming at solving the problems that the transient overvoltage of a power grid easily causes that the grid-side converter of a direct-driven fan reaches the upper limit of the AC voltage regulation, so that the AC / DC power coupling oscillation is caused, and the instability or overvoltage generator tripping protection is caused. According to active control, the VSG technology is improved, a power compensation item is designed, system frequency support is added externally, and bus voltage fluctuation is reduced internally; reactive control is based on industrial standards, and voltage recovery is supported by injecting reactive current into a power grid. The improved control effectively improves the fault continuous ride-through capability of the unit, improves the power generation efficiency and the electric energy quality of the fan, and improves the system stability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

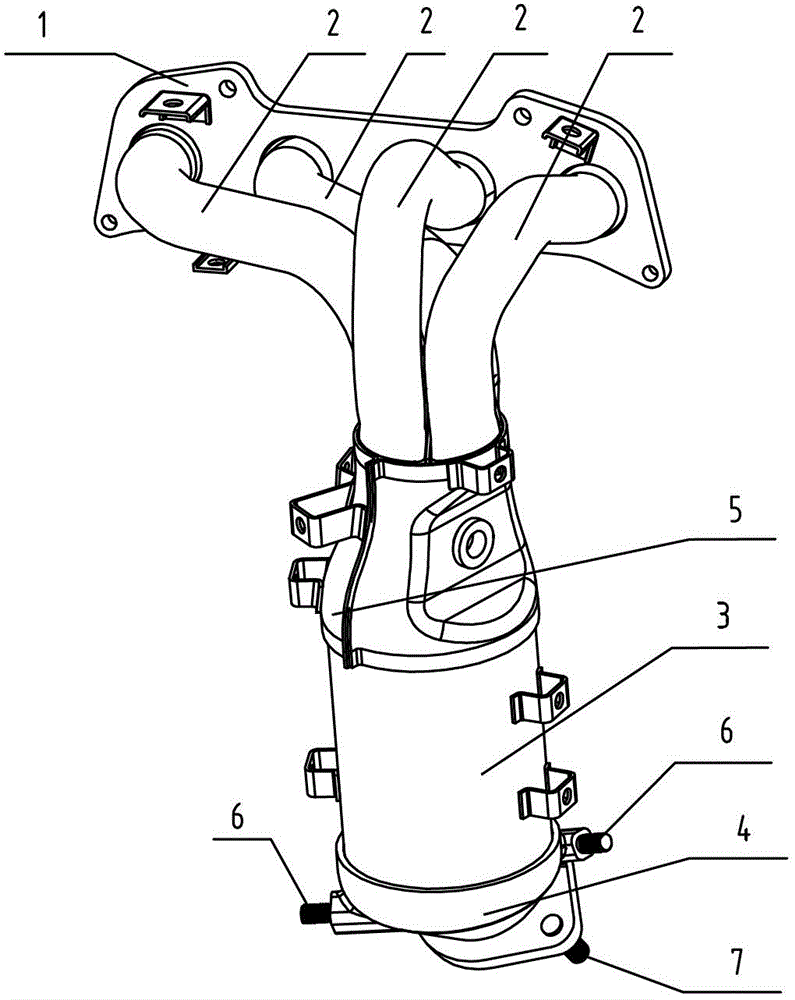

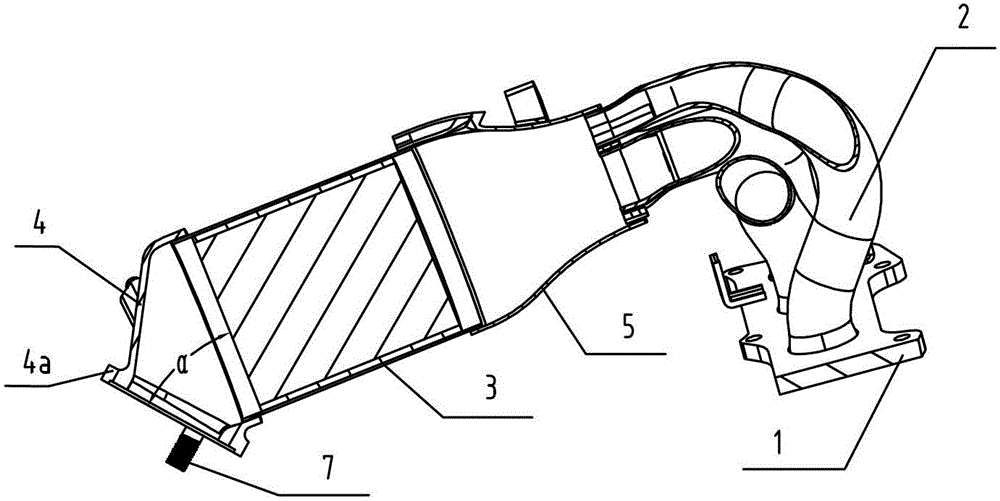

Engine exhaust manifold assembly

InactiveCN103195551BReduce exhaust resistanceSimple structureExhaust apparatusSilencing apparatusEmission standardHeat losses

The invention discloses an engine exhaust manifold assembly. The front end mouth portion of each exhaust manifold is extended and is mounted at intervals on an air inlet flange, a three-way catalyst is cylindrical, the back end of each exhaust manifold is gathered together and connected with the front end of the three-way catalyst through a horn-shaped transition tube, the inner diameter of the horn-shaped transition tube is gradually increased from the front end to the back end, the air inlet flange is a casting part and is sleeved at the back end of the three-way catalyst, an included angle alpha of 20-80 degrees is formed between the front end face and the back end face of the air inlet flange, the inner diameter of the air inlet flange is gradually decreased from the front end to the back end, the back end of the three-way catalyst is inserted into the front end mouth portion of the air inlet flange and is welded with the air inlet flange, and the back end mouth portion of the air inlet flange extends outwards to form a flange mounting plate. The engine exhaust manifold assembly has the advantages of simple structure, low air discharging back pressure, good engine dynamic property, small heat loss, high cold starting property and the like, and requirements of national five emission standards can be met.

Owner:力帆科技(集团)股份有限公司

Vehicle control device

ActiveUS10261516B2Reliable calculationLow reliabilityInstruments for road network navigationExternal condition input parametersEngineeringVehicle control

A vehicle control device includes a map database and at least one electronic control unit. The electronic control unit is configured to calculate a reference arrival position based on a target time or a target distance. The at least one electronic control unit is configured to determine, according to the map information or the external situation at the reference arrival position, as a target arrival position, a position where the vehicle arrives on the potential route in a time different from the target time or over a distance different from the target distance. The at least one electronic control unit is configured to calculate a transition route from the road position to the target arrival position, and generate the target route by connecting the transition route and the potential route following the target arrival position.

Owner:TOYOTA JIDOSHA KK

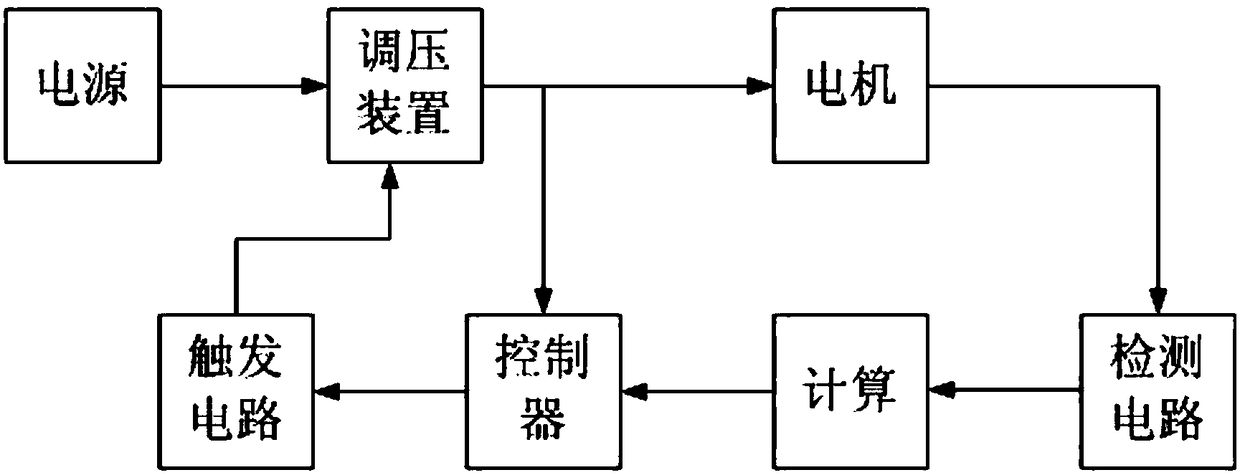

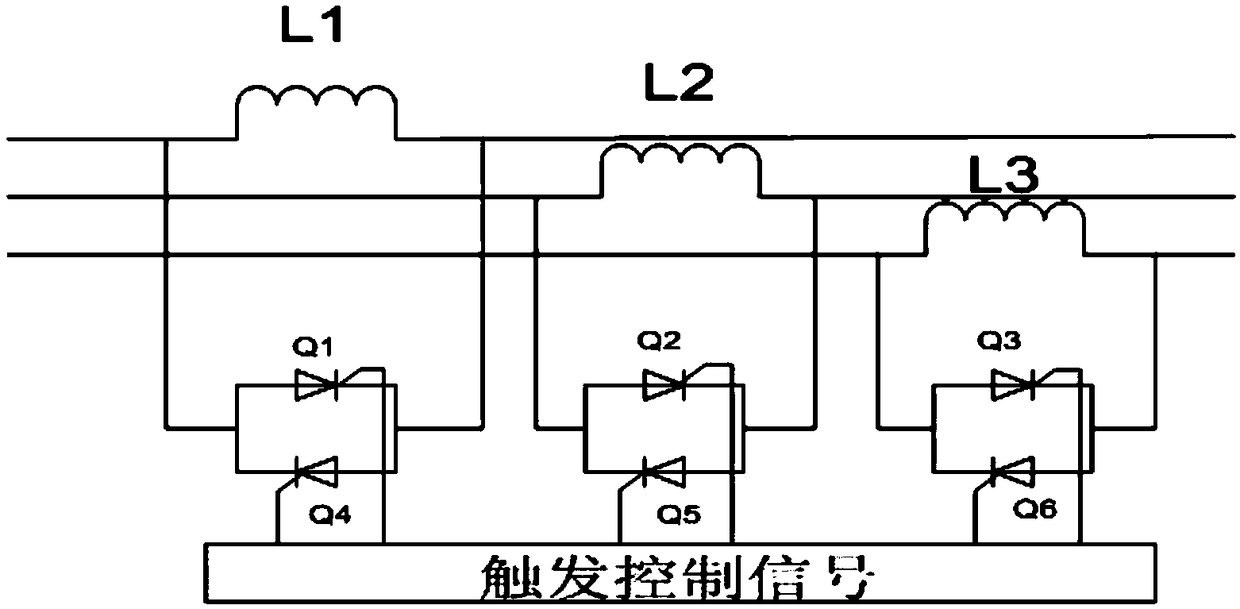

A step-down energy-saving device for an asynchronous motor and its energy-saving control method

ActiveCN106602958BImprove control qualityImprove robustnessGeneral control strategiesPower factor controlInterference resistanceInduction motor

The invention discloses an asynchronous motor step-down energy saver and an energy saving control method thereof. The asynchronous motor step-down energy saver consists of a voltage regulating device, a detection circuit, a computation module, a controller, and a trigger circuit, wherein an input end of the voltage regulating device is connected with an external power grid, and an output end of the voltage regulating device is directly connected with a stator end of a motor; the detection circuit outputs signals to the computation module; the computation module computes the optimal voltage, and inputs the optimal voltage and an actual voltage of a stator into the controller; and the controller controls actions of the voltage regulating device by virtue of the trigger circuit so as to control the input voltage of the stator end of the motor. The asynchronous motor step-down energy saver has the following technical effects: 1, the asynchronous motor step-down energy saver has relatively good control quality, and good anti-disturbance capability, and can achieve high-speed high-precision control especially in a severe environment; and 2, the asynchronous motor step-down energy saver adopts an auto-disturbance rejection control technology, has the characteristics of small overshoot and short transitional process, can adapt to changes of an object model and a surrounding environment in a very large range, does not influence the control quality of the controller, and has very good robustness.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

An energy-saving hydraulic escalator

InactiveCN107140514BRealize energy savingImprove recycling ratesAccumulator installationsEscalatorsDrive shaftHydraulic circuit

The invention discloses an energy-saving type hydraulic escalator which comprises a controller, a descending escalator part, an ascending escalator part, a first variable displacement motor, a second variable displacement motor and a reversing valve; the first variable displacement motor and the second variable displacement motor are each provided with a pump working condition and a motor working condition; the first variable displacement motor, the second variable displacement motor and the reversing valve form a hydraulic circuit; an output shaft of the first variable displacement motor is connected with a transmission shaft of the descending escalator part; an output shaft of the second variable displacement motor is connected with a transmission shaft of the ascending escalator part; when the descending speed of the descending escalator part is greater than a preset threshold, the reversing valve is positioned in a first station, an oil inlet of the reversing valve communicates with a pump working condition oil port of the first variable displacement motor, and an oil return port of the reversing valve communicates with a motor working condition oil port of the first variable displacement motor; and when the descending speed of the descending escalator part is less than a preset threshold, the reversing valve is positioned in a second station, the oil inlet of the reversing valve communicates with a motor working condition oil port of the first variable displacement motor, and the oil return port communicates with a pump working condition oil port of the first variable displacement motor. The gravitational potential energy of the descending escalator part is converted to pressure energy used for driving the ascending escalator part to operate, an energy conversion link is brief, the conversion efficiency is high, no additional space is occupied, and the cost is low.

Owner:GUANGDONG UNIV OF TECH

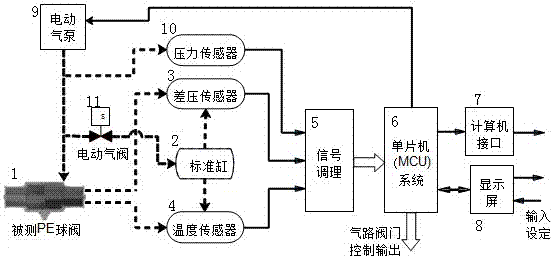

Room temperature and low pressure test method for the tightness of polyethylene valves

ActiveCN104865026BShort equilibration timeShorten test timeMeasurement of fluid loss/gain rateMicrocontrollerLoop control

A room temperature and low pressure test method for the sealing performance of polyethylene valves. On the premise of confirming that the valve end face is reliably sealed and the air circuit of the test bench has no leakage, the indoor air is used as the test medium, and the closed-loop control system of the test bench is used to automatically pressurize the valve test chamber and standard cylinder to the test standard pressure. Use the temperature sensor and differential pressure sensor to simultaneously detect the temperature of the valve test chamber and the test gas in the standard cylinder and the pressure difference between the two, obtain all the two-dimensional data during the pressurization test period or the period before the leakage alarm, and send it to the single-chip computer system Perform cross-correlation analysis. According to the sufficient and necessary condition of no leakage: any point on the fitting curve of the temperature difference and pressure difference of the medium on the same time axis has the same change gradient, and the temperature and pressure values at any time have a single proportional relationship. The pressure drop gradient value of the valve gives the judgment of the sealing performance of the valve. This method does not require a constant temperature environment, and has the characteristics of high resolution, rapidity and high efficiency.

Owner:CHINA JILIANG UNIV

Construction method conversion construction method for ultra-long-span tunnels in ⅳ-level to ⅳ-level surrounding rock sections

ActiveCN109989757BReduce disturbanceAvoid intervalsUnderground chambersTunnel liningArchitectural engineeringEconomic benefits

The invention discloses a construction method conversion construction method for super-long-span tunnels in the surrounding rock section of level V to level IV. Controlled excavation is adopted to keep the same elevation of the arching line, and the double side wall pilot pit method of the surrounding rock is used as the leading and leading method in the construction of the transition section. The temporary middle wall of the left pilot pit and the temporary middle wall of the right pilot pit on both sides of the rear guide move to the middle of the tunnel at the same time, until the temporary middle wall of the left pilot pit and the temporary middle wall of the right pilot pit touch, and the temporary inverted arch Lock-foot anchors are applied on both sides; then the temporary middle wall of the right pilot pit is removed, and the temporary middle wall of the left pilot pit is retained as the middle temporary middle wall of the CRD method. This method transitions from the double-side-wall pilot-pit method to the CRD method in the horizontal direction, avoiding the time interval between construction method conversions, and reducing the disturbance of the surrounding rock caused by the removal of the temporary support of the double-side-wall pilot-pit method in the later stage, thus speeding up the construction. , save the construction period, avoid idle work, and improve the economic benefits of tunnel construction.

Owner:CHANGAN UNIV

UAV delivery system

ActiveCN108045543BHigh speedEnsure safetyAircraft componentsLighter-than-air aircraftUncrewed vehicleAircraft safety

The present invention provides a delivery system for unmanned aerial vehicles, which includes a fixing component for suspending and fixing the unmanned aerial vehicle to be launched. The unmanned aerial vehicle includes a nose and two wings, wherein the suspension and fixing means: The fixing components are respectively connected with the nose and the two wings to form a three-point connection, and the nose is facing the ground, and the body is in a predetermined launching posture. Since the fixing assembly of the present invention is connected at three points with the unmanned aerial vehicle to be released, and the unmanned aerial vehicle is in the predetermined launching posture when it is fixed, it is easier to make it be in this posture when it is released, reducing the number of times to adjust the posture. It is beneficial for the aircraft to gain speed after release, helps the aircraft attitude to level off quickly, reduces the transition process, and ensures the safety of the aircraft. In addition, the structure of the invention is simple to realize, has high safety and reliability, and is convenient for engineering application.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

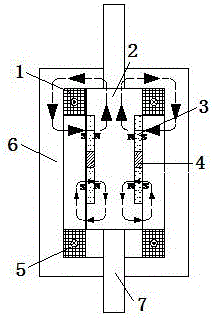

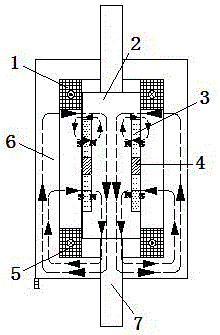

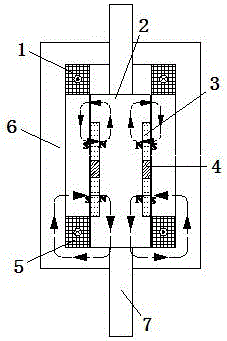

A permanent magnet movable medium and low voltage circuit breaker driving device

InactiveCN103943428BSimple structureLittle influence of temperatureProtective switch operating/release mechanismsLow voltage circuitsElectric power system

A movable medium-low-voltage circuit breaker drive device for permanent magnets is composed of a separating brake winding, movable iron cores, the permanent magnets, a fixing device, a closing winding, a static iron core and a driving connecting rod. The separating brake winding winds the upper portion of the static iron core, and the closing winding winds the lower portion of the static iron core. The movable iron cores are of an I-shaped structure. The permanent magnets and the fixing device are embedded in the movable iron cores in a surrounding mode, the fixing device is embedded in the middle of the movable iron cores, and the two permanent magnets are embedded in the movable iron cores at the two ends of the fixing device respectively. The driving connecting rod and the movable iron cores are connected into a whole. According to the movable medium-low-voltage circuit breaker drive device, the permanent magnets are embedded in the movable iron cores, the permanent magnets and a winding magnetic field act together, the separating-closing transition process is simplified, and the limit steady state is obtained rapidly. The movable medium-low-voltage circuit breaker drive device can be used in protection of transformer substations of electrical power systems, rail traction substations and various feeders.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Fast self-learning improved adrc control method for nonlinear systems

The invention discloses a fast self-learning improved ADRC control method for a nonlinear system, which includes the following steps: Step 1: Create an ADRC: the ADRC includes a tracking differentiator (TD), an expanded state Four parts of observer (ESO), nonlinear error feedback (NLSEF) and disturbance compensation; step 11) establish tracking differentiator (TD) control model; step 12) establish extended state observer (ESO) control model; step 13) establish Nonlinear error feedback (NLSEF) control model; Step 14) Establish a disturbance compensation control model; Step 2: Create a self-learning active disturbance rejection controller (SADRC): apply the self-learning method to the nonlinear error feedback (NLSEF) control model , establish a self-learning nonlinear ADRC control system model; Step 3: Create a fast self-learning ADRC (FSADRC): use the method of adding momentum to design an adaptive mechanism for learning rate, and establish a dynamic adaptive Fast self-learning model with learning rate.

Owner:WUHAN UNIV OF SCI & TECH

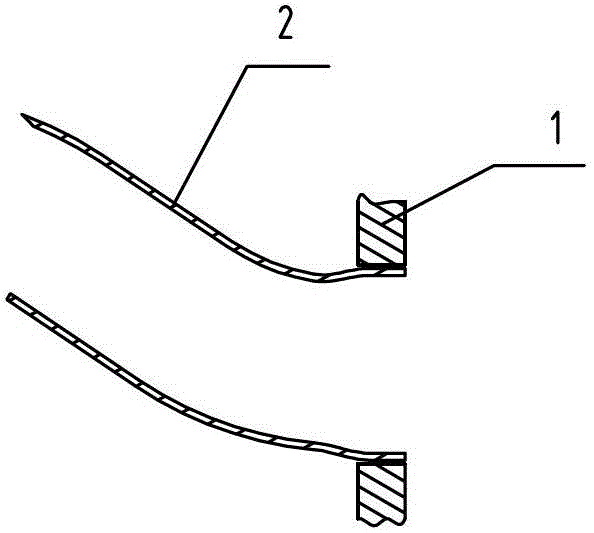

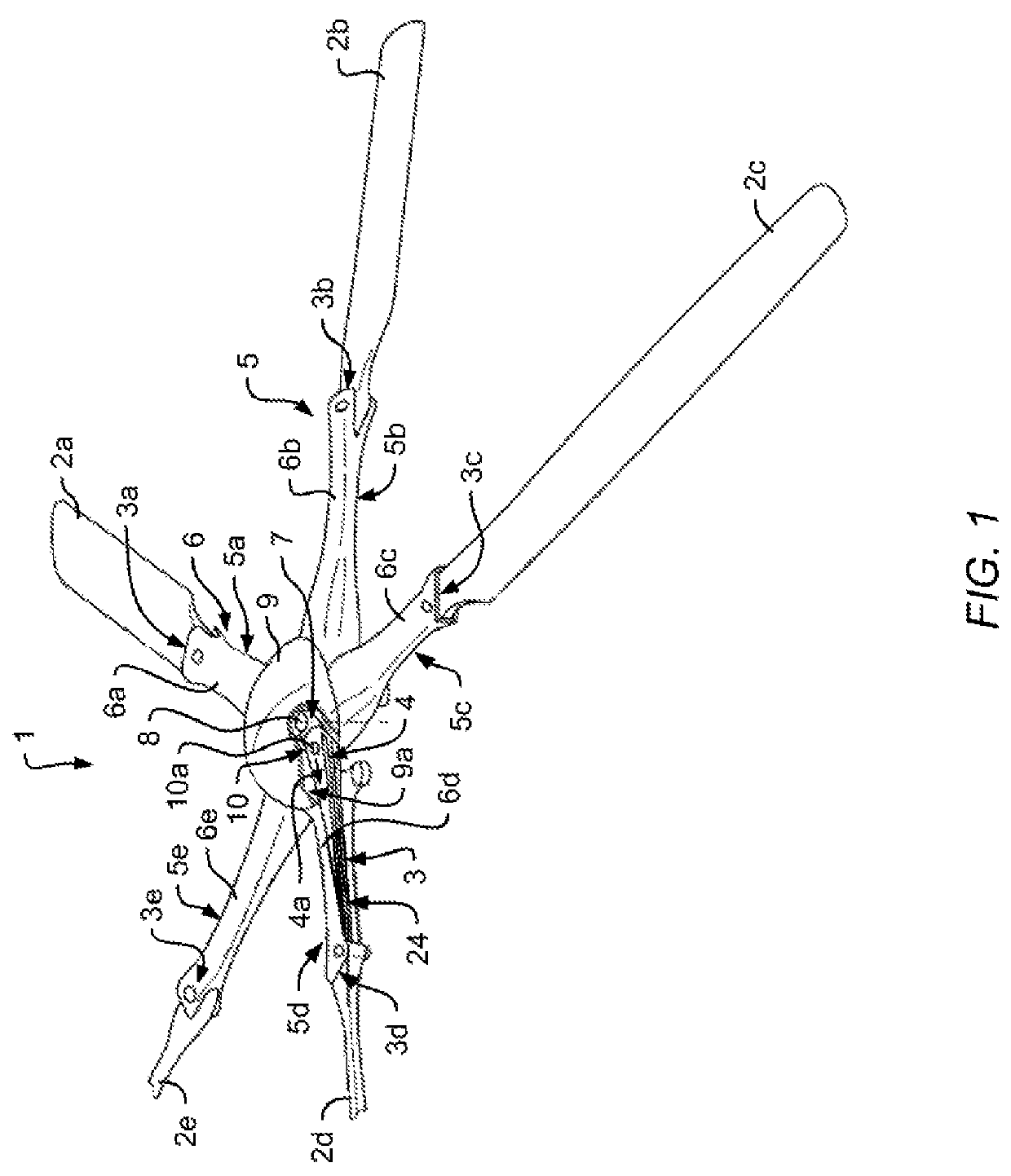

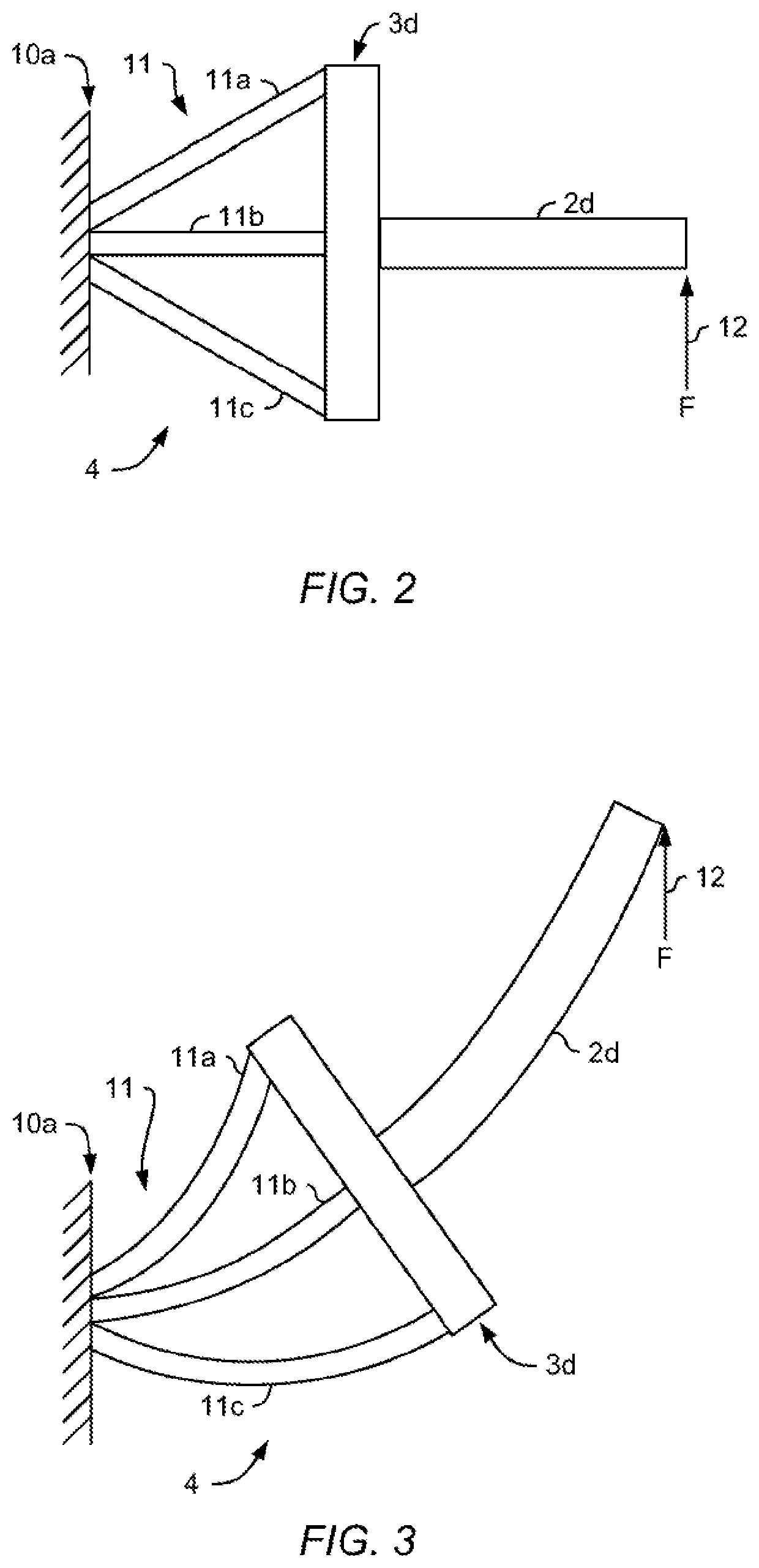

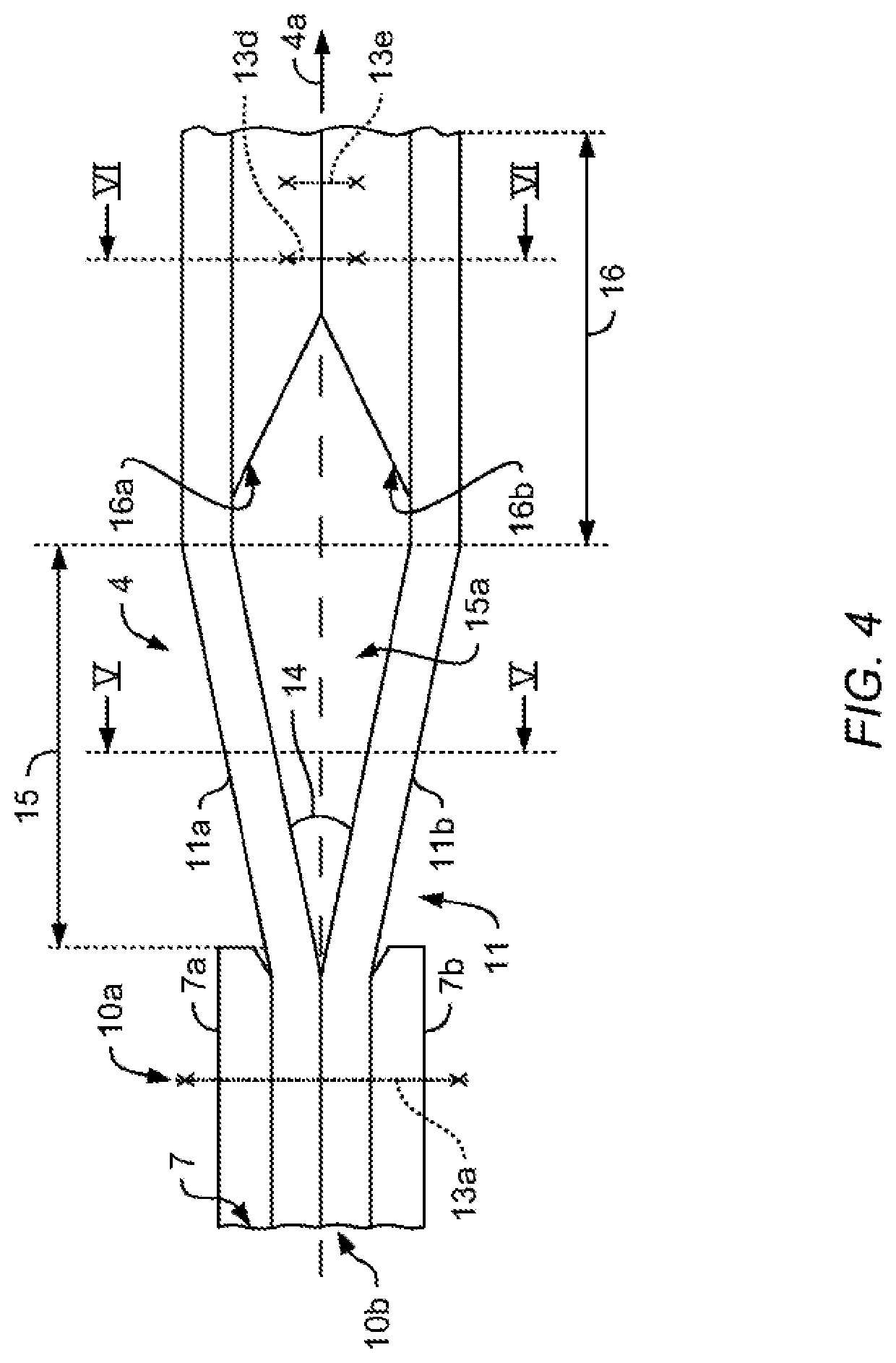

Elastic flapping hinge for connecting a rotor blade to a rotor hub of a rotary wing aircraft

An elastic flapping hinge for connecting a rotor blade to a rotor hub of a rotary wing aircraft, comprising an elastic flapping hinge member arrangement that includes a hub attachment area for attachment to the rotor hub, a connection area for attachment to the rotor blade, and an elastic flapping hinge area that is arranged between the hub attachment area and the connection area and adapted to allow flapping movements, the elastic flapping hinge member arrangement comprising at least two elastic flapping hinge members having a first bending stiffness for flapping movements and a second bending stiffness for lead-lag movements, the first bending stiffness being smaller than the second bending stiffness, wherein the at least two elastic flapping hinge members diverge from each other in the elastic flapping hinge area by a predetermined divergence angle.

Owner:AIRBUS HELICOPTERS DEUT GMBH

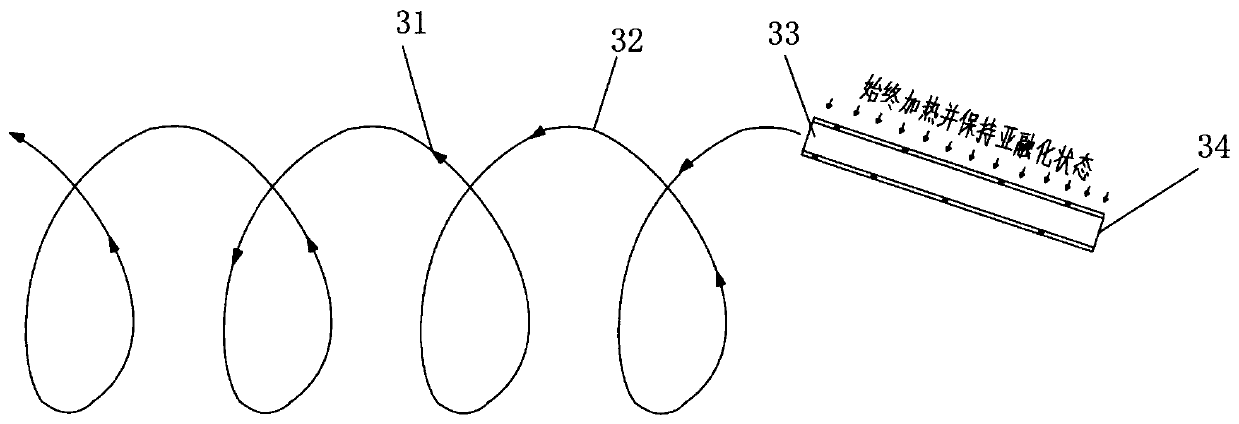

Manufacturing method of three-dimensional spiral glass micro-channel

InactiveCN111393015ASimple processImprove airtightnessGlass reforming apparatusCapillary TubingManufactured material

The invention discloses a manufacturing method of a three-dimensional spiral glass micro-channel. The manufacturing method comprises the following steps: firstly, manufacturing a millimeter-scale glass capillary tube from a glass raw material; heating glass capillary tube to a sub-melting state and keeping the temperature; fixing one end of the glass capillary tube, stretching the other end of theglass capillary tube in a spiral propelling mode, wherein the stretching track is a spiral line and the stretching direction is tangent to the spiral line, adjusting the stretching speed and the heating temperature according to the stretching process, and in the stretching process, restraining a glass pipeline being refined to guarantee the screw pitch and the diameter of the spiral line. According to the manufacturing method of the three-dimensional spiral glass micro-channel, the glass capillary tube is used as a material, and the three-dimensional spiral glass micro-channel with the diameter of less than 50 microns can be manufactured by adopting a method for restraining spiral stretching in a sub-melting state.

Owner:CHANGZHOU INST OF TECH

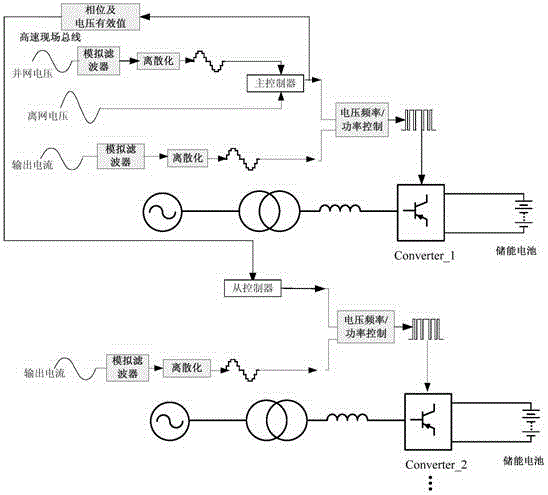

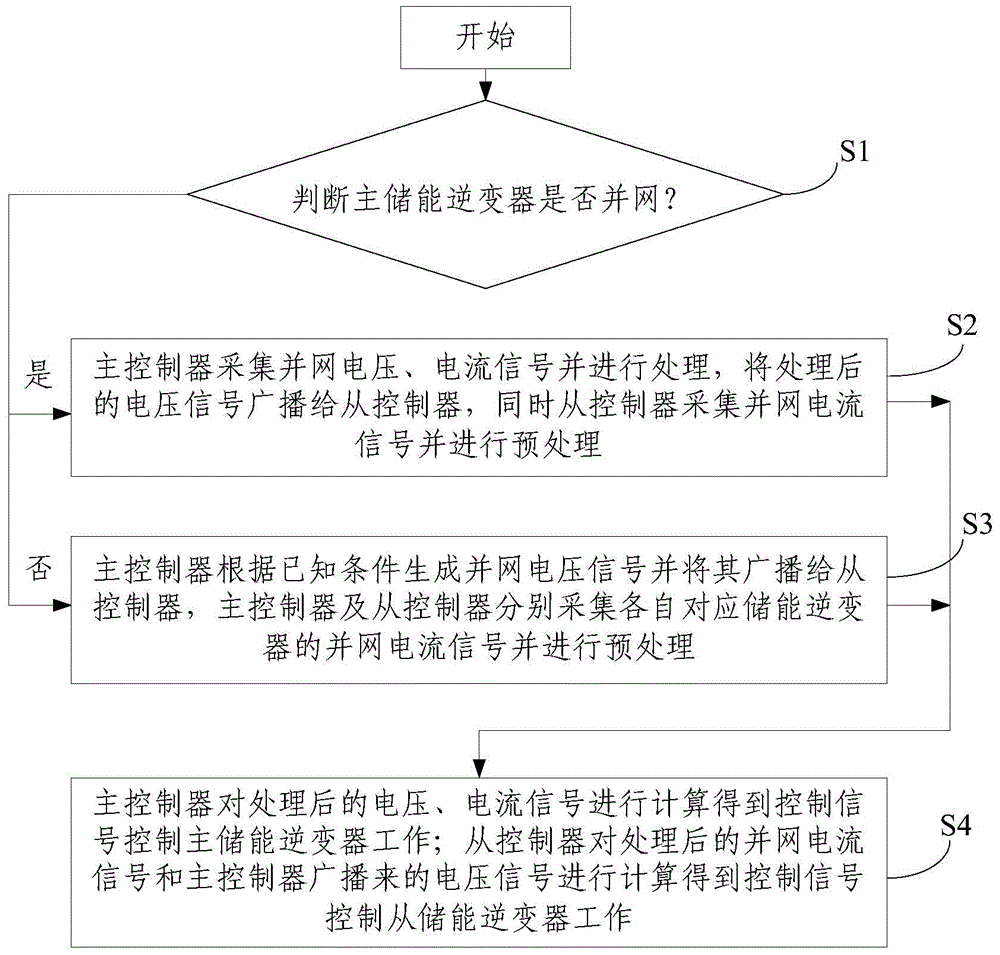

A networked control method for energy storage inverters based on quasi-real-time synchronous signals

InactiveCN103606965BAvoid delayEliminate circulationSingle network parallel feeding arrangementsDc-ac conversion without reversalControl signalEngineering

The invention discloses a networking control method of energy storage inverters based on quasi real-time synchronous signals, and relates to the field of micro-grid operational control. The networking control method includes the steps that the S1, whether a main energy storage inverter is in grid connection is judged, if yes, the S2 is carried out, and if not, the S3 is carried out; the S2, a master controller collects grid connection voltage and current signals, processes the voltage and current signals, broadcasts the processed voltage signals to a slave controller and meanwhile the slave controller collects grid connection current signals from the slave controller and carries out preprocessing; the S3, the master controller generates grid connection voltage signals according to known conditions and broadcasts the grid connection voltage signals to the slave controller, and the master controller and the slave controller collect the grid connection current signals of the corresponding energy storage inverter and carry out preprocessing respectively; the S4, the master controller carries out computation on the processed voltage and current signals to obtain control signals so as to control the main energy storage inverter to work; the slave controller carries out computation on the processed grid connection current signals and voltage signals broadcast from the master controller to obtain control signals to control a slave energy storage inverters to work.

Owner:STATE GRID CORP OF CHINA +3

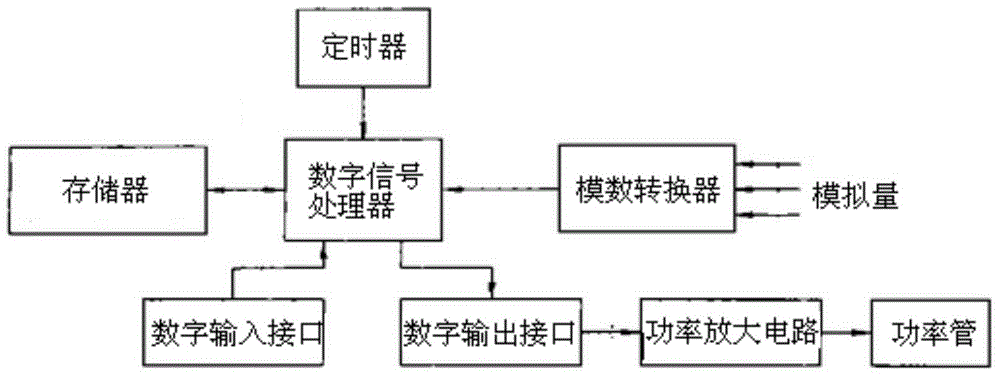

Generator voltage regulator on the basis of digital signal processor control

InactiveCN105634351AShort build-up timeShort transitionGenerator control by field variationDigital signal processingStable state

The present invention discloses a generator voltage regulator on the basis of a digital signal processor control. The generator voltage regulator on the basis of the digital signal processor control comprises a digital signal processor, a memory, a timer, an analog-to-digital converter, a digital input interface, a second digital output interface, a power amplification circuit and a power tube. The memory, the timer, the analog-to-digital converter, the digital input interface, the digital output interface are connected with the digital signal processor, the power amplification circuit is connected with the digital output interface, and the power tube is connected with the power amplification circuit. The generator voltage regulator on the basis of digital signal processor control performs voltage regulation in the control of a digital signal processor and has small overshoot and short voltage buildup time when a generator builds voltage; when the generator is changed in work state, the transition process is short; and when the generator works normally, the stable state error is small.

Owner:无锡圣鑫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com