Manufacturing method of three-dimensional spiral glass micro-channel

A technology of spiral glass and manufacturing method, which is applied in glass manufacturing equipment, manufacturing tools, glass forming, etc., can solve the problems of micro-pipes that are fragile, unmanufacturable, and unable to control the scale and strength of manual stretching, and achieve internal smoothness , good airtightness and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

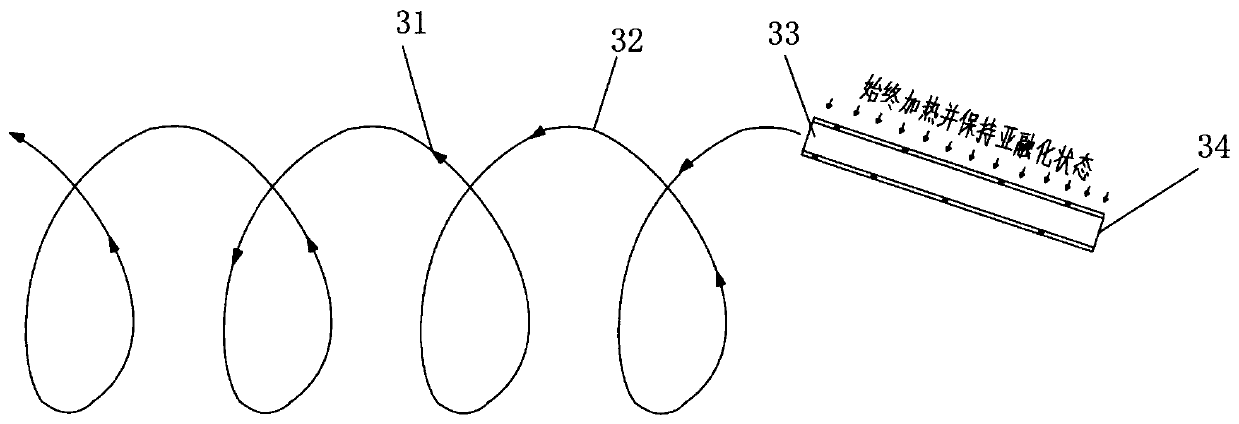

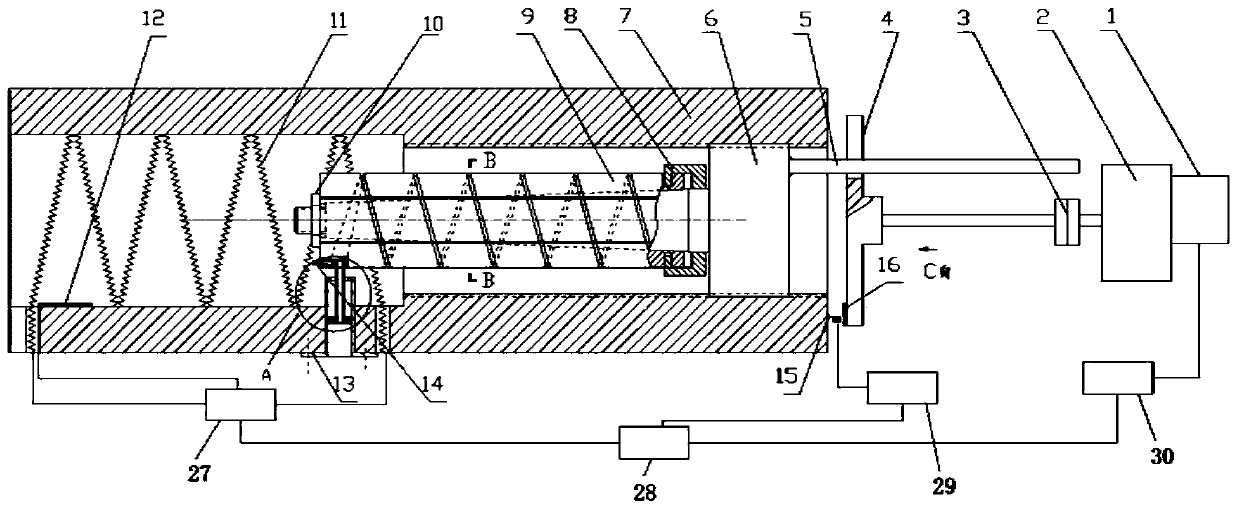

[0034] A kind of three-dimensional spiral glass microchannel manufacturing method of the present embodiment is as follows figure 2 As shown, the glass raw material is first made as figure 1 The shown millimeter-scale glass capillary; then the glass capillary is heated to a sub-melting state to maintain the temperature, and one section of the glass capillary is fixed, which is the fixed end 34, and the other end is stretched by the stretching direction 31 propelled by the screw, Be the stretching end 33, the stretching track 32 is a helix, and the stretching direction is tangent to the helix (as figure 2 (indicated by the middle arrow), the stretching speed and heating temperature can be adjusted according to the stretching process, the stretching speed and heating temperature can be adjusted according to the stretching process. pitch and diameter.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com