Dynamic area optimization and control system of glue mixing and applying of planed fiber artificial board

A dynamic area and optimized control technology, applied in the direction of manufacturing tools, wooden veneer joints, wood processing appliances, etc., can solve the problems of easy pre-curing of glue, inaccurate matching measurement, low level of automatic and continuous production, etc. problems, to achieve the effect of meeting the requirements of precise sizing process, improving the uniformity and stability, and the possibility of large-scale engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

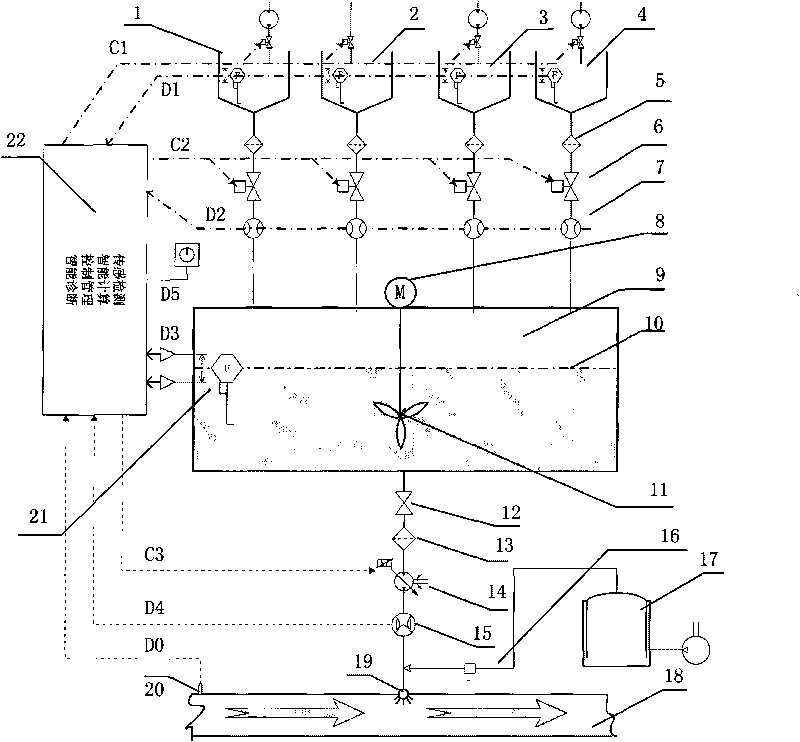

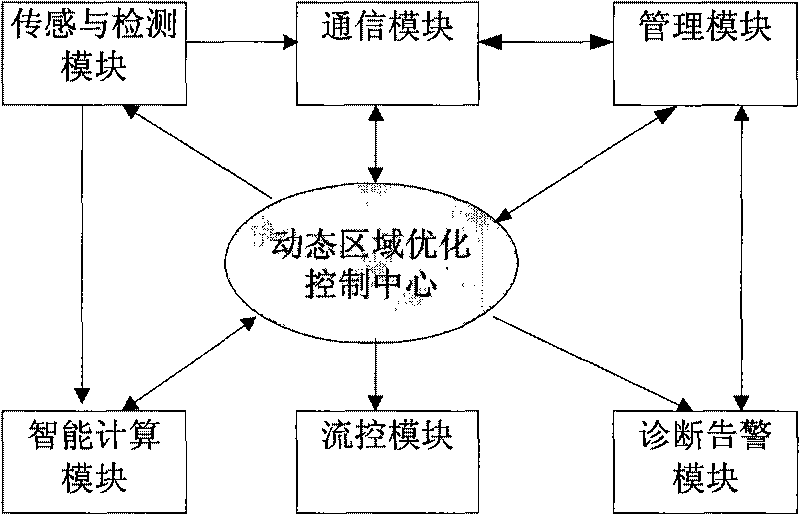

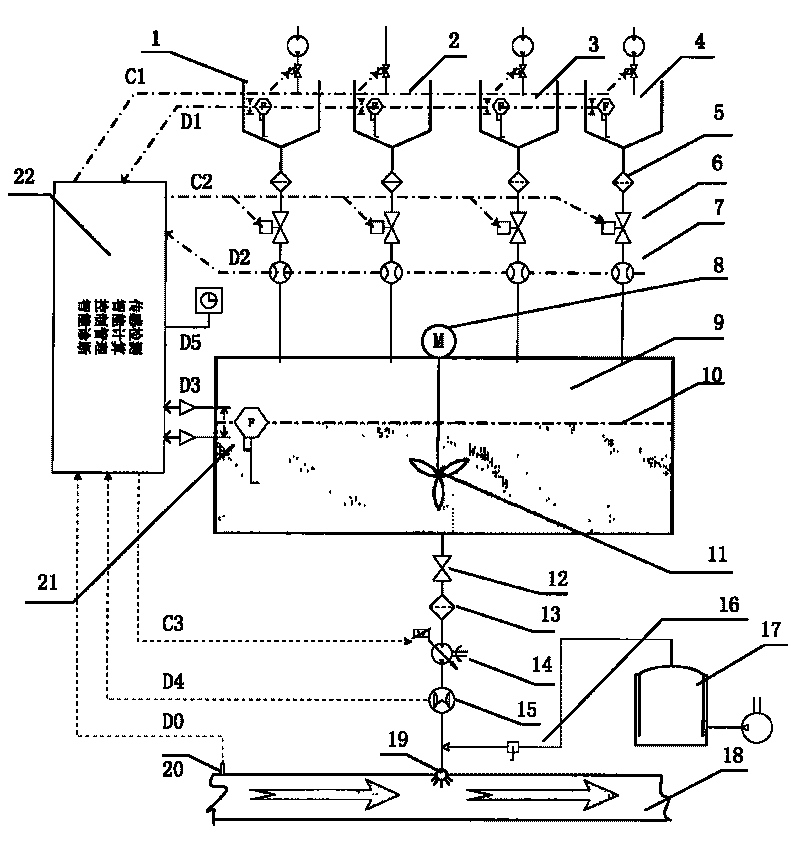

[0034] figure 1 As shown, the dynamic area optimization control system for glue dispensing in the embodiment of the present invention includes a raw glue tank 1, a water tank 2, an additive tank 3, a curing agent tank 4 and other formula injection buffer tank groups, liquid level upper and lower limit sensors, pumps and electromagnetic Automatic material preparation unit composed of valves; glue mixing formula injection pipeline composed of filter 5, servo valve 6, and flow meter 7; glue mixing buffer tank 9 for glue mixing, stirring motor 8, and mixing liquid level 10 and regional liquid level sensor 21 and stirring paddle 11; solenoid valve 12, filter 13, frequency conversion speed regulating pump motor 14, flow meter 15, high-pressure gas tank 17, adjustable air valve 16, nozzle 19, Glue mixing machine or pipeline 18; in addition, there are material flow detection unit 20, liquid level upper and lower limit sensors 21, control cabinet 22; detection channels D0, D1, D2, D3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com