Single-phase motor starting and running device with pure alternating current capacitor

A technology for operating devices and capacitors, which is applied in the field of operating devices and single-phase motor starting, which can solve problems such as limited use, frequent motor failures, and large volume, and achieve the effects of improved pressure bearing capacity, improved product quality, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

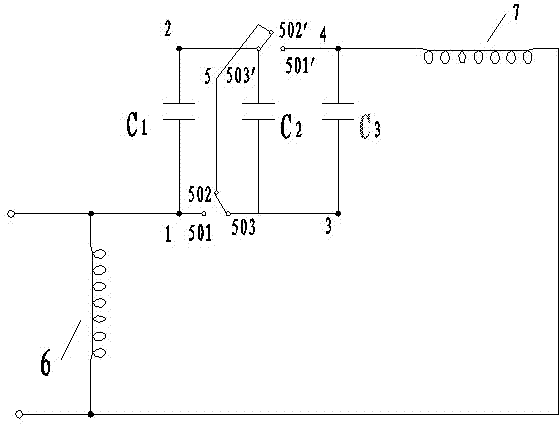

[0016] Such as figure 1 As shown, the present invention has an AC capacitor using a film capacitor (or polypropylene capacitor) and a double-contact centrifugal switch 5. The pure AC capacitor is composed of three capacitive elements C1, C2 and C3 in series, so The first group of contacts of the double-contact centrifugal switch 5 has a moving contact 503, a first static contact 501 and a second static contact 502, and the second group of contacts has a moving contact 503', a first static contact 501' and a second Static contact 502`, the terminals 1 and 4 of the series circuit composed of the three capacitive elements C1, C2 and C3 are respectively connected to the two first static contacts 501 and 501` of the double-contact centrifugal switch, and the two connected The node 3 of the capacitive elements C2 and C3, the node 2 of the capacitive elements C1 and C2 are respectively connected to the two moving contacts 503 and 503` of the double-contact centrifugal switch, and the...

Embodiment 2

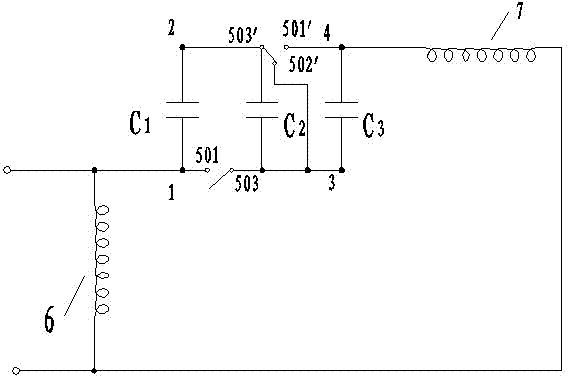

[0019] Such as figure 2 As shown, the present invention is composed of an AC capacitor using a film capacitor (or polypropylene capacitor) and a double-contact centrifugal switch. The pure AC capacitor is composed of three capacitive elements C1, C2 and C3 connected in series in sequence, and the The first group of contacts of the double-contact centrifugal switch has a moving contact 503 and a first static contact 501, the second group of contacts has a moving contact 503`, a first static contact 501` and a second static contact 502`, the three Terminals 1 and 4 of a series circuit composed of capacitive elements C1, C2 and C3 are respectively connected to the two first static contacts 501 and 501` of the double-contact centrifugal switch, and the nodes 3 of the capacitive elements C2 and C3 connected in pairs , Node 2 of the capacitive elements C1 and C2 are respectively connected to two moving contacts 503 and 503` of the double-contact centrifugal switch, the moving conta...

Embodiment 3

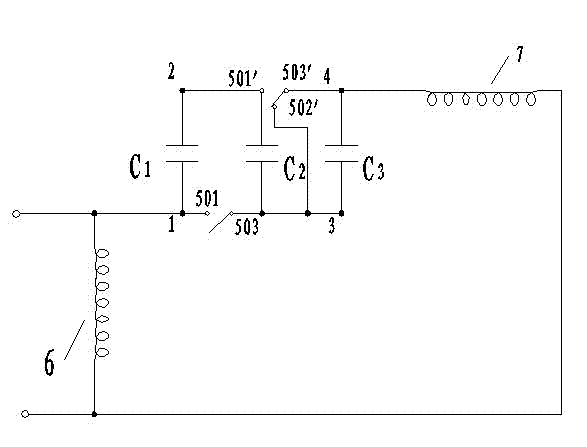

[0022] Such as image 3 As shown, the present invention is composed of an AC capacitor using a film capacitor (or polypropylene capacitor) and a double-contact centrifugal switch. The pure AC capacitor is composed of three capacitive elements C1, C2 and C3 connected in series in sequence, and the The first group of contacts of the double-contact centrifugal switch has a moving contact 503 and a first static contact 501, the second group of contacts has a moving contact 503`, a first static contact 501` and a second static contact 502`, the three Terminals 1 and 4 of the series circuit composed of three capacitive elements C1, C2 and C3 are respectively connected with the first static contact point 501 of the first set of contacts and the moving contact point 503′ of the second set of contacts, and the capacitive element C2 connected in pairs and the node 3 of C3 and the node 2 of the capacitive elements C1 and C2 are respectively connected with the moving contact 503 of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com