An Ultrasonic Penetrating Metal Communication Device

A communication device, ultrasonic technology, applied in ultrasonic/sonic/infrasonic transmission systems, electrical components, transmission systems, etc., can solve problems such as difficult communication methods and inability to receive signals, and achieve the elimination of inter-symbol interference and error-free high-speed transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

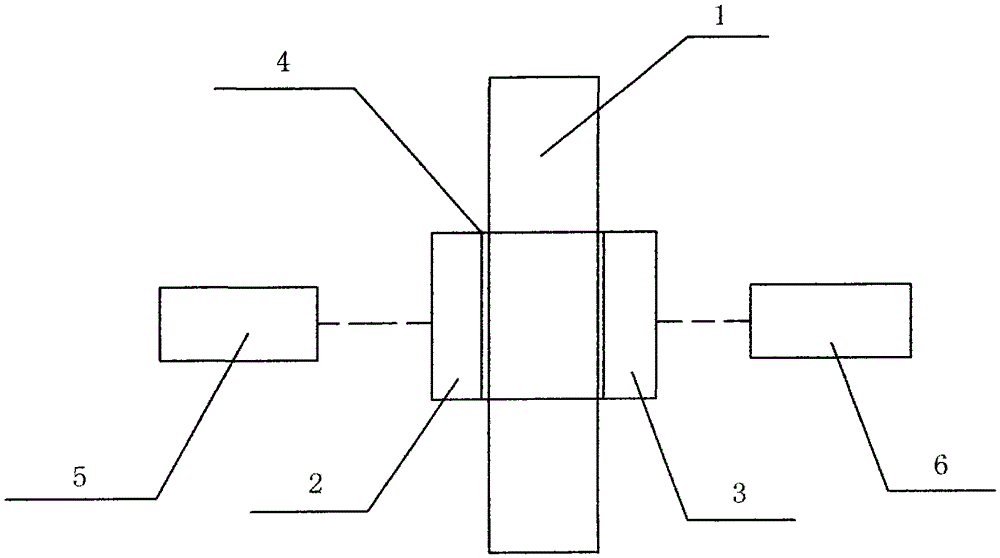

[0012] Reference Figure 1-3 This specific implementation adopts the following technical solutions: its production method is to prepare curing agent and epoxy resin in a ratio of 1:4, mix them evenly to form coupling agent 4, and use sandpaper to polish the outer walls on both sides of the steel plate 1 to ensure that they are parallel Smooth, use couplant 4 to align the transmitting transducer 2 and the receiving transducer 3 on the two side walls of the steel plate 1 to ensure that the piezoelectric wafer and the steel plate wall are tightly bonded without leaving any gaps. The transmitting transducer 2 and The driving signal circuit 5 is connected, and the receiving transducer 3 is connected to the signal processing circuit 6.

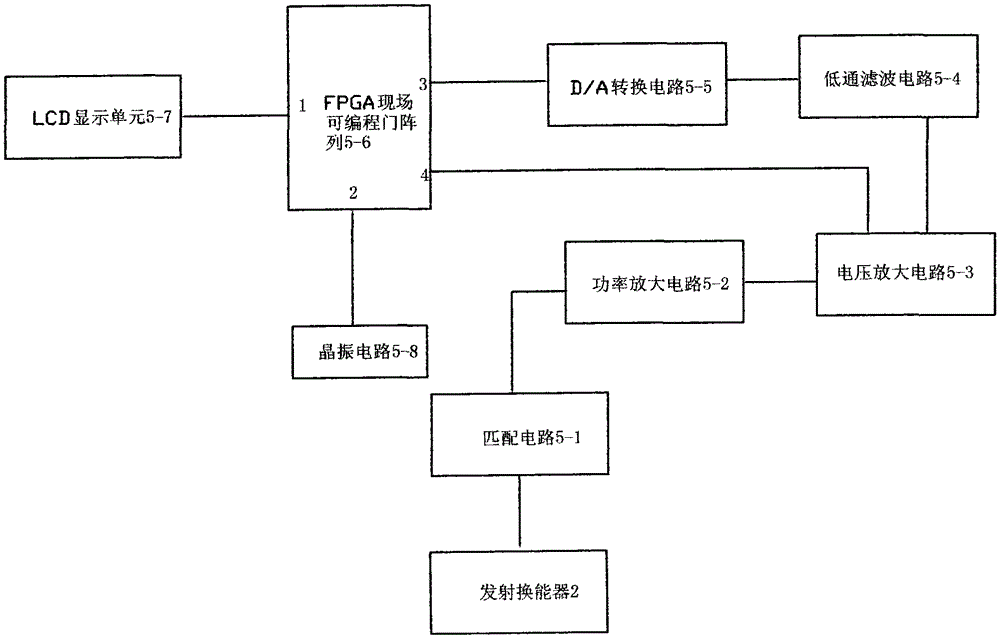

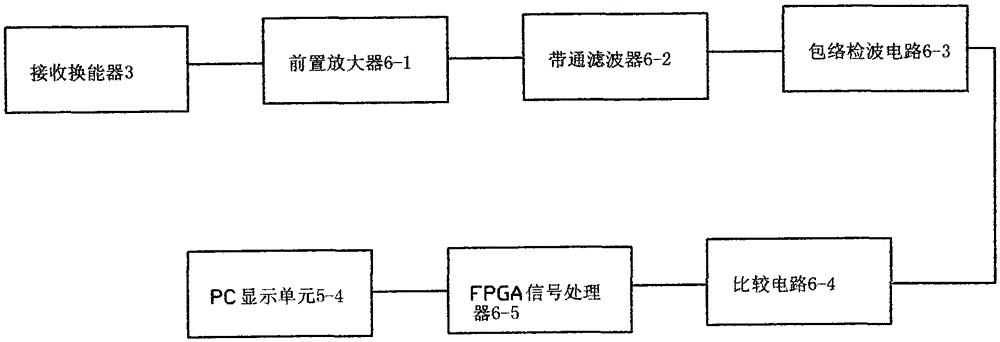

[0013] The driving signal circuit 5 includes a matching circuit 5-1, a power amplifier circuit 5-2, a voltage amplifier 5-3, a low-pass filter circuit 5-4, a D / A conversion circuit 5-5, and an FPGA field programmable gate array 5-6, LCD display unit 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com