Toothing for operation at a deflection angle and production method

A technology of deflection angle and tooth section, which is applied to the driving device of metal rolling mills, manufacturing tools, metal rolling, etc., and can solve the problems of not meeting the requirements of torque transmission, wear, and inability to transmit torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] First of all, it should be noted that concepts such as pitch circle, addendum circle, dedendum circle, generatrix, tooth line, mesh angle, deflection and others are generally known to experts and are therefore used without further elaboration in the instructions below.

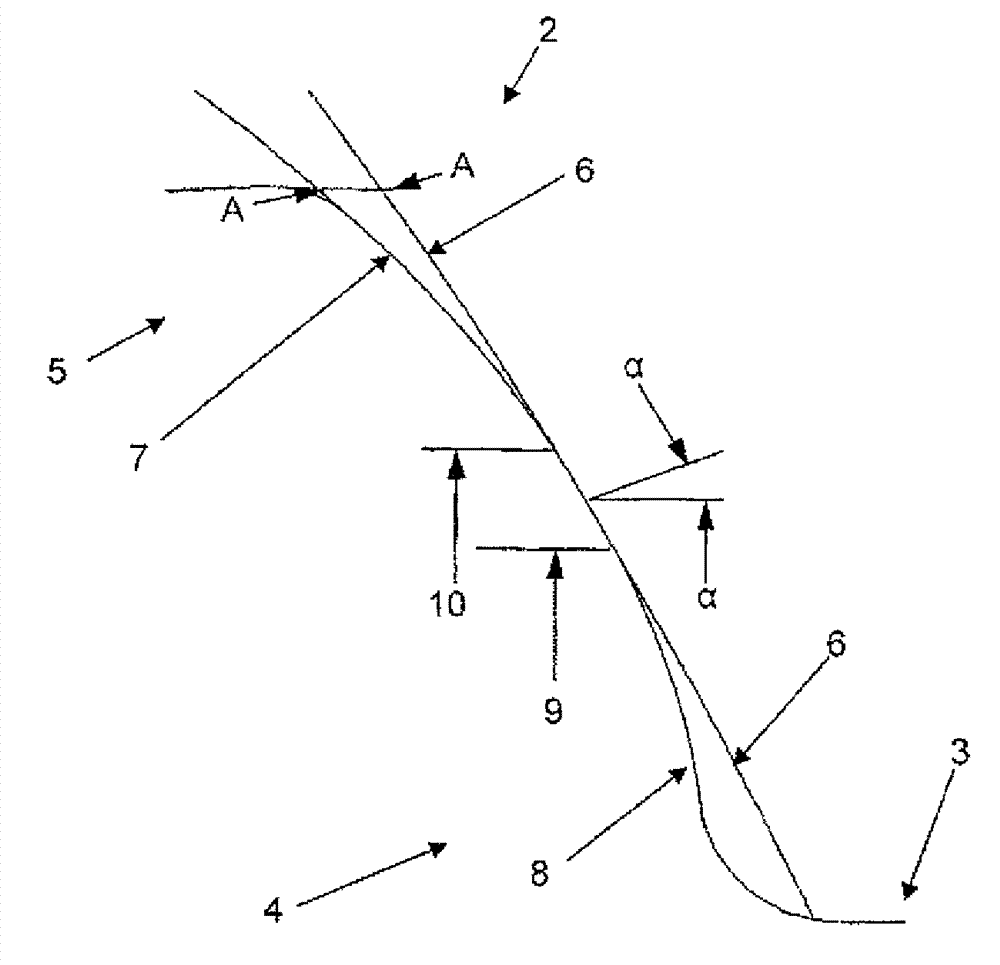

[0039] figure 1 A schematic cross section through the flank of a tooth 2 of the toothing 1 is shown. The tooth line runs in a convexly curved manner, so in principle it can also be called a curved tooth. To the right of this tooth flank there is a backlash 3 . The axis of rotation of the toothing 1 is perpendicular to the cross-sectional plane shown. The engagement angle α of the toothing can have different values, it can particularly preferably assume a value between 26° and 34°. The line 6 represents the contour of the tooth 2 in the form of a conventional involute 6 of the known involute toothing. According to the invention, however, the dedendum 4 and / or also the tooth tip 5 of the tooth 2 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com