Built-in ditcher of supporting reloading of operation modules

A technology of operation device and trencher, which is applied in the direction of excavation/covering of trenches, agriculture, planting methods, etc., can solve the problems of poor fertilization effect, oversized operation machinery, and inability to operate in orchards, and achieves reduction in length and height. , The effect of improving the passability under the tree and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The substantive features and advantages of the present invention will be further described below in conjunction with examples, but the present invention is not limited to the listed embodiments.

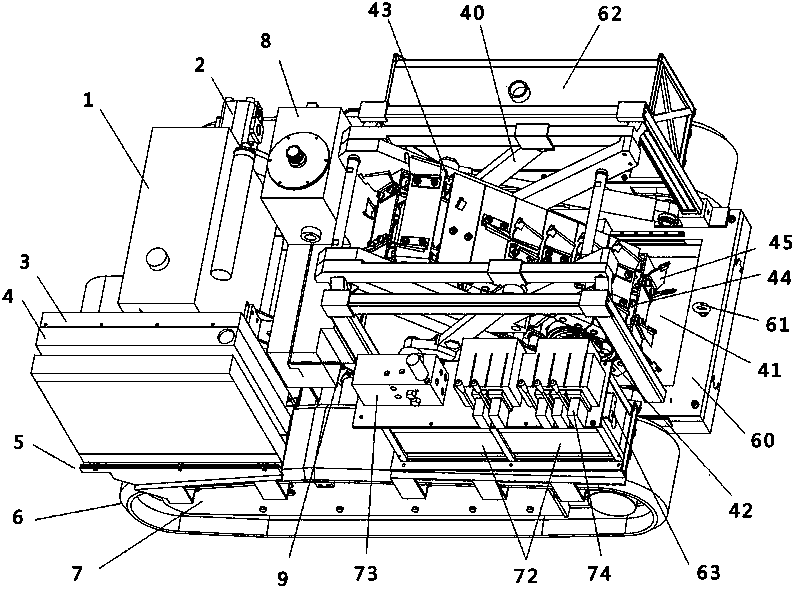

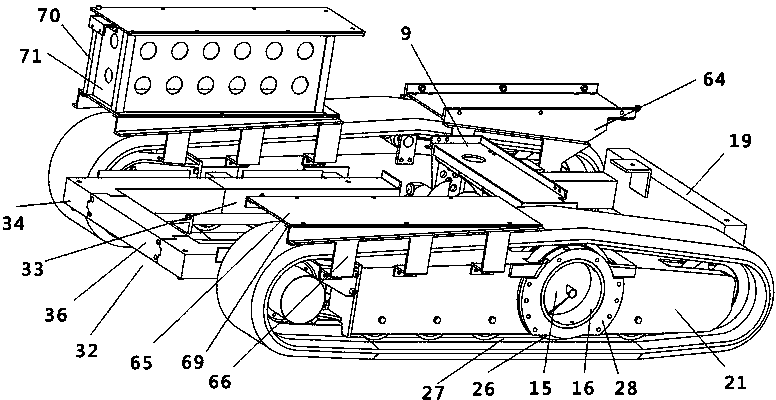

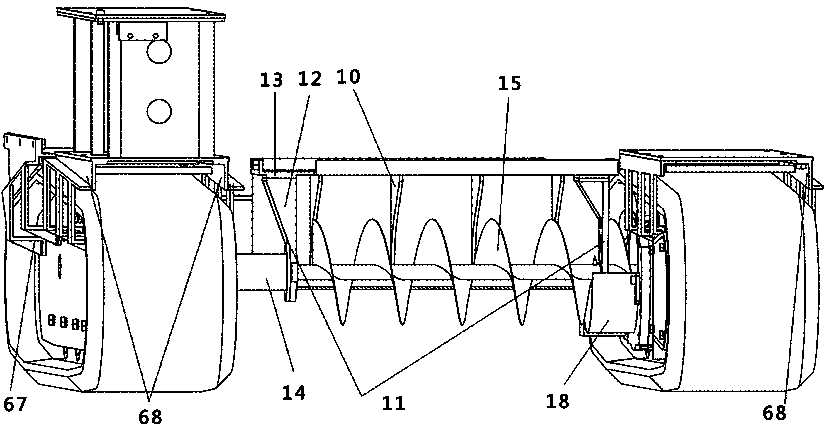

[0045] see Figure 1~12 As shown, the diesel engine 1 of the ditching machine of the present invention is horizontally arranged between the crawlers 6, one side of the diesel engine 1 is connected to the hydraulic pump 2, and the fan side is equipped with a fan cover 3 and a heat dissipation system 4, and the heat dissipation system 4 is arranged on the radiator bracket 5, the radiator bracket 5 is connected with the left crawler beam 7.

[0046] The diesel engine 1 is installed on the diesel engine bracket 19, and the mounting feet 20 on both sides of the diesel engine bracket 19 are connected to the left crawler beam 7 and the right crawler beam 21.

[0047] The hydraulic oil tank 8 and the hydraulic oil tank bracket 9 are placed in the middle of the vehicle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com