How Paper is Made

A manufacturing method and paper technology, applied in the field of paper manufacturing, can solve the problems of low physical strength indicators such as tensile strength, cohesion, and folding resistance, and achieve the improvement of physical strength indicators, strong shear resistance, and good bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

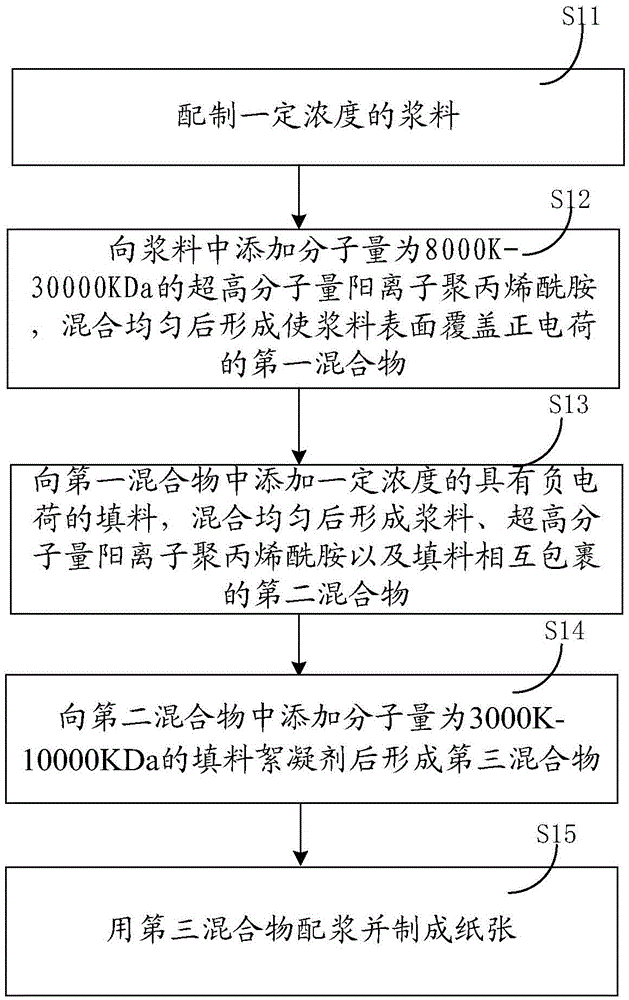

Method used

Image

Examples

no. 2 example

[0033] The second embodiment of paper manufacturing method of the present invention is as follows:

[0034] Present embodiment is to make handwritten sheet in laboratory, and the manufacturing method of paper comprises the following steps:

[0035] In the first step, take 10 g of chemical hardwood pulp and dilute it with white water to a concentration of 5.0%.

[0036]In the second step, 0.5Kg / T filler is added to the chemical hardwood pulp, the ultra-high molecular weight cationic polyacrylamide with a charge of 15meq / g and a molecular weight of 30000KDa is stirred for 60s to form the first mixture.

[0037] In the third step, 2 g of precipitated calcium carbonate (filler) was added to the first mixture, and the second mixture was formed after stirring again for 60 s.

[0038] Step 4: Add 4.5Kg / T filler flocculant with a charge of 10meq / g and a molecular weight of 3000KDa to the second mixture, stir for 60s to form a third mixture and keep it warm at 50°C for later use.

[...

no. 3 example

[0044] The third embodiment of the paper manufacturing method of the present invention is as follows:

[0045] Present embodiment is to make handwritten sheet in laboratory, and the manufacturing method of paper comprises the following steps:

[0046] Step 1: Take 4g of BCTMP, disperse it with hot water and dilute it with white water to a concentration of 0.8%.

[0047] In the first step, BCTMP can also be replaced with APMP or other mechanical pulps.

[0048] Step 2: Add 5Kg / T filler to the BCTMP, the ultra-high molecular weight cationic polyacrylamide with a charge of 5meq / g and a molecular weight of 8000KDa, and stir for 60s to form the first mixture.

[0049] Step 3: Add 8 g of talcum powder (filler) to the first mixture, and stir again for 60 seconds to form the second mixture.

[0050] Step 4: Add 0.5Kg / T filler, a filler flocculant with a charge of 30meq / g and a molecular weight of 10,000KDa to the second mixture, stir for 60s to form a third mixture and keep it warm ...

no. 4 example

[0055] The fourth embodiment of the paper manufacturing method of the present invention is as follows:

[0056] Present embodiment is to make handwritten sheet in laboratory, and the manufacturing method of paper comprises the following steps:

[0057] Step 1: Take 6g of chemical coniferous wood pulp, dilute it with white water to a concentration of 4.0% after dispersion.

[0058] Step 2: Add 2.0Kg / T filler to the coniferous wood pulp, ultra-high molecular weight cationic polyacrylamide with a charge of 7.5meq / g and a molecular weight of 10000KDa, and stir for 60s to form the first mixture.

[0059] Step 3: Add 6 g of ground calcium carbonate (filler) to the first mixture, and stir again for 60 seconds to form the second mixture.

[0060] Step 4: Add 3.5Kg / T filler, a filler flocculant with a charge of 25meq / g and a molecular weight of 10,000KDa to the second mixture, stir for 60s to form a third mixture and keep it warm at 50°C for later use.

[0061] Step 5: Take 10g of ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com