Working condition concentration control system of mixed working medium throttling refrigerating machine and working condition concentration control method

A technology of throttling refrigerators and mixed working fluids, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of poor effect, inability to improve refrigeration efficiency, and no energy saving, so as to overcome the high pressure and excessive start-up. High and maintain the effect of high efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

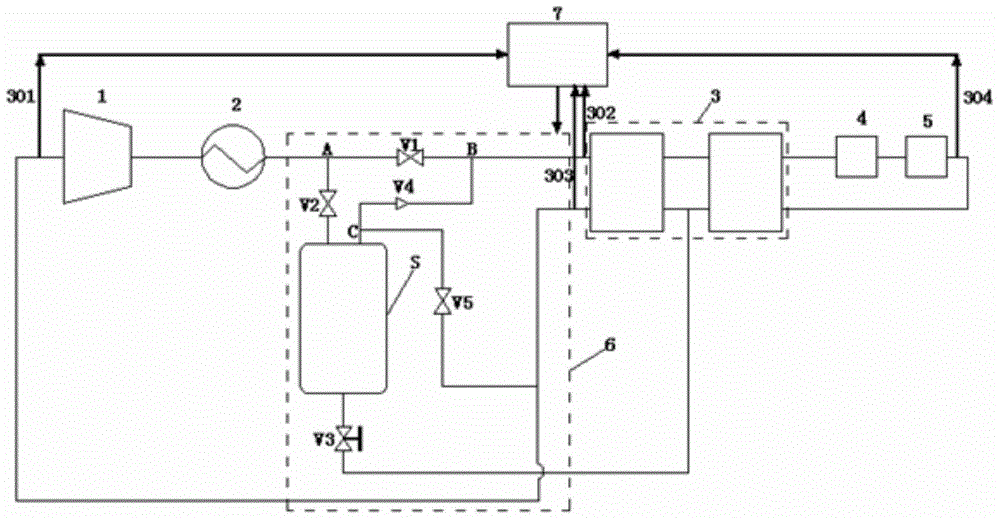

[0056] as the picture shows. The present invention is a mixed working medium throttling refrigerator operating condition concentration control system, comprising a compressor unit 1, a condensing cooler unit 2, a recuperation heat exchanger unit 3, a throttling unit 4, an evaporator unit 5, and a controllable passage Working fluid concentration and flow adjustment unit 6, control unit 7;

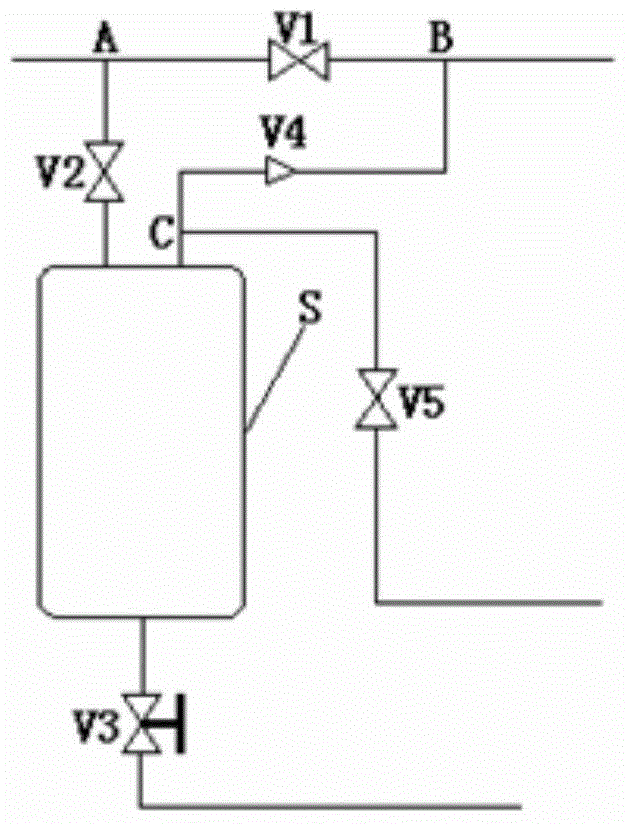

[0057] The controllable passage working medium circulation concentration and flow adjustment unit 6 includes: a controllable main circuit valve V1, a controllable bypass tank inlet valve V2, a controllable working medium outlet valve V3, a tank outlet one-way valve V4 and a controllable Low pressure tank valve V5;

[0058] It is connected by pipelines, and the connection method is: the inlet port of the controllable main circuit valve V1 is connected to the first outlet of the three-way fitting A, and the second outlet of the three-way fitting A is connected to the controllable bypass tank ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap