Rotary calcination device and rotary calcination process

A technology of rotary roasting and rotary devices, which is applied in the direction of rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of unfavorable reactions and purification of roasted products, unstable product quality, low equipment operation rate, etc., and achieve increased tail gas treatment The effect of reducing the energy consumption of equipment operation and heating evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

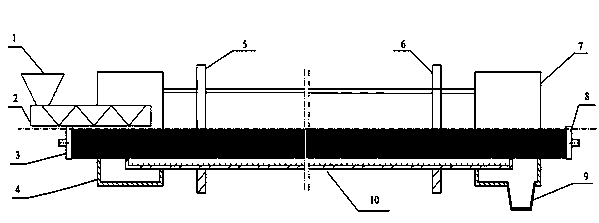

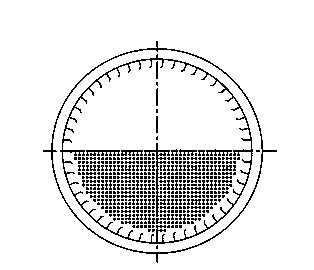

[0032] figure 1 Among them, the silo 1 and the feeder 2 are connected to form a conveying device, the sealing devices Ⅰ4 and Ⅱ7 are connected with the rotary drum 10, and the two ends of the rotary drum 10 are equipped with a sealing device Ⅰ4 and a sealing device Ⅱ7, and the sealing device is connected to a static heat soaking device Ⅰ3 , Soaking device Ⅱ8, soaking device Ⅰ3, and Ⅱ8 are connected by heating tubes, and the tubes run through the entire kiln body. No tubes are installed in the upper part of the kiln, and the inner wall of the kiln is equipped with lifting plates. The conveying device is composed of a silo 1 and a feeder 2, and the material in the silo 1 enters the kiln for roasting through the feeder 2. Sealing device Ⅰ4 and sealing device Ⅱ7 are shaft end contact seals. The rotary part is a rotary cylinder 10, the front roller 5 and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap