Experimental method for measuring the amount of solvent replacement required for polyvinyl acetate in cleaning equipment and pipelines

A polyvinyl acetate, cleaning equipment technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of not being able to confirm the cleaning of polyvinyl acetate, and achieve the effects of saving production costs, saving solvent volume, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

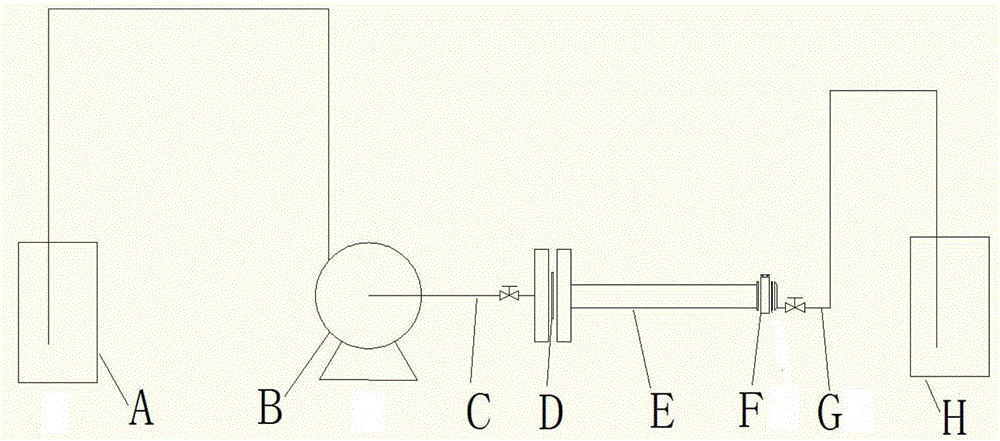

[0019] in such as figure 1 On the device shown, the solvent is methanol, the test steel pipe E is 304 stainless steel, 1.5m long, 0.05m in diameter, and then the required cleaning density is 241.78kg / m 3 1. Fill the steel pipe with low-viscosity polyvinyl acetate, fill the steel pipe, and calculate the amount m1 of polyvinyl acetate added through the quality difference with the steel pipe, which is 2.847kg. Then turn on the plunger feeding pump B, flush the methanol in the solvent tank A into the test steel pipe E, and the polyvinyl acetate and methanol mixture enters the waste liquid tank H through the pipeline G. With the continuous addition of methanol, the test steel pipe The polyvinyl acetate in E is completely replaced, the test steel pipe E is filled with methanol (can be measured by mass), the mixed solution of polyvinyl acetate and methanol in the waste liquid tank H is collected, and the weight m2 of the mixture after washing is weighed as 10.9589 kg.

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com