Vacuum assisted resin infusion fabric compacting characteristic and permeability performance integrated testing device

A fiber fabric and testing device technology, applied in measuring devices, textile testing, permeability/surface area analysis, etc., can solve the problems of high testing cost and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

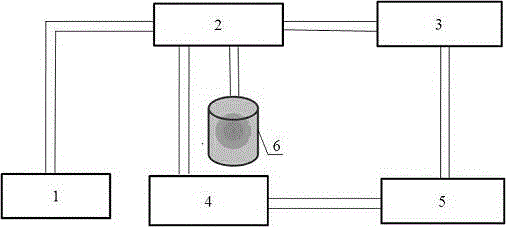

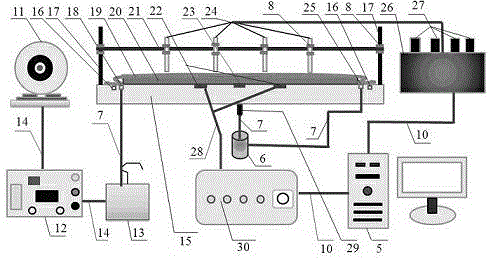

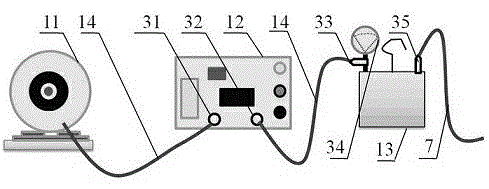

[0025] The present invention is an integrated test device for the compaction characteristics and permeability performance of fiber fabrics applied in the vacuum-assisted forming process (please refer to figure 1 and figure 2 ), the test device is composed of a pressure control system 1, a fabric performance test device 2, a fiber fabric thickness test system 3, a fiber fabric pressure test system 4, a container 6 for soaking liquid, and a host computer 5. The pressure control system 1 passes through the guide The flow pipe 7 is connected with the fiber fabric performance testing device 2, and the fiber fabric thickness testing system 3 is connected with the fiber fabric performance testing device 2 by using nuts 8 on the upper and lower sides of the aluminum plate beam 21, and is connected with the host computer 5 through a USB data connection line 10 connected....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com