Graduated dry type inversion capacitor

A technology of capacitors and inverters, which is applied in the field of capacitors, can solve problems such as excessive use of parts, easy drop in capacity, and large film damage, and achieve the effects of low production cost, low loss, and small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

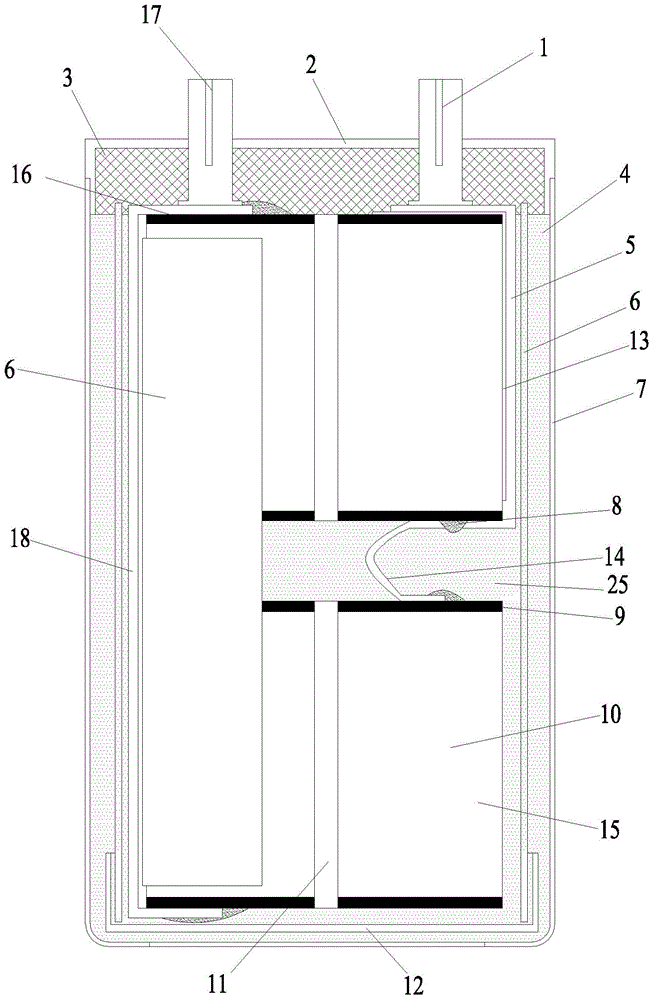

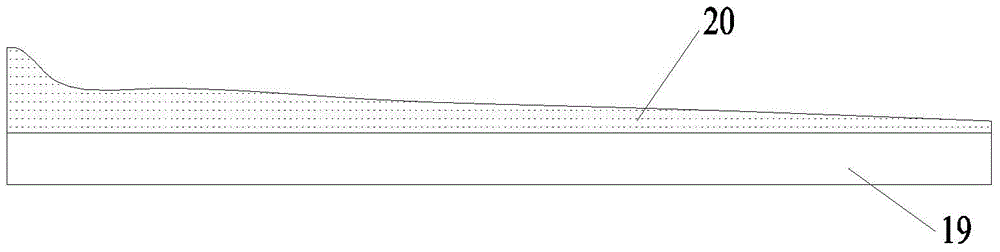

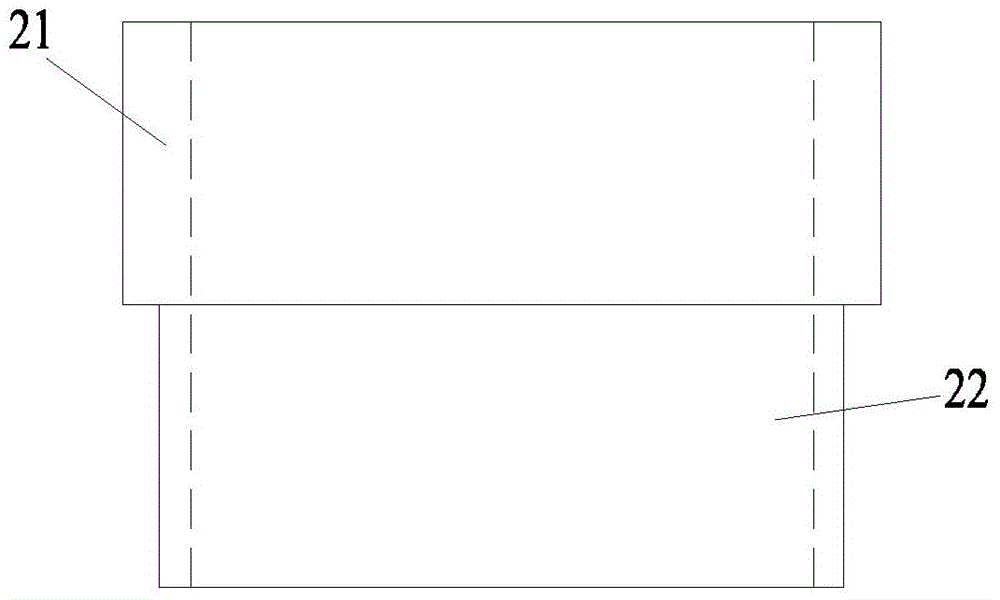

[0021] Such as figure 1 Shown: In order to improve the high voltage resistance, high temperature resistance and impact resistance of the capacitor, the present invention includes a capacitor case and a first lead-out connection terminal 1 and a second lead-out connection terminal 17 at the top of the capacitor case; the capacitor A core 10 is packaged in the shell, and the core 10 includes a core film 15 with a gradually changing distribution of square resistance and a first gold-spraying layer 9 and a second gold-spraying layer 16 on the core film 15. One lead-out connection terminal 1 is electrically connected to the first gold-sprayed layer 9 , and the second lead-out connection terminal 17 is electrically connected to the second gold-spray layer 16 .

[0022] Specifically, the first lead-out connection terminal 1 is electrically connected to the first gold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com