Method for avoiding film poisoning caused by ion implantation layer rear photoresist

An ion implantation and thin film technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of affecting yield, thin film deposition, and residues that cannot be completely removed, so as to avoid film poisoning and yield Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

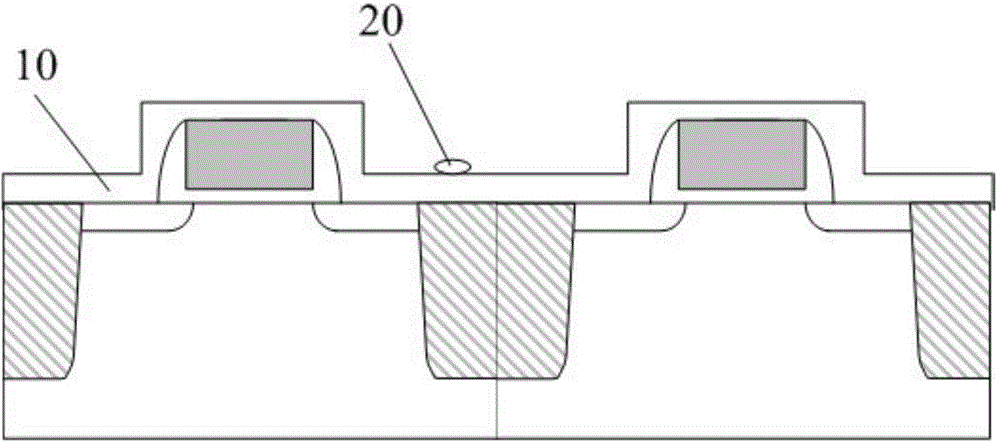

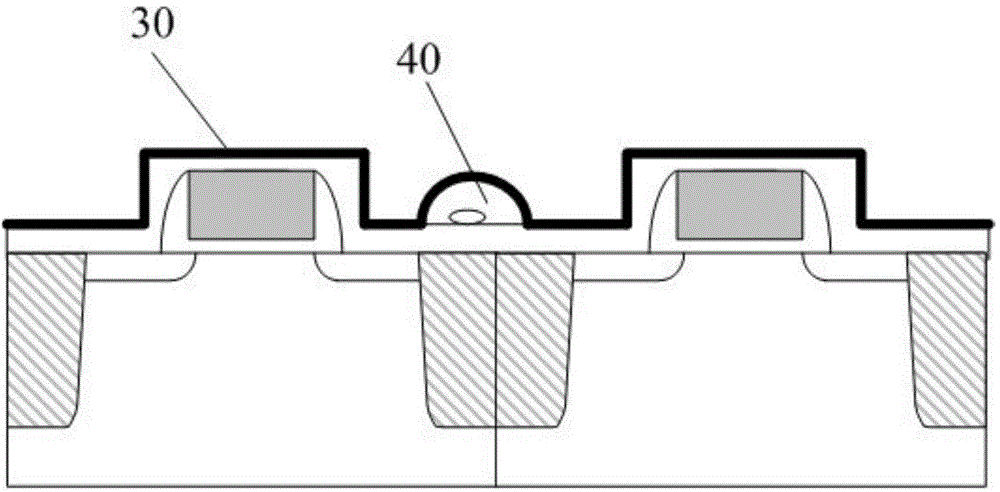

[0021] Figure 4 to Figure 8 Each step of the method for avoiding film poisoning caused by photoresist after ion-implantation layer according to a preferred embodiment of the present invention is schematically shown.

[0022] Specifically, such as Figure 4 to Figure 8 As shown, the method for avoiding film poisoning caused by photoresist after ion implantation layer according to a preferred embodiment of the present invention includes:

[0023] Form the photoresist layer 11 of the ion implantation layer directly on the dielectric film 10, and utilize the photoresist layer 11 of the ion implantation layer to perform ion implantation, such as Figure 4 shown; for example, the dielectric film 10 may be a silicon oxide layer or a silicon nitride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com