Low-cost tunable dfb semiconductor laser with integrated modulator and its preparation method

A technology for tuning lasers and modulators, which is applied in the field of optoelectronics, can solve the problems of not being able to achieve a high direct tuning rate and weaken the advantages of tunable solutions, and achieve the effects of simplifying packaging structure design, easy packaging, and reducing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

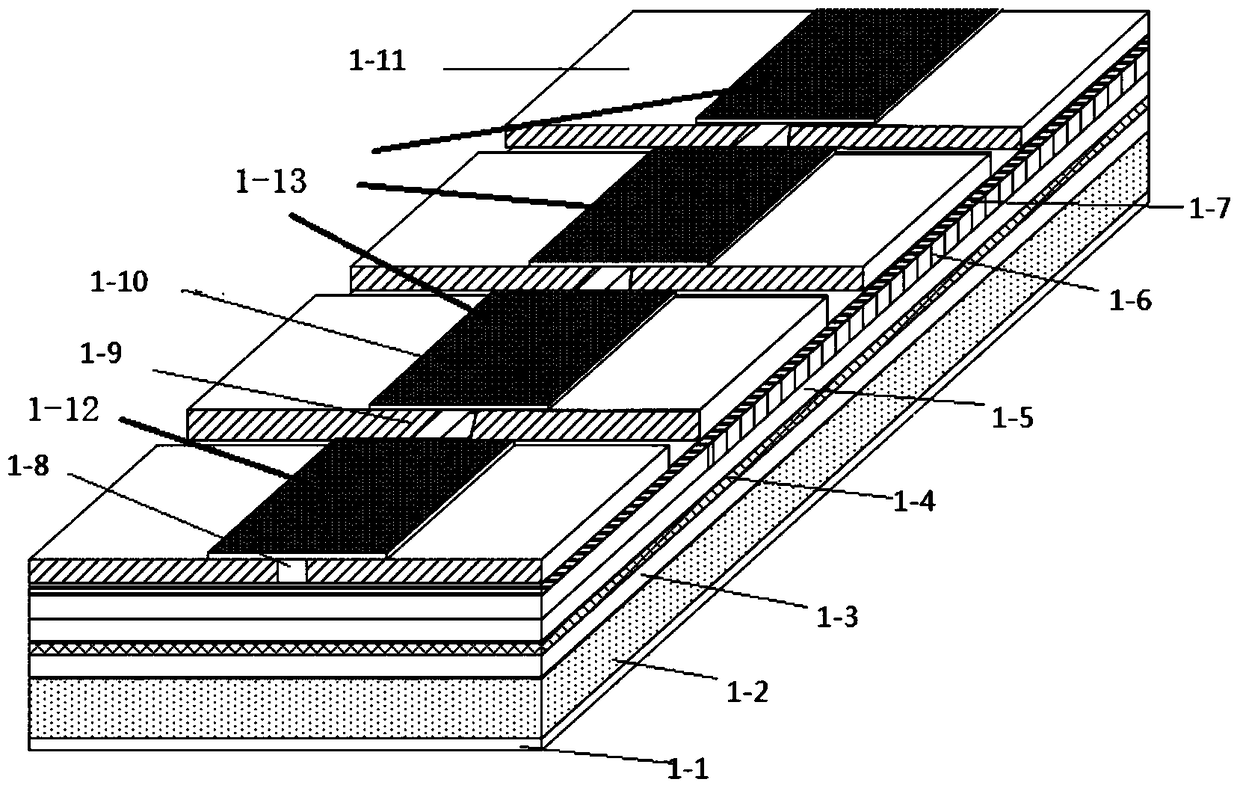

[0034] [Example 1] The working wavelength is 1555 ~ 1561nm based on the same epitaxial structure integrated SOA modulator four-section series tunable DFB semiconductor laser (such as figure 1 shown):

[0035] First, design and manufacture the photolithography plate according to the process steps. The process flow of manufacturing DFB semiconductor lasers based on the reconstruction-equivalent chirp technology is one step more than the standard process flow. The second exposure process of the seed grating, the second Exposure is achieved by sampling a raster plate. The equivalent pi phase shift is introduced by adding a mutation of half the sampling period in the middle of the uniform sampling grating, so as to produce a DFB semiconductor laser with an equivalent pi phase shift. The different lasing wavelengths of the laser are realized by changing the sampling period. The design makes three lasers The lasing wavelengths are 1555nm, 1558nm and 1561nm respectively (the specific...

Embodiment 2

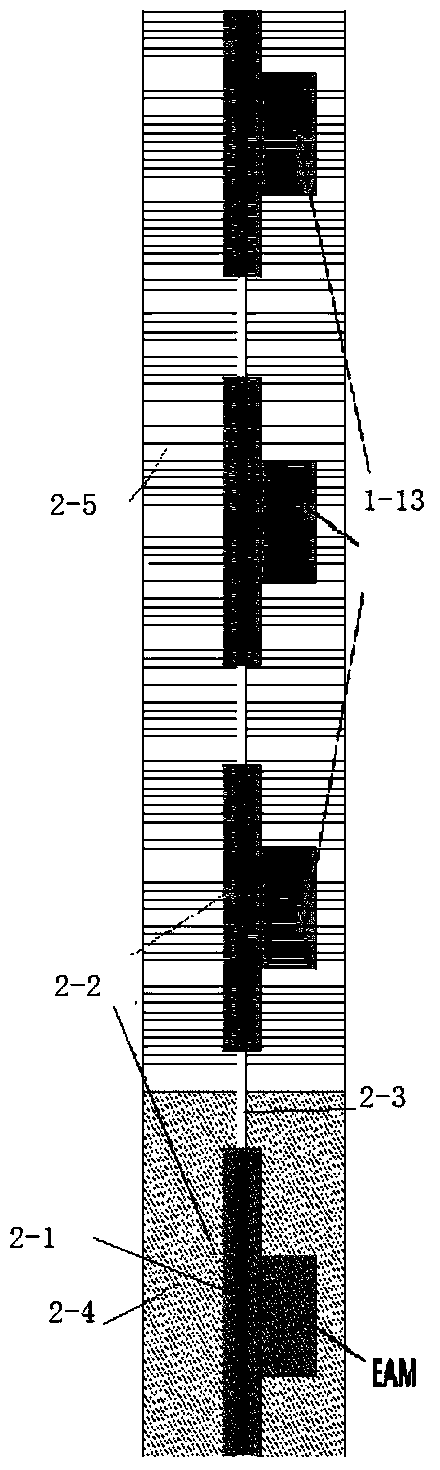

[0042] [Example 2] The four-section series-connected tunable DFB semiconductor laser (such as figure 2 shown, produced by SAG technology):

[0043] First, design and manufacture the photolithography plate according to the process steps. The process flow of manufacturing DFB semiconductor lasers based on the reconstruction-equivalent chirp technology is one step more than the standard process flow. The second exposure process of the seed grating, the second Exposure is achieved by sampling a raster plate. The equivalent pi phase shift is introduced by adding a mutation of half the sampling period in the middle of the uniform sampling grating, so as to produce a DFB semiconductor laser with an equivalent pi phase shift. The different lasing wavelengths of the laser are realized by changing the sampling period. The design makes three lasers The lasing wavelengths are 1555nm, 1558nm and 1561nm respectively (the specific arrangement order can be optimized according to the situati...

Embodiment 3

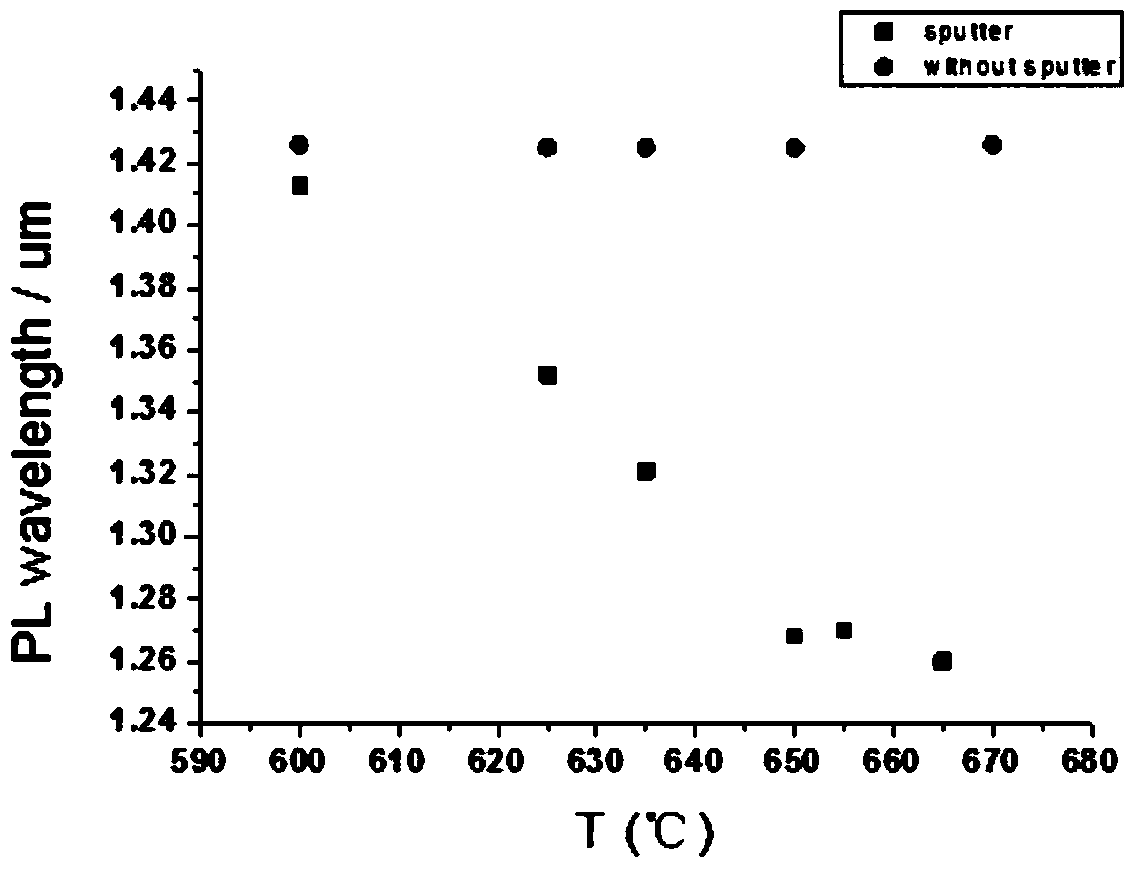

[0050] [Example 3] The tunable DFB semiconductor laser (such as the tunable DFB semiconductor laser with an integrated EAM modulator and coupled through a passive Y-branch waveguide) with an operating wavelength of 1544 to 1559 nm Figure 4 As shown, the blue shift of the PL spectrum is produced by the QWI technique):

[0051] First, design and manufacture the photolithography plate according to the process steps. The process flow of manufacturing DFB semiconductor lasers based on the reconstruction-equivalent chirp technology is one step more than the standard process flow. The second exposure process of the seed grating, the second Exposure is achieved by sampling a raster plate. The equivalent pi phase shift is introduced by adding a mutation of half the sampling period in the middle of the uniform sampling grating, so as to produce a DFB semiconductor laser with an equivalent pi phase shift. The different lasing wavelengths of the laser are realized by changing the samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com