Micro-water detection system based on distributed feedback fiber laser

A fiber laser and distributed feedback technology, which is applied in the direction of phase influence characteristic measurement, etc., can solve the problems of complex structure and difficult simultaneous detection of multiple points, and achieve the effects of high sensitivity, simple packaging structure design, and large dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

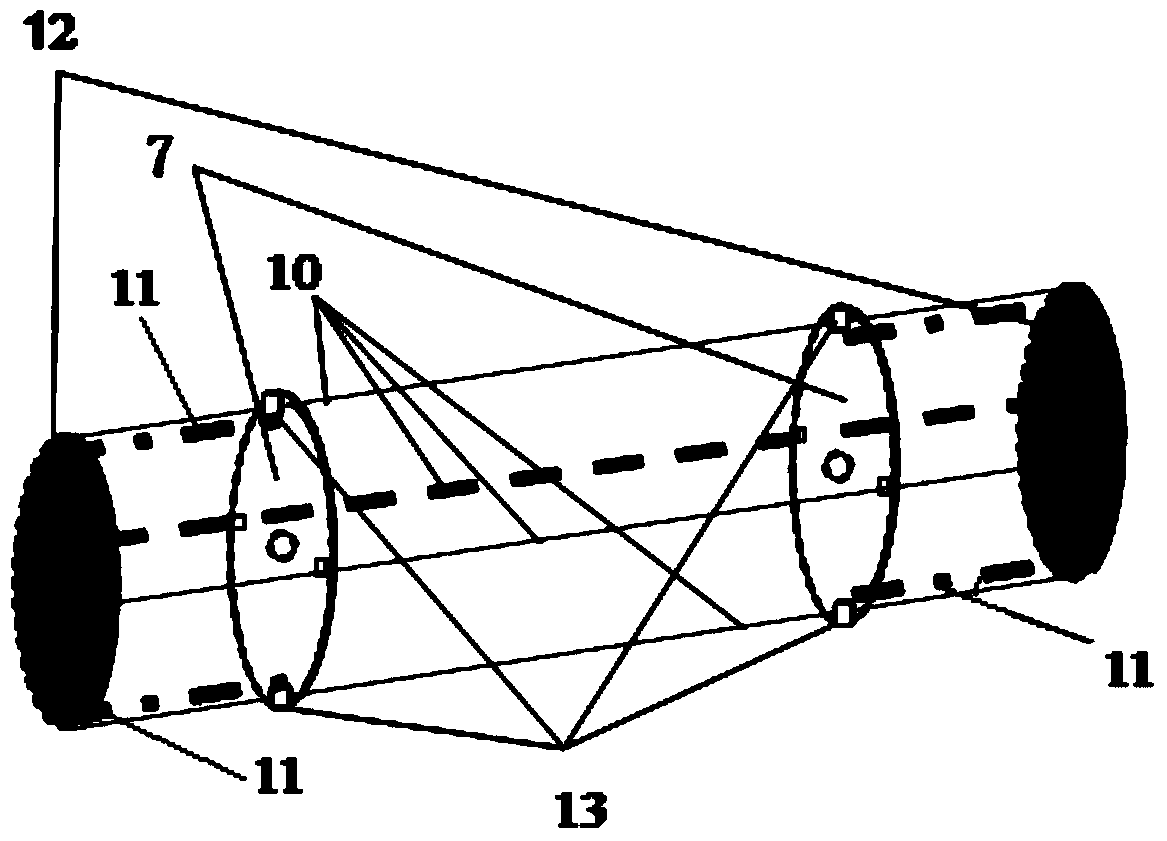

[0034] Embodiment 1 of the present invention such as Figure 4 As shown, a micro-water detection system based on distributed feedback fiber laser, including 980nm pump light source (LD) 16, wavelength division multiplexer (WDM) 17, isolator (ISO) 20, distributed feedback fiber laser (DFB- FL) array 19 and demodulation system, it is characterized in that 980nm pump light source 16 is connected with the 980nm input end of wavelength division multiplexer 17 by its pigtail; The common end of wavelength division multiplexer 17 is made of common single mode The optical fiber 18 is connected to the distributed feedback fiber laser array 19; the 1550nm end of the wavelength division multiplexer 17 is connected to the positive input end of the isolator 20 through a single-mode optical fiber, and the other end of the isolator 20 is connected to the demodulation system; the demodulation system Including unbalanced Michelson (Michelson) interferometer 21, dense wavelength division multipl...

Embodiment 2

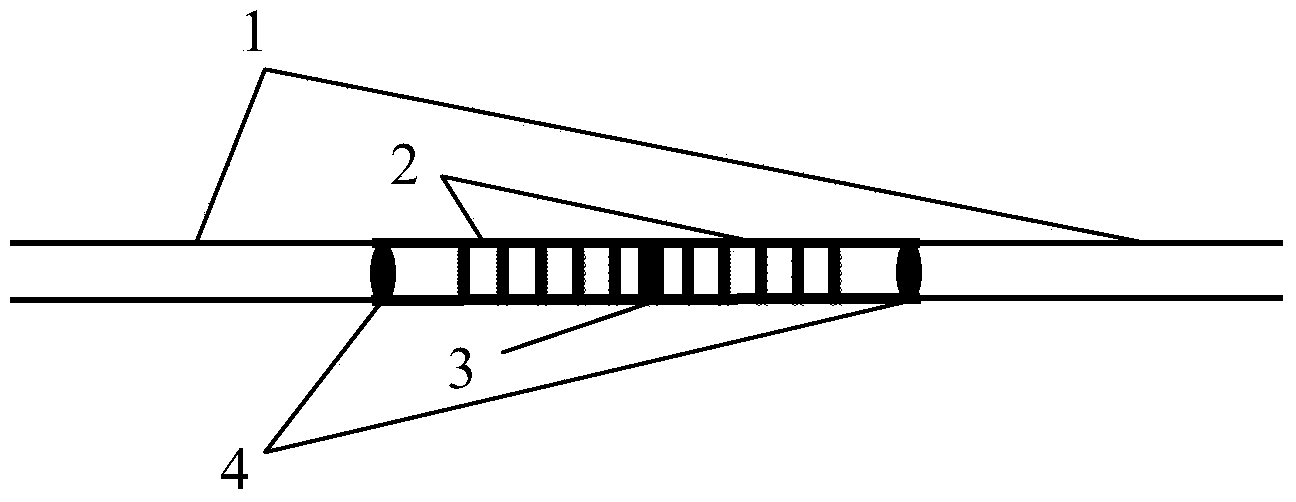

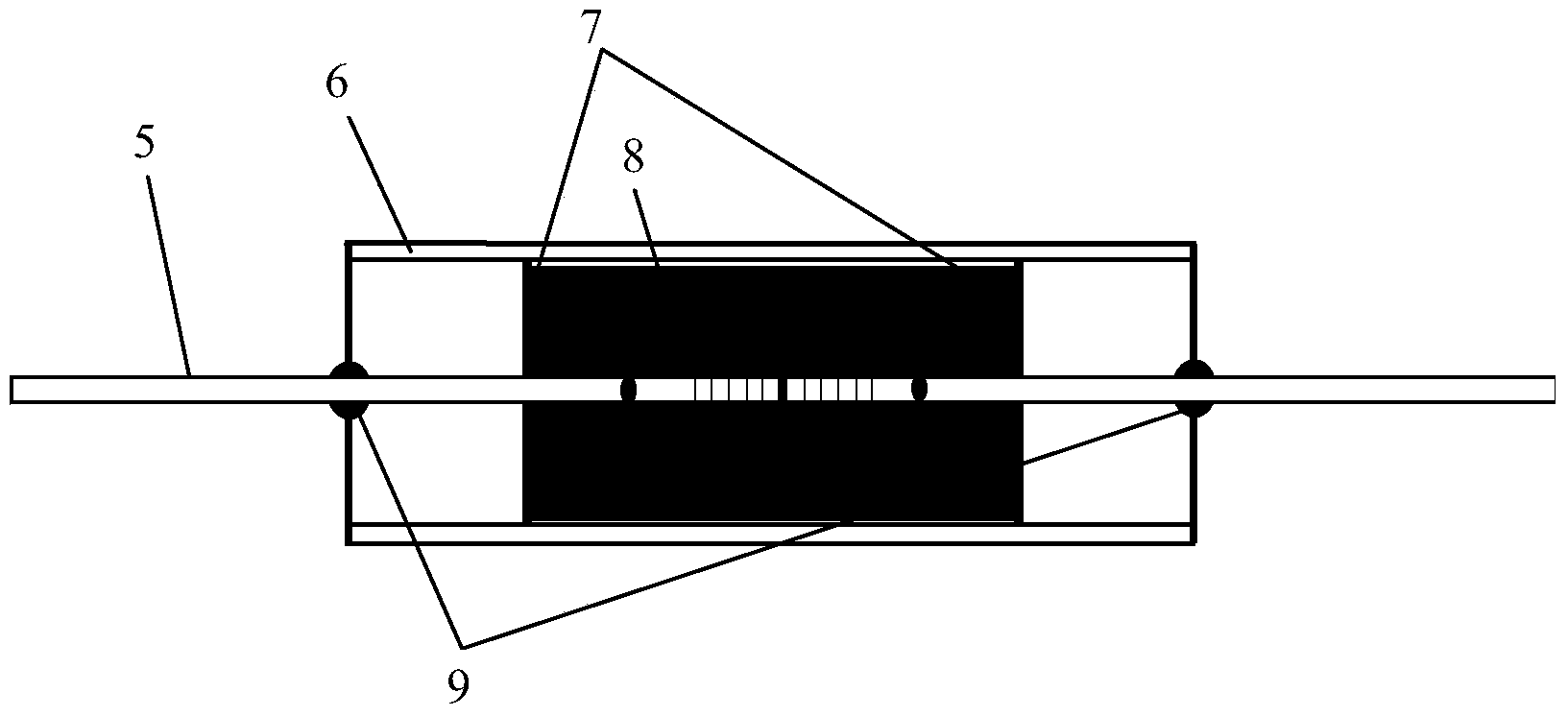

[0042] A manufacturing and packaging method of a distributed feedback fiber laser (DFB-FL) array, such as Figure 1-3 As shown, the steps are as follows:

[0043] 1) Select a section of rare-earth-doped optical fiber, write a Bragg grating in the rare-earth-doped optical fiber and insert a π phase shift in the process of writing the grating, and the π phase shift is in the middle of the grating;

[0044] 2) A section of 980nm transmission optical fiber is respectively connected to both ends of the rare earth element-doped optical fiber after writing the phase shift grating as a pigtail, and the optical fiber connection method is directly fused by a fusion splicer;

[0045] 3) Select water-absorbing swellable rubber as the internal filling material of the DFB-FL packaging structure, make the water-absorbing swellable rubber into a cylinder shape, pass the distributed feedback fiber laser through the cylinder made of water-swellable rubber and the distributed feedback fiber lase...

Embodiment 3

[0051] The same manufacturing and packaging method as in Embodiment 2 is adopted, except that in Embodiment 3, 16 packaged DFB-FLs with different wavelengths are selected to form a 16-element array. The wavelength intervals of the 16 DFB-FLs are 0.8nm and 2.4nm, and the wavelengths are arranged in the following order: 1532nm, 1532.8nm, 1535.2nm, 1536nm, 1538.4nm, 1539.2nm, 1541.6nm, 1542.4nm, 1544.8nm, 1545.6nm, 1548nm, 1548.8nm, 1551.2nm, 1552nm, 1554.4nm, 1555.2nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com