Composite insulator ultra-wideband radio-frequency sensing intelligent armour clamp and using method thereof

A composite insulator and radio frequency sensing technology, which is applied in the direction of using microwave flaw detection, can solve the problems of high labor intensity, high risk, and bulky volume, and achieve the effects of reducing detection cost and difficulty, ensuring safe use, and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

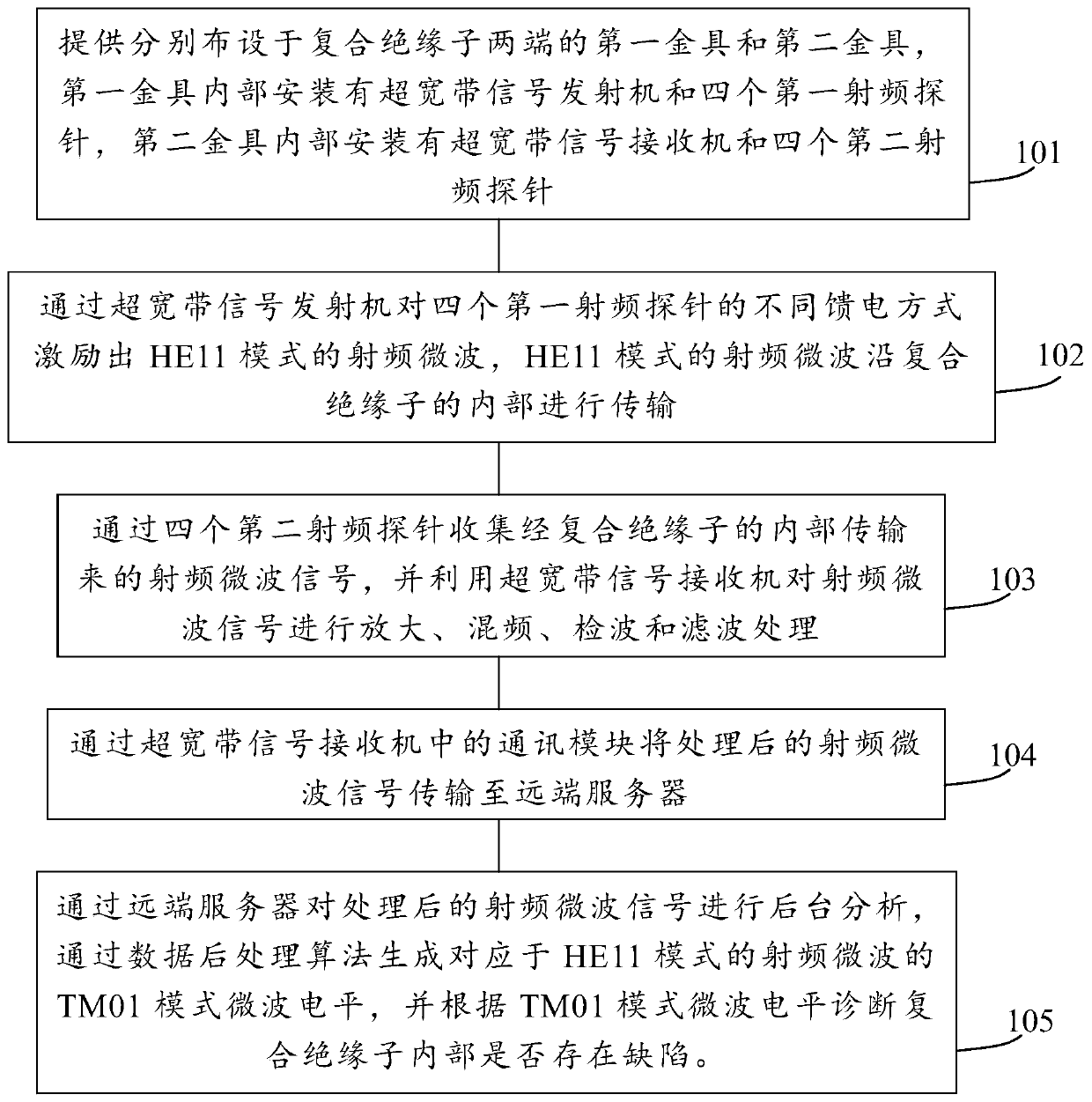

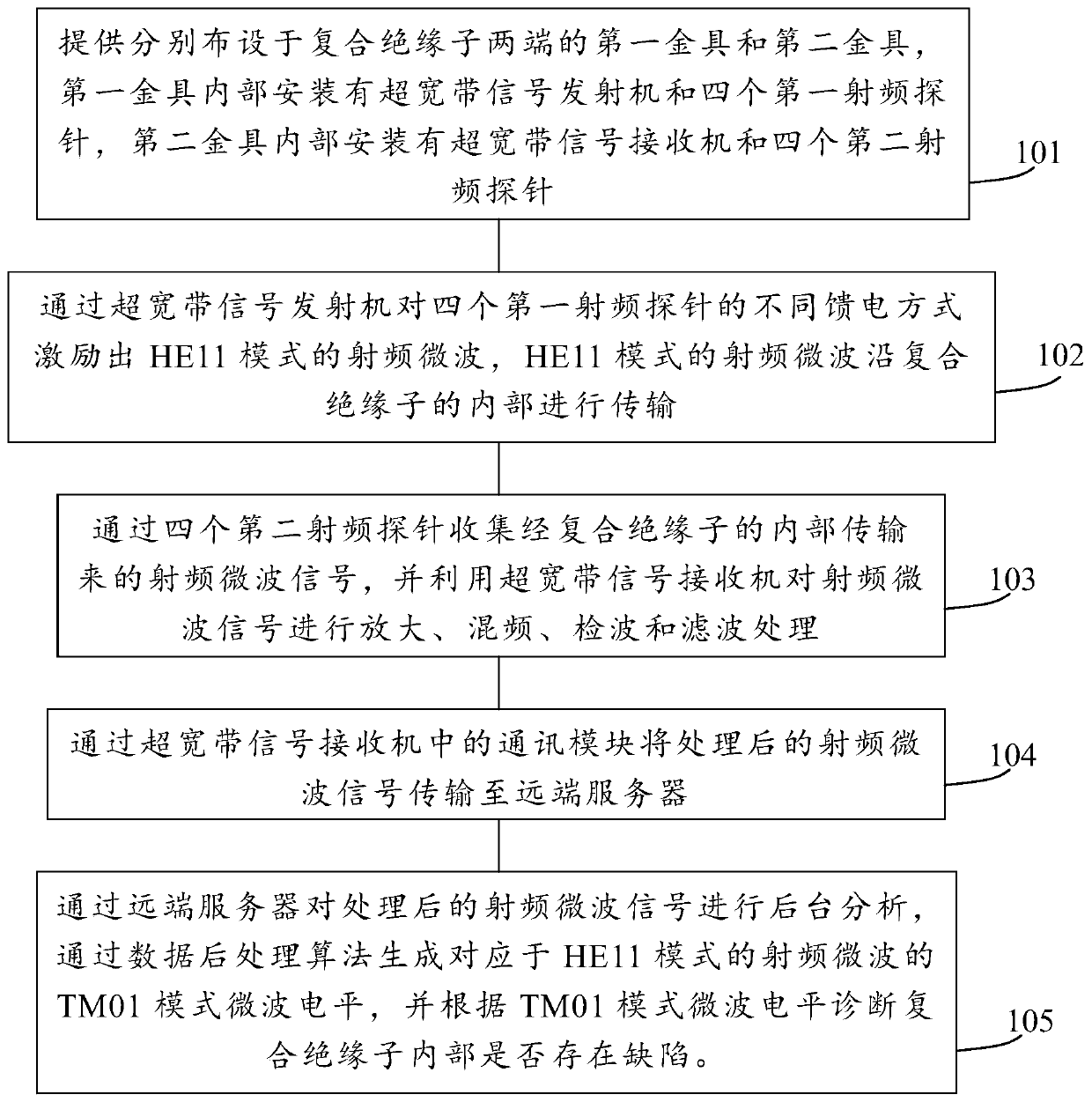

[0021] refer to figure 1 It can be seen that the present invention discloses a method for using a composite insulator ultra-broadband radio frequency sensing smart fitting, including the following steps:

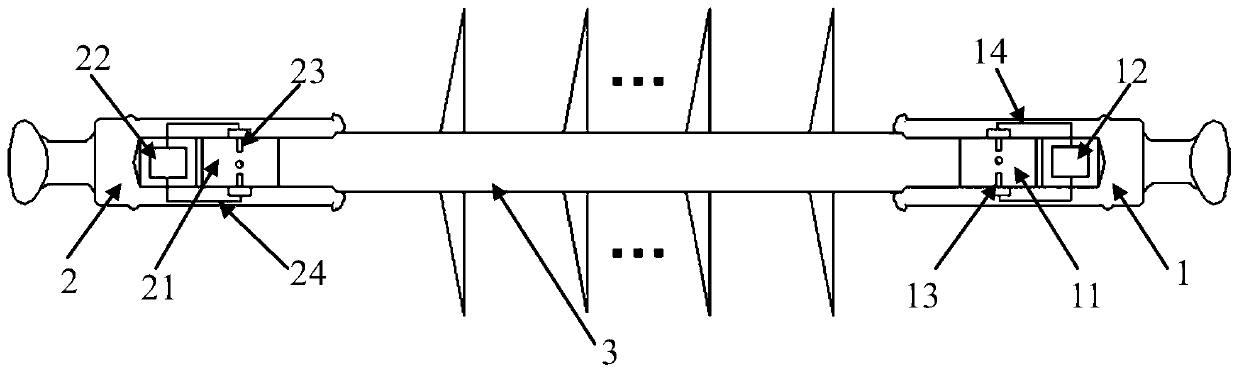

[0022] Step 101: Provide the first fitting 1 and the second fitting 2 respectively arranged at both ends of the composite insulator, the first fitting 1 is equipped with an ultra-wideband signal transmitter 12 and four first radio frequency probes 13, and the second fitting 2 is installed inside There are ultra-wideband signal receivers 22 and four second radio frequency probes 23;

[0023] Step 102: Using the ultra-wideband signal transmitter 12 to feed the four first radio frequency probes 13 in different feeding ways to excite HE 11 Mode RF Microwave, HE 11 Mode radio frequency microwaves are transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com